Automatic loading and unloading device

An automatic loading and unloading and feeding technology, which is applied in metal processing and other directions, can solve problems such as industrial accidents and fatigue, and achieve the effects of fast feeding, compact structure and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

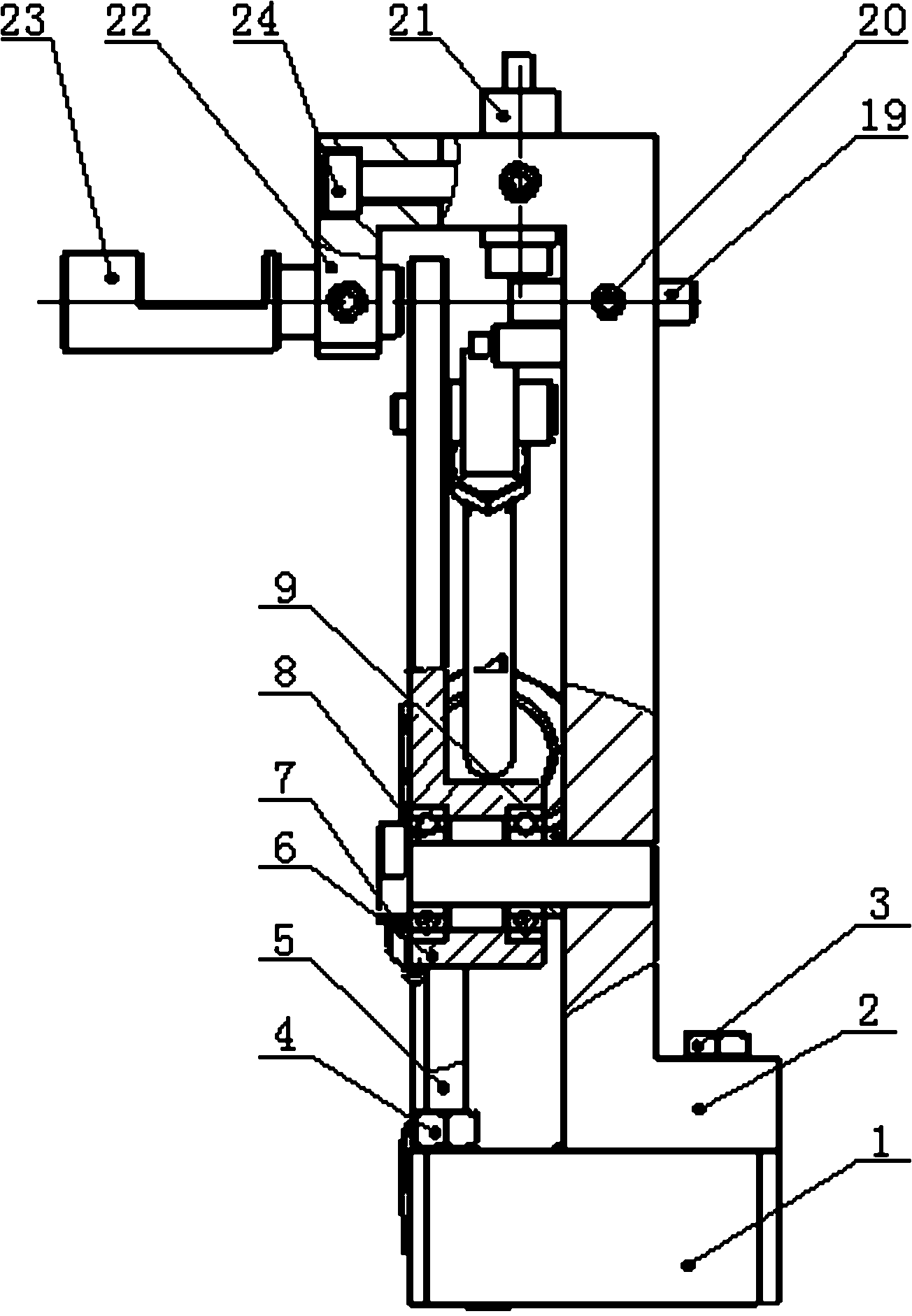

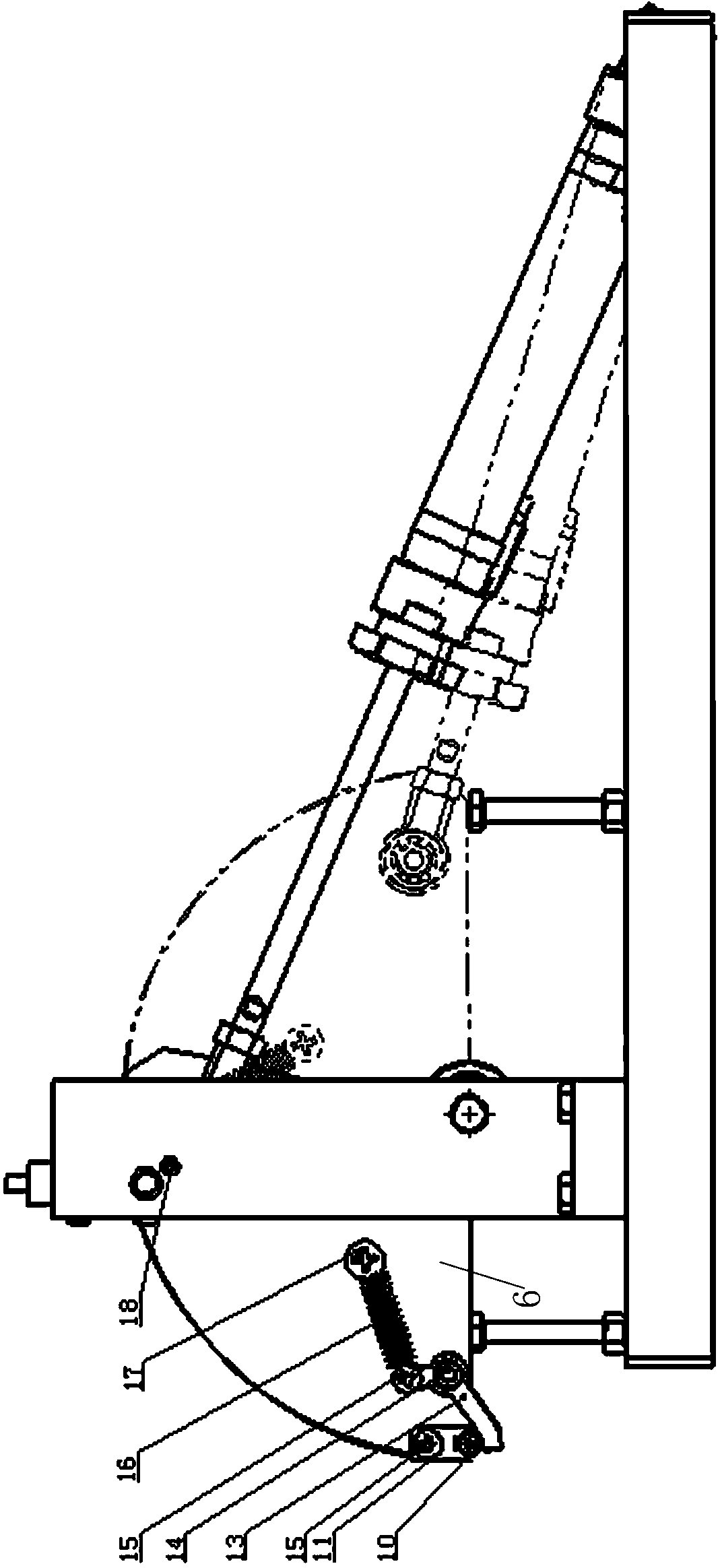

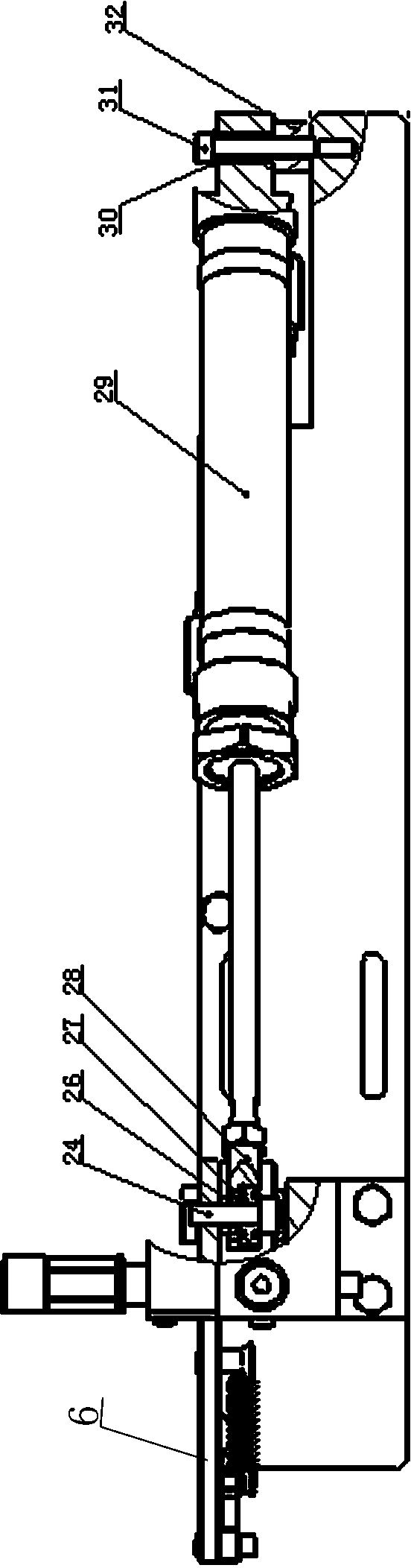

[0014] Refer to attached figure 1 , 2 , 3. An automatic loading and unloading device includes a bottom plate 1, a bracket 2, a feeding tray 6, a small shaft 7, two deep groove ball bearings 8, a large spacer 9, a "V"-shaped positioning block 11, a movable pressing block 13, Extension spring 16, back plate 19, induction switch 21, feeding support 22, feeding guide sleeve 23, small spacer ring 26, union 28, cylinder 29, rotating shaft 32 and flat gasket 31.

[0015] The bracket 2 is fixed on the bottom plate 1 by two hexagonal bolts 3; the two hexagonal socket head screws 5 are fixed on the bottom plate 1, which are used to adjust the feeding and returning position of the feeding tray 6, and are tightened with two hexagonal nuts 4 to prevent loosening; Two deep groove ball bearings 8 are installed in the disc 6, the small shaft 7 passes through its inner hole and the large spacer 9, and the feeding disc 6 is fixed on the side of the bracket 2; the front end of the feeding disc ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com