Electroslag remelting process of titanium-containing alloy steel

A technology of electroslag remelting and titanium alloy steel, which is applied in the field of steelmaking technology, can solve the problems of increasing production costs, achieve the effects of ensuring quality, shortening the process flow, and reducing the investment in slag purification equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

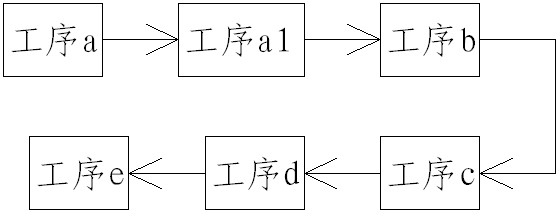

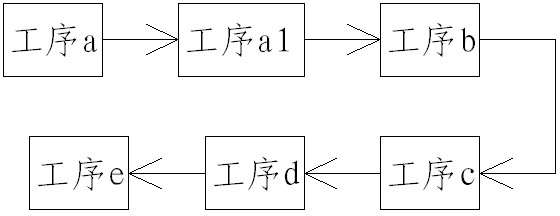

[0033] figure 1 It is a flow chart of the electroslag remelting process of the titanium-containing alloy steel of the present invention.

[0034] As shown in the figure, the electroslag remelting process of titanium-containing alloy steel in this embodiment includes the following steps:

[0035] a. Prepare consumable electrodes;

[0036] b. Electroslag preparation;

[0037] c. Electroslag forming;

[0038] d. Electroslag remelting;

[0039] In the process of electroslag slagging in the process c, one-third of the total amount of slag is added to the crystallizer to make slagging, and the remaining slag is mixed with an appropriate amount of a mixture including Al powder and FeTi powder, and then added to the crystallizer to make slagging . In specific implementation, the proportion relationship of remaining slag, Al powder and FeTi powder needs to be adjusted according to different titanium-containing alloy steels in order to obtain the best protection effect and en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com