Heavy lifting vehicle

A technology for heavy-duty trucks and vehicles, applied in the direction of cranes, etc., can solve the problems of needing outriggers, unsuitable for running on soft or muddy fields, and unable to drive under load, etc., to improve production efficiency, and the effect of safe and reliable lifting process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

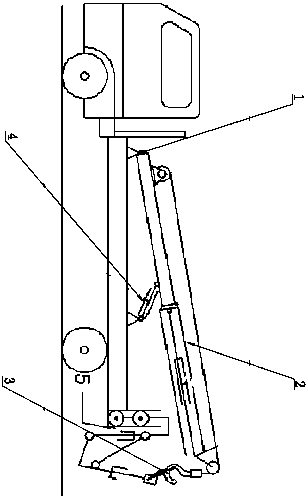

[0012] The purpose of the present invention is achieved in this way: the purpose of the present invention is achieved in this way: a heavy-duty lifting vehicle, including a heavy truck, the heavy truck includes a headstock and a compartment, and the compartment is set in a flat plate, and it is characterized in that the A front-end support mechanism 1 and a rear-end support mechanism 4 are arranged in the compartment, and a lifting device 2 is arranged on the front-end support mechanism 1 and the rear-end support mechanism 4, and the head end of the lifting device 2 is fixed on the front-end support mechanism 1. Together, the middle part of the lifting device 2 is fixed with the rear end support mechanism 4; the head end of the lifting device 2 is hinged with the front end support mechanism 1, and the lifting device 2 includes a front pulley and a rear pulley, and the front pulley and the rear pulley are provided with a steel cable; the end of the steel cable is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com