Silver-coated copper powder, preparation method thereof and electronic paste

A technology of silver-coated copper powder and electronic paste, which is applied in conductive materials, conductive materials, circuits, etc., can solve the problems of reducing the resistivity of silver-coated copper powder, etc., to improve the coating rate, low resistivity, and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

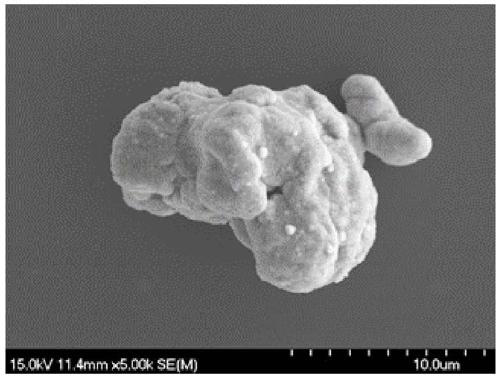

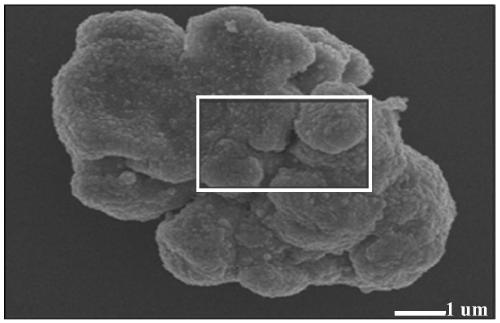

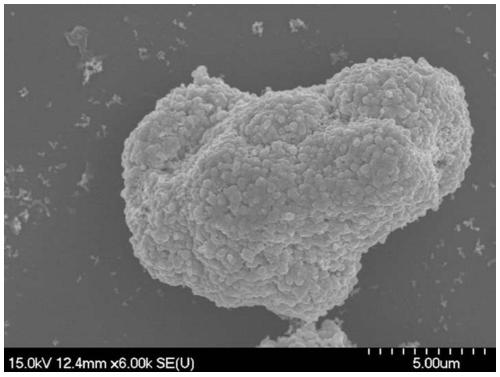

Image

Examples

preparation example Construction

[0038] The embodiment of the present invention provides a method for preparing silver-coated copper powder, comprising the following steps:

[0039] S10. Obtain copper powder, mix the copper powder with the first silver ammonia solution and the first reducing agent, add ammonia water, mix and process, and separate to obtain an intermediate product; wherein, the copper powder and the first silver ammonia solution The molar ratio to the first reducing agent is 1.26: (0.06-0.30): (0.05-0.25);

[0040]S20. After the intermediate product is mixed and reacted with the second silver ammonia solution and the second reducing agent, the silver-coated copper powder is obtained by separating; wherein, the molar amount of the copper powder and the second silver ammonia solution and the second reducing agent The ratio is 1.26:(0.06~0.20):(0.02~0.15).

[0041] The preparation method of the silver-coated copper powder provided by the embodiment of the present invention, first, according to t...

Embodiment 1

[0061] A kind of silver clad copper powder, its preparation comprises steps:

[0062] ①Copper powder pretreatment: The purchased copper powder is first ultrasonically cleaned with octylphenol polyoxyethylene ether-10 on micron copper for 5-10 minutes, and repeated ultrasonic cleaning with deionized water three times to remove octylphenol polyoxyethylene ether-10 ; Then use 5% dilute sulfuric acid to ultrasonically clean the micron copper powder for 5-10 minutes to remove the oxide film on its surface, and then use deionized water to repeatedly ultrasonically clean it three times until the washing solution is neutral, and the obtained copper powder is ready for use.

[0063] ② Configuration of silver ammonia solution: Dissolve 4.5g of silver nitrate in 100ml of aqueous solution, and drop ammonia water with a volume fraction of 20% into the silver nitrate solution while stirring, until the precipitate just disappears, and set aside.

[0064] ③ Take 40ml of prepared silver ammoni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com