Double-propping head incubator for low-temperature CTOD (Crack Tip Opening Displacement) tests

A low-temperature chamber and testing technology, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., can solve the problems of high labor intensity of test personnel, difficult to guarantee test accuracy, and low test work efficiency, etc. Achieve the effect of reducing the demand for test equipment, simple and practical structure, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

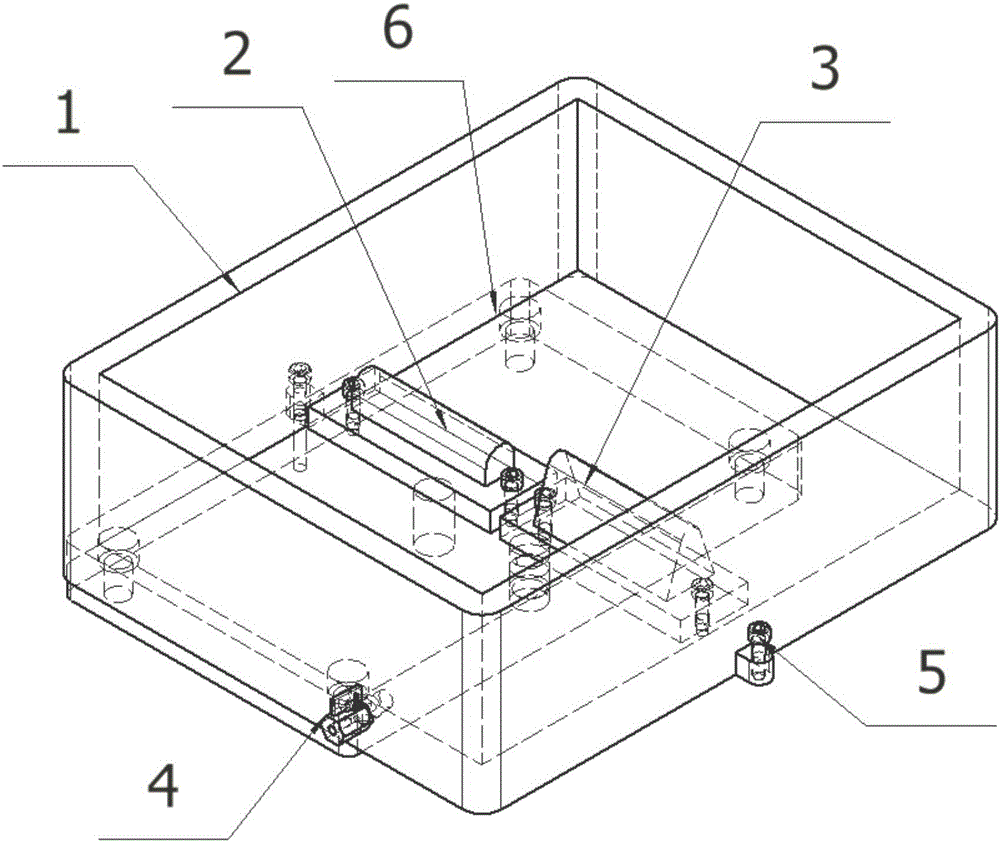

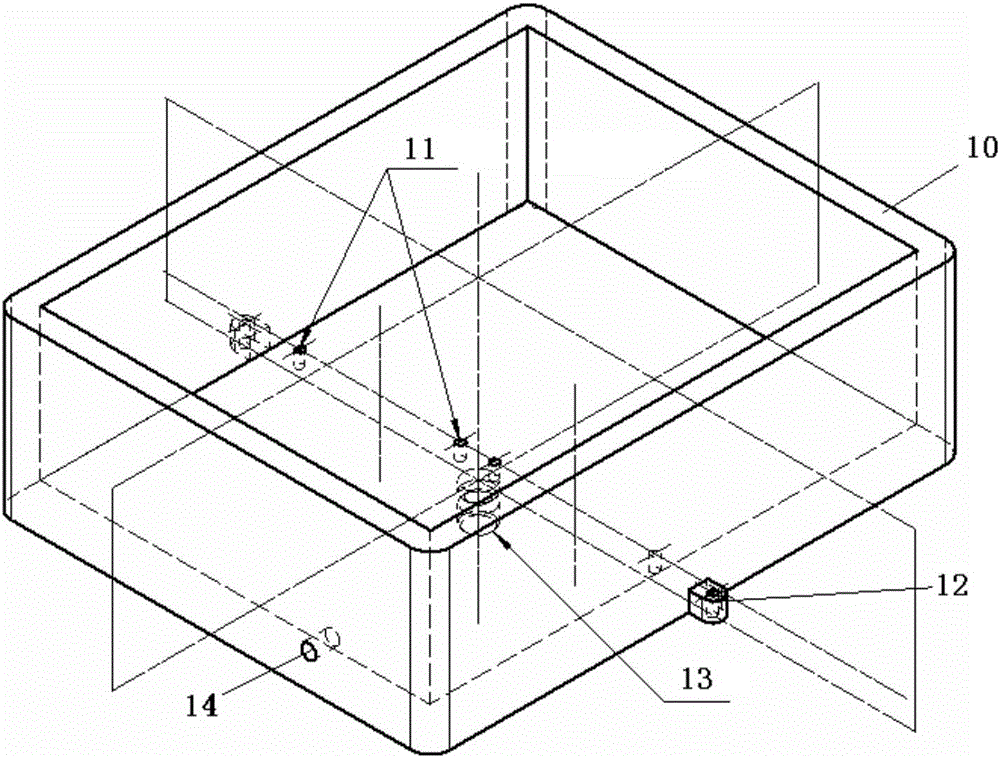

[0024] see figure 1 , shows the double-head incubator for low-temperature CTOD test of the present invention. Taking the rotating double-head low-temperature box for low-temperature CTOD test designed on the Meters 1000KN electro-hydraulic universal testing machine as an example, the present invention is further described in detail.

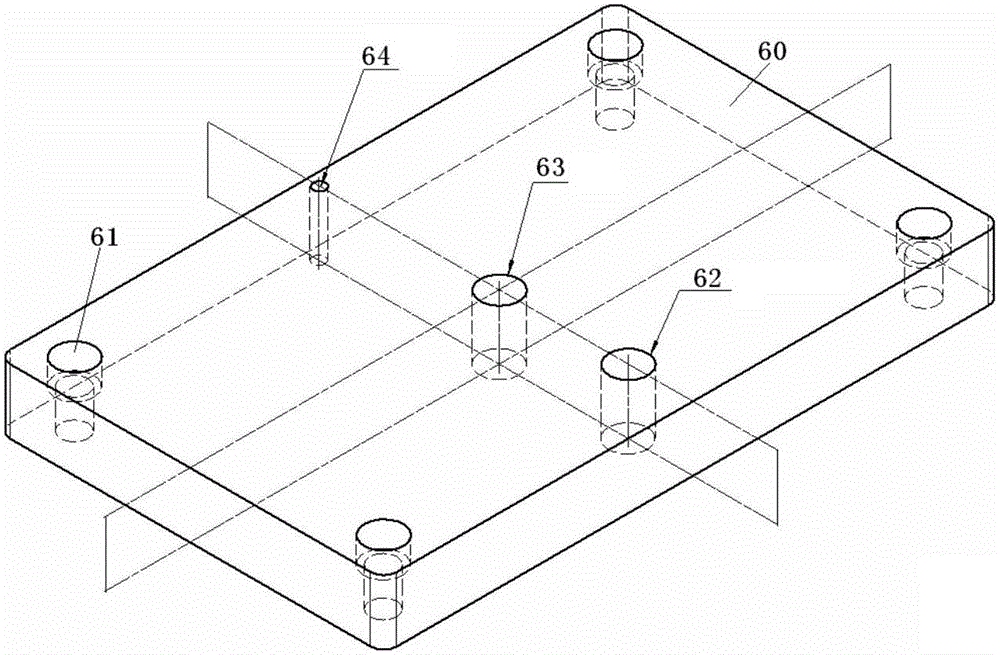

[0025] The double-plug incubator for the low-temperature CTOD test includes a rotatable low-temperature box 1, an unstable and damaged plug 2, a crushed plug 3, a liquid discharge miniature ball valve 4, a limit screw 5, and a testing machine connecting plate 6. The rotatable low-temperature The box 1 is a box body with an upper end opening, and the box body can be in a suitable shape such as a rectangle or a square. The destabilizing and breaking plug 2 and the crushing plug 3 are arranged in the rotatable low-temperature box 1, and the liquid discharge miniature ball valve 4 is installed. On the side wall of the rotatable low-temperature box 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com