Large-span light subway evacuation platform plate and manufacturing process thereof

An evacuation platform, large-span technology, applied in manufacturing tools, ceramic forming cores, mining equipment, etc., can solve the problems of inability to take into account fire prevention, corrosion resistance, crack resistance, difficult and cumbersome construction, heavy weight, etc., and achieve high compressive strength. , facilitate construction, improve the effect of load-bearing and anti-deformation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

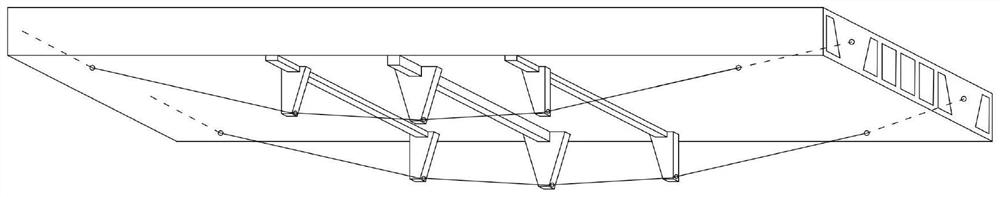

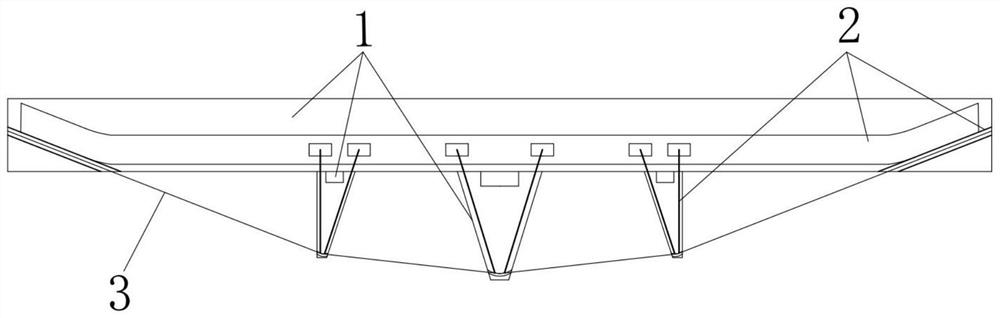

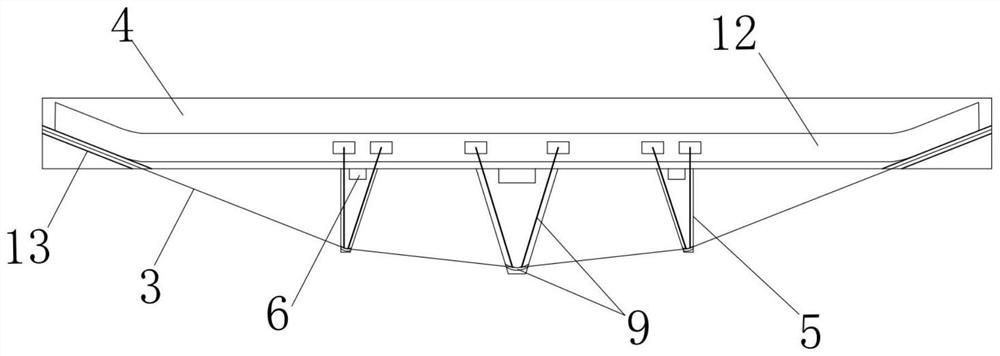

[0035] Embodiment 1: This embodiment describes a large-span light-weight subway evacuation platform plate, the platform plate includes a hollow plate 1, a steel pipe system 2 and a prestressed tendon 3;

[0036] The steel pipe system 2 is pre-buried in the hollow plate 1, and the prestressed ribs 3 are below the hollow plate 1, forming a mechanical equilibrium system with the steel pipe system 2 and the hollow plate 1;

[0037] The hollow plate 1 includes a main plate 4, a rib foot 5 and a rib beam 6; the main plate 4 includes a plurality of hollow structures, wherein the two sides of the steel pipe system 2 are trapezoidal hollow structures, and the hollow structure away from the steel pipe system 2 has a rectangular cross-sectional shape. , a square or a circle; the lower end of the main plate 4 is provided with a rib foot 5 and a rib beam 6, and the rib beam 6 is perpendicular to the hollow structure of the main plate 4, and penetrates the upper end of the rib foot 5;

[00...

specific Embodiment approach 2

[0042] Embodiment 2: For a large-span light-weight subway evacuation platform plate described in Embodiment 1, the cross-sectional shape of the steel pipe body 12 is one of a circle, a square, or a rectangle. When the rectangular hollow structure is matched with the main body of the round steel pipe, the effect is optimal.

specific Embodiment approach 3

[0043] Embodiment 3: According to the large-span light-weight subway evacuation platform plate described in Embodiment 1, the adjacent two sides of the cross-sectional corners of the rectangular and trapezoidal hollow structures are smoothly connected.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com