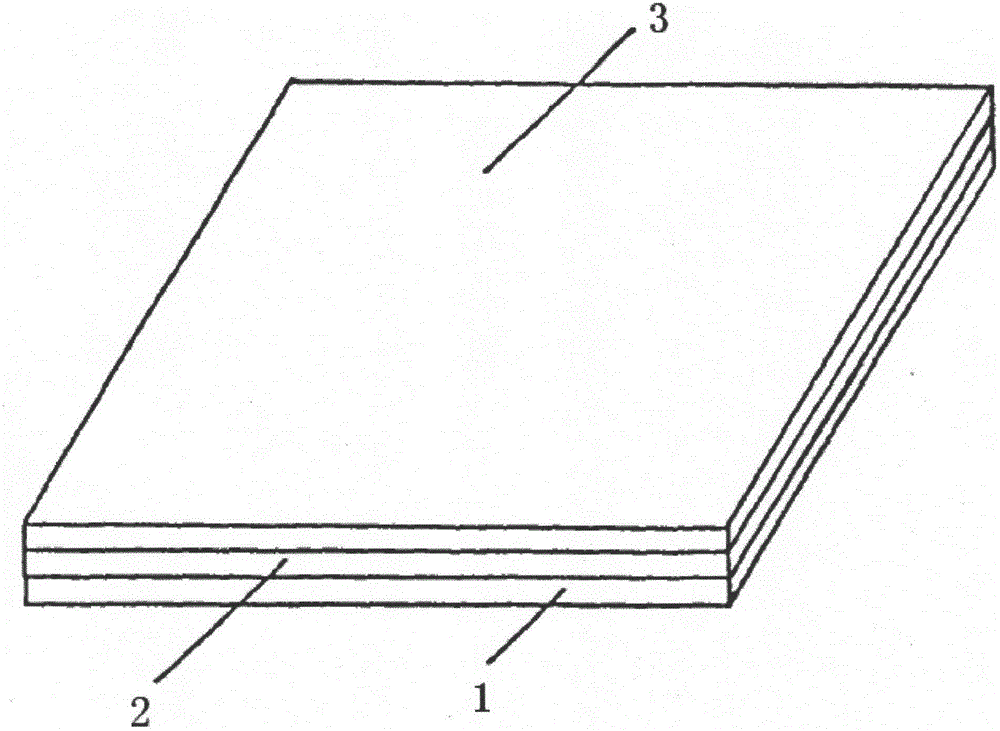

Power lithium ion battery and composite diaphragm thereof

A technology of lithium-ion batteries and composite diaphragms, which is applied in the field of lithium-ion batteries and their composite diaphragms, power lithium-ion batteries and their polytetrafluoroethylene composite diaphragms, can solve the problems of large internal resistance and difficulty in assembling batteries, and reduce short circuits chance, anti-oxidation and reduction performance, and the effect of improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

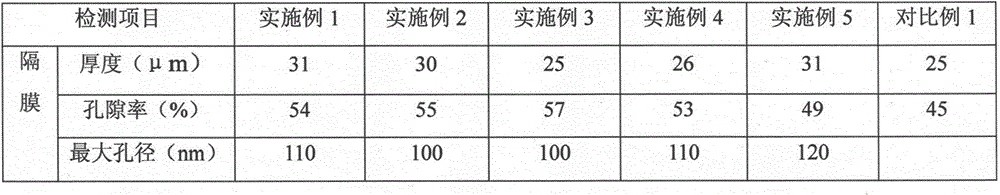

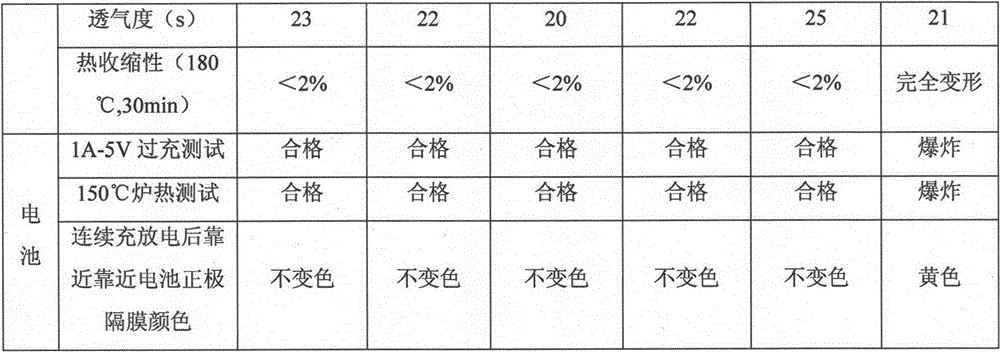

Embodiment 1

[0040] 1. Preparation of composite separator S-1

[0041] The first step: add methyltriethoxysilane to ethanol solvent to make a dilute solution with a concentration of 0.5% (mass ratio), adjust the pH value of the solution to 3.5 with 5% hydrochloric acid, stir evenly, and spray on the thickness The surface of the polyester non-woven fabric with a porosity of 8 μm and a porosity of 70% was baked at 150° C. for 5 minutes to form a support layer of a cured adhesion aid;

[0042] The second step: adding 15g mass concentration of 5% hydrochloric acid and 20g epoxy silane into 160g ethanol, after stirring evenly, spraying on the surface of the polytetrafluoroethylene layer modified by plasma treatment, polytetrafluoroethylene The thickness is 3 μm, the porosity is 80%, and it is baked at 200 ° C for 2 minutes to form a polytetrafluoroethylene layer with a cured adhesion aid;

[0043] Step 3: Add 50 grams of N-methylpyrrolidone into the beaker, stir with a mechanical stirrer at a ...

Embodiment 2

[0049] 1. Preparation of composite separator S-2

[0050] The first step: add methyltriethoxysilane to ethanol solvent to make a dilute solution with a concentration of 2.0% (mass ratio), adjust the pH value of the solution to 4.0 with 5% hydrochloric acid, stir evenly, and spray on the thickness The surface of the polyester non-woven fabric with a porosity of 15 μm and a porosity of 70% was baked at 150° C. for 5 minutes to form a support layer of a cured adhesion aid;

[0051] The second step: adding 15g mass concentration of 5% hydrochloric acid and 20g epoxy silane into 160g ethanol, after stirring evenly, spraying on the surface of the polytetrafluoroethylene layer modified by plasma treatment, polytetrafluoroethylene The thickness is 10 μm, the porosity is 78%, and it is baked at 200 ° C for 2 minutes to form a polytetrafluoroethylene layer with a cured adhesion aid;

[0052] Step 3: Add 50 grams of N-methylpyrrolidone into the beaker, stir with a mechanical stirrer at ...

Embodiment 3

[0058] 1. Preparation of composite separator S-3

[0059] The first step: add methyltriethoxysilane to ethanol solvent to make a dilute solution with a concentration of 1.0% (mass ratio), adjust the pH value of the solution to 5.5 with 5% hydrochloric acid, stir well, and spray on the thickness The surface of the polyester non-woven fabric with a porosity of 10 μm and a porosity of 81% was baked at 150° C. for 5 minutes to form a support layer of a cured adhesion aid;

[0060] The second step: adding 15g mass concentration of 5% hydrochloric acid and 20g epoxy silane into 160g ethanol, after stirring evenly, spraying on the surface of the polytetrafluoroethylene layer modified by plasma treatment, polytetrafluoroethylene The thickness is 5 μm, the porosity is 88%, and it is baked at 200 ° C for 2 minutes to form a polytetrafluoroethylene layer with a cured adhesion aid;

[0061] Step 3: Add 50 grams of N-methylpyrrolidone into the beaker, stir with a mechanical stirrer at a s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com