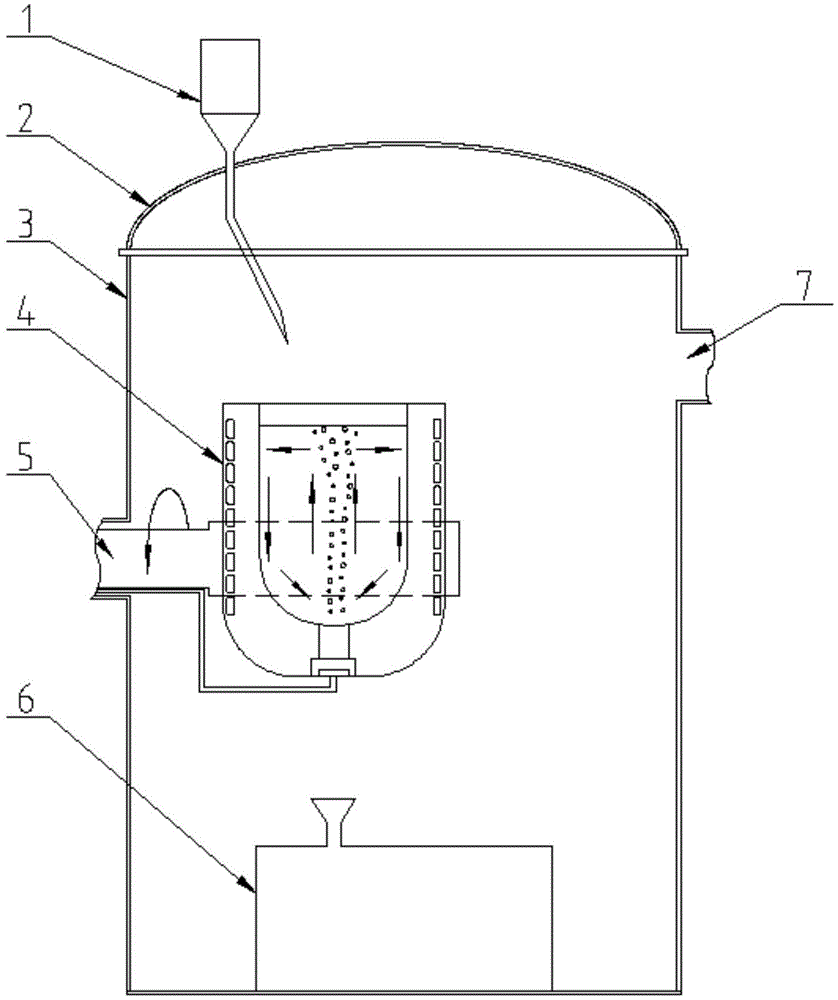

High phosphorous cast iron inoculating treatment method device in vacuum induction furnace

A vacuum induction furnace and inoculation treatment technology, applied in the field of metallurgical technology, can solve the problems of low yield, splashing, poor safety, etc., and achieve the effects of high yield, improved uniformity, and prevention of oxidative burning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0043] In order to introduce the embodiment of the present invention more clearly, the following introduces it from the usage method of the embodiment of the present invention.

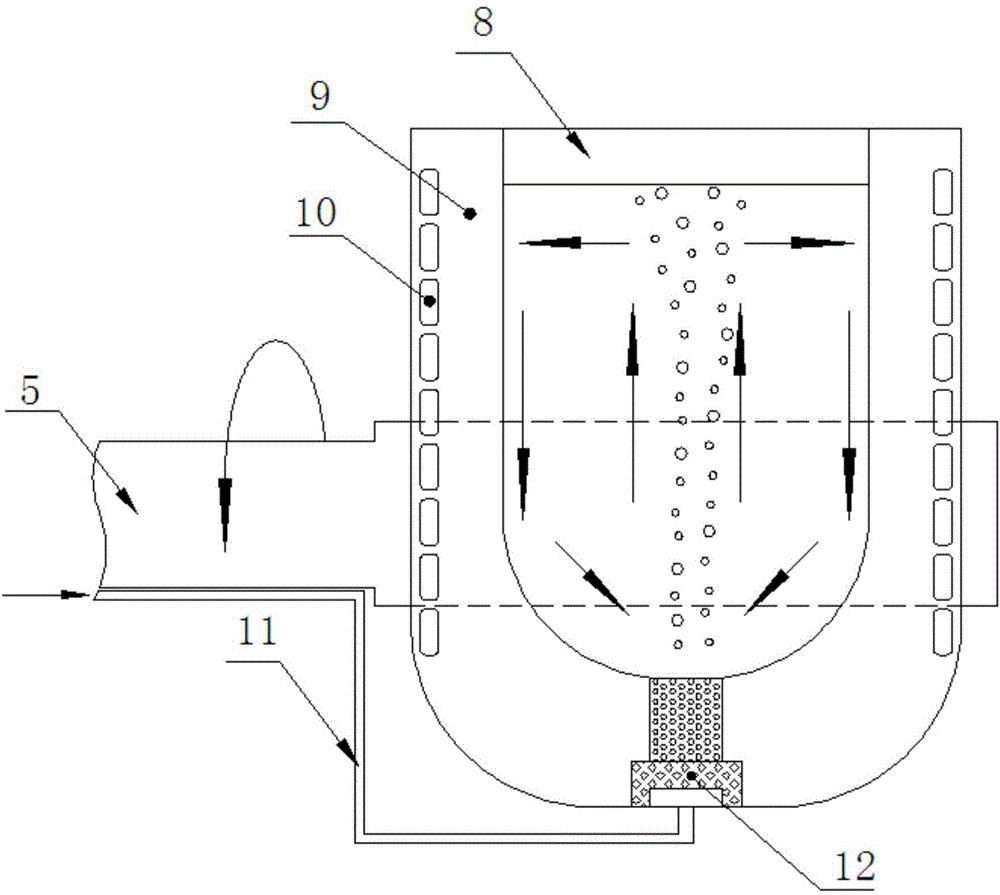

[0044] First open the furnace cover 2, put industrial pure iron in the furnace chamber 8, close the furnace cover 2, energize the induction coil 10, the induction coil 10 heats up the induction furnace 4, start the air pump, and evacuate the vacuum through the vacuum pumping pipe 7. The air in the chamber 3 is exhausted, and the vacuum chamber 3 is kept in a vacuum state. The furnace cavity 8 is heated to 1360° C. through the induction coil 10 and then kept warm. After the pure iron in the furnace cavity 8 is completely melted, alloys such as ferrosilicon, ferromanganese and ferrophosphorus are added according to the composition ratio. After the various alloys are melted, stop heating, keep warm in a vacuum environment, add an inoculant (usually the density of the inoculant is lower than the molten ir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com