A lift-type manned loading and unloading high-rise shelf

A lifting and shelf technology, applied in the field of storage shelves, can solve problems such as difficult loading and unloading of high-rise goods, and achieve the effects of improving structural safety, stable operation, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

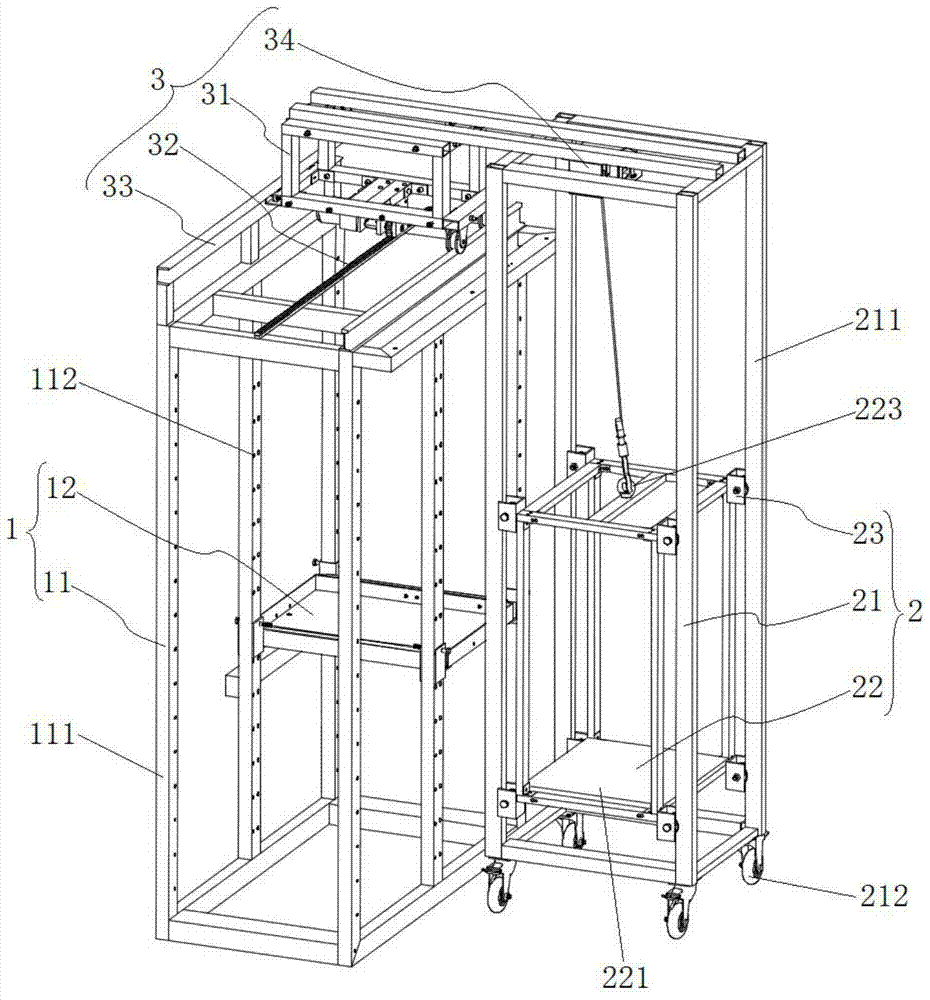

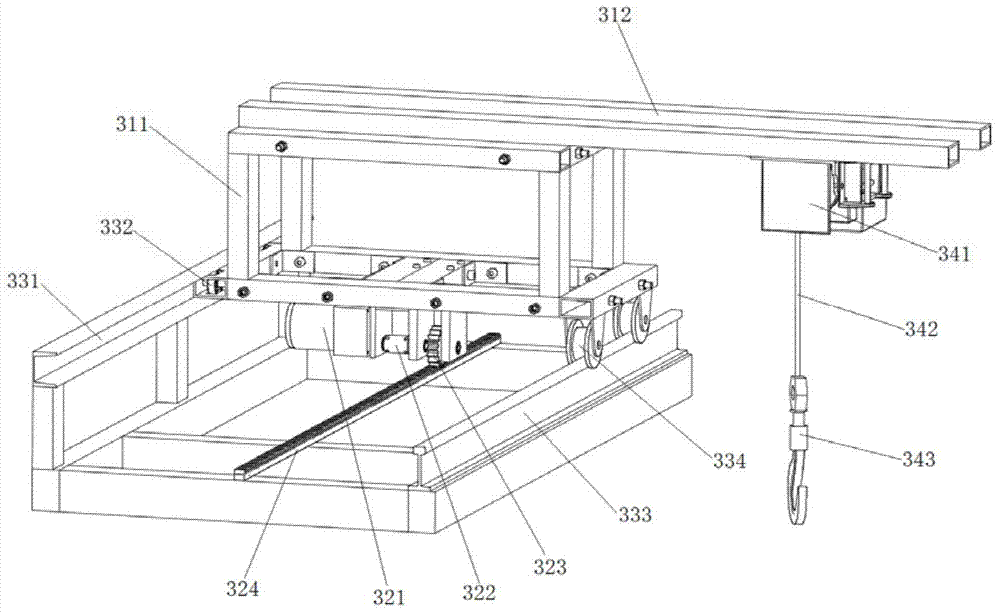

[0038] combine figure 1 As shown, an elevating type manned loading and unloading high-rise shelf in this embodiment includes a storage shelf 1, a movable cage 2 and an electric control trolley 3, and the electric control trolley 3 is installed on the top of the storage shelf 1, and the movable cage The frame 2 is arranged on the side of the storage shelf 1, and the electric control trolley 3 is connected with the movable cage 2, and is used to drive the movable cage 2 to move laterally along the side of the storage shelf 1; The lateral direction of the storage rack 1 moves throughout the whole process, so the movable cage 2 can cover the entire storage rack 1 to realize loading and unloading of goods at various positions of the storage rack 1 .

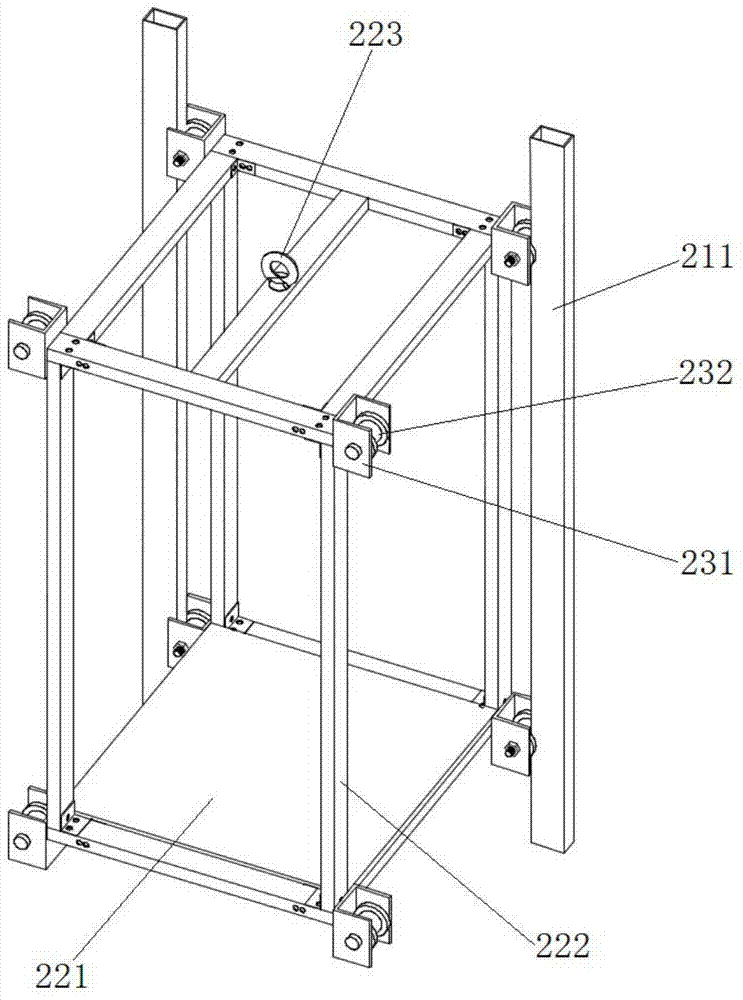

[0039]Wherein, the movable cage 2 in the present embodiment comprises an outer frame body 21, an inner frame body 22 and a lifting guide mechanism 23, and the inner frame body 22 is installed in the outer frame body 21 through the lif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com