Bearing steel high temperature heating protective coating and using method thereof

A technology for high-temperature heating and coating protection, applied in coating and other directions, can solve problems such as billet sticking to steel, billet oxidative burning problems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

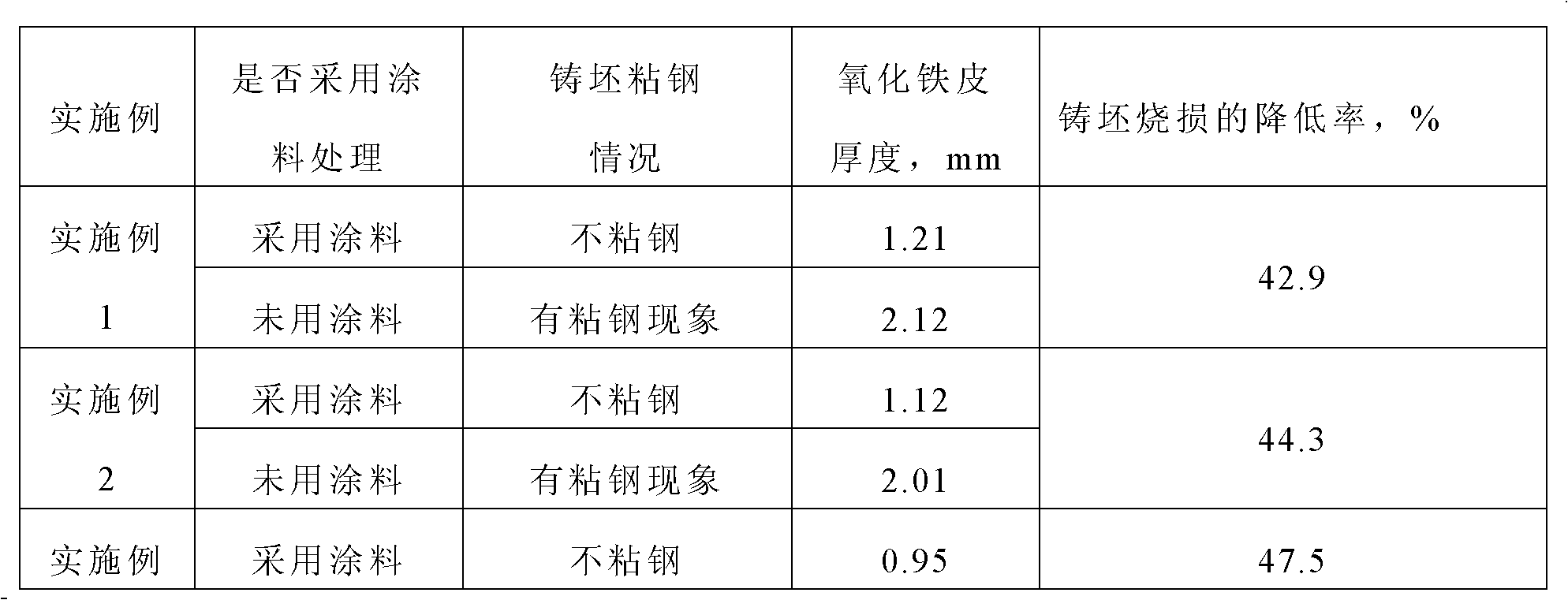

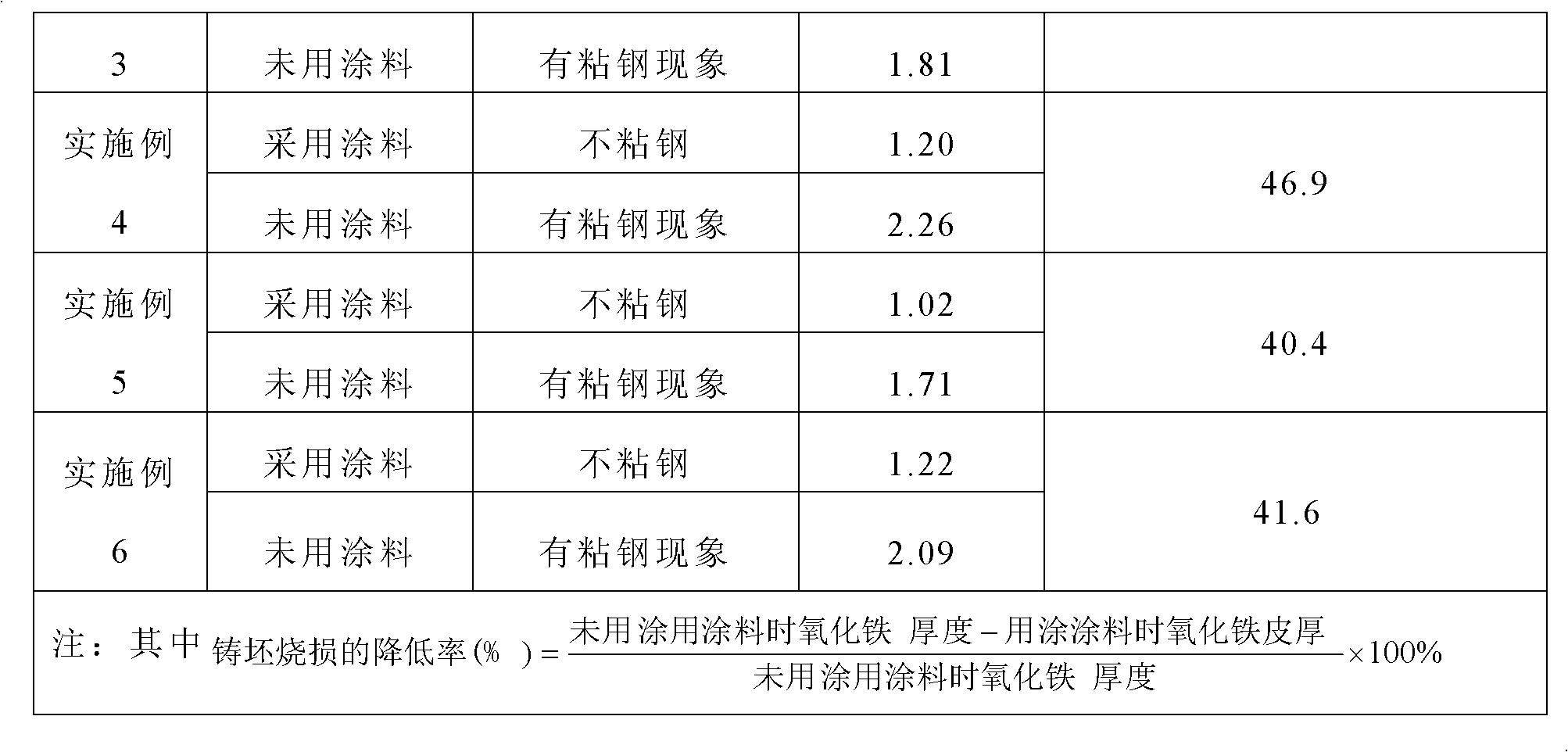

Examples

Embodiment 1

[0017] Divide the continuous casting high-carbon chromium bearing steel billet with the same batch number of 200×200 mm in section into two parts, one part of the billet is not treated with protective coating, and the other part of the billet is directly sprayed on the surface with the protective coating of the present invention, and the two parts of the billet are Send them together into a pusher-type heating furnace for heating. The heating time is 3 to 5 hours. The maximum temperature in the heating furnace is 1260 ° C, and the holding time of the high temperature section above 1200 ° C is 80 min. The specific operation method is:

[0018] 1) According to the weight percentage, the content is: MgO: 55%, CaO: 8%, TiO 2 : 30%, P 2 o 5 : 4%, Na 2 O: 3%, configure solid components;

[0019] 2) reconcile the solid component with water equivalent to 40% by weight of the solid component to make a slurry;

[0020] 3) Then, under the condition that the surface temperature of th...

Embodiment 2

[0023] Divide the continuous casting high-carbon chromium bearing steel billet with the cross-section specification of 200×200mm in the same batch number into two parts, one part of the billet is not treated with protective coating, and the other part of the billet is directly sprayed on the surface with the protective coating of the present invention, and then the two parts are The steel billets are sent together into the push steel heating furnace for heating. The heating time is 3 to 5 hours. The maximum temperature in the heating furnace is 1260°C, and the holding time of the high temperature section above 1200°C is 80 minutes. The specific operation method is:

[0024] 1) According to the weight percentage, the content is: MgO: 75%, CaO: 6%, TiO 2 : 11.5%, P 2 o 5 : 5%, Na 2 O: 2.5% configured solid components;

[0025] 2) reconcile the solid component with water equivalent to 30% by weight of the solid component to make a slurry;

[0026] 3) Then, under the conditio...

Embodiment 3

[0029] Divide the continuous casting high-carbon chromium bearing steel billet with the cross-section specification of 200×200mm in the same batch number into two parts, one part of the billet is not treated with protective coating, and the other part of the billet is directly sprayed on the surface with the protective coating of the present invention, and then the two parts are The steel billets are sent together into the push steel heating furnace for heating. The heating time is 3 to 5 hours. The maximum temperature in the heating furnace is 1260°C, and the holding time of the high temperature section above 1200°C is 80 minutes. The specific operation method is:

[0030] 1) According to the weight percentage, the content is: MgO: 63%, CaO: 9%, TiO 2 : 18%, P 2 o 5 : 5%, Na 2 O: 5%, configure solid components;

[0031] 2) reconcile the solid component with water equivalent to 25% by weight of the solid component to make a slurry;

[0032] 3) Then, under the condition th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com