Preparation method for micro-oil storage laser grid composite solid lubricating layer

A solid lubrication and meshing technology, which is applied in the direction of superimposed layer plating, solid diffusion coating, coating, etc., can solve problems such as wear and failure, and achieve the effects of high load bearing, reduced maintenance costs, and low friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

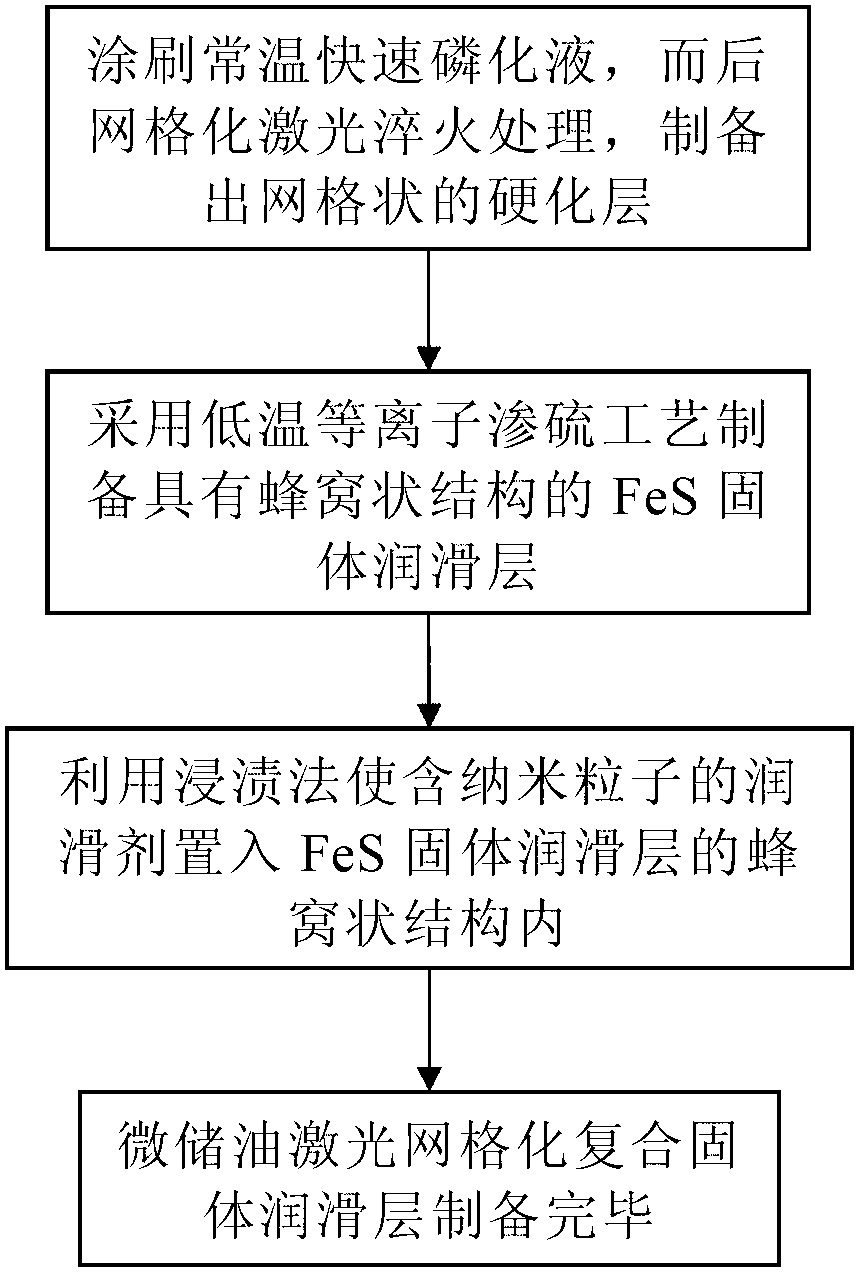

[0020] Such as figure 1 , the preparation method of the micro-oil storage laser grid composite solid lubricating layer of the present invention comprises the following steps:

[0021] Step 1: Brush the surface of the chromium molybdenum copper (CrMoCu) alloy cast iron of the mechanical equipment parts to be treated with a normal temperature rapid phosphating solution (known process liquid) that can speed up the laser quenching treatment speed, and wait for the normal temperature rapid phosphating solution After the liquid is dried, a gridded laser quenching treatment is carried out in a large laser processing system (a known processing system) to form a grid-like hardened layer on the surface of the chromium-molybdenum-copper alloy cast iron;

[0022] Step 2: using a low-temperature plasma sulfurizing process on high-frequency pulse plasma sulfurizing equipment (known equipment), and preparing a FeS solid lubricating layer with a honeycomb structure on the surface of the harde...

Embodiment

[0034] First, degrease and derust the surface of the chromium-molybdenum-copper alloy cast iron of the mechanical equipment parts to be treated, and then brush the normal temperature rapid phosphating solution on the surface of the chromium molybdenum copper alloy cast iron. After the normal temperature rapid phosphating solution dries, Gridded laser quenching treatment is carried out in a large laser processing system. The process parameters are: laser output power 350W, laser scanning speed 40mm / s, laser spot diameter 1.5mm, grid units are prepared on the surface of chrome-molybdenum-copper alloy cast iron A hardened layer with a diamond shape and a thickness of 0.45 mm.

[0035] Then, the low-temperature plasma sulfurizing process is adopted on the high-frequency pulse plasma sulfurizing equipment. The process parameters are: use sulfur vapor, working voltage 750V, working pressure 150Pa, sulfurizing temperature 210°C, holding time 2h, so that the surface of the hardened lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com