Preparation method of aluminum-calcium alloy used for vacuum refining molten steel deoxidation and device thereof

An aluminum-calcium alloy and vacuum refining technology, which is applied in the field of preparation of aluminum-calcium alloy for deoxidation of molten steel in RH vacuum refining, can solve the problems of difficulty in making aluminum-calcium alloy, lack of production, and low metal calcium content. Achieve the effect of reducing process operation steps, convenient transportation and storage, and low melting temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

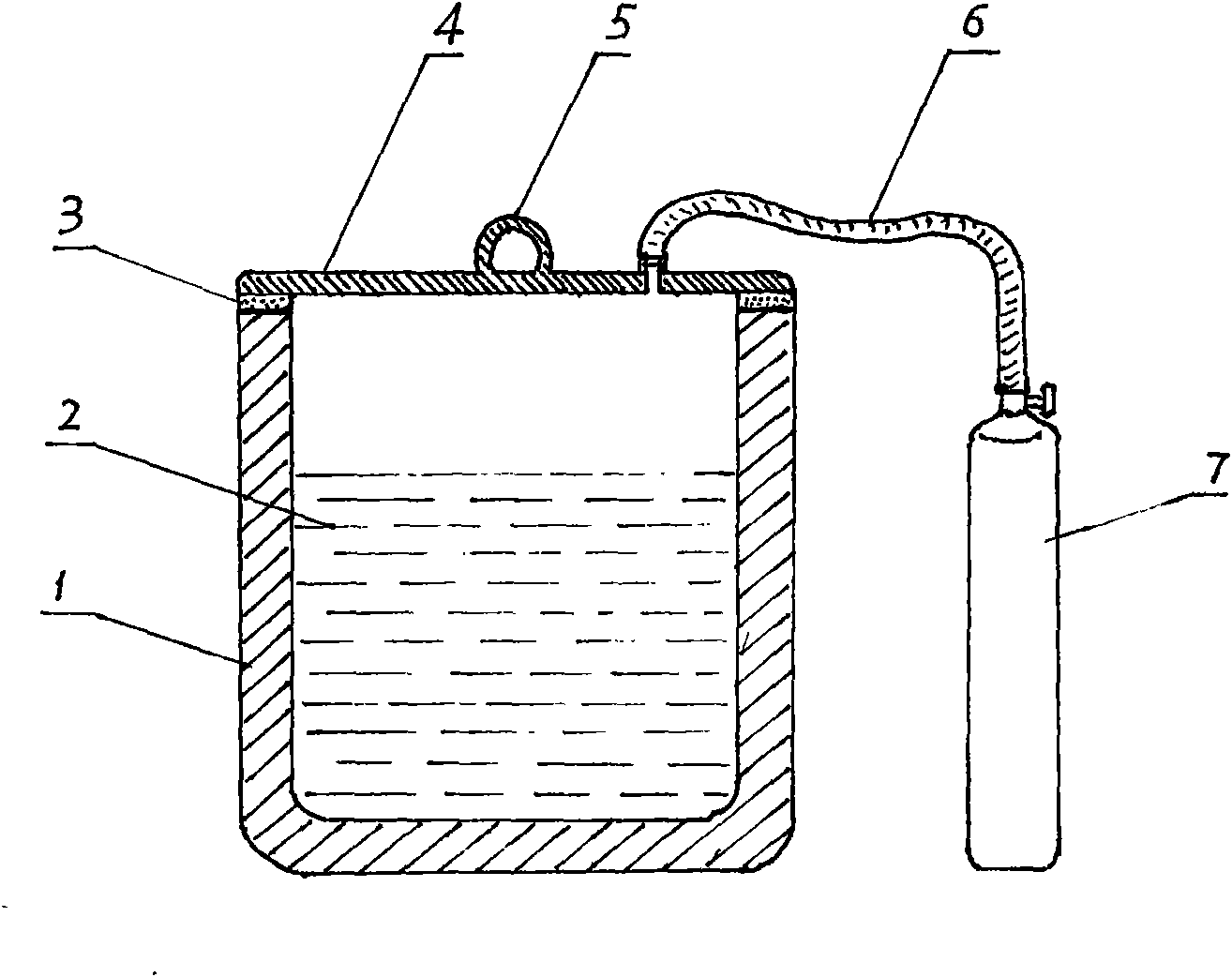

[0023] Referring to the accompanying drawings, the device for preparing aluminum-calcium alloy for deoxidation of molten steel in vacuum refining according to the present invention is composed of a low-frequency induction furnace 1 and a matching furnace cover 4, and an asbestos sealing gasket is provided on the lower edge of the furnace cover in contact with the induction furnace 3. There is a hook 5 above the furnace cover, and the furnace cover is connected to the argon cylinder 7 through the gas delivery pipe 6 .

[0024] The following is an embodiment of using the device to prepare aluminum-calcium alloy for vacuum refining molten steel deoxidation, and the specific steps are as follows:

[0025] (1) Get aluminum with a purity of 99.9% and calcium with a purity of 99.5% as raw materials;

[0026] (2) lift the furnace cover 4 of the low-frequency induction furnace 1 by the hook 5, use the above-mentioned raw materials, by weight aluminum 80%, calcium 20% batching, first pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com