Front steering drive axle assembly

A drive axle assembly and front steering technology, applied in axles, wheels, transportation and packaging, etc., can solve problems such as uncompact wheel-side reducers, oil-leaking wheel-side planetary gears, and low load-carrying capacity, and achieve structural The effect of simplicity, large reduction ratio, and large carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific embodiments of the present invention will be further described below in conjunction with the drawings.

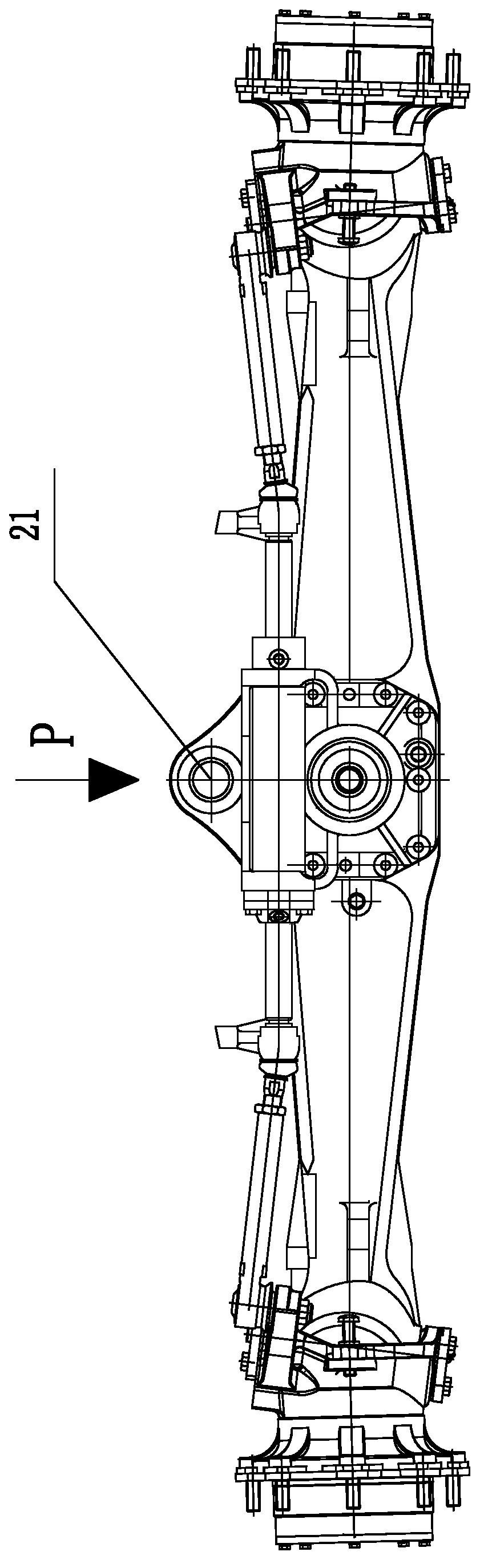

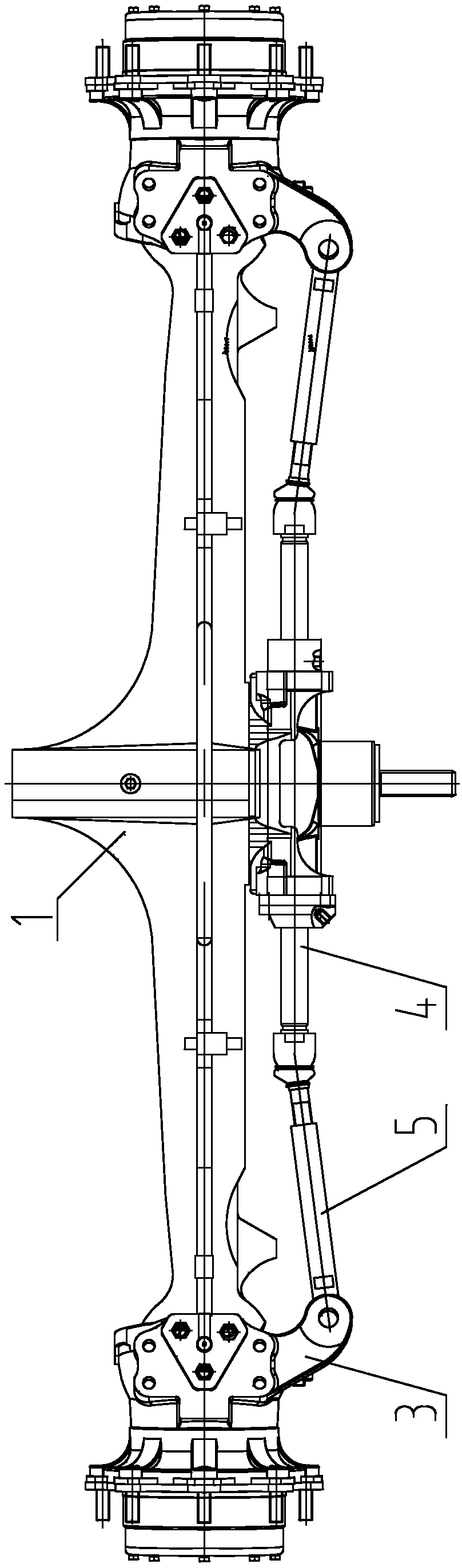

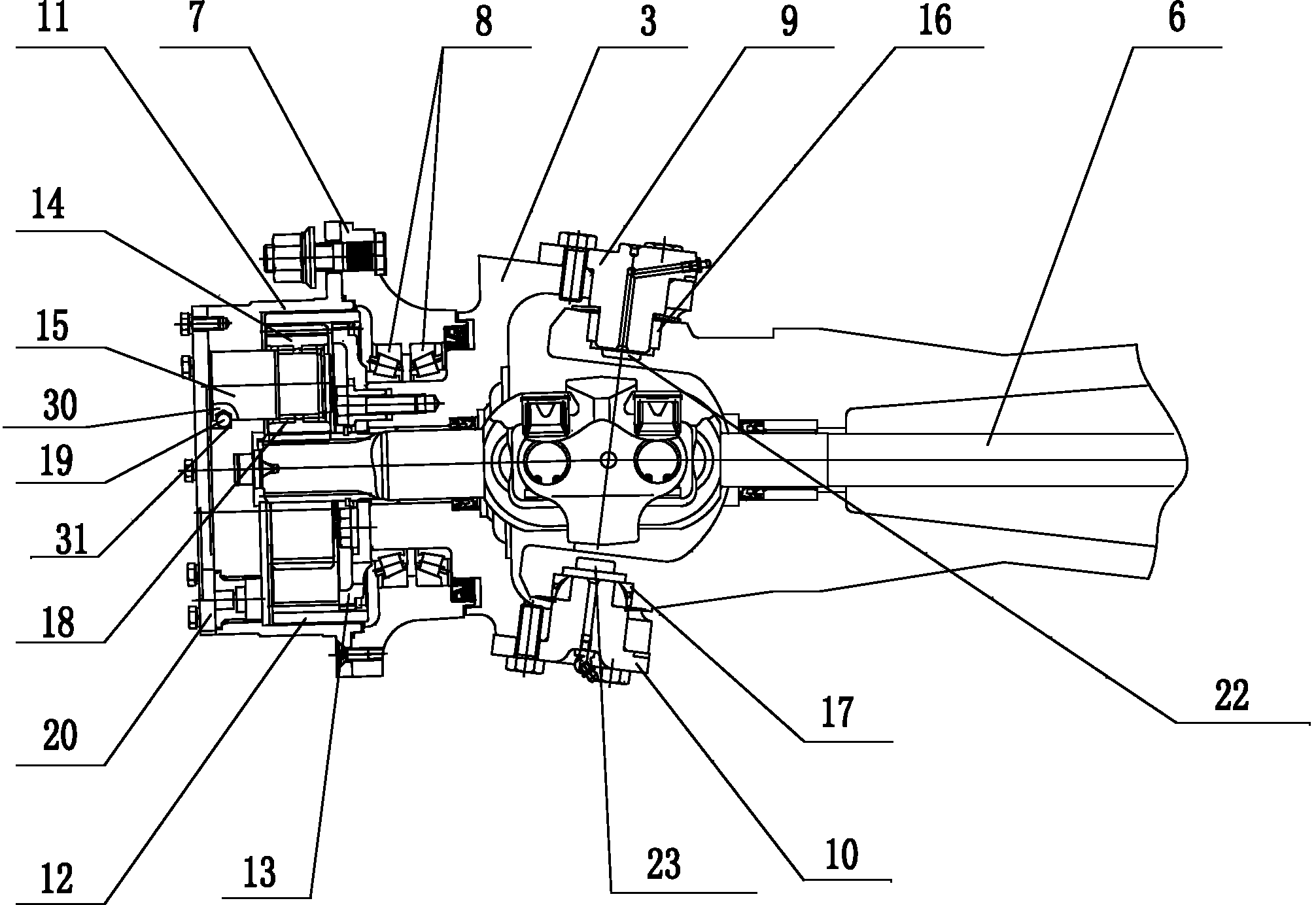

[0020] Such as Figure 1 to Figure 5 The front steering drive axle assembly of the present invention shown includes an axle housing 1, two wheel hubs 7, a main reducer with a differential assembly and a wheel side reducer; the axle housing 1 is an integrally cast beam structure, There is a swing pin hole 21 connected to the vehicle chassis. The two hubs 7 are connected to the left and right ends of the axle housing 1 through the hub steering structure 3. The axle housing 1 is provided with a cavity in the middle, and the main reducer is installed in it With a differential assembly, the main reducer with a differential assembly is rotatably connected to a drive shaft 6 on both sides of the assembly, and the drive shaft 6 is rotatably connected to the wheel reducers at both ends of the axle housing 1; A wheel steering drive device 4 is provided. The wheel st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com