60 Kg-scale low temperature-quenched and tempered steel plate with good weldability and manufacture method thereof

A low-temperature tempering and weldability technology, applied in the direction of temperature control, can solve the problems of low-temperature toughness and low uniform elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

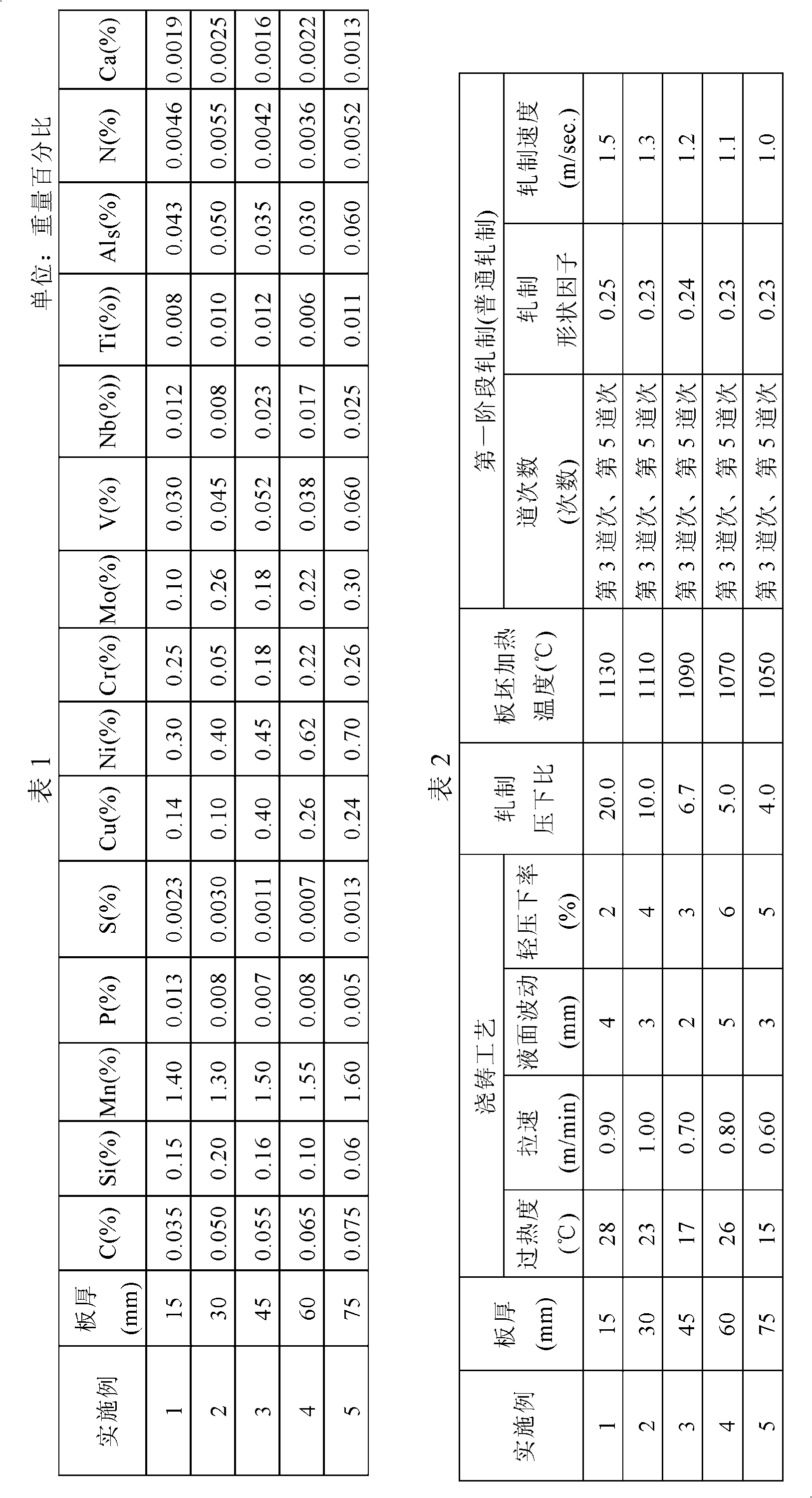

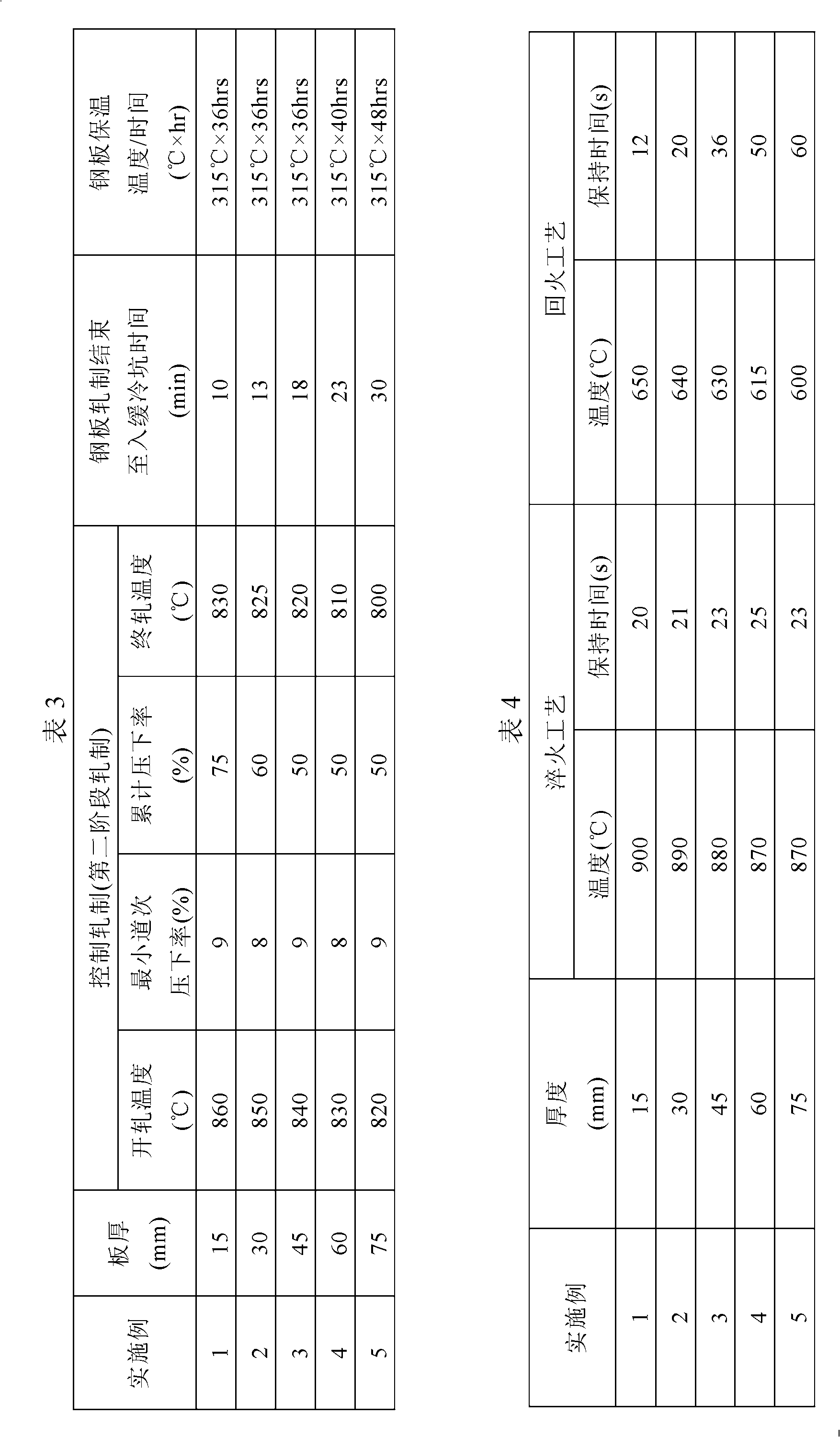

[0069] See Table 1 for the composition examples of the present invention, and Table 2 to Table 4 show the manufacturing process of the examples of the present invention. Table 5 is the performance of the embodiments of the present invention.

[0070] Such as figure 1 As shown, the microstructure of the steel of the present invention is ultra-fine tempered upper bainite, and the grain size is below 15 μm.

[0071] In the present invention, through the combined design of steel plate alloy elements, controlled rolling and low-temperature quenching and tempering process, while obtaining excellent low-temperature quenched and tempered steel plate strength, low-temperature toughness and strength-toughness matching, the weldability of the steel plate is also excellent, and successfully It solves the matching problem between the strength, uniform elongation, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com