Method for preparing low-temperature interconnected high-temperature in-service joint by using single-phase nano silver-copper alloy solder paste

A high-temperature service, nano-silver technology, applied in the field of micro-connection, can solve problems such as affecting the performance of sintered joints, easy oxidation, and restricting applications, and achieves strong resistance to electromigration and electrochemical migration, strong oxidation resistance, and compatibility. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

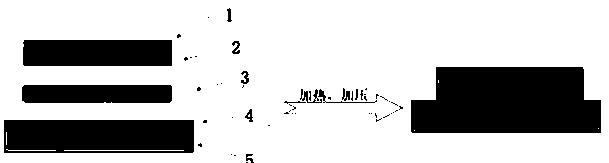

[0029] The low-temperature interconnection high-temperature service joint includes a part to be welded 1, a pad I2, a solder paste 3, a pad II4 and a substrate 5, the substrate 5 is welded with a pad II4, and the part to be welded 1 is welded with a pad I2 , the solder paste 3 is located between the pad I2 and the pad II4, and in the following specific implementation manner, the solder paste 3 is a single-phase nano-silver-copper alloy solder paste.

[0030] A method for preparing low-temperature interconnection high-temperature service joints by adopting single-phase nano-silver-copper alloy solder paste, comprising the following steps:

[0031] Lay the single-phase nano-silver-copper alloy solder paste on the pad II4 by screen printing or dispensing, align the pad I2 with the pad II4, and apply a pressure of 0.2~10Mpa to the part to be welded 1;

[0032] Step 2: Put the above system into a reflow furnace, heat it to 180-200°C at a rate of 2-10°C / min to complete the preheatin...

Embodiment 1

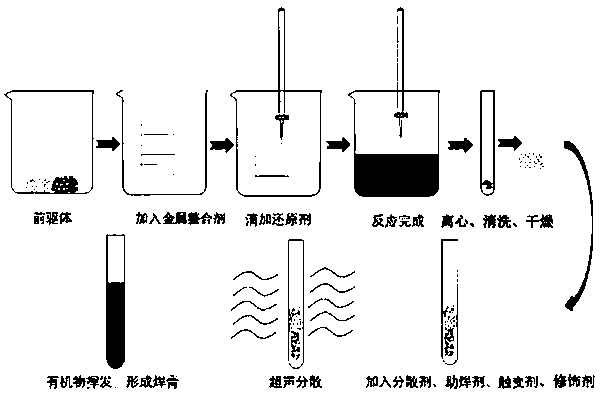

[0049] Such as figure 1 , 2 As shown, when a lower pressure is applied, the single-phase nano-alloy particle solder paste interconnection joint forming method includes the following steps:

[0050] Step 1: Incorporate AgNO 3 and CuCl 2 As a precursor, it is placed in a reaction vessel with a molar ratio of 1:1;

[0051] Step 2: adding deionized water into the reaction vessel as a solvent to completely dissolve the metal precursor to obtain a precursor solution;

[0052] Step 3: Add a metal chelating agent to the precursor solution and fully stir to obtain a reaction solution, wherein the molar ratio of the precursor to the metal chelating agent is 4:1, the stirring speed is 200r / min, and the stirring time is 2min; the metal The chelating agent is 2-hydroxypropane-1,2,3-tricarboxylic acid and 2-hydroxypropane-1,2,3-tricarboxylic acid potassium salt;

[0053] Step 4: Add a reducing agent solution with a concentration of 4 mol / L dropwise to the reaction solution at a rate of...

Embodiment 2

[0060] Such as figure 1 , 2 As shown, when a higher pressure is applied, the single-phase nano-alloy particle solder paste interconnection joint forming method includes the following steps:

[0061] Step 1: Incorporate AgNO 3 and CuSO 4 As a precursor, it is placed in a reaction vessel with a molar ratio of 3:1;

[0062] Step 2: adding deionized water into the reaction vessel as a solvent to completely dissolve the metal precursor to obtain a precursor solution;

[0063] Step 3: Add a metal chelating agent to the precursor solution and fully stir to obtain a reaction solution, wherein the molar ratio of the precursor to the metal chelating agent is 10:1, the stirring speed is 400r / min, and the stirring time is 10min; the metal The chelating agent is 2-hydroxypropane-1,2,3-tricarboxylic acid sodium salt and disodium edetate;

[0064] Step 4: Add a reducing agent solution with a concentration of 2 mol / L to the reaction solution dropwise at a rate of 3 ml / min, the volume rat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com