High-speed elevator balancing compensation chain and production method of anchor chain thereof

A technology of balance compensation and high-speed elevators, applied in elevators, transportation and packaging, etc., can solve problems such as easy to twist, difficult to adapt to high-speed elevators, insufficient strength of elevator balance compensation chains, etc. The effect of verticality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

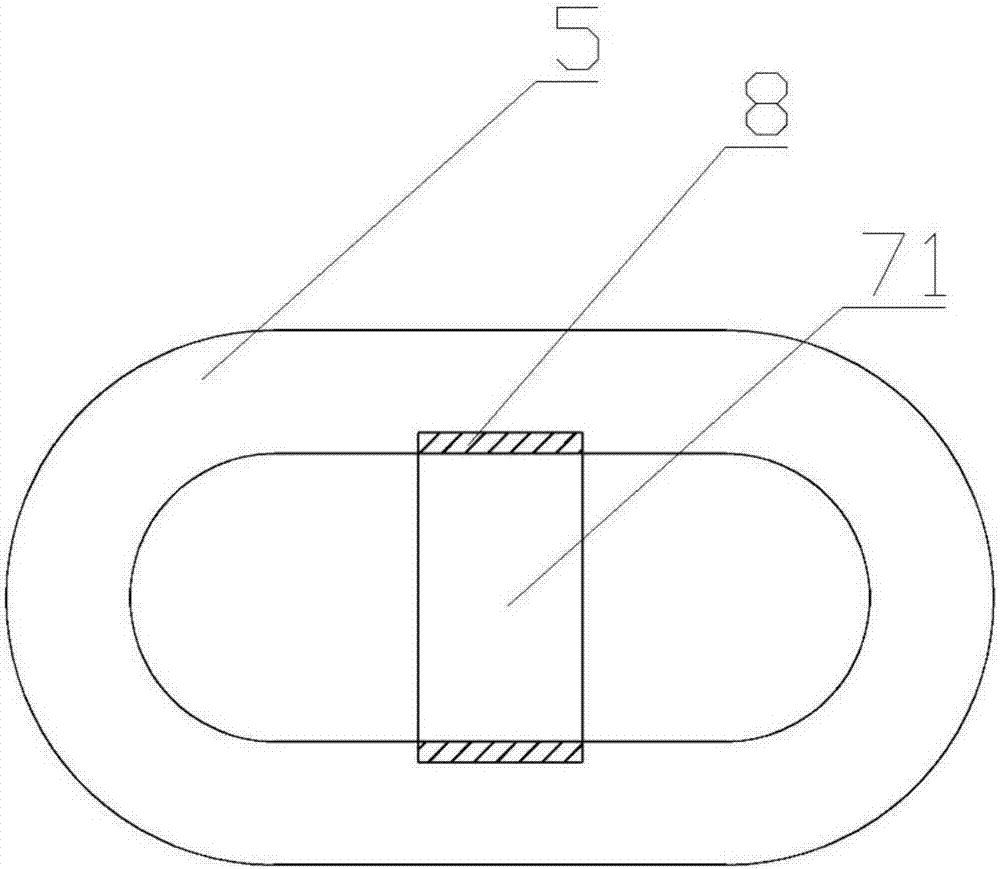

[0043] refer to figure 1 , the internal added anchor chain 4 includes a chain ring I5 and a brace 7, the brace 7 and the chain ring I5 are connected through a connecting buckle 8, the brace 7 is composed of a connecting part I71, and the connecting part I71 The shape is vertical.

Embodiment 2

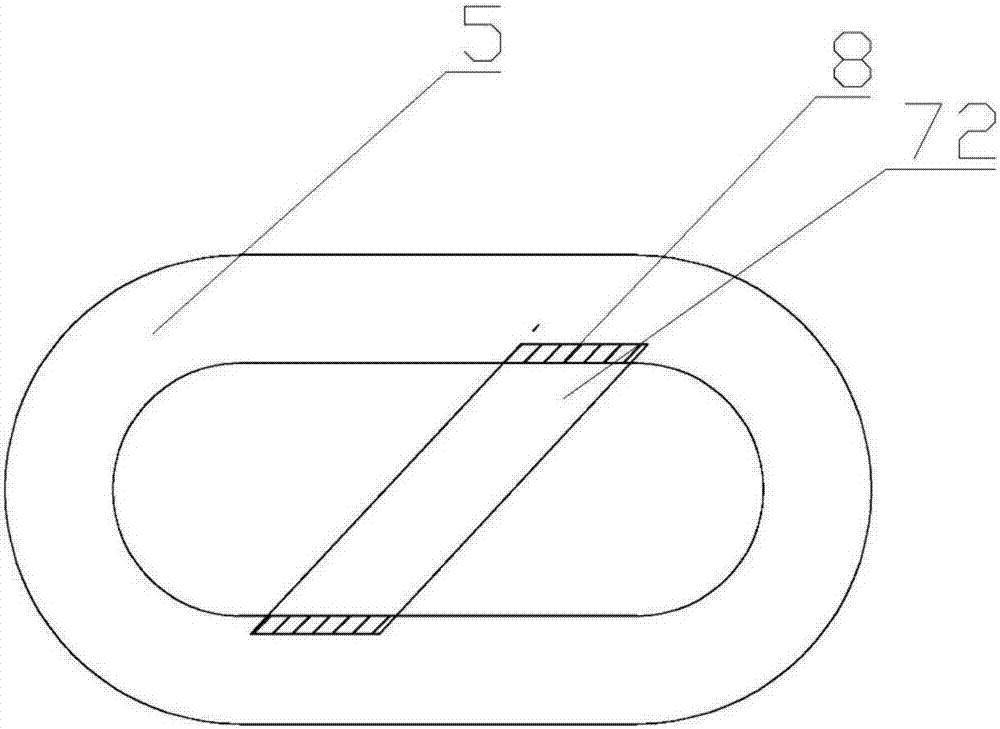

[0045] refer to figure 2 , the internal added anchor chain 4 includes a chain ring I5 and a brace 7, the brace 7 and the chain ring I5 are connected by a connecting buckle 8, the brace 7 is composed of a connecting part II72, and the connecting part II72 The shape is oblique.

Embodiment 3

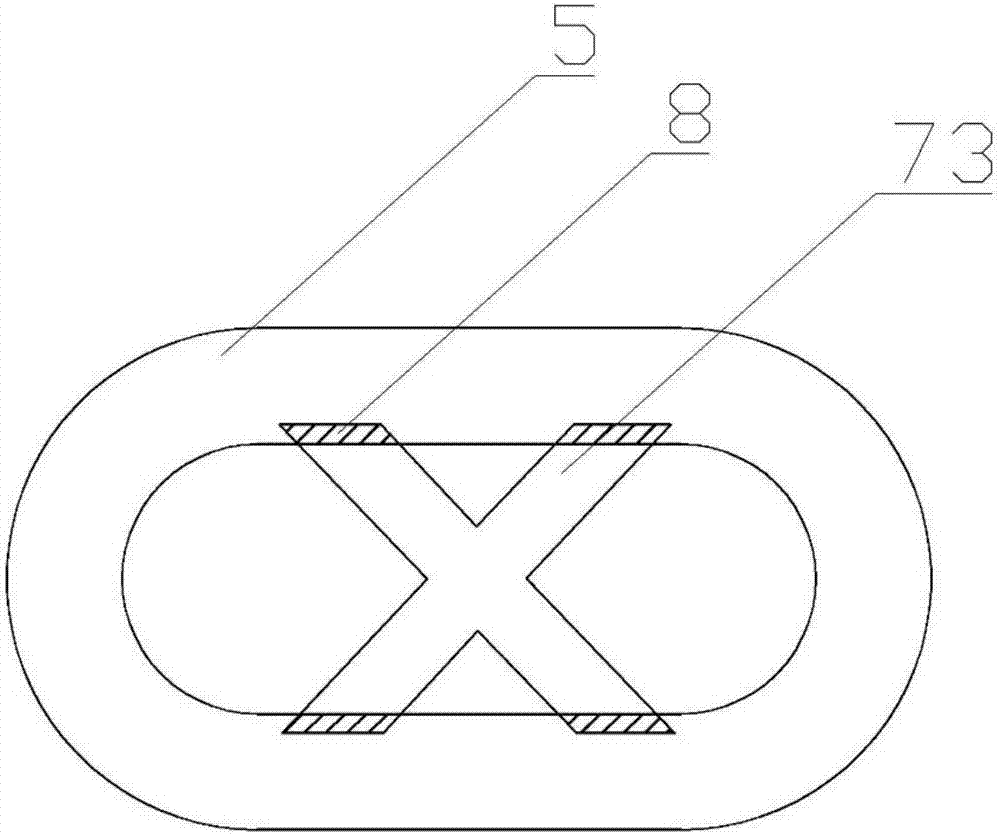

[0047] refer to image 3 , the internal added anchor chain 4 includes a chain ring I5 and a brace 7, the brace 7 and the chain ring I5 are connected by a connecting buckle 8, the brace 7 is composed of a connecting part III73, and the connecting part III73 The shape is a cross.

[0048] In the above three embodiments, the braces are designed as separate connecting parts, the connecting parts include one connecting part or two connecting parts, one connecting part is vertical or oblique in shape, and the two connecting parts are in the shape of Cross-shaped; the connecting parts are all set in the middle of the anchor chain, connecting the upper and lower parts of the chain ring I5, which plays a role in strengthening the strength of the anchor chain. In addition, by connecting the buckle 8 with the chain ring I5, not only the preparation process is simple, but also the connection and disassembly of the brace and the chain ring are convenient, the design is flexible, and the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com