Formwork support system for cast-in-place slabs with large-span steel beams

A technology of cast-in-place slabs and slab templates, which is applied to the preparation of formwork/formwork/work frames, construction components on site, and construction. It can solve the problems of large volume, inconvenient installation and movement, and heavy weight, and achieve repeat The effect of high utilization rate, reduced formwork cost and reduced steel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of the present invention are described in detail below, examples of which are illustrated in the accompanying drawings, wherein like reference numerals refer to like elements throughout. The embodiments described below are used to explain the present invention by referring to the figures, and the embodiments are exemplary and should not be construed as limitations of the present invention.

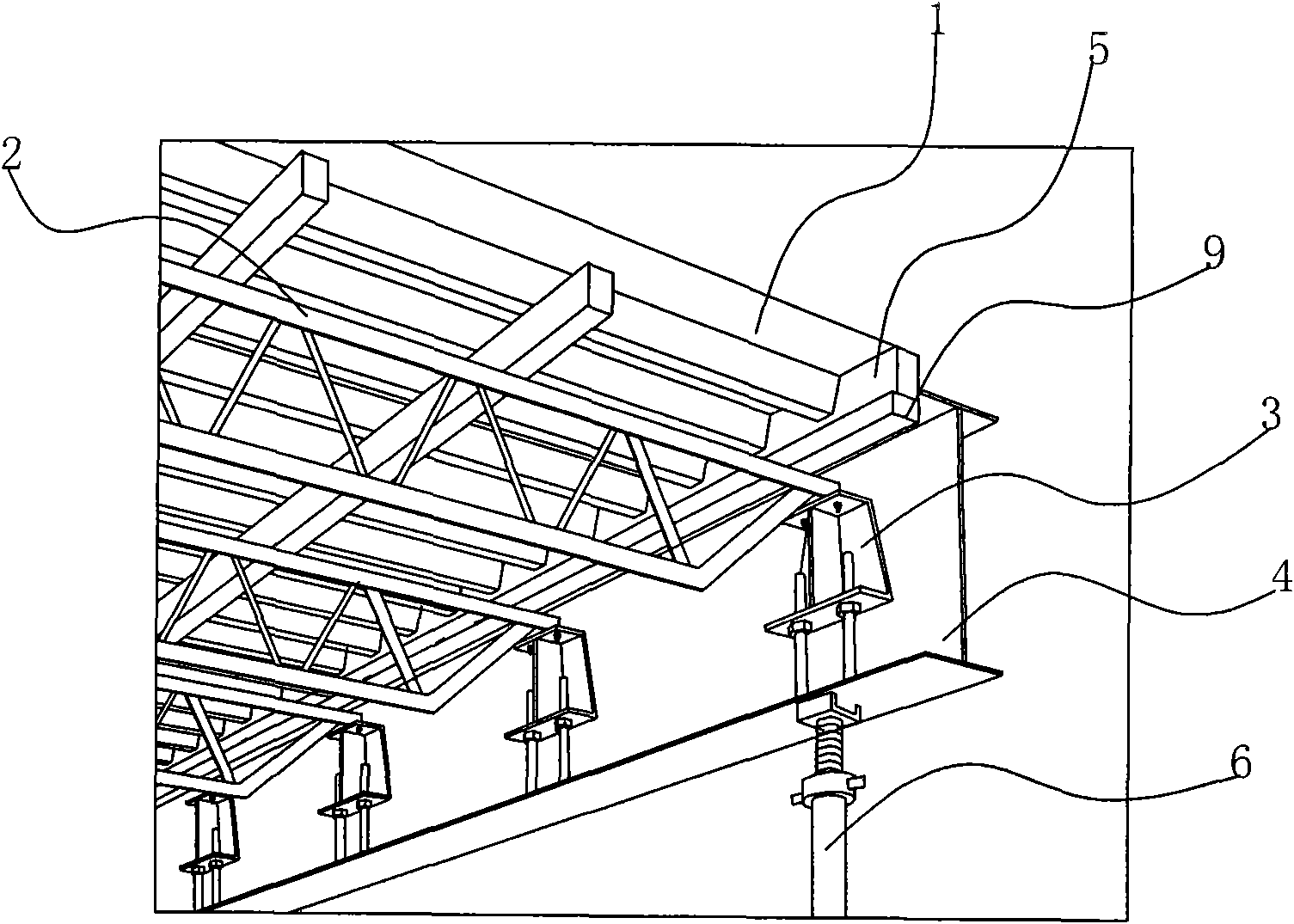

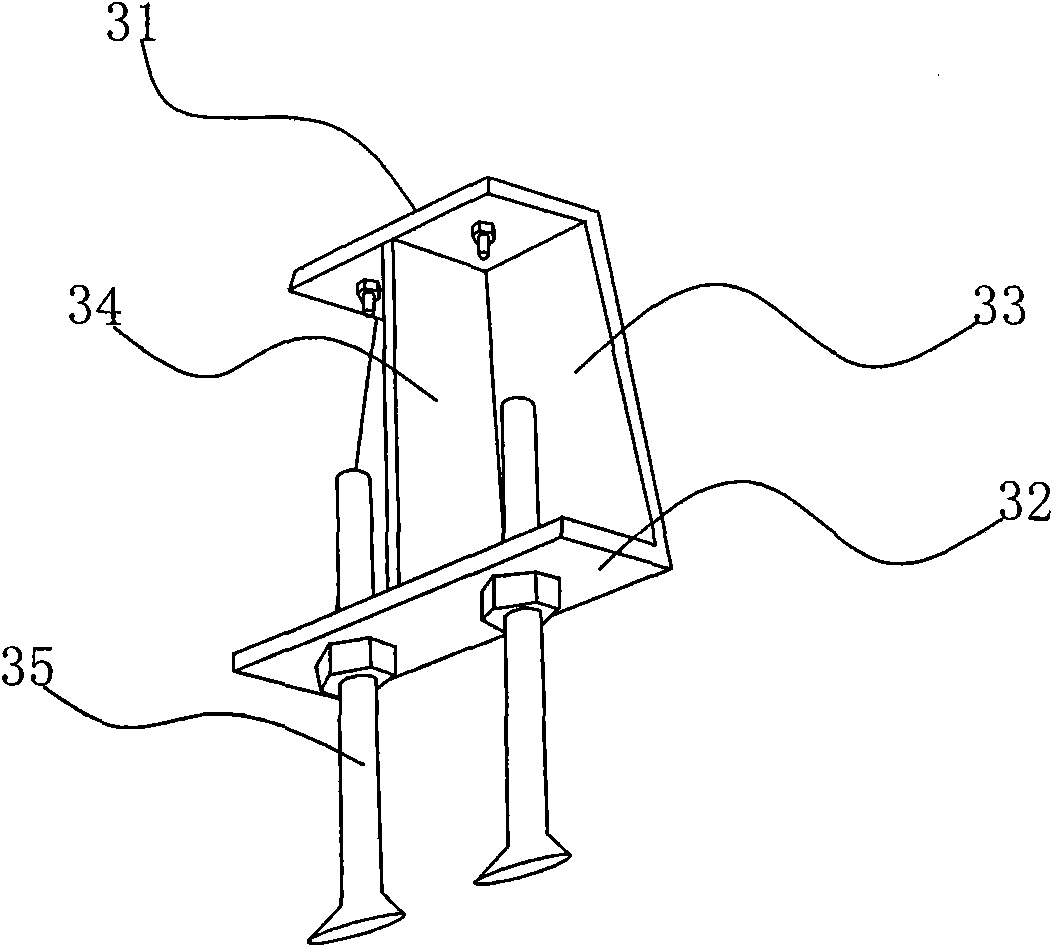

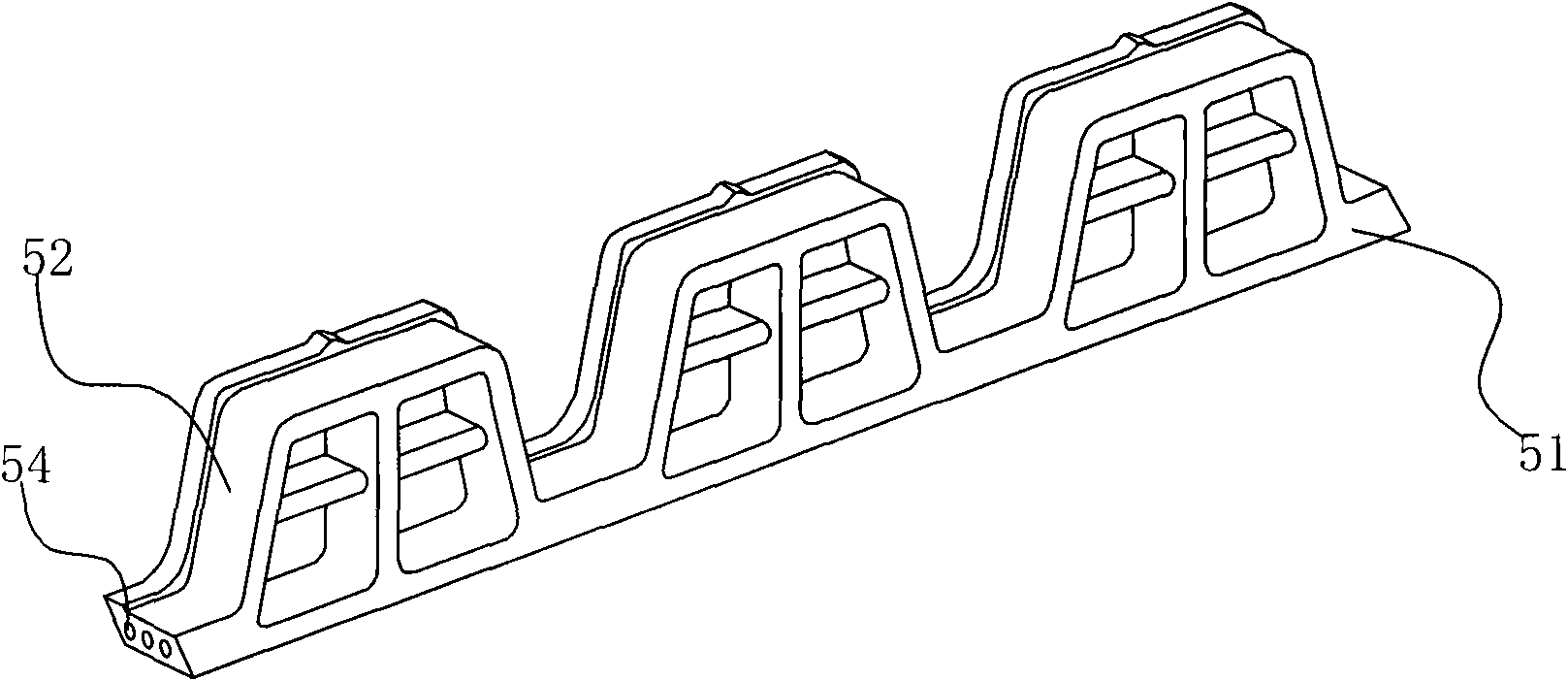

[0027] see Figure 1 to Figure 5 As shown, the cast-in-place slab formwork system for large-span steel beams provided by the present invention includes a slab formwork 1, an adjustable truss 2 and an adjustable shelving support 3 for supporting the truss 2, on which the adjustable truss 2 A grid 9 is laid, the floor template 1 is laid on the grid 9 , and the adjustable shelving support 3 is arranged on the lower flange of the I-beam 4 . The adjustable truss 2 is a telescopic combined truss, and the adjustable truss 2 is connected to the upper end of the adjustable shelv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com