Fe-X-C grain refiner and preparation method thereof

A grain refiner, fe-x-c technology, applied in the field of metal materials, can solve problems such as easy segregation, and achieve the effects of simple preparation, low cost and grain refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

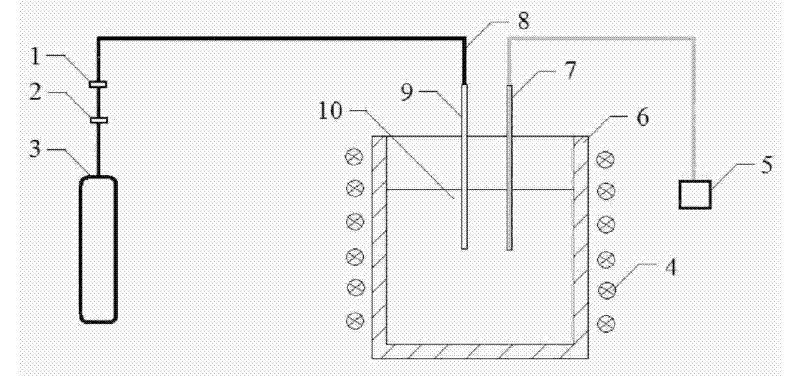

[0027] As shown in Table 1, the preparation process of this embodiment includes the following steps:

[0028] Step 1, mixing Fe-C alloy with metal Ti, melting the mixture in a vacuum intermediate frequency induction furnace to obtain a melt; the mixing needs to make the mass percentage of each element in the obtained mixture: Fe 99.4%, Ti 0.5% , C 0.1%;

[0029] Step 2, when the temperature of the melt is 1650°C, feed argon into the melt, the flow rate of the argon is 1000ml / min, and the time is 3h;

[0030] Step 3: Stop feeding the argon gas, cut off the power, and obtain the steel grain refiner.

[0031] The TiC particle size in the grain refiner prepared in this example is mainly concentrated in 0.5-5 μm, and the TiC density is 10 4 piece / mm 3 .

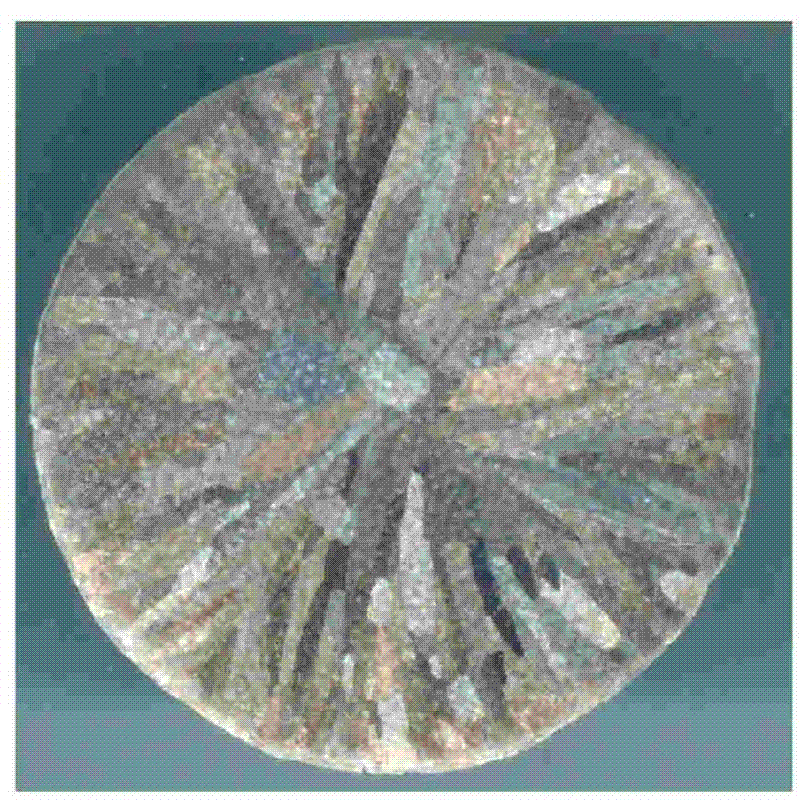

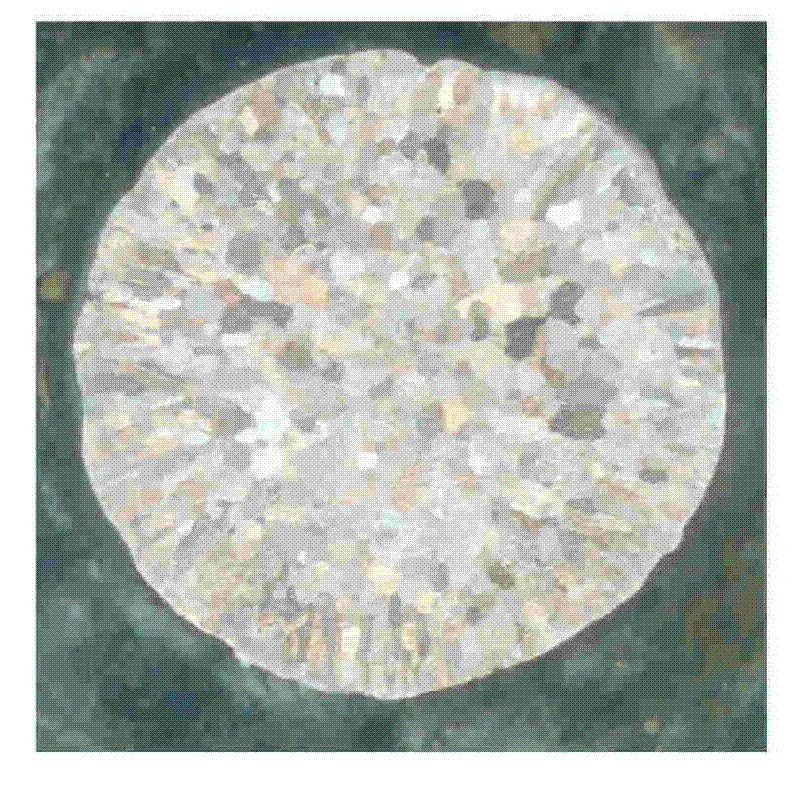

[0032] After heating 409L ferritic stainless steel to 1530°C in a vacuum intermediate frequency induction furnace, the molten steel is cast. The macrostructure of 409L steel without adding refiner is as follows figure 2 As ...

Embodiment 2

[0034] As shown in Table 1, the preparation process of this embodiment includes the following steps:

[0035] Step 1, mixing Fe-C alloy with metal Ti, metal V and metal Nb, melting the mixture in a vacuum intermediate frequency induction furnace to obtain a melt; the mixing needs to make the mass percentage of each element in the obtained mixture: Fe 35%, Ti25%, Nb 25%, C 15%;

[0036] Step 2, when the temperature of the melt is 1600°C, argon is introduced into the melt, the flow rate of the argon is 500ml / min, and the time is 1.5h;

[0037] Step 3: Stop feeding the argon gas, cut off the power, and obtain the steel grain refiner.

[0038] The particle density of XC in the grain refiner prepared in this embodiment is 10 7 piece / mm 3 . The grain refiner prepared in this embodiment can refine the grains of the steel, so that the proportion of equiaxed grain regions in the as-cast structure of the billet can be increased.

Embodiment 3

[0040] As shown in Table 1, the preparation process of this embodiment includes the following steps:

[0041] Step 1, mix pure iron, graphite with metal Ti, metal V and metal Nb, and melt the mixture in a vacuum intermediate frequency induction furnace to obtain a melt; the mixing needs to make the mass percentage of each element in the obtained mixture: Fe 67.5%, Ti10%, V 5%, Nb 10%, C 7.5%;

[0042] Step 2, when the temperature of the melt is 1550°C, feed argon into the melt, the flow rate of the argon is 100ml / min, and the time is 10s;

[0043] Step 3: Stop feeding the argon gas, cut off the power, and obtain the steel grain refiner.

[0044] The XC density in the grain refiner prepared in this embodiment is 10 8 piece / mm 3 . The grain refiner prepared in this embodiment can refine the grains of the steel, so that the proportion of equiaxed grain regions in the as-cast structure of the billet can be increased.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com