Reducing tapered roller bearing for single-row matching

A technology of tapered roller bearings and tapered rollers, applied in the direction of roller bearings, etc., can solve the problems of difficult adjustment, fixed radial or axial force capacity of symmetrical double-row tapered roller bearings, and affecting service life, etc., to achieve Reliable performance, simple structure and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

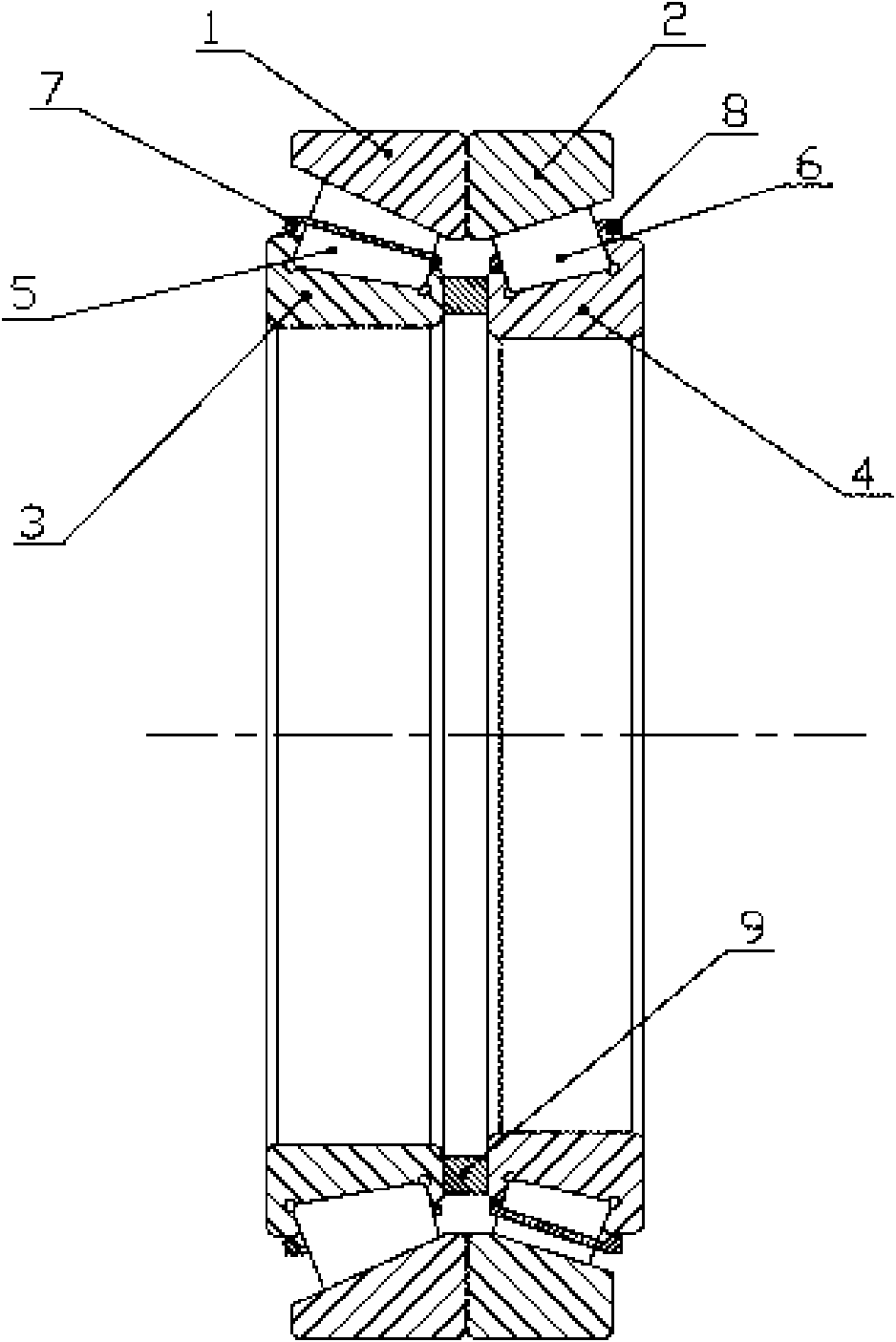

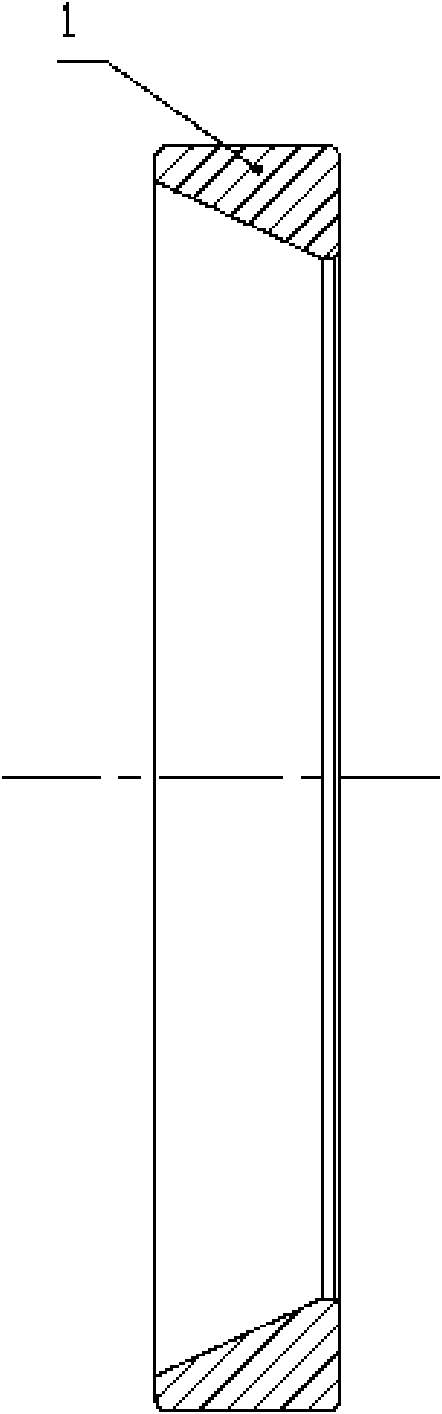

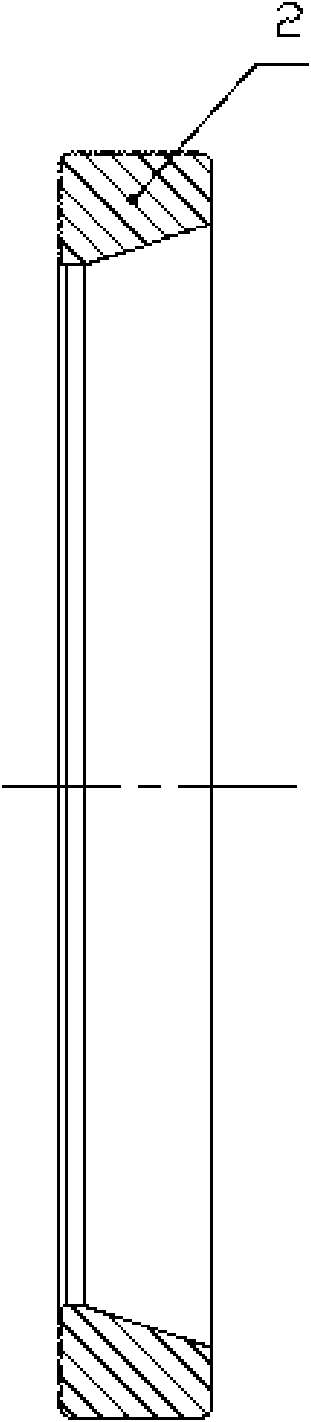

[0014] like Figure 1-6 As shown, the tapered roller bearing of the present invention includes outer rings 1 and 2, inner rings 3 and 4, and tapered rollers 5 and 6, and an inner spacer ring 9 is arranged between two rows of inner rings 3 and 4. Tapered rollers 5 and 6 are defined on cages 7 and 8, respectively. in, figure 1 The cone angle of the left outer ring 1 is greater than the cone angle of the right outer ring 2; the width of the outer ring 1 is greater than the width of the outer ring 2; the inner diameter of the left inner ring 3 is larger than the inner diameter of the right inner ring 4, and the inner ring 3 The width is greater than the width of the inner ring 4.

[0015] In the figure, the inner diameters and widths of the two rows of inner rings are different. The row with the larger inner diameter is used to bear the main load, and the row with the smaller inner diameter bears the secondary load and plays a role in slightly aligning the whole set of bearings....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com