Preparation method for EGCC phosphatide compound

A phospholipid complex and phospholipid technology, which can be used in food preparation, medical preparations with non-active ingredients, food science, etc., and can solve the problems of preparation and application of EGCG phospholipid complexes that have not been seen before.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

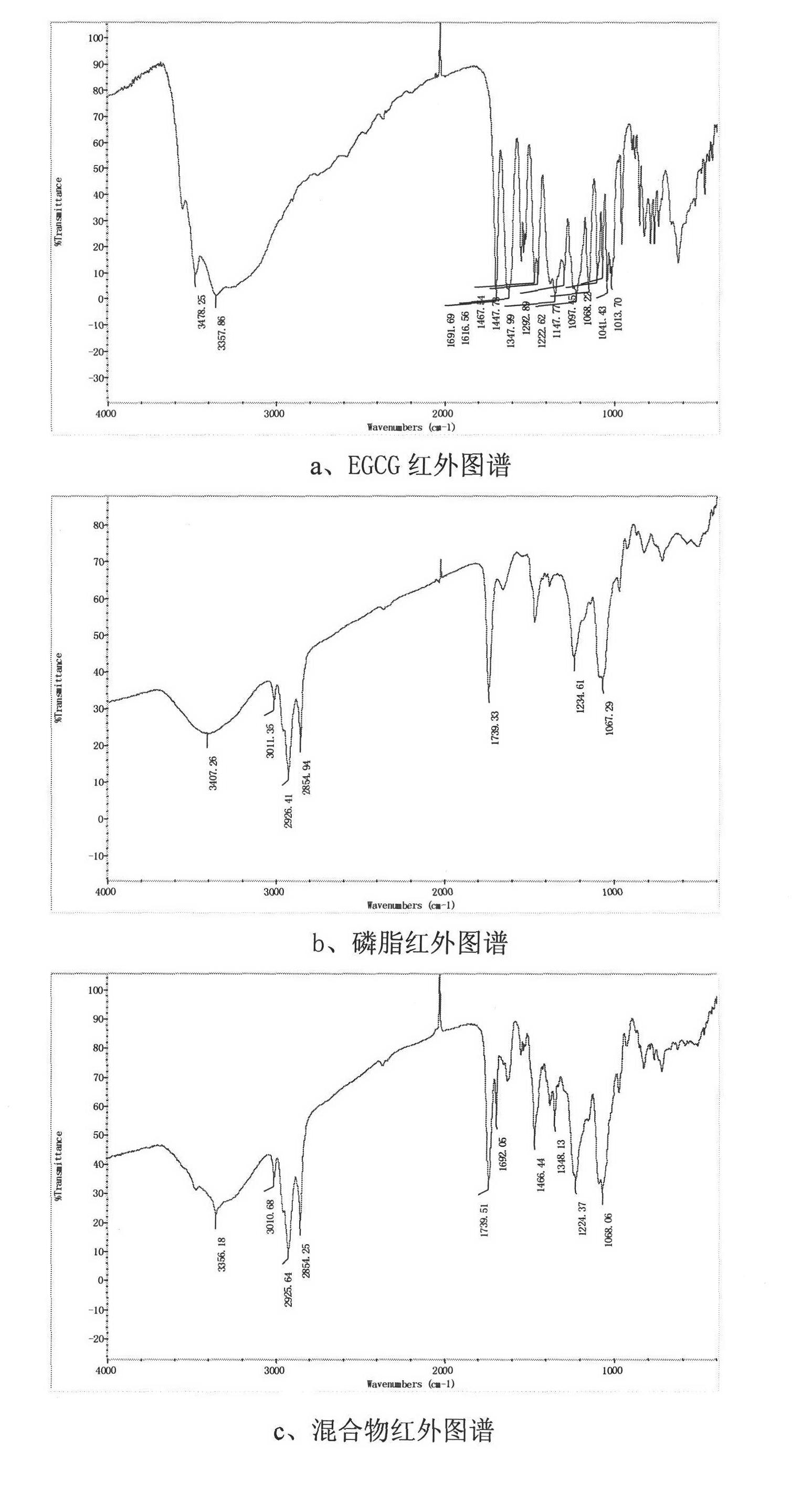

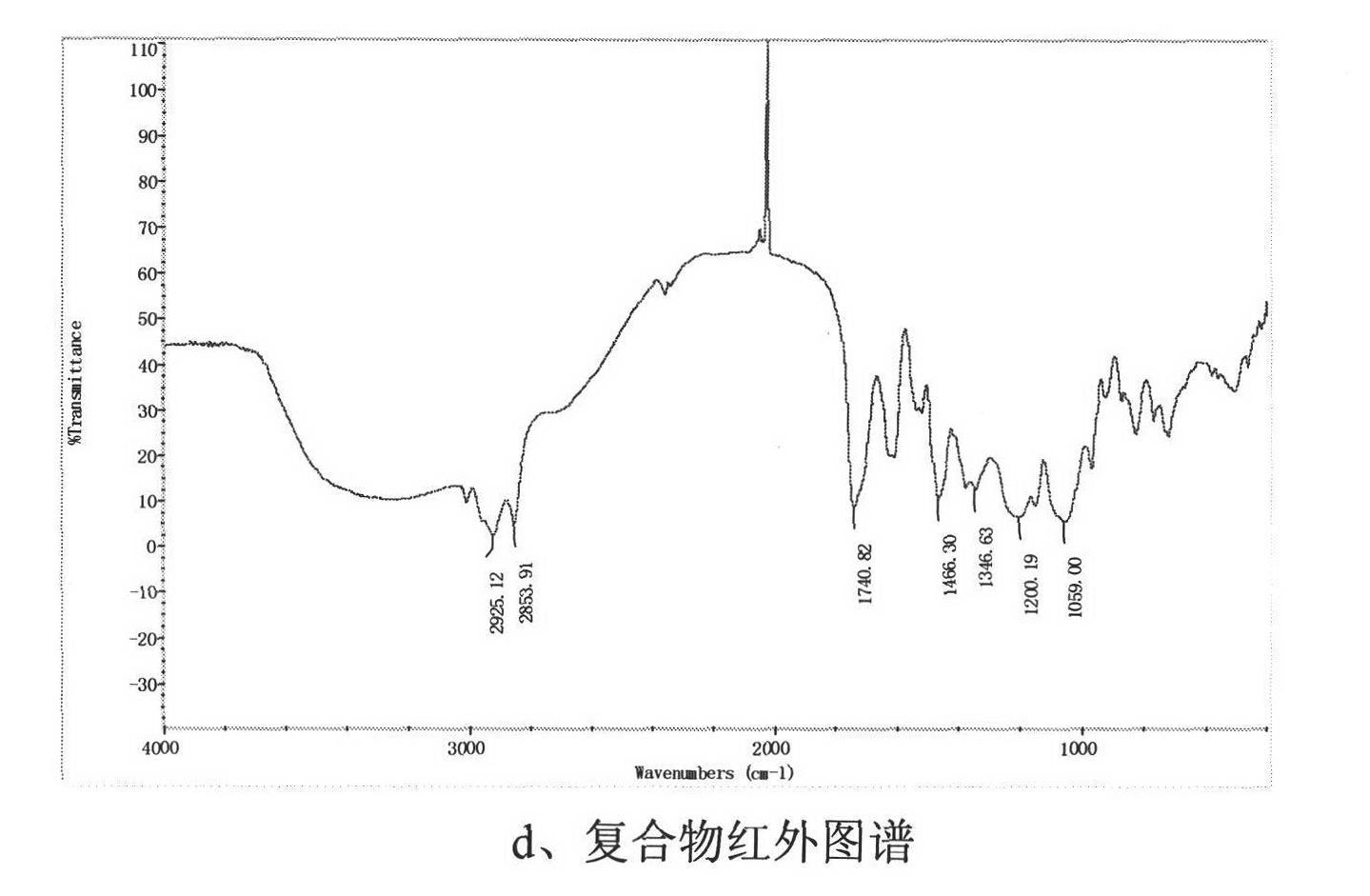

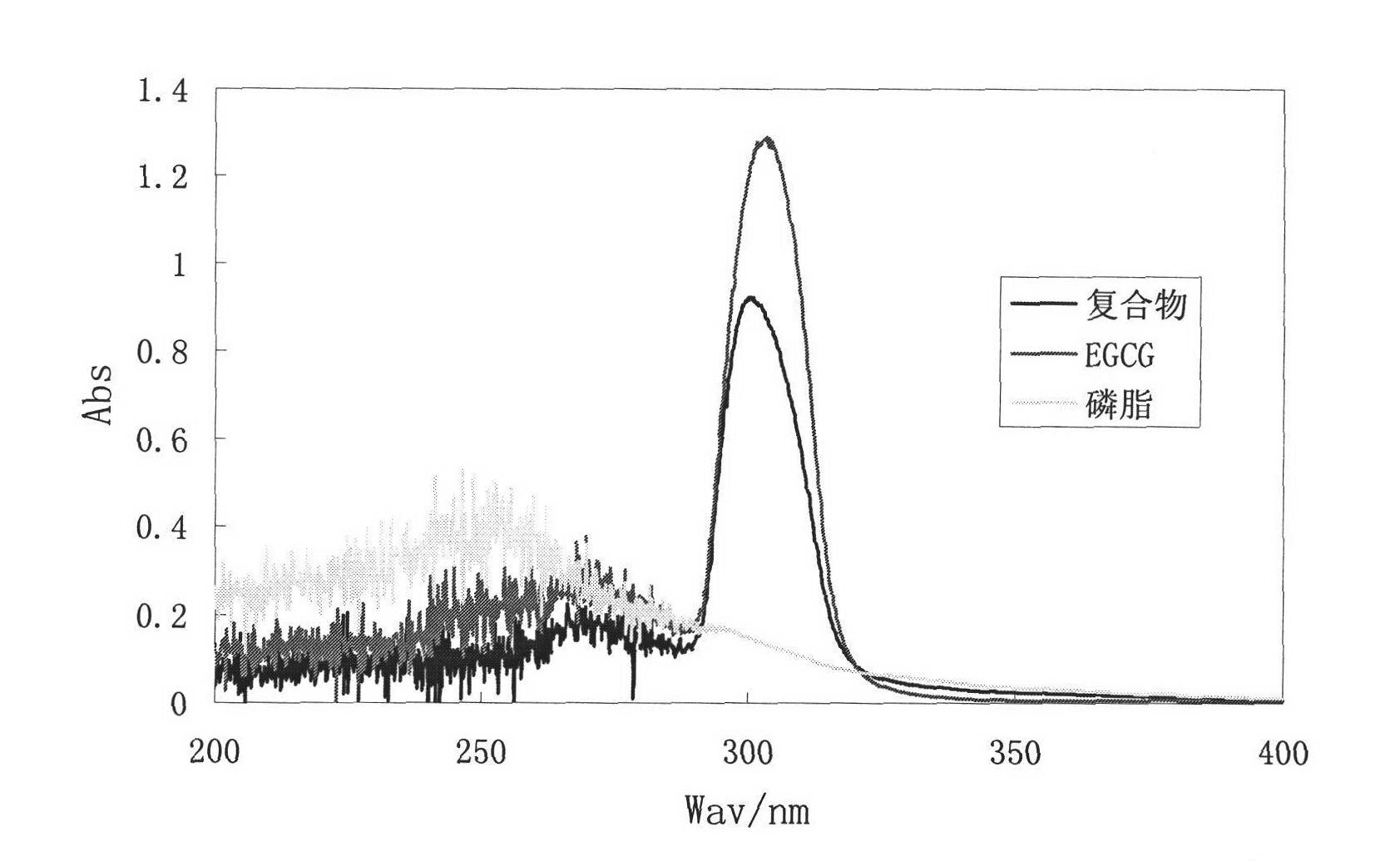

Image

Examples

Embodiment 1

[0018] Put 4.9 grams of soybean lecithin in a round-bottomed flask, add 100 milliliters of ethanol and stir to dissolve at room temperature, then gradually add 1 gram of EGCG while stirring, gradually raise the temperature to 40 ° C, and continue to stir and condense and reflux for 4 hours. Vacuum drying to obtain EGCG phospholipid complex products.

Embodiment 2

[0020] Dissolve 1 g of EGCG in 5 ml of ethanol. Another 1.8 grams of soybean lecithin was placed in a round bottom flask, and 35 milliliters of chloroform was added to dissolve at room temperature, then gradually added EGCG ethanol solution while stirring, and the temperature was gradually raised to 30°C, and the reaction was continuously stirred and condensed for 2 hours. Vacuum drying to obtain EGCG phospholipid complex products.

Embodiment 3

[0022] Dissolve 1 g of EGCG in 5 ml of ethanol. Another 3.4 grams of soybean lecithin was placed in a round-bottomed flask, and 70 milliliters of ethyl acetate was added to dissolve at room temperature, and then EGCG ethanol solution was gradually added while stirring, and the temperature was gradually raised to 40 ° C, and the reaction was continuously stirred and condensed for 3 hours. Vacuum drying to obtain EGCG phospholipid complex products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com