Suspensible integrated steel cylinder cage trolley

A trolley and hoistable technology, which is applied in the field of trolleys, can solve the problems of low transportation efficiency of steel cylinders, horizontal transportation cannot vertical transportation, long process time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

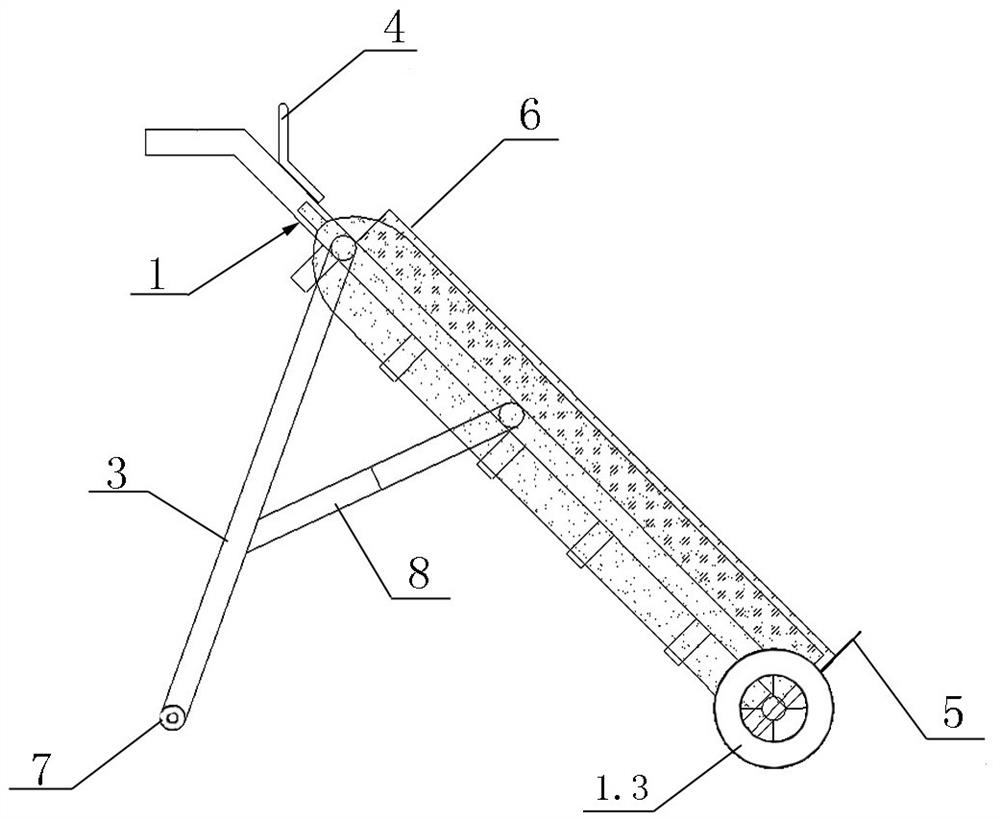

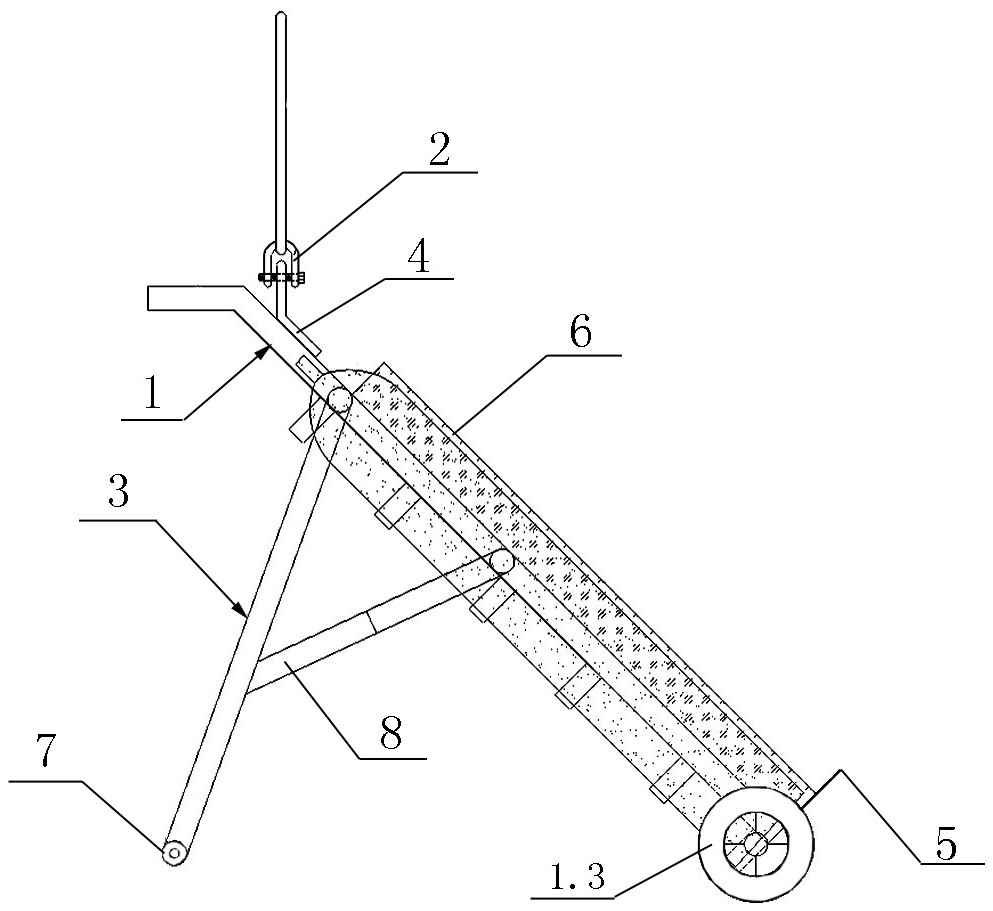

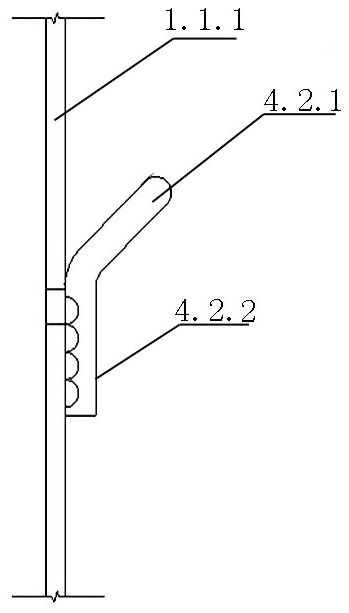

[0023] Such as Figure 1-6 As shown, this hoistable integrated steel cylinder cage trolley includes a trolley main body 1; it also includes a folding bracket 3 and a bent lifting ring 4; the top cover of the trolley main body 1 is provided with a shading cover 6 , and one side of the sunshade 6 is hingedly connected to the cart body 1; on the cart body 1, a supporting plate 5 is arranged at the end of the sunshade 6; the folding bracket 3 is hingedly connected to the bottom of the cart body 1 , and a universal wheel 7 is connected to the lower end of the folding bracket 3; a diagonal strut 8 is hingedly connected between the folding bracket 3 and the cart main body 1; On both sides of the main body 1, close to the front end of the main body 1 of the cart; the bent lifting ring 4 is an inverted U shape, including a top edge 4.1 and a side edge 4.2; the side edge 4.2 is bent, including There are a first hem 4.2.1 and a second hem 4.2.2; the second hem 4.2.2 is attached to the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com