Automatic tray filling device of electronic chip tray filling machine

A technology of electronic chips and loading machines, which is used in conveyors, stacking of objects, and destacking of objects, etc., can solve the problems of difficulty in moving trays, low success rate of unloading trays, and re-opening of reclaiming trays. , to achieve the effect of ensuring one-way passability, preventing movement and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

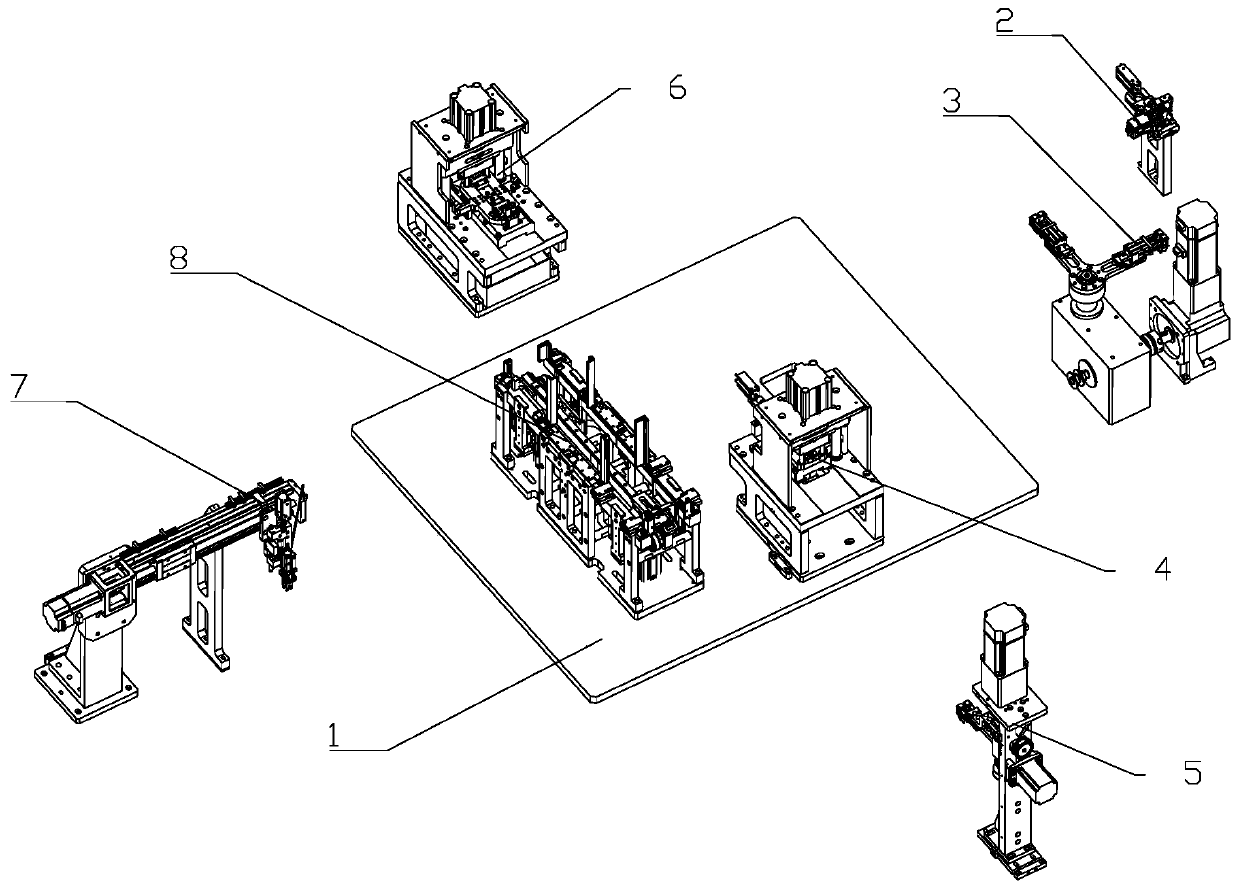

[0028] Such as figure 1As shown, an electronic chip loading machine includes a frame 1 and a distributing device 2 installed on the frame 1, a rotating conveying device 3, a pin pressing device 4, a transition conveying device 5, and a pin cutting device 6 , linear conveying device 7 and loading device 8; rotating conveying device 3 connects material distribution device 2 and pin pressing device 4, and described material distribution device 2 feeding end is provided with chip feeding device; Lead cutting device 6 Set opposite to the pin pressing device 4, the transition transfer device 5 connects the pin pressing device 4 and the pin cutting device 6; the said loading device 8 is arranged on the side of the pin cutting device 6, and transport The device 7 is located above the disk loading device 8 , and the linear conveying device 7 connects the lead cutting device 6 and the disk loading device 8 .

[0029] The distributing device 2 is used to sort out a single electronic chi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com