Cutting device for expandable polystyrene package

A foam packaging and cutting technology, applied in metal processing and other directions, can solve the problems of reducing product qualification rate, increasing worker burden, uneven cutting edges, etc., and achieving the effect of improving quality, fast cutting speed and efficient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

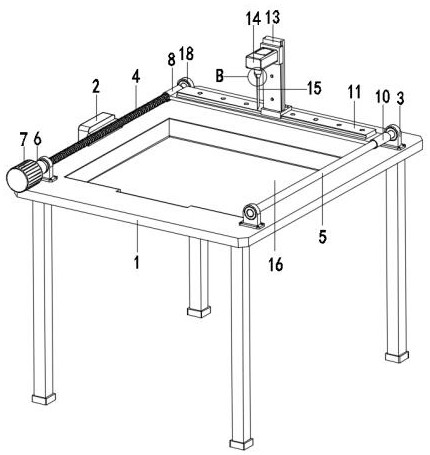

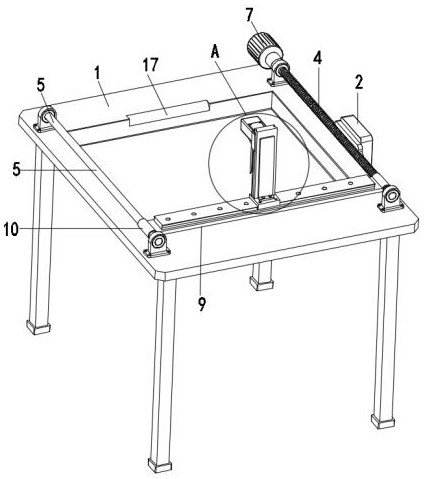

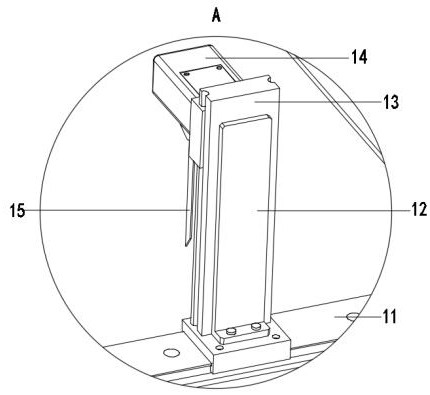

[0030] A cutting device for foam packaging of the present embodiment, refer to Figure 1-4 : Including the frame 1 and the controller 2, the four corners of the top surface of the frame 1 are fixedly installed with supports 3, wherein the left support 3 is rotatably connected with a screw 4, and the right support 3 is rotatably connected with a One end of the guide rod 5 and the screw 4 is fixedly connected with the servo motor 7 through the coupling 6, and at the same time, the threaded cylinder 8 is screwed on the screw 4, and one side of the threaded cylinder 8 is fixedly connected with the connecting plate 9, and the other end of the connecting plate 9 The side is fixedly connected with a guide cylinder 10, and the guide cylinder 10 is slidably sleeved on the guide rod 5, and the top surface of the connection plate 9 is fixedly connected with the first linear module 11, and the screw on the slider of the first linear module 11 A support plate 12 is connected, and the suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com