Hoisting method for top push climbing and moving type cable hoisting arch bridge

A hoisting method and jacking technology, which is applied to arch bridges, bridges, bridge forms, etc., can solve the problems of hidden safety hazards in tower movement, complicated and cumbersome movement, etc., and achieve the effects of reducing hoisting risks, broad vision, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

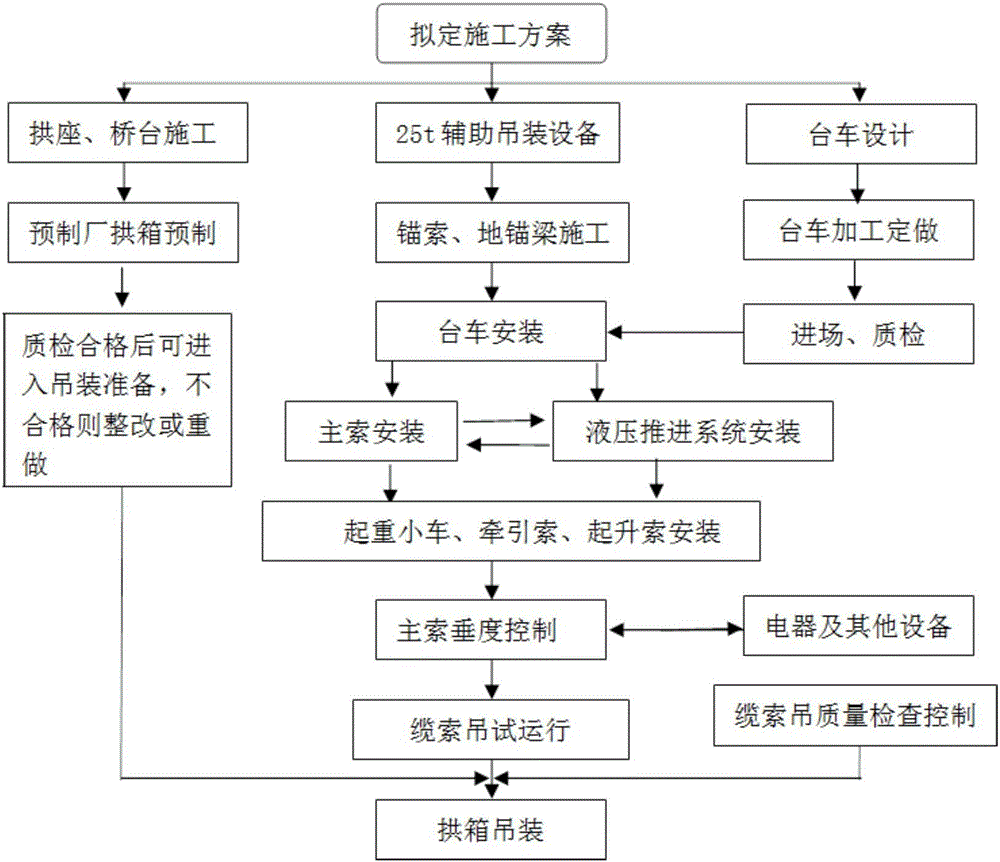

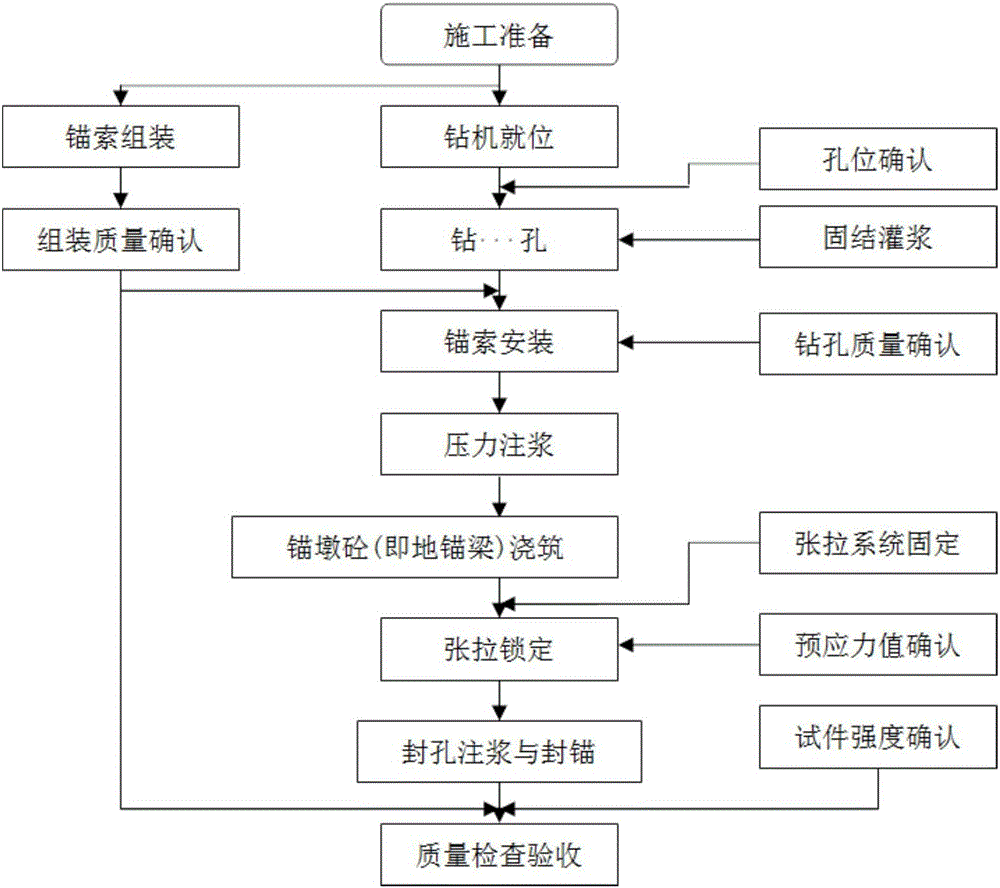

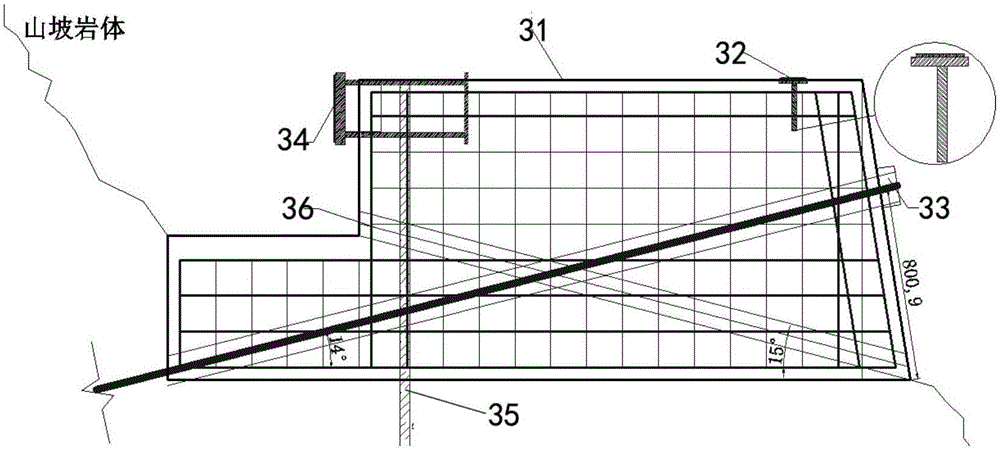

Method used

Image

Examples

Embodiment 1

[0169] Such as Figure 12 As shown, the total length of Tuoba Bridge is 135.12m+13.90m+10.53m=159.55m. The bridge type is an overhead box-shaped arch bridge, which is hoisted and constructed by jacking and climbing cable cranes on both sides of the tower without towers. The calculated span of the main arch is 100m, and the calculated rise-span ratio is 1 / 5. The superstructure of the main arch is prefabricated columns, cover beams and 11×10m prefabricated T-beams. 12m reinforced concrete cast-in-place box girder.

[0170] The main arch rib of the Tuoba Bridge is a horizontal single-box 6-chamber section, and each rib is hoisted in 5 sections, with a maximum hoisting weight of about 75 tons. Compared with the conventional cable crane, the hoisting of 30 pieces of arch boxes saves 12 days of construction period, closes the arch boxes and saves nearly 40% of the construction period, and hoisting the upper structure of the arch ring saves about 30% of the construction period. The...

Embodiment 2

[0172] The Kawagebo Bridge is located in Deqin County, Diqing Prefecture, Yunnan Province, across the Lancang River, 33 kilometers away from Deqin County, connecting the Meili Snow Mountain Scenic Road and the branch line of the Dewei Secondary Highway. The width of the bridge deck is 10 meters, the bridge length is 115.624 meters, the design vehicle load road - II level, the net span of the main arch ring is 80 meters, the rise-span ratio is 1 / 6, the height of the arch ring is 1.7 meters, and the concrete of the arch ring is C40.

[0173] The Kawagebo Bridge has a tight construction schedule and high quality requirements. In order to ensure the construction quality of Kawagebo, reduce costs, ensure the construction period and prevent safety accidents, Yunling Expressway Construction Group Co., Ltd. Construction Method of Climbing Cable Suspension Arch Bridge". Construction started in June 2014 and was completed and opened to traffic in July 2015.

Embodiment 3

[0175] The Huangdeng Bridge is located about 900m downstream of the dam of the Huangdeng Hydropower Station. It is the main transportation hub connecting the left and right banks during the construction of the Huangdeng Hydropower Station and during the operation of the power station. The clear span of the bridge is 114m, the length of the whole bridge is 168.272m, and the length of the approach bridges on both sides is 25m. The total length of the whole bridge is about 170m. 1.5m, design load steam-63, hanging-120, designed by PowerChina Kunming Survey and Design Research Institute Co., Ltd., and constructed by Yunnan Yunqiao Construction Co., Ltd. The "Histing Method of Lifting and Climbing Cable Suspension Arch Bridge without Tower on Both Banks" is adopted for construction.

[0176] The field application shows that this construction method effectively improves the construction quality, greatly increases the hoisting speed, and has significant benefits in saving the constru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com