Composite modified asphalt metering and batching device

A technology of compound modified asphalt and metering barrel, which is applied in feeding device, chemical/physical/physical-chemical fixed reactor, chemical instrument and method, etc. and other problems to achieve the effect of fast hoisting and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

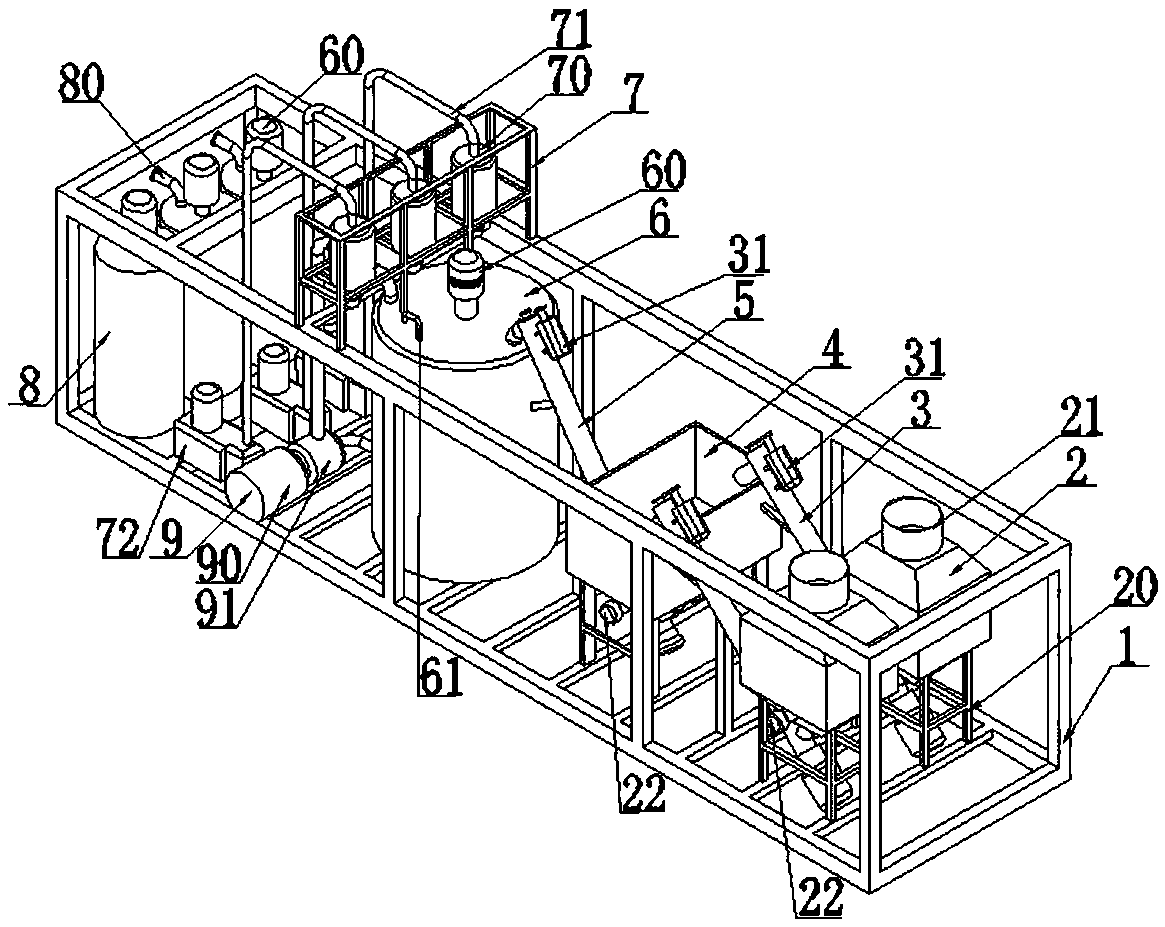

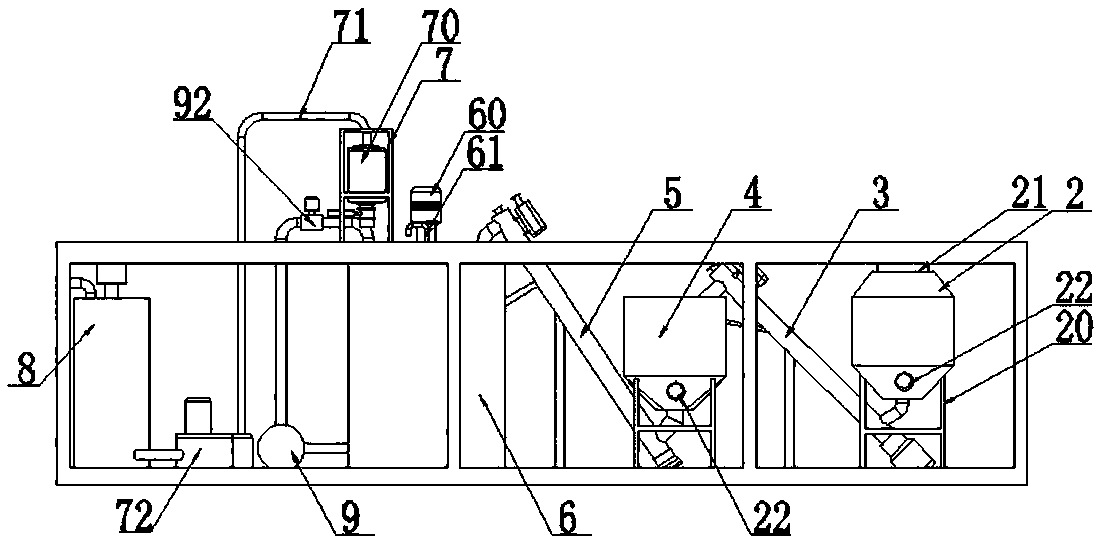

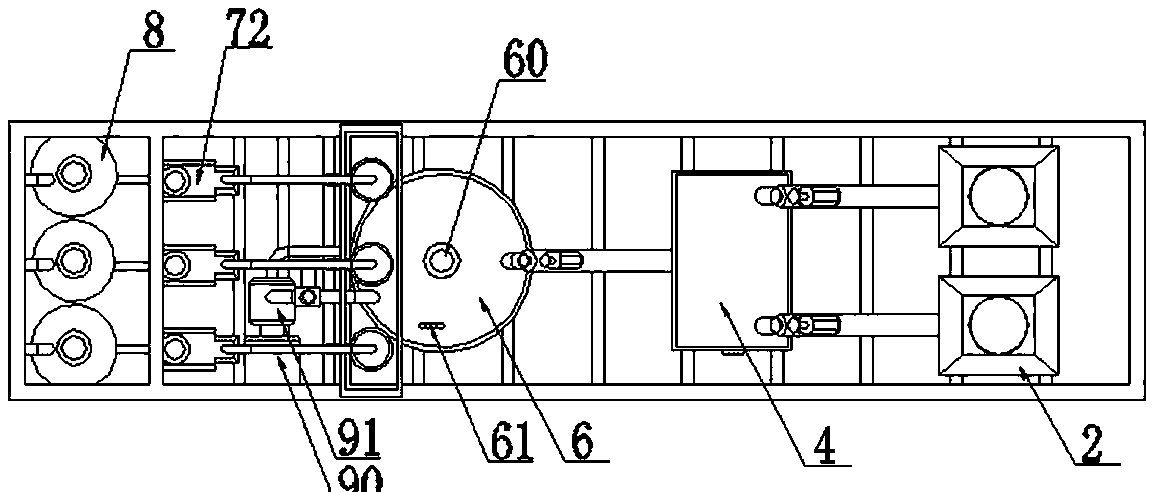

[0017] Referring to the figure, the present invention proposes a structure of a composite modified asphalt metering and batching device, as shown in the attached figure 1 As shown, it includes a container-type frame structure 1, and a plurality of powdery material storage bins 2 are arranged inside the frame structure 1, and the plurality of powdery material storage bins 2 are respectively supported by the powdery material storage bins. 20 is welded or bolted in the frame structure 1, and the powdery material storage bin is provided with a material inlet 21, and various powdery materials can be stored in the powdery material storage bin 2 through external feeding equipment.

[0018] The bottom of each powdery material storage bin 2 is provided with a primary material conveying auger 3, the feed inlet of the primary material conveying auger 3 and the discharge port on the powdery material storage bin 2 are connected to one, and a plurality of primary material The conveying auge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com