Automatic sponge wrapping device

A sponge, automatic technology, used in packaging, transportation and packaging, packaging/bundling items, etc., can solve the problems of inconsistent quality of sponge packaging, unfavorable production efficiency, large workload, etc., saving manpower and time, maintaining Consistency, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

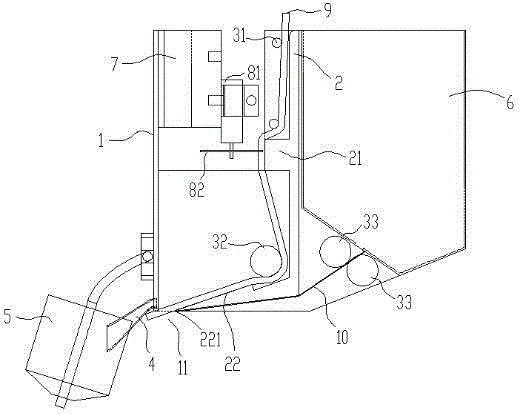

[0019] Such as figure 1 As shown, a kind of automatic bag sponge device comprises casing 1, guide mechanism, traction mechanism, shaping mechanism and cutting mechanism:

[0020] The bottom of the casing 1 is provided with a sponge discharge port 11;

[0021] The guide mechanism arranged in the casing 1 includes a guide plate 2 and a first pressure roller 31 and a second pressure roller 32 pivotally connected to the casing 1 along the width direction of the casing 1. The first pressure roller 31 and the second pressure roller A first gap is formed between the roller 32 and the guide plate 2 for the passage of the sponge strip 9 with the release paper 10. The bottom end of the guide plate 2 is provided with an extension plate 22 extending to the inner side of the sponge discharge port 11. The end of the extension plate 22 away from the guide plate 2 fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com