Ring steel structure support platform

A technology for supporting platforms and steel structures, applied in the direction of building structure support, building structure support, building structure, etc., can solve problems such as low work efficiency, high labor intensity, and support structures without rotation functions, and achieve stable connection performance, The effect of reducing labor intensity and not being easily damaged or deformed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

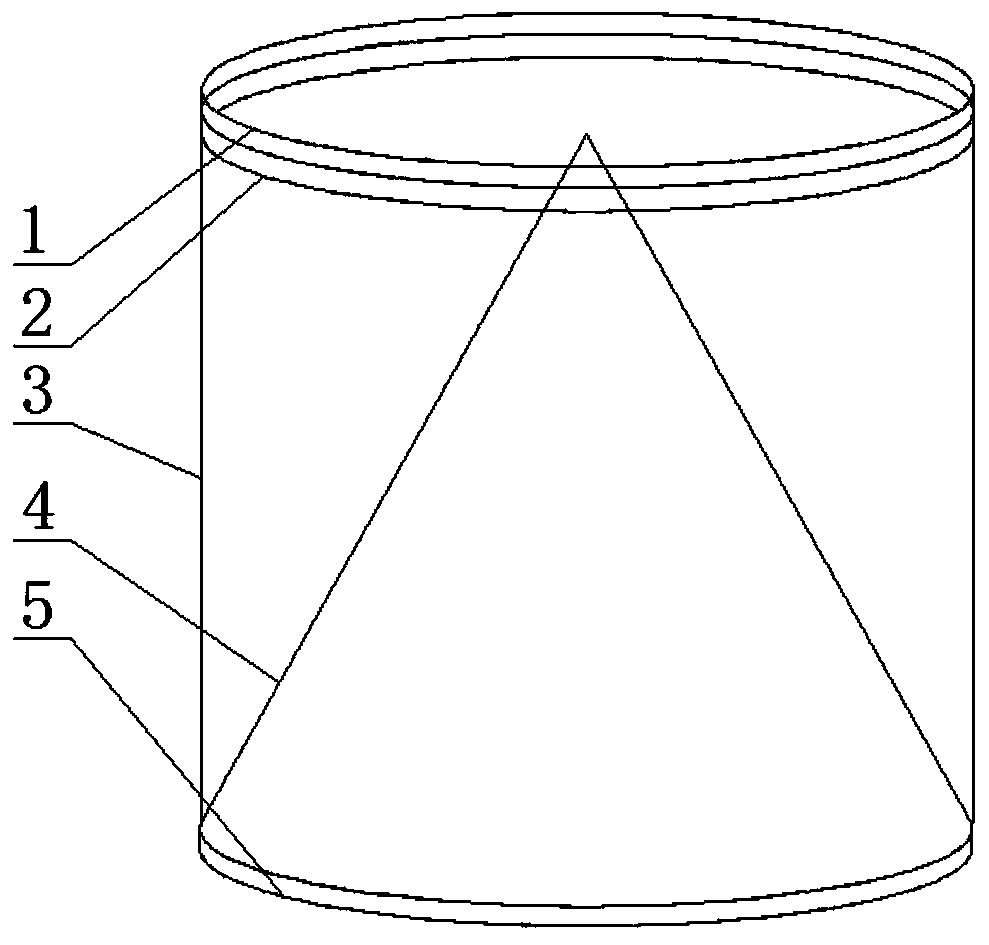

[0017] like figure 1 As shown, the ring-shaped steel structure support platform includes a base and a workbench. The base includes an upper ring and a lower ring arranged in parallel, and the upper ring and the lower ring are connected by several support frames at equal intervals. , extending from the center of the upper circular ring to the periphery of the downward circular ring, a tapered column is arranged, and the tapered column is set as a solid cylindrical structure to play a role of supporting stability. The parallel arrangement of the upper and lower rings is conducive to providing a horizontal support force that meets the requirements of the workbench. The synergy between the vertical support frame and the tapered column can increase the bearing capacity in the vertical direction and avoid part of the installation process of the workbench. The load and deformation caused by the upper and lower ring parts in the center achieve the purpose of shortening the installatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com