Automatic production line device of pancakes

An automatic production line, dorayaki technology, applied in baking, baking workshops, food science, etc., can solve the problem of inability to vigorously promote dorayaki golden cakes, difficulty in ensuring consistent quality of dorayaki, and inability to form large-scale production, etc. Problems, to achieve the effect that is conducive to marketing, completely consistent taste, and improve competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

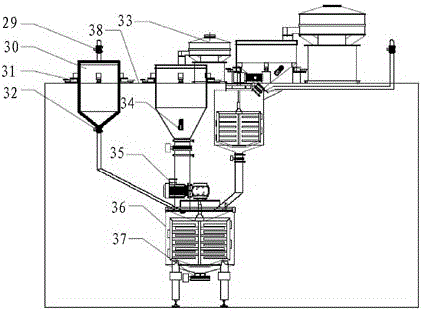

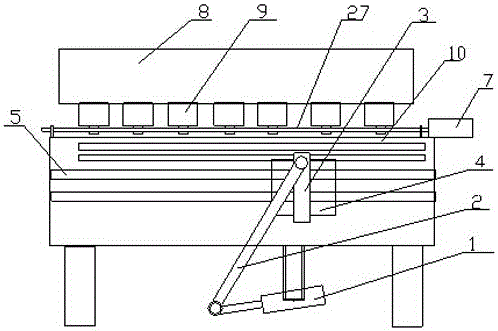

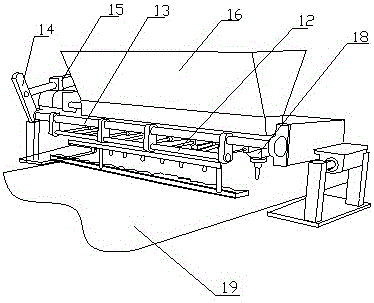

[0021] Such as figure 1 As shown, the dorayaki automatic production line device is composed of two parts: the automatic weighing feeding and mixing system and the dorayaki forming machine, and the dorayaki forming machine is connected to the rear side of the automatic weighing, feeding and mixing system. Connected with the automatic weighing feeding and mixing system, the automatic weighing feeding and mixing system adds slurry to the dorayaki forming machine quantitatively; the dorayaki forming machine includes a dough forming production line and a filling and pie filling production line; Described dough molding production line is made up of front frame 28, baking conveying line 10, wiping oil mechanism, dough blanking mechanism and oven; The stuffing mechanism and the flipping and combining mechanism are composed; the rear conveying line 19 of the stuffing and combining cake production line is surrounded on the drum of the rear frame 26, the stuffing mechanism is erected on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com