rotatable brick clamp

A technology of brick clamp and front clamp, which is applied in the direction of vehicles with cranes, load suspension components, transportation and packaging, etc., can solve the problems of incomplete loading and unloading, difficult loading and unloading, etc., achieve all-round loading and unloading, smooth loading and unloading, and solve loading and unloading difficulties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

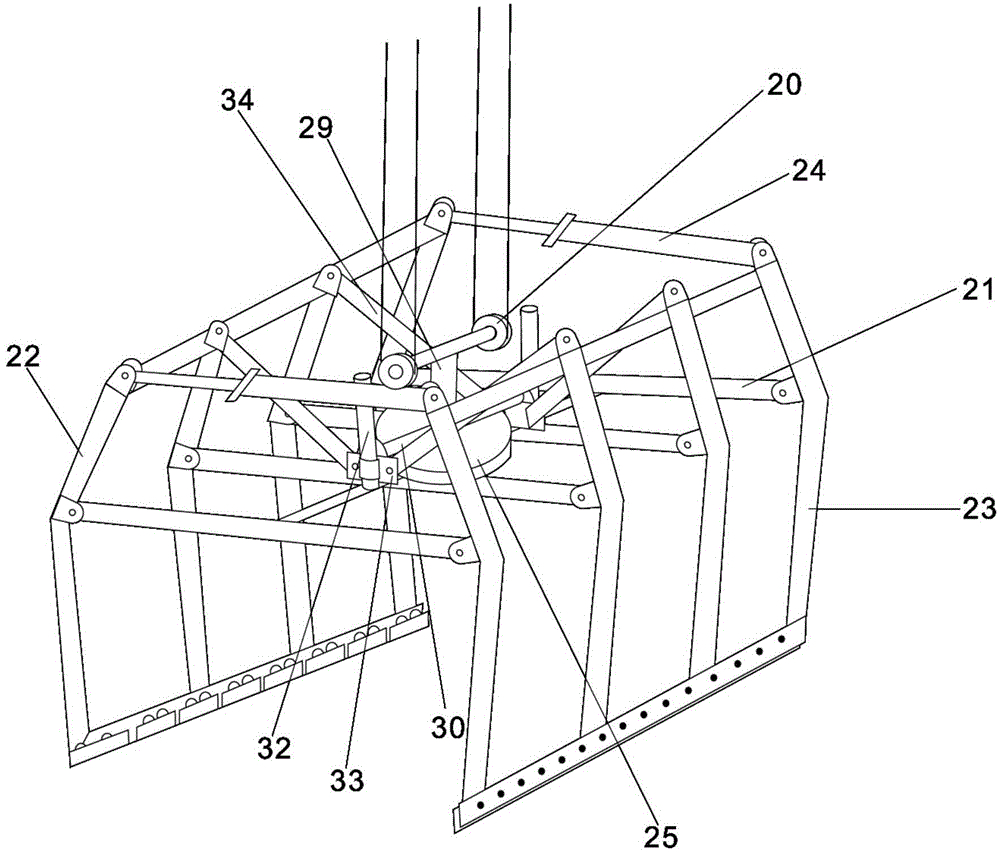

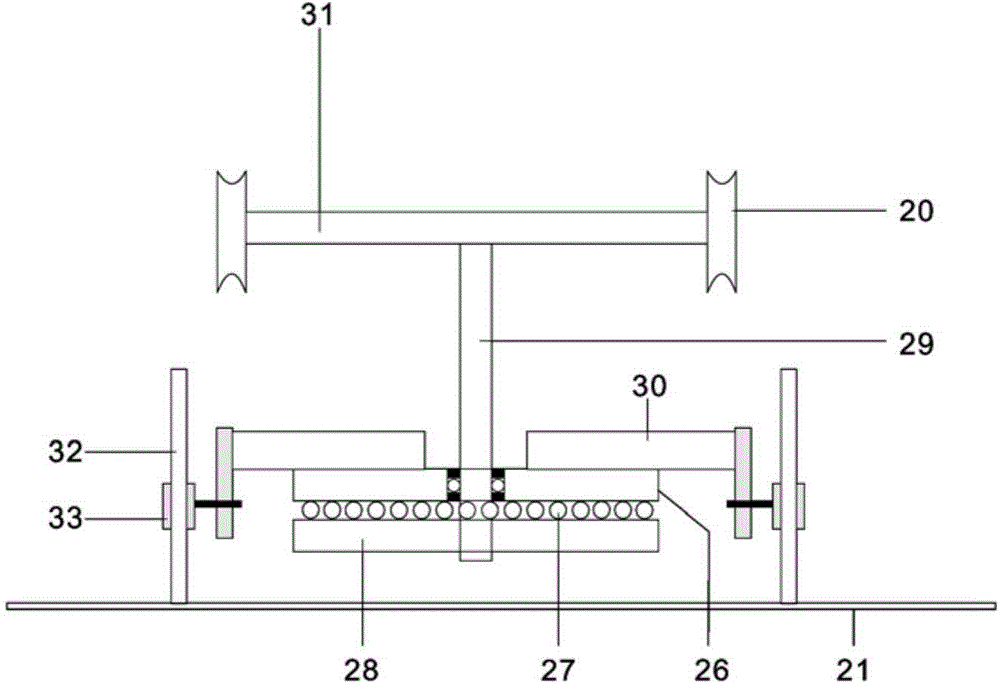

[0010] Attached below figure 1 , 2 An embodiment of the present invention is described.

[0011] A rotatable brick clamp is composed of a horizontal bracket 21, a front clamp arm 22, a rear clamp arm 23 and a clamping oil cylinder 24; Both sides, and the clamping oil cylinder 24 is hinged between the front clamping arm 22 and the rear clamping arm 23 upper ends; the top of the horizontal support 21 is provided with a rotating device 25, and the rotating device 25 consists of an upper turntable 26, a pressure bearing 27 and The lower turntable 28 is composed of a vertical shaft 29 fixed on the lower turntable 28, the upper turntable 26 is mounted on the vertical shaft 29 through a bearing, a horizontal connecting rod 30 is fixed on the upper turntable 26, a horizontal shaft 31 is fixed on the upper end of the vertical shaft 29, and the two movable pulleys 20 are respectively Installed on the two ends of the horizontal shaft 31, the two ends of the horizontal connecting rod 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com