Steel structure flexible shed frame

A technology for steel structures and scaffolding, which is applied to building components, building structures, roofs, etc., can solve the problems of low headroom, waste, and limited scope of use, so as to improve work efficiency, save manpower and material resources, and achieve universality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

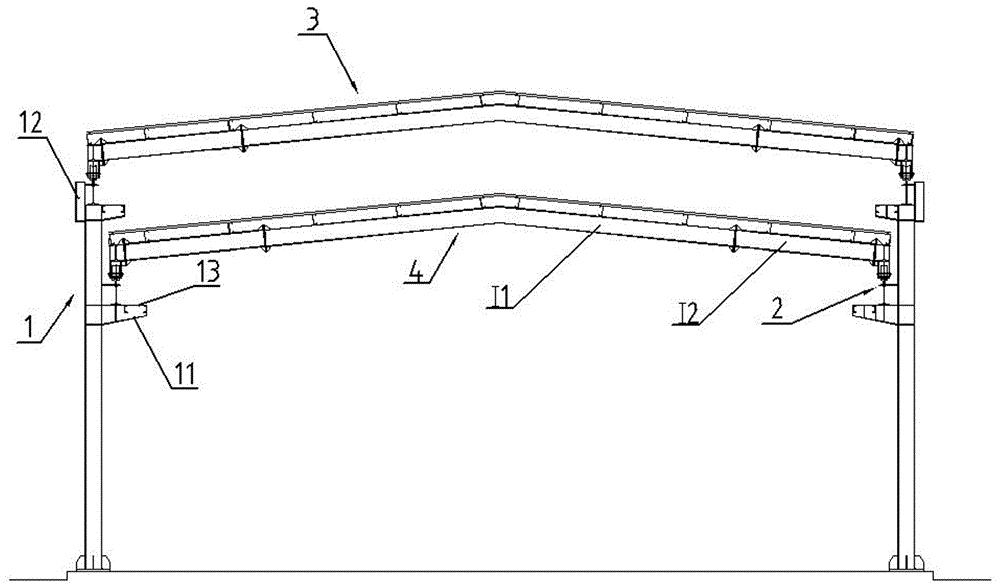

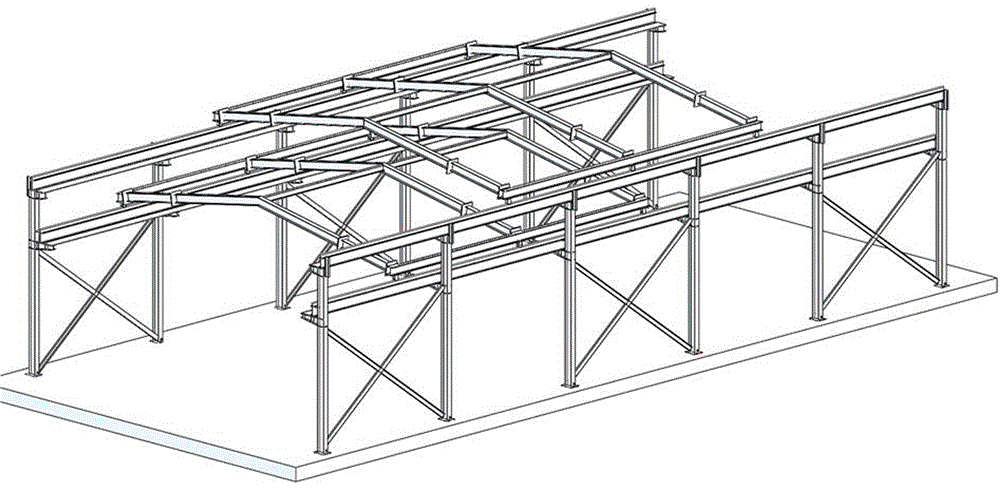

[0019] like figure 1 As shown, the steel structure movable scaffolding disclosed in this embodiment includes a column 1 , a rail longitudinal beam 2 , an upper movable ceiling 3 and a lower movable ceiling 4 .

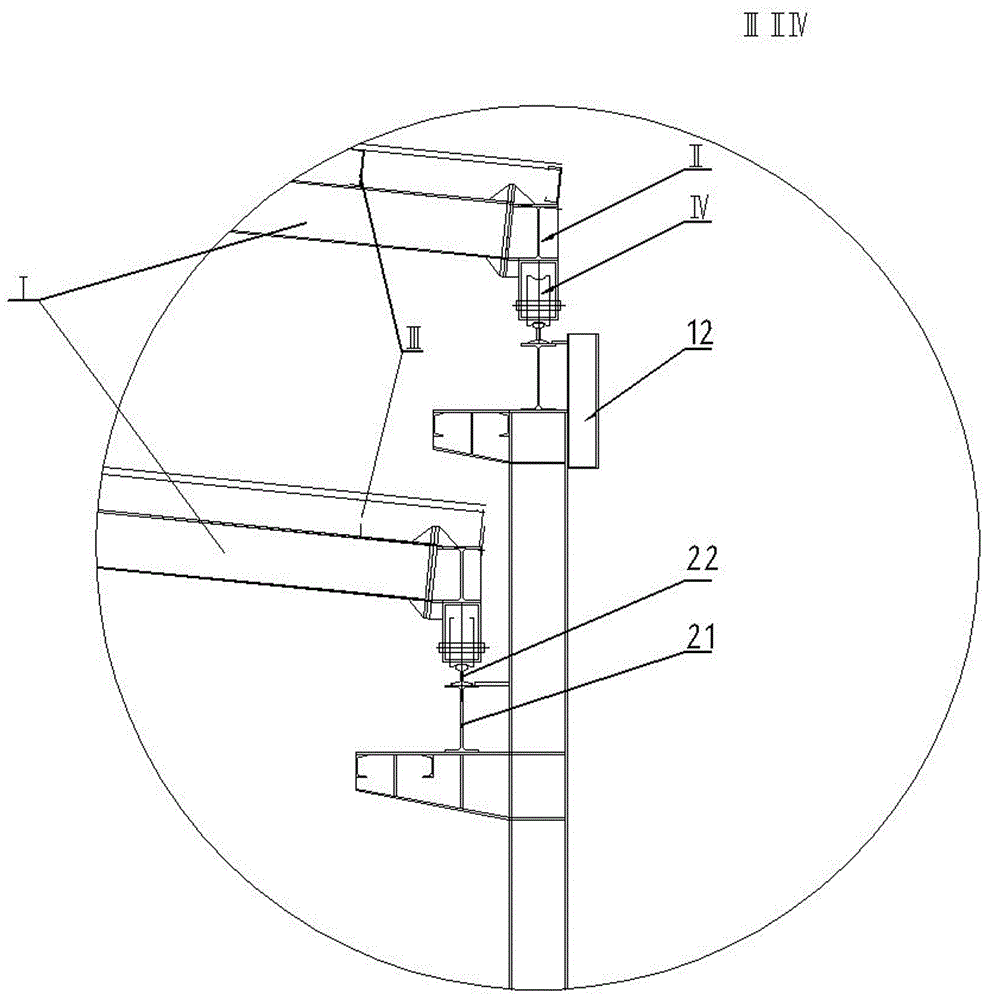

[0020] like figure 1 As shown, two rows of columns 1 are arranged symmetrically, and the bottom of each column 1 is fixed to the foundation by anchor bolts to ensure the stability of the entire scaffold. Corbels 11 are respectively arranged on the upper part and the inner side of the top of each column 1 , and an inspection platform 13 is arranged on the corbels 11 . The setting of the maintenance platform 13 enables the maintenance personnel to carry out inspections conveniently, so as to avoid the phenomenon of rail jumping of the movable roof.

[0021] like figure 2 As shown, oblique supports 14 are arranged between the columns 1 on the same side to further improve the stability of the entire scaffold. The inspection platform is equipped with an inspection ladd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com