Method for predicting high-low-cycle composite fatigue crack growth life of turbine joggle structure

A technology for fatigue crack growth and life prediction, which is applied in the testing of machine/structural components, measuring devices, and engine testing, etc. It can solve problems such as difficulty in guaranteeing prediction accuracy, lack of applicability, and failure to consider the structural characteristics of turbine tenon joint parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

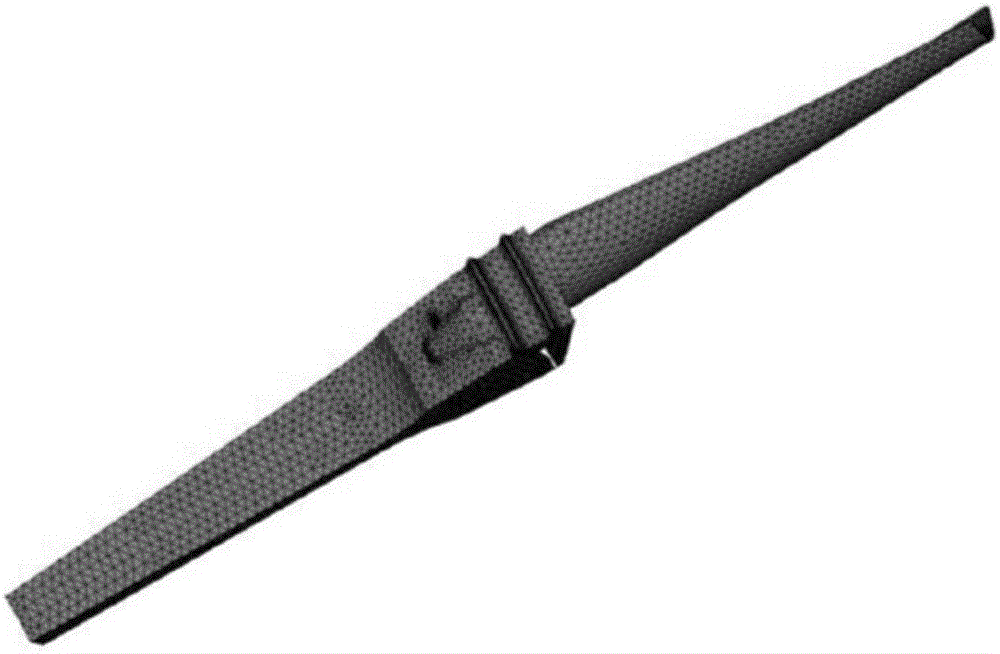

[0065] In the following, the technical solution of the reliability design method for the structural strength of the turbine blisk according to the present invention will be further described in conjunction with the accompanying drawings.

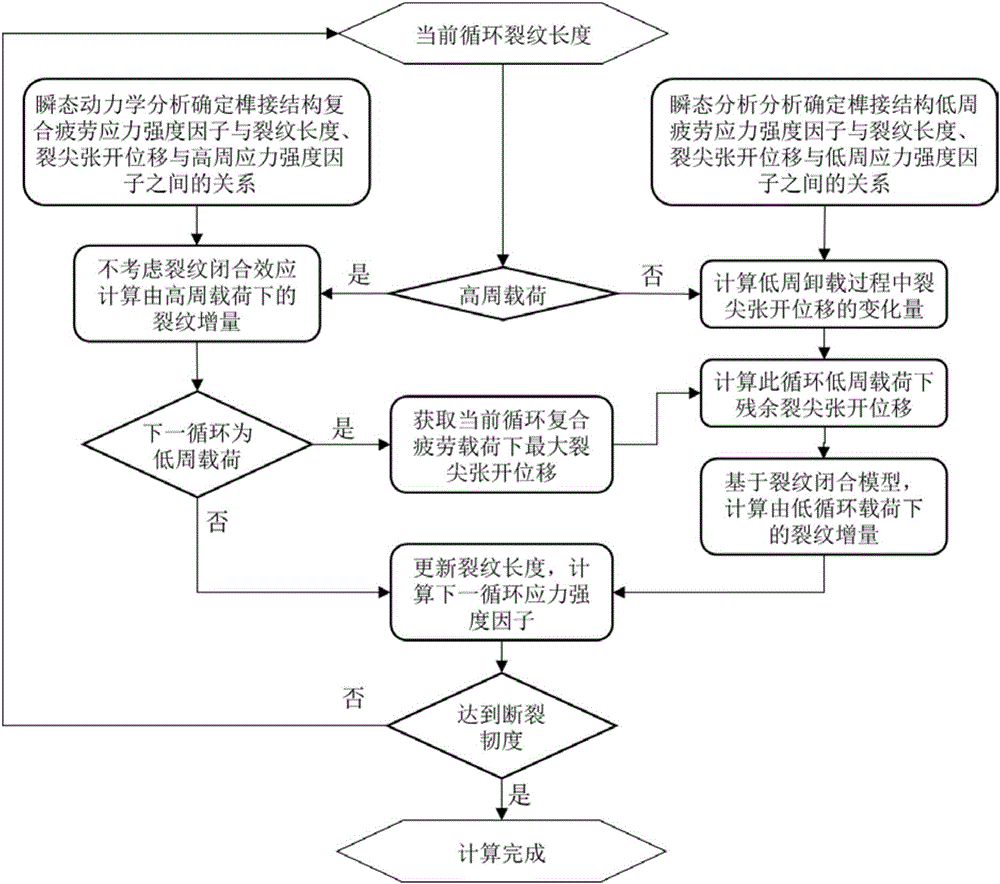

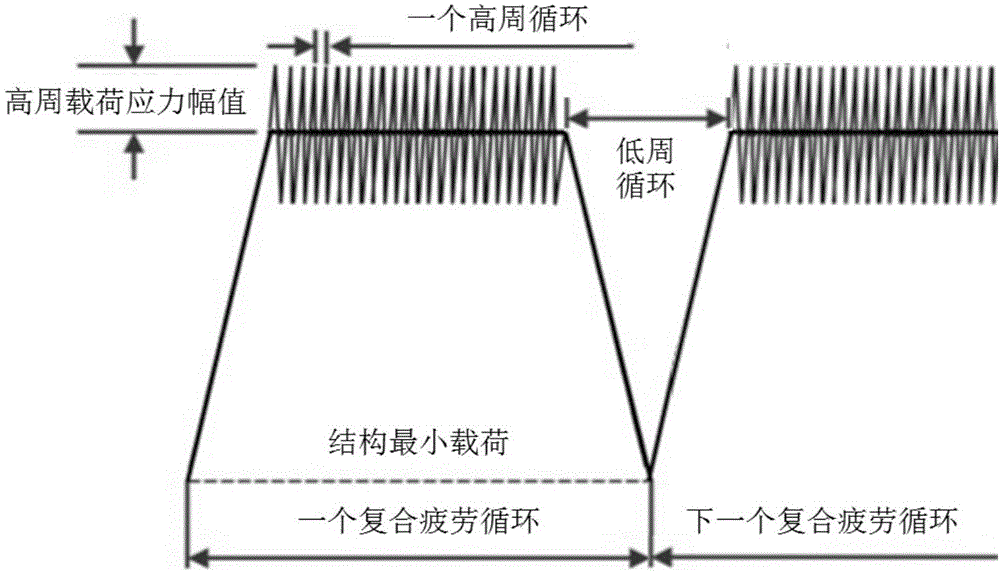

[0066] The present invention starts from the high-low-cycle composite fatigue crack growth mechanism, that is, the superposition of high-cycle loads increases crack growth damage and accelerates crack growth, but at the same time increases the opening displacement of the residual crack tip and increases the crack closure level. Crack growth suppression, the crack growth of turbine mortise joint structure under combined fatigue load is restricted by the mutual restriction of the moving speed of these two aspects. Considering the coupling effect of high cycle load and low cycle load of turbine tenon joint structure, the concept of small time scale is introduced, that is, the crack tip opening displacement, stress intensity factor and crack incr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com