Tungsten electrode inert gas protected welding gun in double-layered airflow structure

A tungsten inert gas and shielded welding technology, which is applied to the characteristics of electrodes, welding equipment, arc welding equipment, etc., can solve the problems of easy oxidation and burning of tungsten, shallow penetration, etc., to avoid oxidation burning, increase penetration, improve The effect of welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

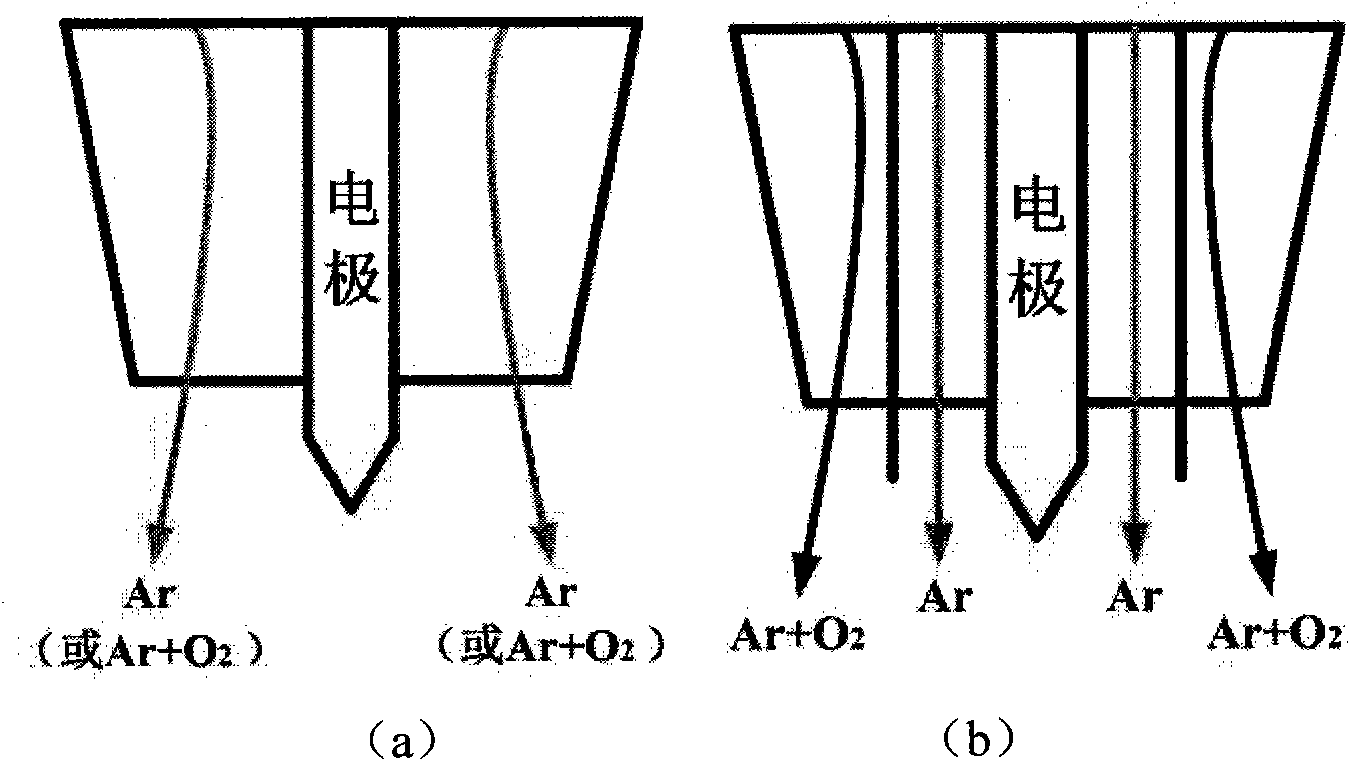

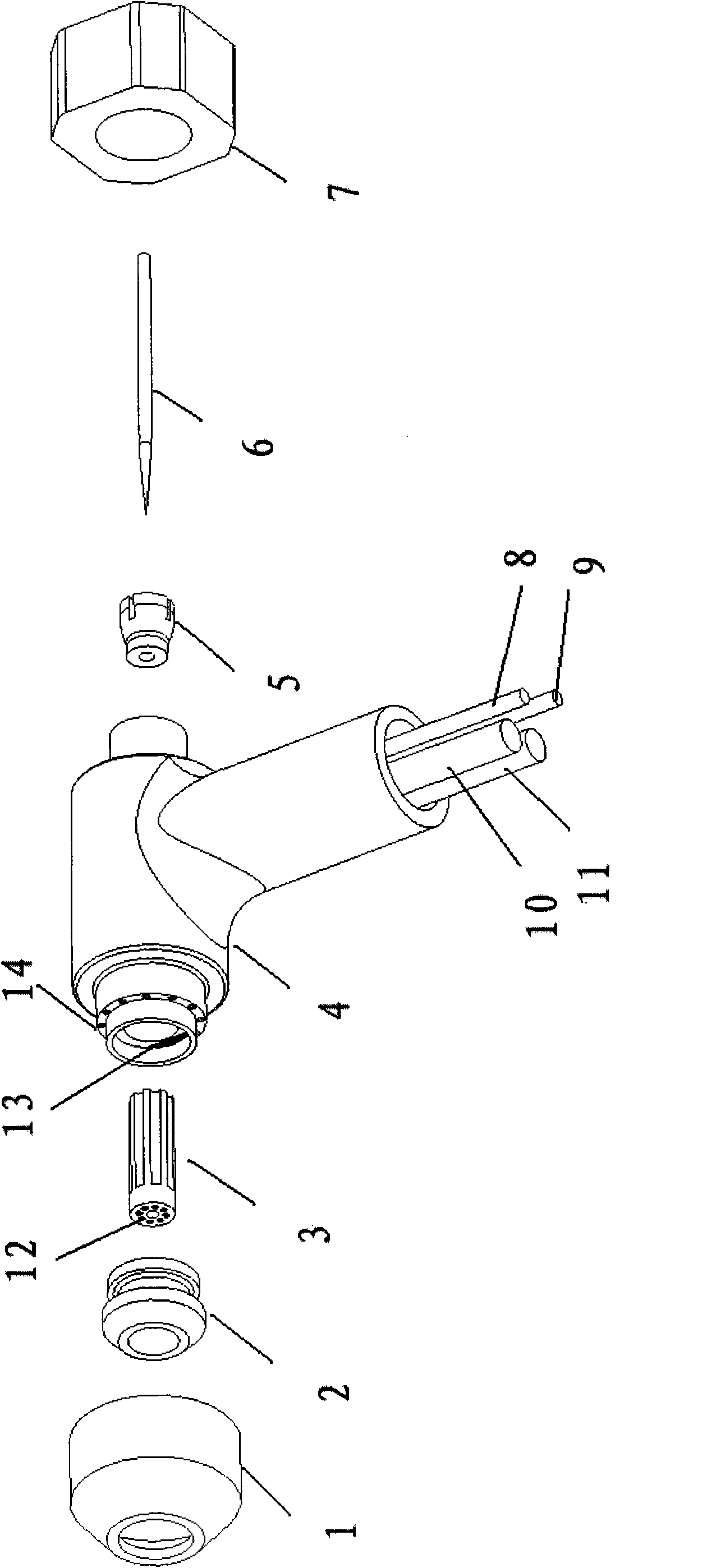

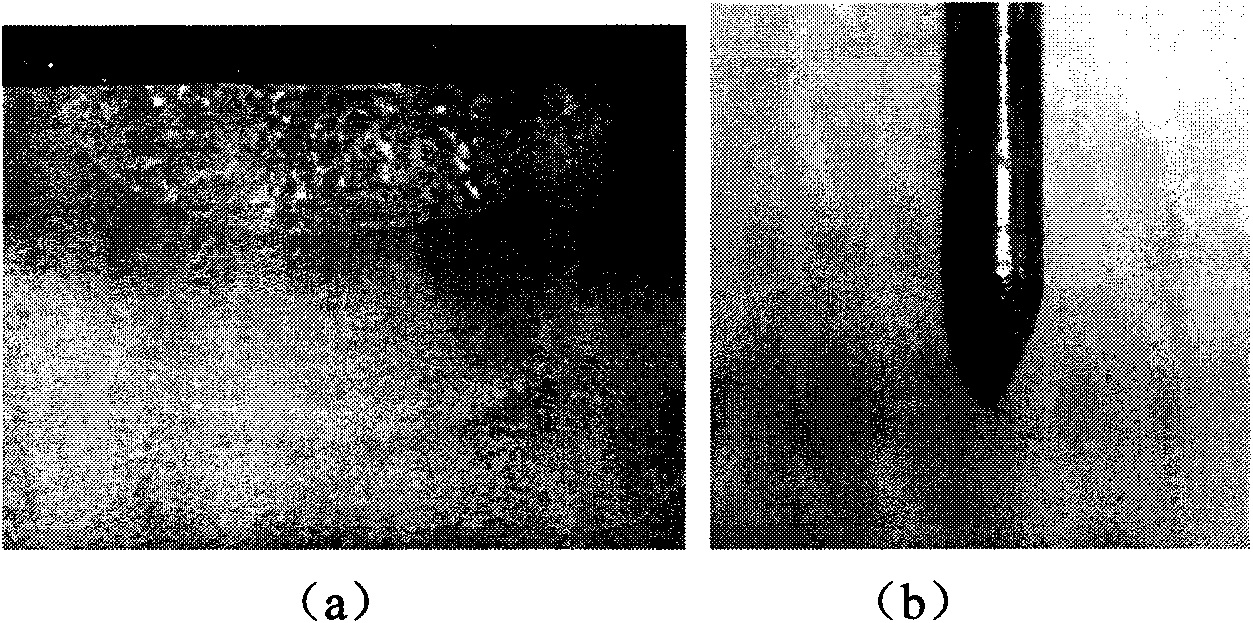

[0025] Such as figure 1 As shown, the common single-channel TIG torch uses pure inert gas Ar(He), or uses Ar+O 2 (He+O 2 ) and other mixed gases, as a protective air flow, during the welding of stainless steel parts and repair welding of large castings, it is found that the electrodes are oxidized. Using the welding torch of the present invention to replace the ordinary single-channel TIG welding torch can effectively avoid the oxidation of the electrodes. , and effectively increase the depth of the molten pool and improve welding efficiency. The tungsten inert gas shielded welding torch of the double-layer gas flow structure proposed by the present invention, that is, the inner layer is a pure inert gas (Ar or He, etc.), which protects the tungsten electrode from oxidation and burning; 2 or CO 2 etc.) to transition the active components to the molten pool, and adjust the content of active components in the liquid molten pool and the morphology of the molten pool.

[0026]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com