Weak-smell low-corrosion gear lubricant additive composition and preparation method thereof

A gear lubricating oil, the technology of the composition, applied in the low-corrosion gear lubricating oil additive composition and its preparation, the gear lubricating oil additive composition and its preparation, the field of low odor, can solve the application limitation, rust and anti-corrosion and The problems of unsatisfactory anti-oxidation and anti-foaming properties have achieved broad application prospects, improved rust and oxidation resistance, and good compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

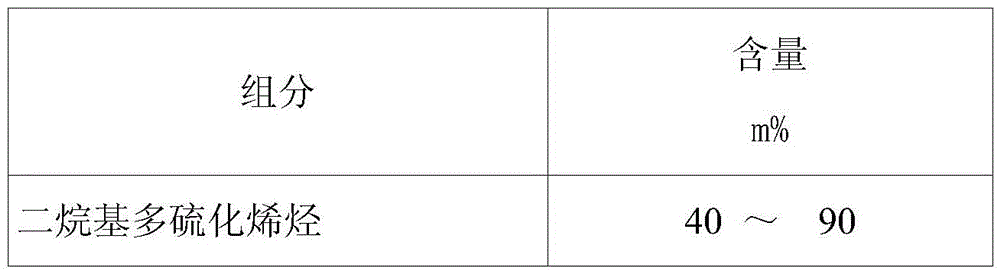

[0038] Lubricating oil additive composition (I), is made up of following composition by weight percentage:

[0039] 50.0% dialkyl polysulfide olefin (component A) with the structure R 1 -S n -R 2 , where n is an integer from 2 to 10, R 1 and R 2 for C 4 ~C 18 straight-chain or branched-chain alkyl groups, the active sulfur content of which accounts for more than 90m% of the total sulfur;

[0040] 12.0% dialkyl dithiophosphate (component B);

[0041] 0.5% organic molybdenum friction reducer (component C);

[0042] 1.0% dodecenylsuccinic acid (component D);

[0043] 5.0% thiadiazole derivatives (component E);

[0044] 2.0% dinonyl diphenylamine and 2.0m% sulfurized alkylphenol antioxidant (component F);

[0045] 27.5% 150SN Neutral Oil (Component G).

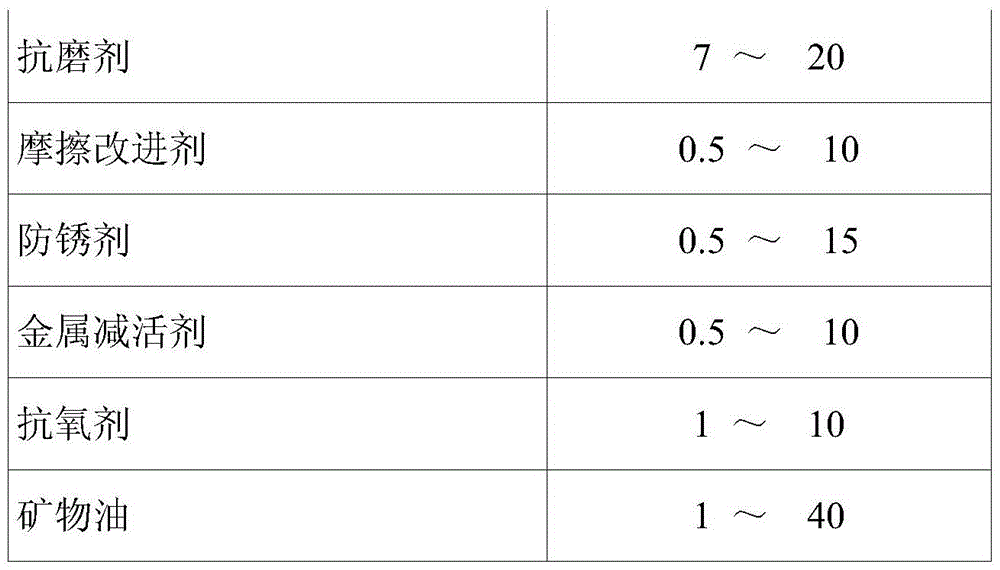

[0046] Lubricating oil composition (II) is the same as composition (I) except that component E is replaced by 3.5m% thiadiazole derivatives and 1.5m% alkylimidazoline derivatives. The main properties of composition (I)...

Embodiment 2

[0050] The lubricating oil additive composition (III) consists of the following components by weight percentage:

[0051] 55% dialkyl polysulfide olefin (component A), its structure is R1-Sn-R2, wherein n is an integer of 2 to 10, R1 and R2 are C4 to C18 linear or branched alkyl groups Group, the active sulfur component of which accounts for more than 90m% of the total sulfur;

[0052] 9% di-n-butyl phosphite (component B);

[0053] 1.0% triethyl borate (component C);

[0054] 1.5% alkenyl succinate half ester (component D);

[0055] 7% methyl benzotriazole (component E);

[0056] 2.5% phenol ester type antioxidant and 2.5% octyl butyl diphenylamine (component F);

[0057] 21.5% 150SN Neutral Oil (Component G).

[0058] Lubricating oil additive composition (IV) is the same as composition (III) except that component E is replaced by 3.5% LZ5955A and 3.5% commercially available T551 metal deactivator. The main properties of composition (III) and composition (IV) are shown ...

Embodiment 3

[0062] The lubricating oil additive composition (V) consists of the following components by weight percentage:

[0063] 60% dialkyl polysulfide olefin (component A), its structure is R1-Sn-R2, wherein n is an integer of 2 to 10, R1 and R2 are C4 to C18 linear or branched alkyl groups Group, its active sulfur component accounts for more than 90m% of the total sulfur;

[0064] 5% Alkyl Phosphate Derivative Antiwear Agent and 8% Phosphate Phosphate Amine Salt (Component B);

[0065] 1.5% fatty acid methyl ester (component C);

[0066] 1.0% alkenyl succinate and 1.0% fatty acid amide (component D);

[0067] 8% commercially available Hitec4313 thiadiazole compound and 0.5% benzotriazole derivative (component E);

[0068] 2% phenol ester type antioxidant and 2% dinonyl diphenylamine (component F);

[0069] 11% 150SN Neutral Oil (Component G).

[0070] Lubricating oil component (VI) is the same as composition (V) except that 8% of commercially available Hitec4313 thiadiazole compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com