Flexible transparent silver grid composite electrode and production method thereof

A composite electrode and manufacturing method technology, applied in cable/conductor manufacturing, circuits, electrical components, etc., can solve the problem of electrode absence, and achieve the effect of improving flexibility, reducing surface roughness, anti-oxidation ability, and excellent comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

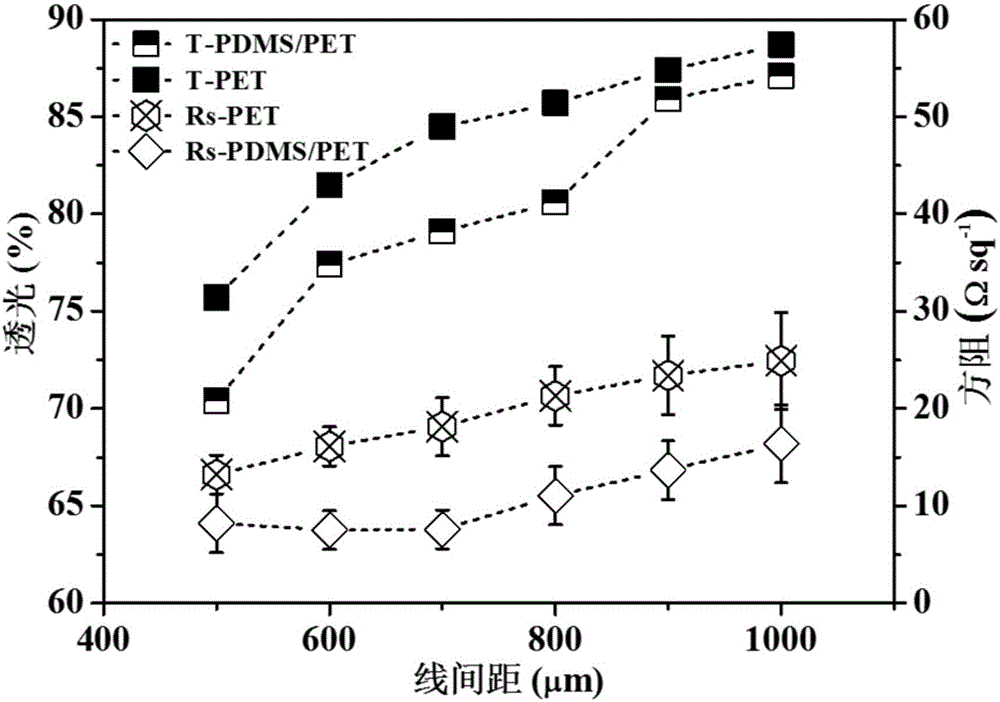

Embodiment 1

[0014] The PDMS substrate was plasma treated for 3s, placed on the printing platform and heated to 55°C. The control point spacing is 50μm, the line spacing is 1000μm, and a silver grid is printed on the processed PDMS substrate. Place on the heating table and anneal at 120°C for 1h. After cooling, the dot pitch was controlled to 40 μm, and a layer of PEDOT:PSS doped with 6% ethylene glycol and 2% surfactant was printed on it. Place on the heating table and anneal at 120°C for 15 minutes.

Embodiment 2

[0016] Place the PET on the printing platform and raise the temperature to 55° C., control the dot pitch to 50 μm and the line pitch to 1000 μm, and print a silver grid on it. Place on the heating table and anneal at 120°C for 1h. After cooling, the dot pitch was controlled to 40 μm, and a layer of PEDOT:PSS doped with 6% ethylene glycol and 2% surfactant was printed on it. Place on the heating table and anneal at 120°C for 15 minutes.

Embodiment 3

[0018] The PDMS substrate was plasma treated for 3s, placed on the printing platform and heated to 55°C. The control point spacing is 50μm, the line spacing is 1000μm, and a silver grid is printed on the processed PDMS substrate. Place on the heating table and anneal at 120°C for 1h. After cooling, the dot pitch was controlled to 40 μm, and a layer of ZnO nanoparticle dispersion was printed on it. Place on the heating table and anneal at 120°C for 15 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com