Method for adding additive for electroslag remelting alloy tool and die steel

A technology for tool and die steel and electroslag remelting, which is applied in the field of adding additives for electroslag remelting alloy tool and die steel, can solve the problems of large oxidation burning loss of active metamorphic elements, low yield and less metamorphism, and achieves Avoid oxidative burning loss, high yield, good effect of deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] A method for adding additives for electroslag remelting alloy tool and die steel, comprising the following steps:

[0016] (1) The additives are evenly dropped on the surface of the low-carbon mild steel strip through the funnel of the wrapping machine, and the steel strip with additives passes through multiple cold-bending rolls of the wrapping machine, and gradually deforms the radial deformation on both sides of the strip, bends and rolls it Closed metal cored wire; mild steel strip wall thickness 0.3 mm, width 40 mm; metal cored wire inner diameter φ12 mm.

[0017] (2) Hang the metal cored wire directly into the steel mold of the consumable electrode.

Embodiment 2

[0018] Embodiment 2 impact resistance test

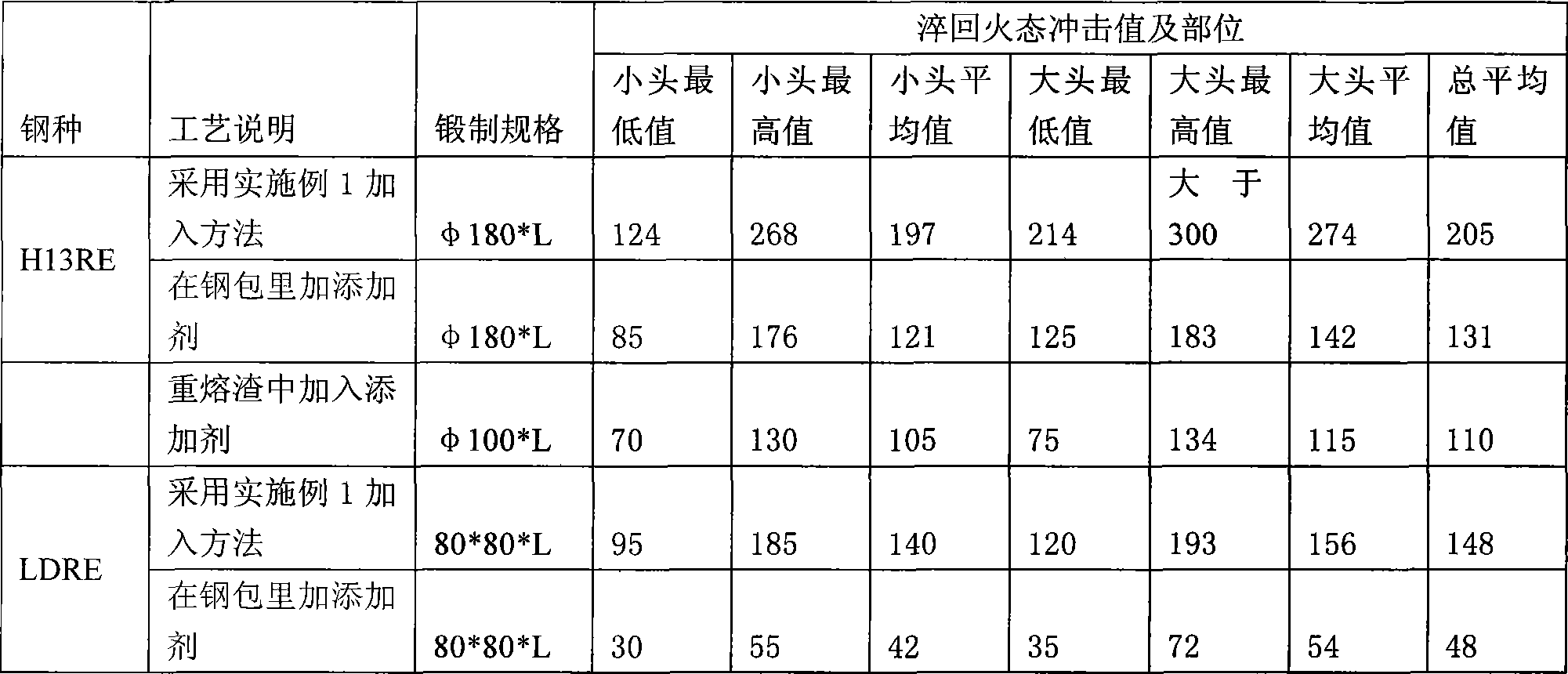

[0019] Electroslag remelted die steels were tested with different additive addition methods, and the impact resistance of the electroslag remelted die steels was tested. The test results are shown in Table 1:

[0020] Table 1 Effect of different processes on the impact resistance of die steel

[0021]

[0022] Note: The additives in different processes are the same formula.

[0023] As can be seen from the results in Table 1, the addition method of the present invention can greatly improve the impact resistance of the mold steel.

Embodiment 3

[0025] Using different additive addition methods for electroslag remelting die steel H13, the thermal fatigue test was carried out on the electroslag remelting die steel. The test results are shown in Table 2:

[0026] Table 2 Effect of different processes on thermal fatigue properties of die steel

[0027] parameter Adding additives to the ladle Adding additives to heavy slag Adopt embodiment 1 to add method surface damage factor 2.99×10 -4 2.89×10 -4 3.50×10 -4 depth damage factor 2.34×10 -2 2.36×10 -2 1.23×10 -2 total damage factor 7.00×10 -6 7.12×10 -6 4.31×10 -6

[0028] Note: The additives in different processes are the same formula.

[0029] From the above analysis and comparison, it can be seen that the thermal fatigue performance of the mold steel is greatly enhanced by hanging the metal cored wire wrapped with additives in the electroslag remelting process in the method of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com