Pt-Sn-based mesoporous catalyst for anaerobic dehydrogenation of propane as well as preparation and application thereof

A catalyst and mesoporous-based technology, which is applied in the field of platinum-tin-based mesoporous catalysts for anaerobic dehydrogenation of propane, can solve problems such as poor crystallization performance, limited dispersion of active components, serious alkane cracking and carbon deposition reactions, and achieve The effect of improving conversion rate and selectivity, large specific surface area, and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] Pt 0.5 sn 1.0 Preparation of / SBA-16 catalyst (CTAB / F127=0.2, platinum loading is 0.5wt%, tin loading is 1.0wt%)

[0082] First, dissolve 3g of F127 in 144g of deionized water, add 0.6g of CTAB, stir thoroughly, add 5.94g of concentrated hydrochloric acid, stir in a water bath for 60min, then add 14.2g of tetraethyl orthosilicate, stir in a water bath for 24h, and crystallize in a 100°C oven 24h, then filter and wash the liquid in the crystallization tank, and then dry it in an oven at 100°C for 12h, at 2°C·min -1 The heating rate was roasted at 550°C for 6h to obtain the SBA-16 sample. Then take 0.133g H 2 PtCI 6 ·6H 2 O was dissolved in 10ml of deionized water, and then weighed 0.2649g of SnCl 4 ·5H 2 Dissolve O in 10ml of deionized water, take 5g of SBA-16 molecular sieve after it is completely dissolved, then add 5ml of the prepared precursor liquid to the molecular sieve dropwise with a pipette gun, stir while adding, after stirring evenly, ultrasonically cl...

Embodiment 2

[0084]The morphology of the as-prepared PtSn / SBA-16 catalyst was observed by transmission electron microscope (TEM). The BET specific surface area analyzer was used to analyze the specific surface area and pore size distribution of the catalyst, and ultraviolet-visible diffuse reflectance spectroscopy (UV-Vis DRS) was used to further understand the charge transfer and coordination structure of the sample.

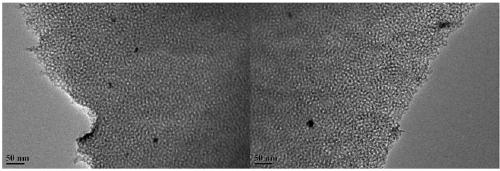

[0085] figure 1 For the Pt prepared in Example 1 0.5 sn 1.0 / SBA-16 (0.2CTAB) (left) and Pt 0.5 sn 1.0 / SBA-16 (right) Transmission electron microscope (TEM) photo of the catalyst. It can be seen from the figure that on the one hand, the average particle size of Pt added with CTAB is much smaller than that of pure SBA-16, which improves the utilization efficiency and reactivity of Pt; on the other hand, it also improves the dispersion of Pt, so that the catalyst has better stability.

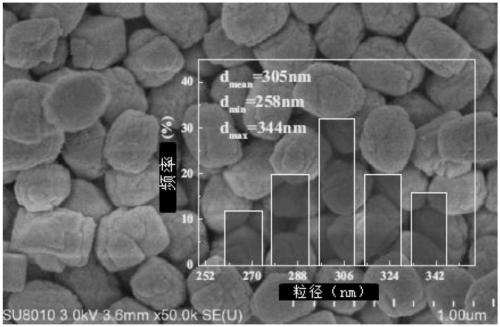

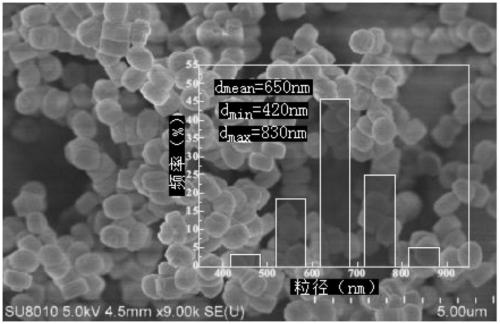

[0086] figure 2 and image 3 For the Pt prepared in Example 1 0.5 sn 1.0 / SBA-...

Embodiment 3

[0092] Catalyst Performance Evaluation:

[0093] Before the reaction activity test, about 0.15 g of the catalyst was weighed, and then put into a tablet machine for tableting and sieving, and a part of 40-60 mesh was taken to obtain a catalyst with a certain particle size. The reduction was performed under a hydrogen atmosphere and then tubed for activity testing.

[0094] The test device for catalyst activity is a fixed bed reactor. The fixed-bed reactor is connected to a gas chromatograph SP-2100 equipped with a nickel reformer, and the resulting catalyst activity will be analyzed on a computer.

[0095] Slowly put the sieved catalyst particles into the quartz reaction tube, fix the catalyst from both ends of the catalyst with quartz wool, and insert the thermocouple into the catalyst particle, so that the thermocouple can be in contact with the catalyst particle to obtain more accurate The reaction temperature of the catalyst. Open the flow switch of each gas, adjust to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com