Large-truss-height adjustable suspended splicing combined type frame steel arch frame and large-span arch ring integral pouring process

An adjustable and combined technology, applied in arch bridges, buildings, bridge forms, etc., can solve the problems of steel arch segment transportation and construction, high construction cost, weak force and other problems, and achieves reduction of construction cost and construction period. The effect of saving and facilitating centralized management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

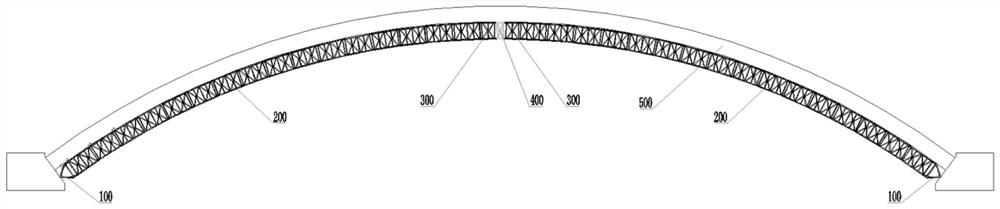

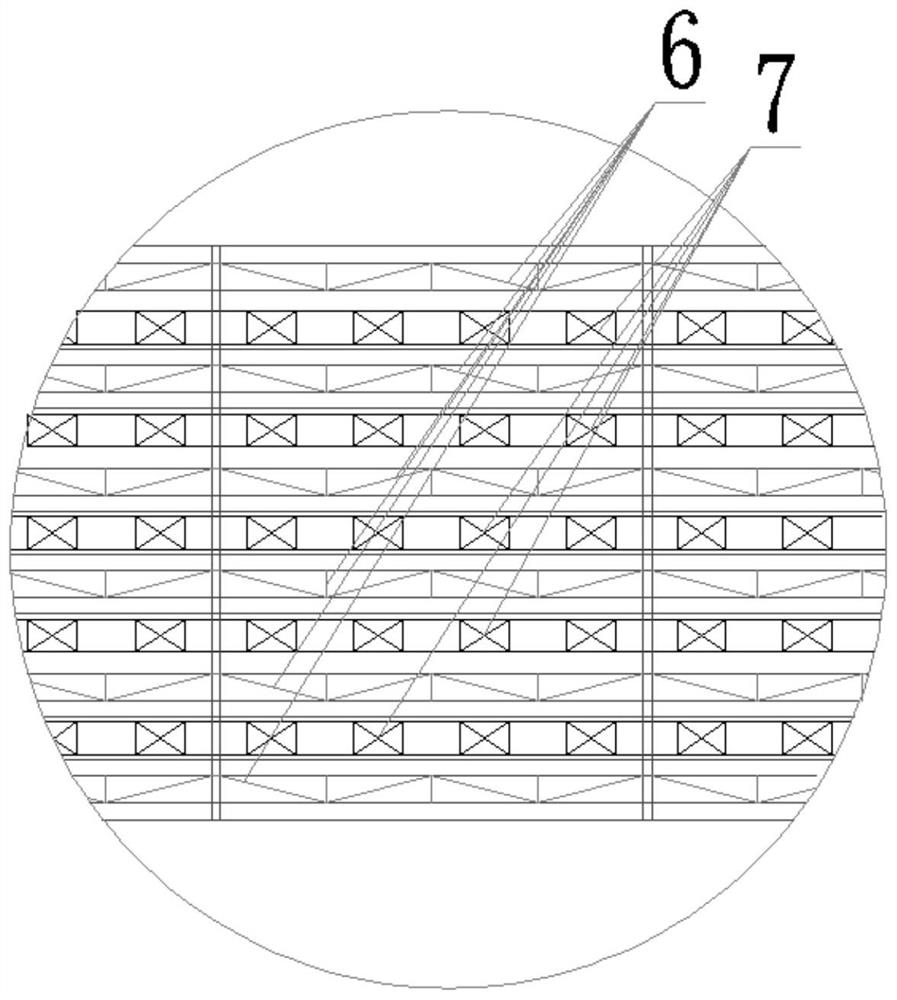

[0044] Such as Figure 1 to Figure 11 As shown, a large truss height-adjustable cantilever combined frame steel arch frame has a truss height of 5 meters and a span of 260 meters. The steel arch frame includes arch foot joints connected in sequence along the arc direction segment 100, a plurality of standard segments 200 (the segments between the arch foot segment 100 and the adjustment segment 300 all adopt the standard segment 200), the adjustment segment 300, the closing segment 400 and the closing device (the closing device adopts the current There is a closing device in the patent CN207862786U), multiple segments arranged side by side along the arch width direction form an arch rib, and the horizontal joints 4 and vertical joints 5 are used to connect adjacent arch ribs in the horizontal direction, and the upper and lower layers of truss and vertical Frames 3 are spliced together to form an overall force-bearing arch frame, and the connection between the upper truss and...

Embodiment 2

[0061] A large truss height-adjustable cantilever combined frame steel arch frame, referring to Example 1 and combining Figure 14 to Figure 16 As shown, the main difference between it and Embodiment 1 is that two upper truss closed frame structural units 1 and two lower truss closed frame structural units 2 are arranged on each standard segment, and the standard segment The closed frame structure unit 1 of the upper truss can be snapped into the concave area 27 between adjacent trusses on the standard segment.

[0062] By adopting the scheme in the embodiment, it is only necessary to adopt the conventional span (within 150 meters) steel arch construction technology (including the facilities and equipment used in this process) to construct a 260m-span fabricated steel arch, which is suitable for large-scale facilities and equipment in mountainous areas The construction of the main arch ring of the large-span (200-300m) arch bridge in the valley / canyon that cannot be reached, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com