Patents

Literature

85results about How to "Cutting fast" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

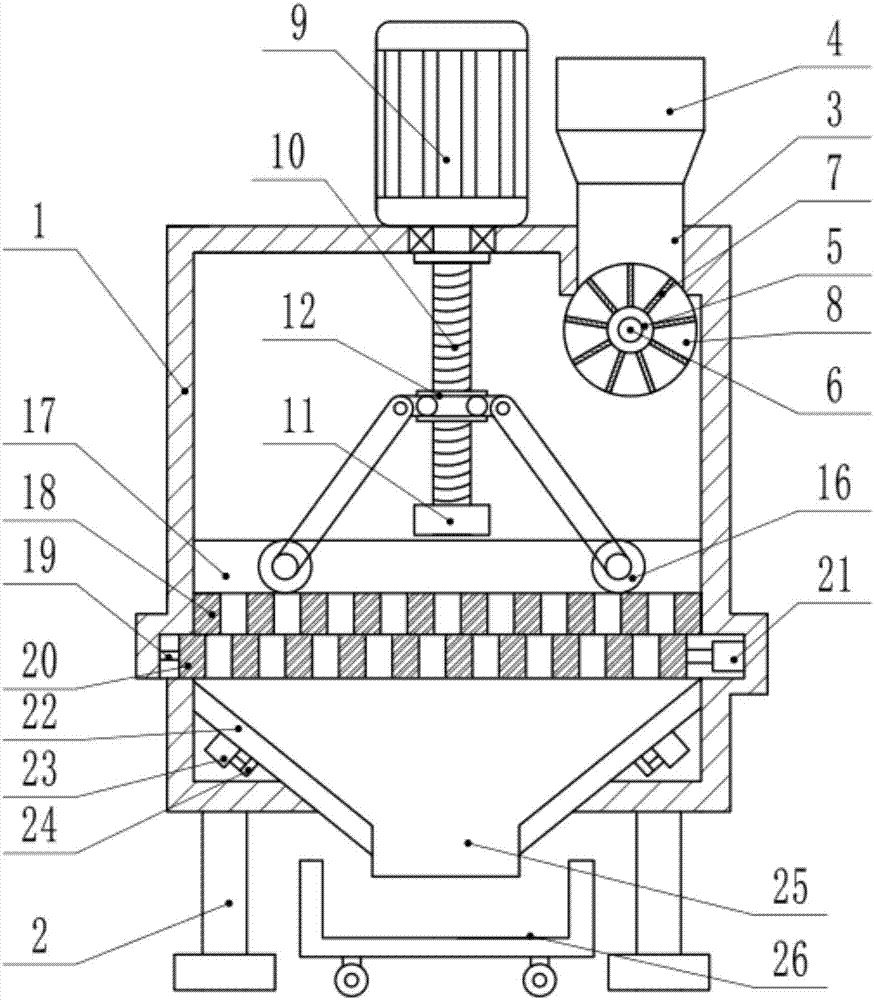

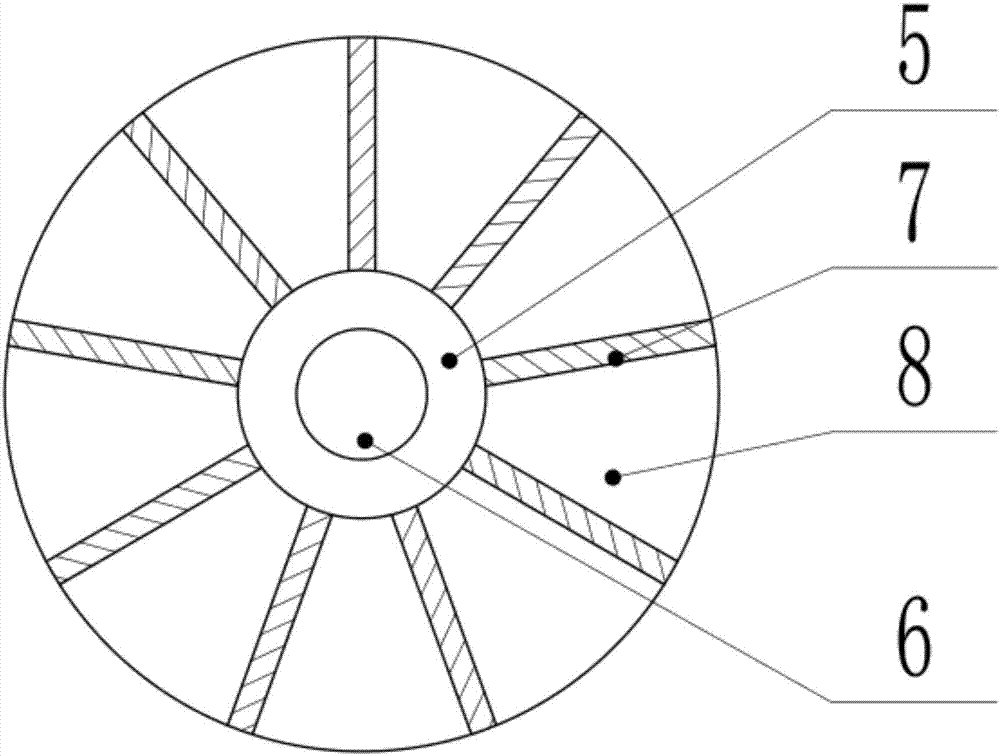

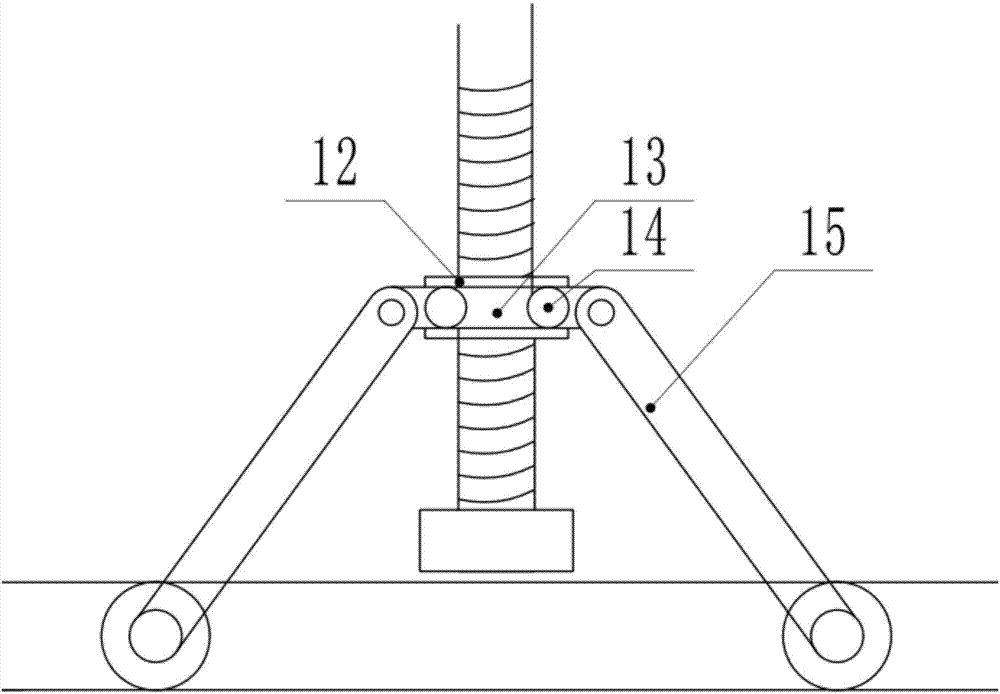

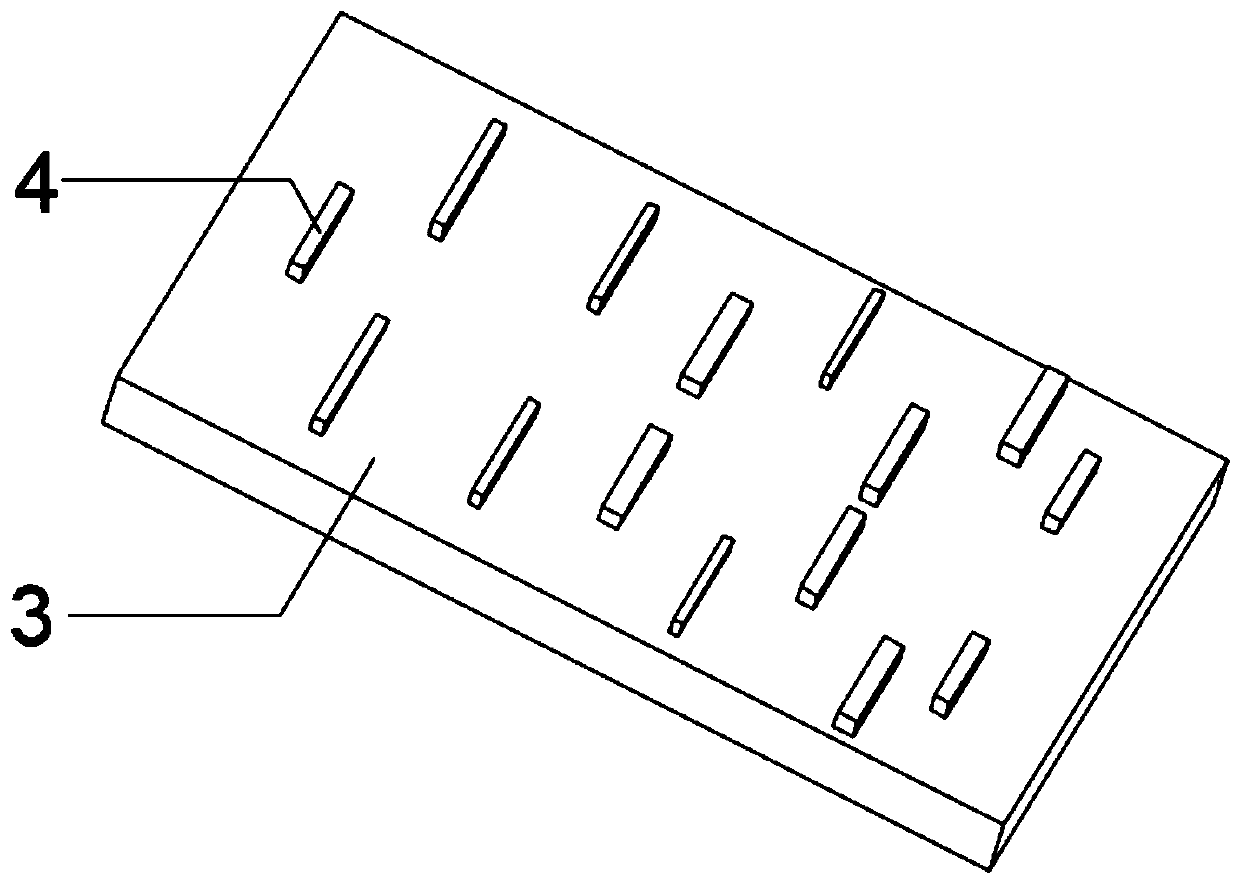

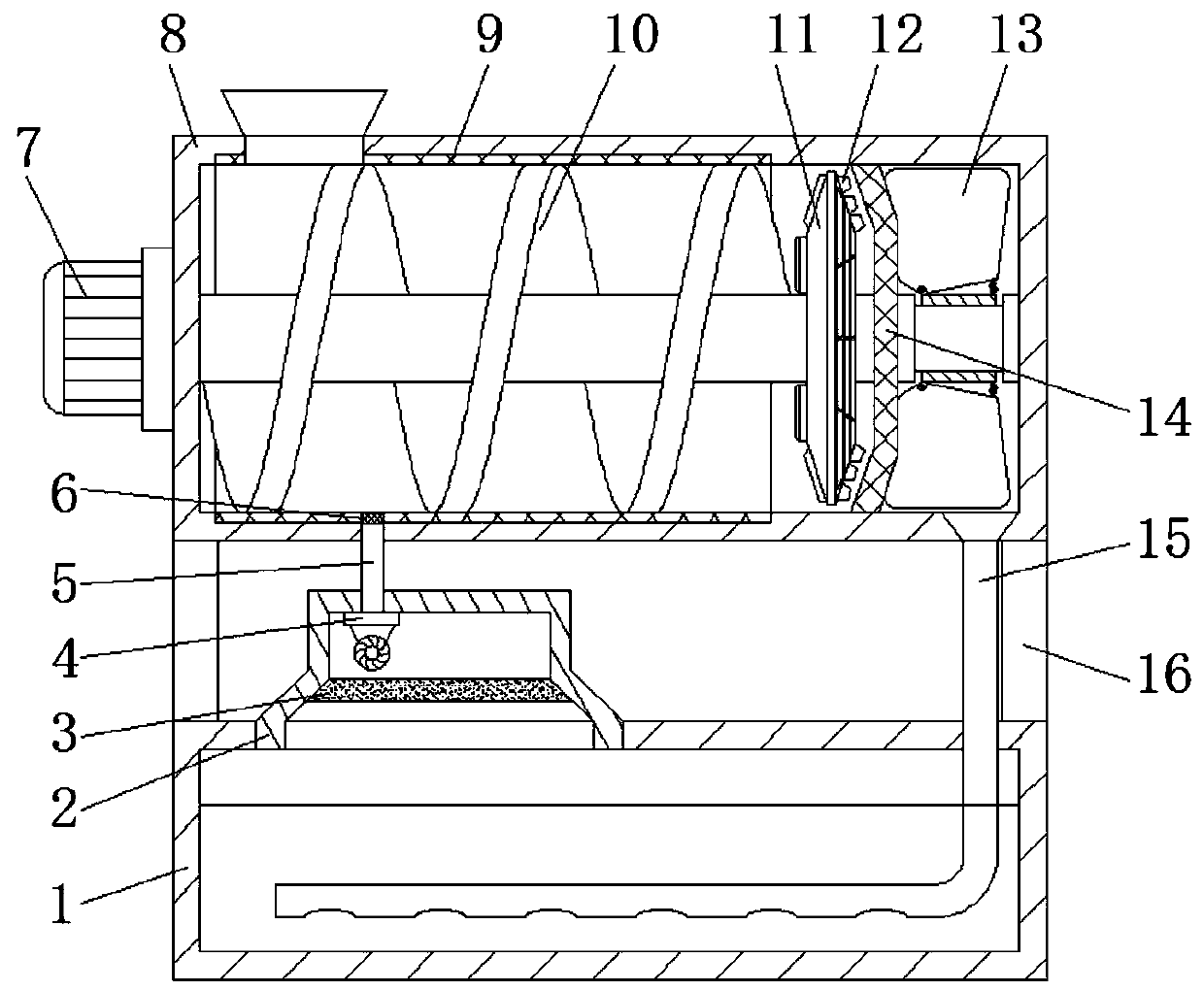

Building paint powder ingredient grinding device

InactiveCN107127015APrevent upward windAvoid strandedGrain treatmentsReciprocating motionAdditive ingredient

The invention discloses a building paint powder batching and grinding device, which comprises a machine casing, a feeding funnel, a first driving motor, a screw rod, a sliding sleeve, a connecting rod, a grinding roller, a grinding table, a fixed sieve plate, a sliding rod, a second Drive motor and vibrating hammer, a windproof device is installed under the feed inlet, a sliding sleeve is installed on the thread of the screw rod, a grinding roller is installed on the other end of the connecting rod, and a fixed sieve plate is installed on the grinding table , a sliding sieve plate is slidably installed on the sliding rod. The installation of the windproof device can effectively prevent the wind from blowing up inside the casing, and prevent the architectural coating powder inside the casing from going up and back; through the cooperation of the sliding sleeve and the screw rod, the grinding roller can move back and forth to improve the grinding effect; at the same time, the sliding can be adjusted by sliding The overlapping position of the sieve plate and the fixed sieve plate can adjust the actual sieve plate aperture of the fixed sieve plate, and the size of the ground powder can be adjusted at any time without changing the sieve plate to improve work efficiency.

Owner:蔡政伟

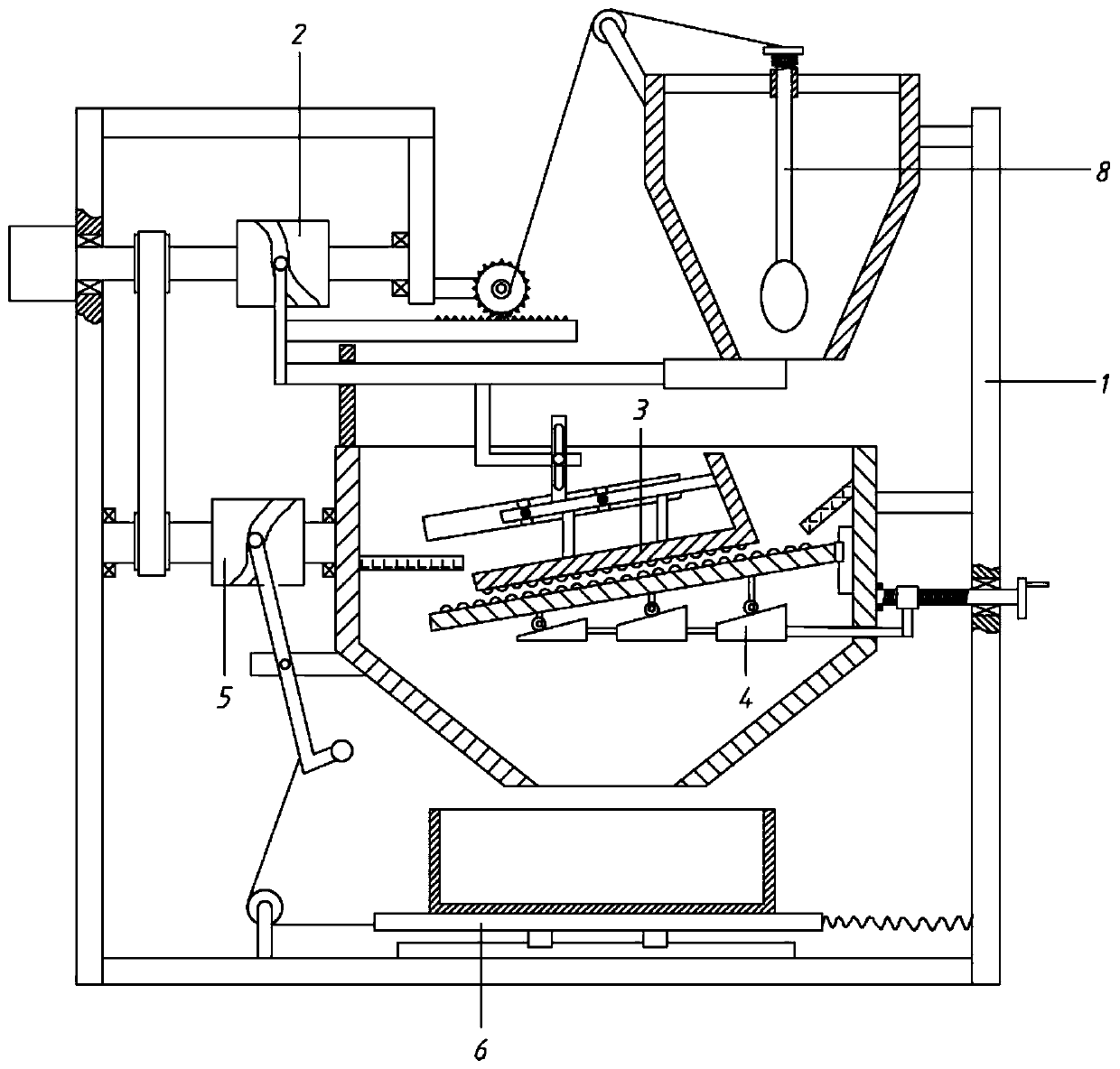

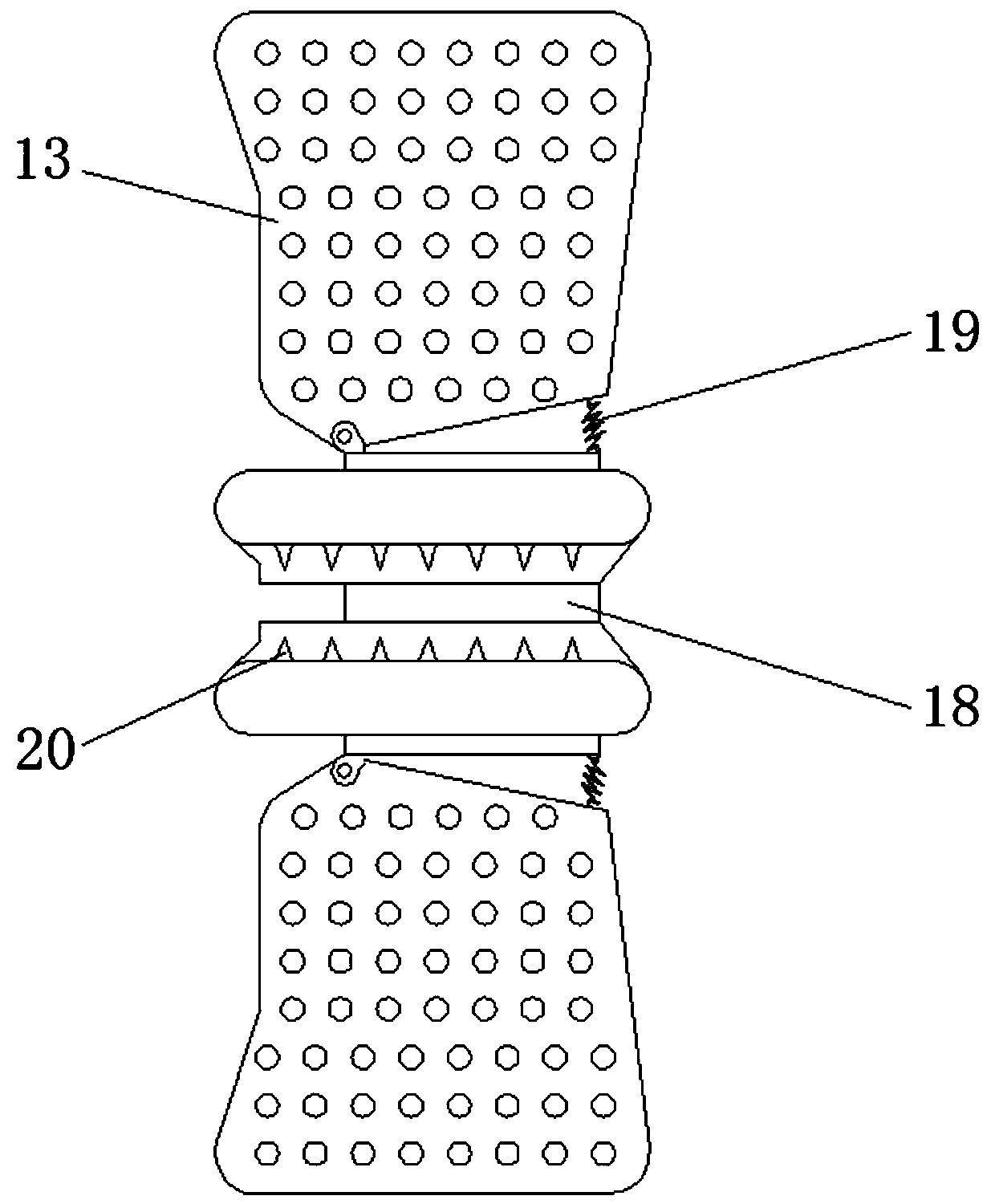

Convenient-to-adjust vegetable and fruit enzyme grinding equipment

The invention belongs to the technical field of vegetable and fruit enzyme production equipment and relates to convenient-to-adjust vegetable and fruit enzyme grinding equipment. According to the equipment, a servo motor is adopted for driving a first rotating shaft to rotate, so that a first cylindrical cam rotates along with the first rotating shaft; a second connecting rod drives a blocking plate to move leftwards and rightwards, and therefore, an outlet in the bottom of a material storage cavity is blocked or opened for intermittent discharging. A bending rod moves along with the second connecting rod; a sliding shaft is matched with a linear hole, so that a third connecting rod drives a fourth connecting rod to move in the direction of a sliding groove; and therefore, an upper grinding plate reciprocates to be matched with a lower grinding assembly below the upper grinding plate to grind enzyme blocks. A gap between the upper grinding plate and a lower grinding plate is convenientto adjust; an adjusting screw rod is rotated through a hand wheel, so that a movable nut drives a seventh connecting rod to move through a sixth connecting rod; and therefore, a wedge-shaped block moves leftwards or rightwards. Since the inclined surface of the wedge-shaped block is matched with a third roller, the lower grinding plate moves upwards or downwards, so that the gap between the uppergrinding plate and the lower grinding plate is changed; and therefore, the size of ground particles can be adjusted.

Owner:安徽易码数据科技有限公司

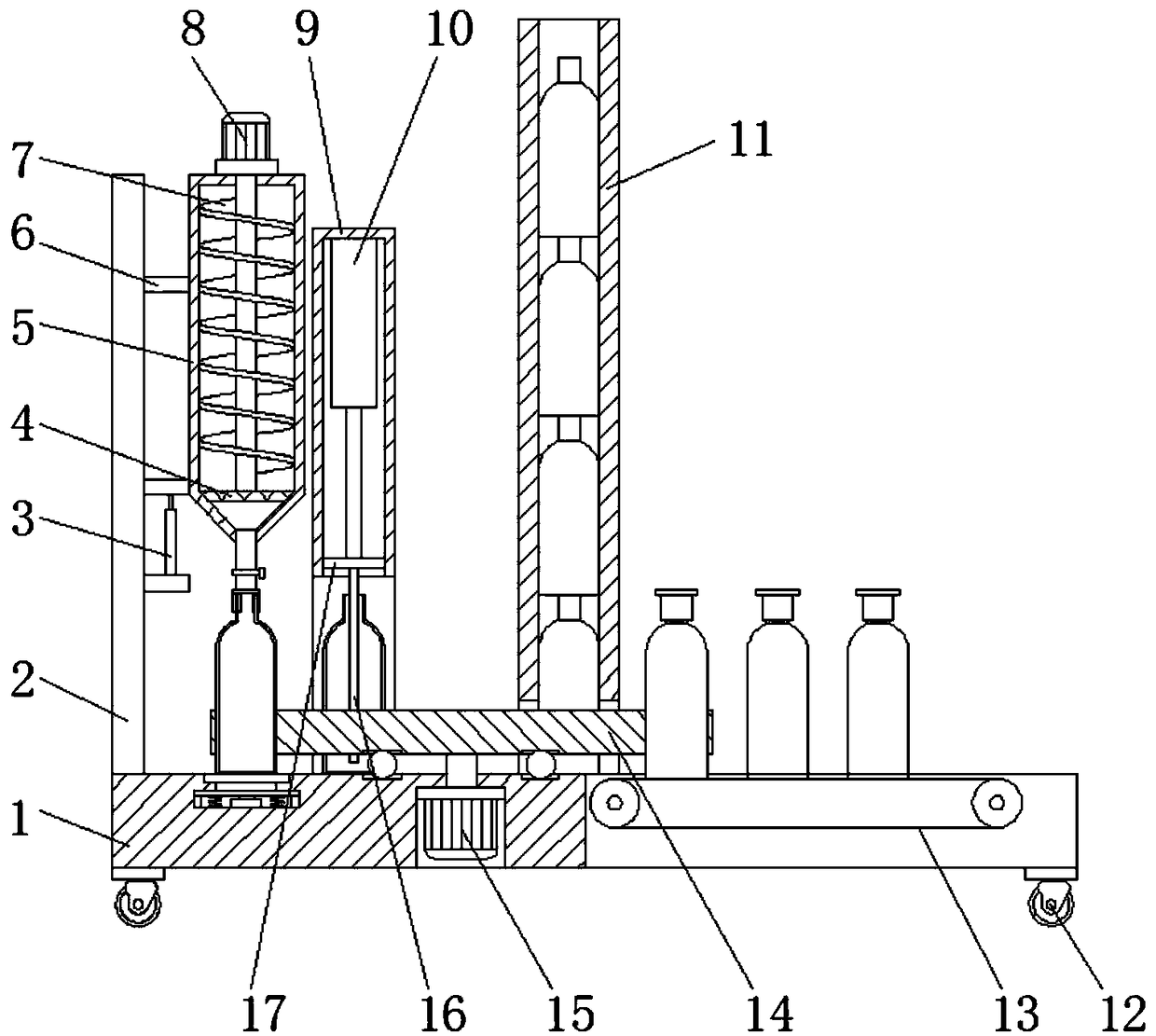

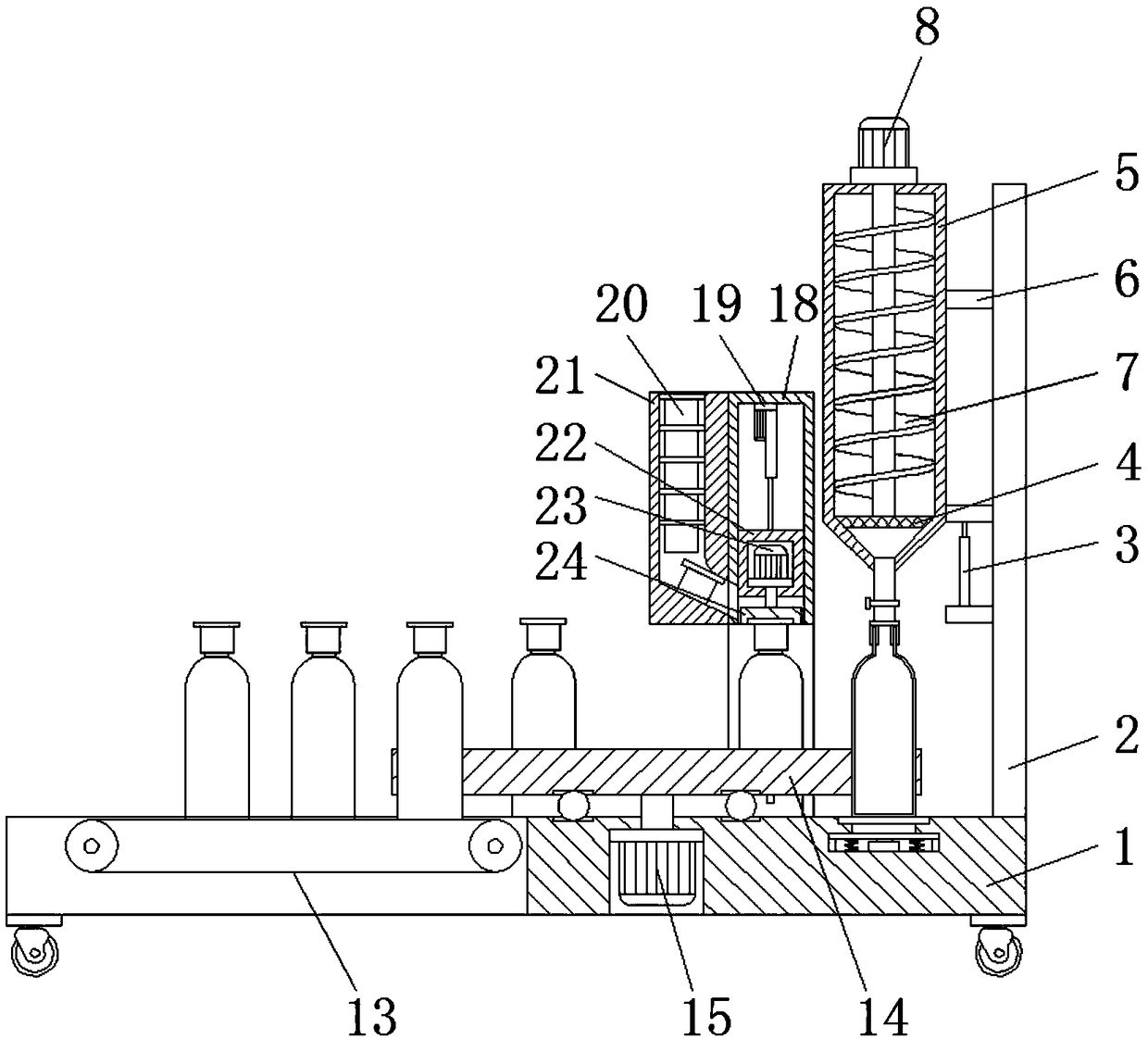

Automatic shampoo filling equipment for production of personal hygiene products

ActiveCN109160474AWeight real-time monitoringAvoid waste of raw materialsLiquid bottlingCouplingElectric machinery

The invention belongs to the technical field of shampoo production and in particular relates to automatic shampoo filling equipment for production of personal hygiene products. Aiming at the problem that the conventional shampoo filling equipment is inconvenient for quantitative filling, the following scheme is provided. The automatic shampoo filling equipment comprises a base, wherein universal wheels are fixed at four corners of the outer wall of the bottom of the base by virtue of screws; supporting shaft mounting holes are formed in outer walls of the top of the base; the inner walls of the supporting shaft mounting holes are connected with a supporting shaft by virtue of a bearing; a rotating table is connected with the top of the outer wall on one side of the supporting shaft by virtue of keys; a drive motor is fixed on the inner wall of the top of the base by virtue of screws; the output shaft of the drive motor is fixed on the outer wall at one end of the supporting shaft by virtue of a coupling. According to the equipment disclosed by the invention, the phenomenon that raw materials are wasted due to bottle-free filling can be effectively avoided, the filling amount is conveniently controlled, the occurrence probability of a phenomenon that the discharge pipe is blocked by the raw materials is reduced, the labor intensity of workers is reduced, and the influence of dust impurities in air on the product quality is reduced.

Owner:LOOBI GUANGZHOU HEALTH IND CO LTD +1

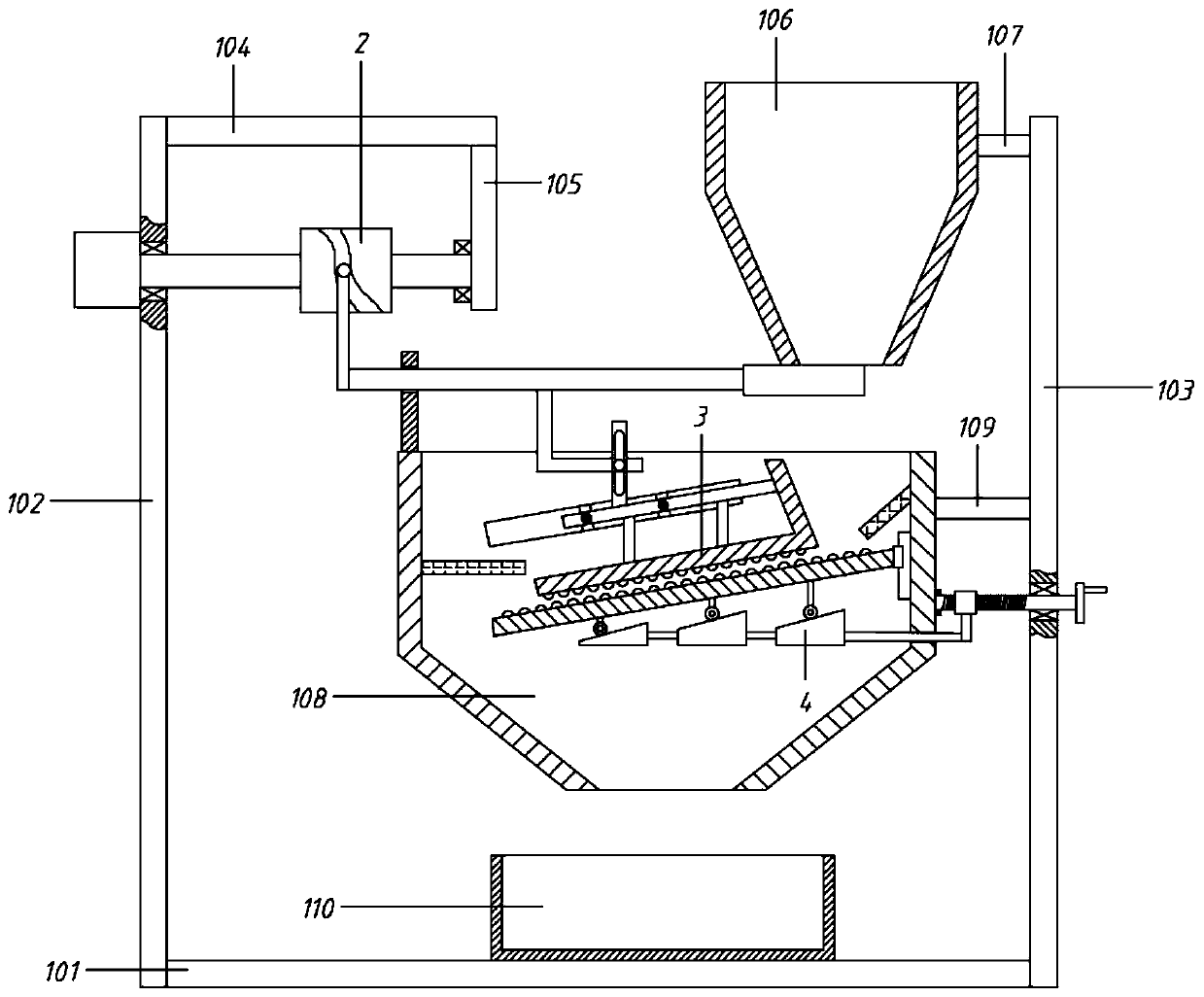

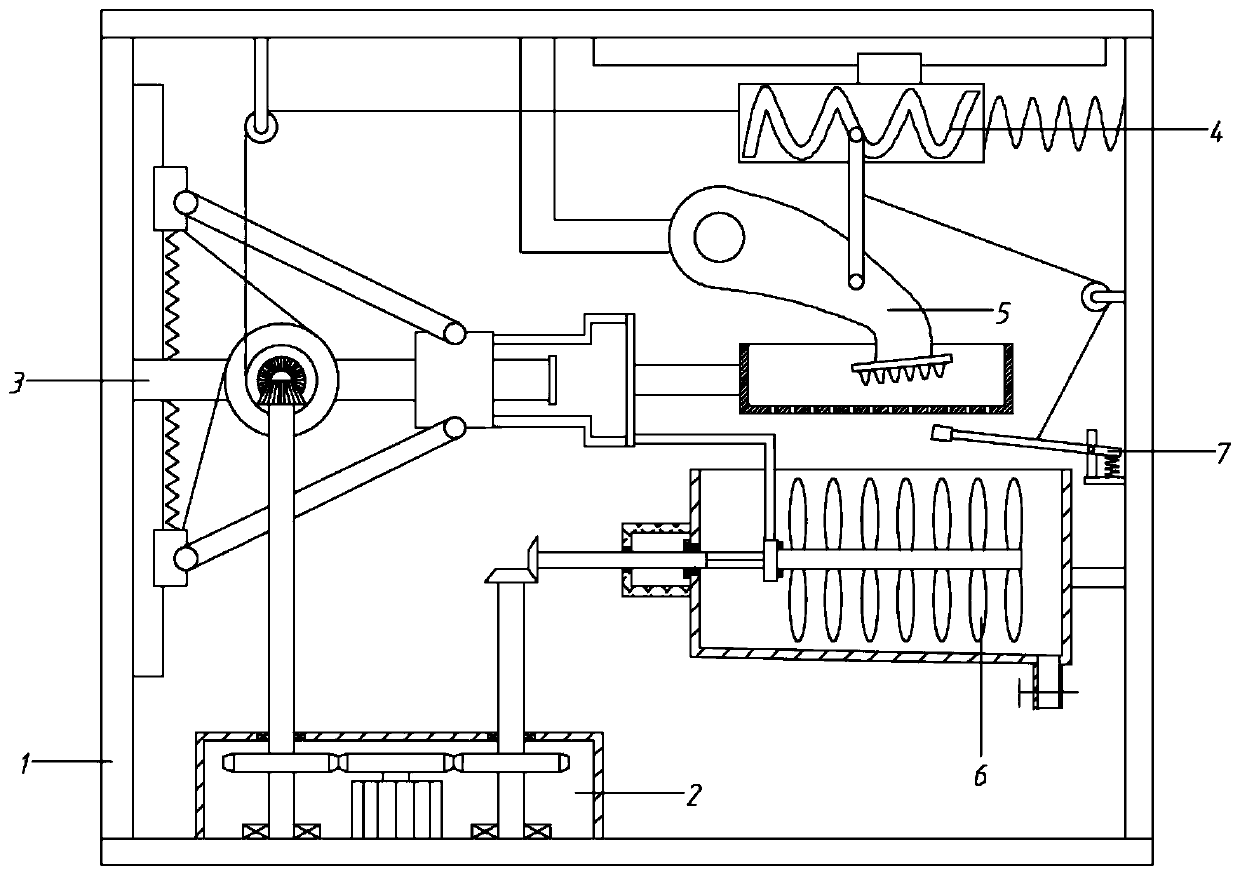

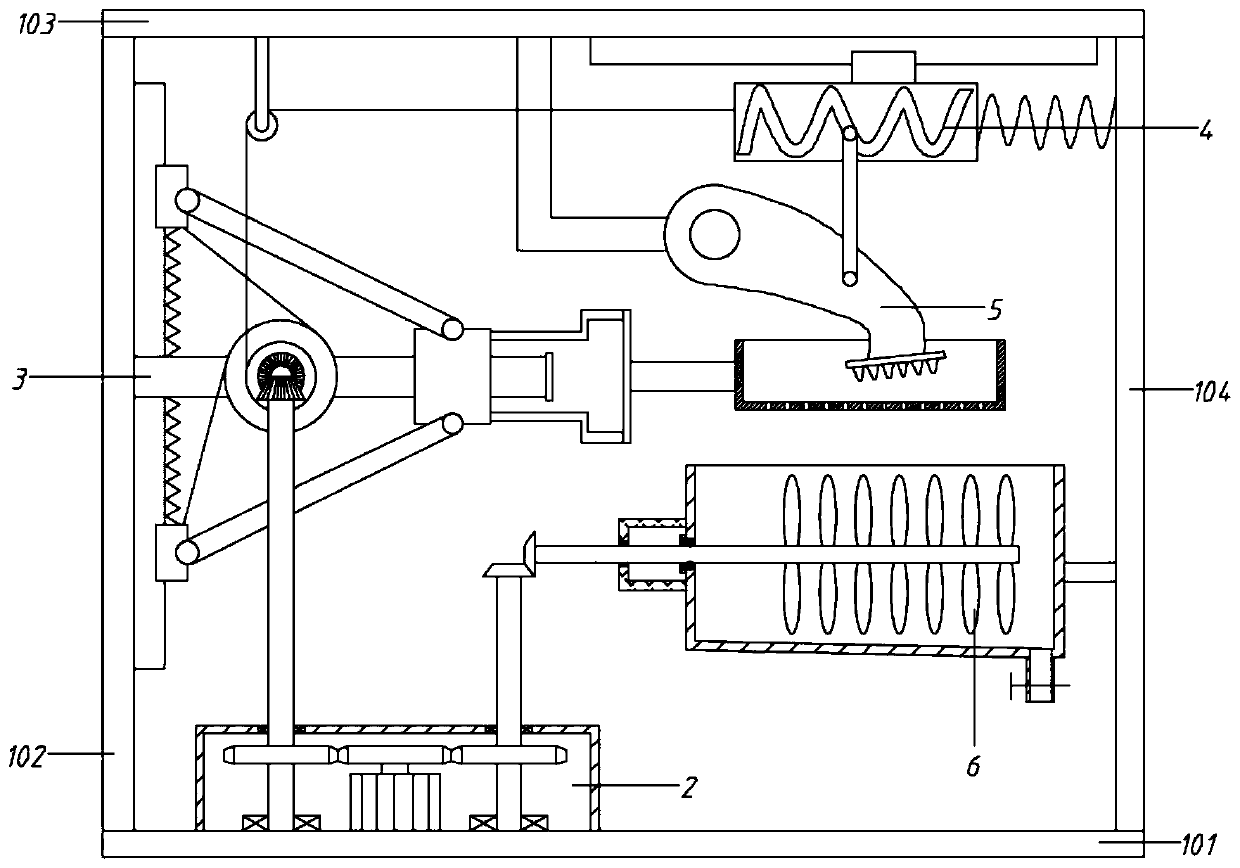

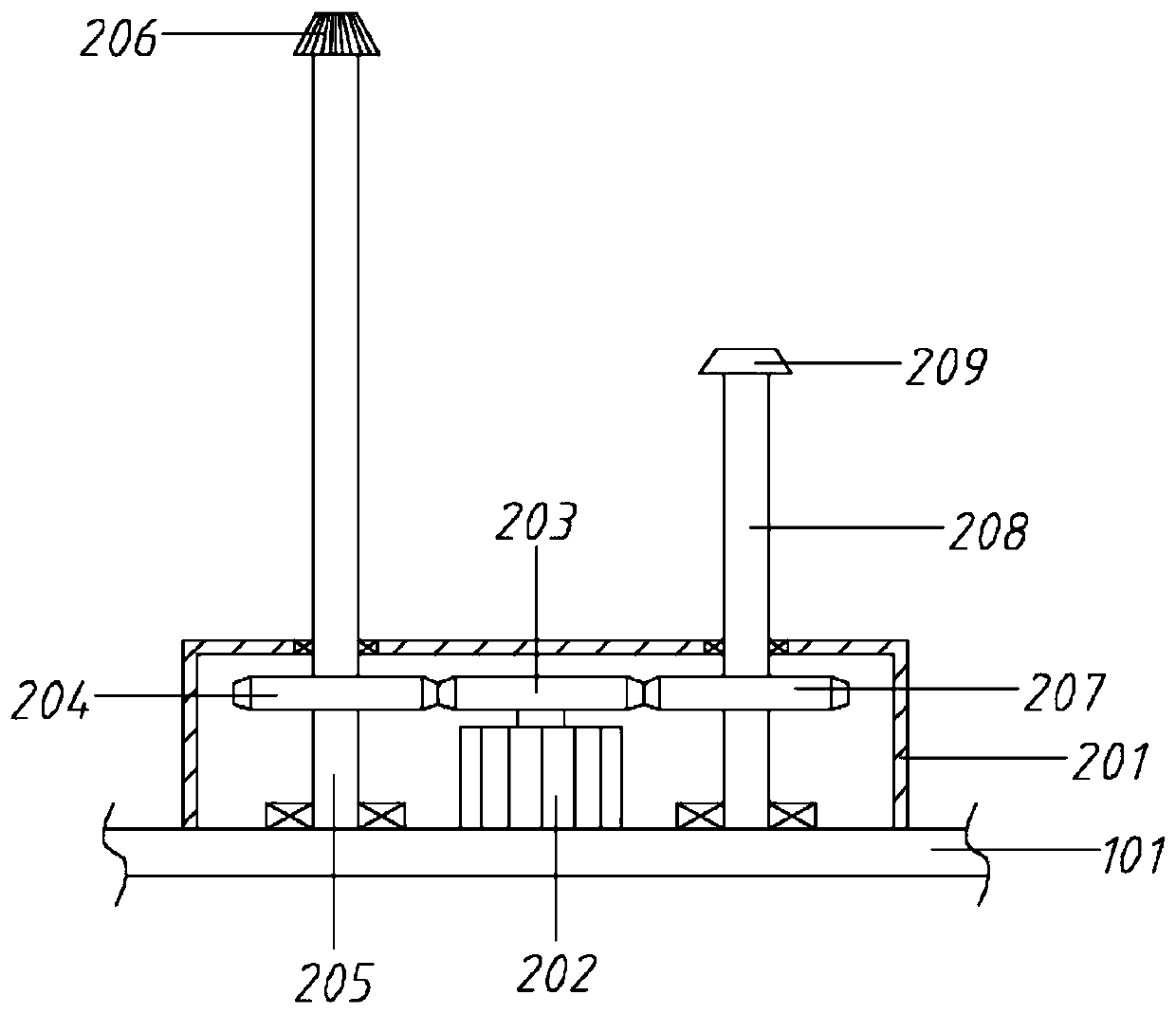

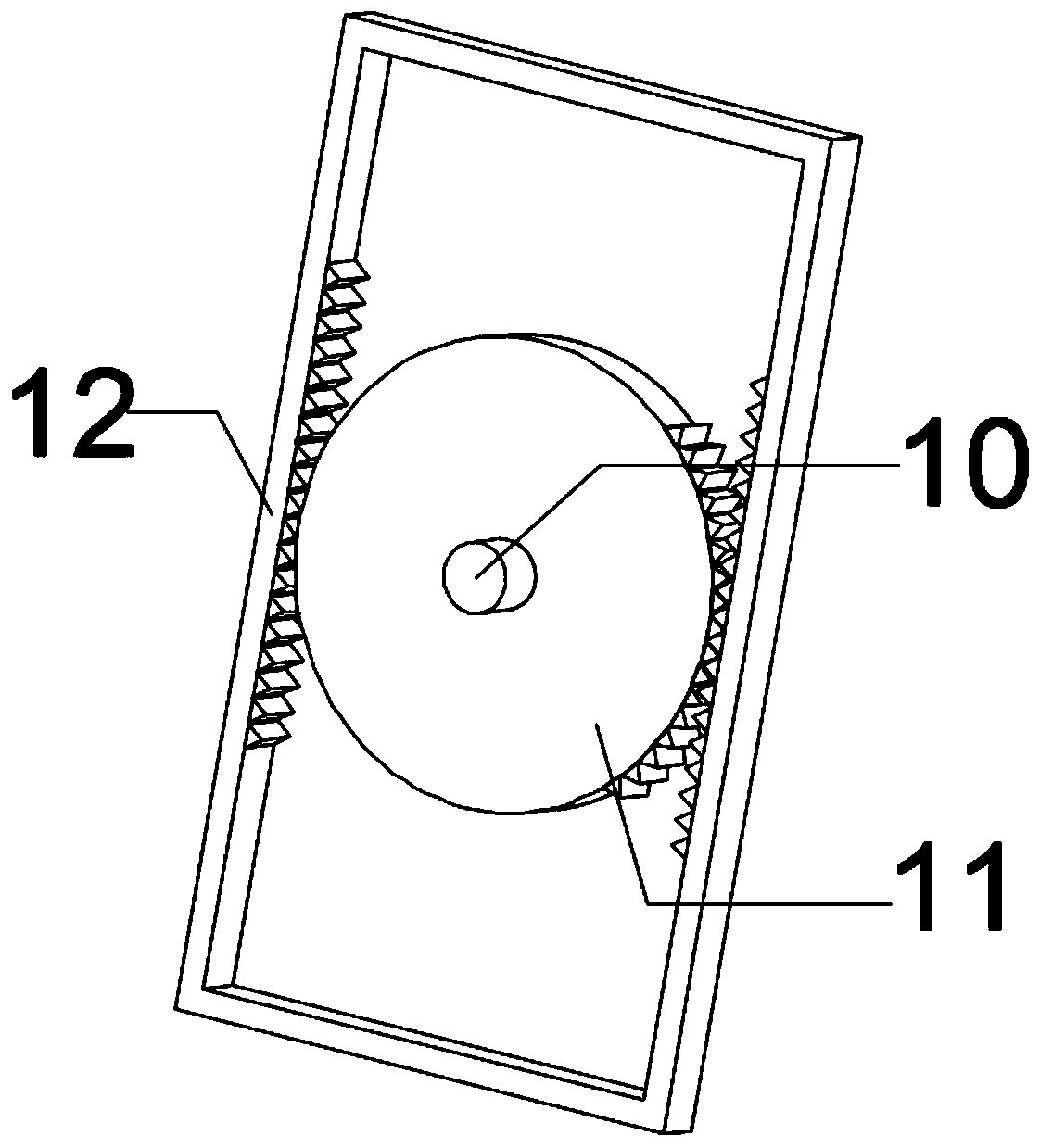

Impurity separator for rare earth permanent magnetic materials for civil engineering

InactiveCN110947459AEasy to operateGood effect of removing impuritiesSievingScreeningGear wheelEngineering

The invention relates to the technical field of impurity separation equipment for rare earth permanent magnetic materials, and in particular to an impurity separator for rare earth permanent magneticmaterials for civil engineering. A servo motor rotates a first rotating shaft through gear rotation, so that a reel rotates along with the first rotating shaft to tighten or loosen a first pull rope.A sliding sleeve is moved up and down under the effect of the first pull rope and a first spring, and moves a first sliding block through a rotating rod, so that a first spring rod moves a crushing roller to crush the materials. Impurities and magnetic materials are separated, the crushed materials fall into an impurity removal box from a through hole. Magnetic adsorption is generated by using anelectromagnetic chuck such that the magnetic parts in the materials falling into the impurity removal box are adsorbed, and nonmagnetic impurities are automatically guided to the right end along withthe gradient of an inclined plane and are discharged from a discharge pipe. The impurity separator is easy and convenient to operate, and good in impurity removal effect.

Owner:ZHENGZHOU INST OF TECH

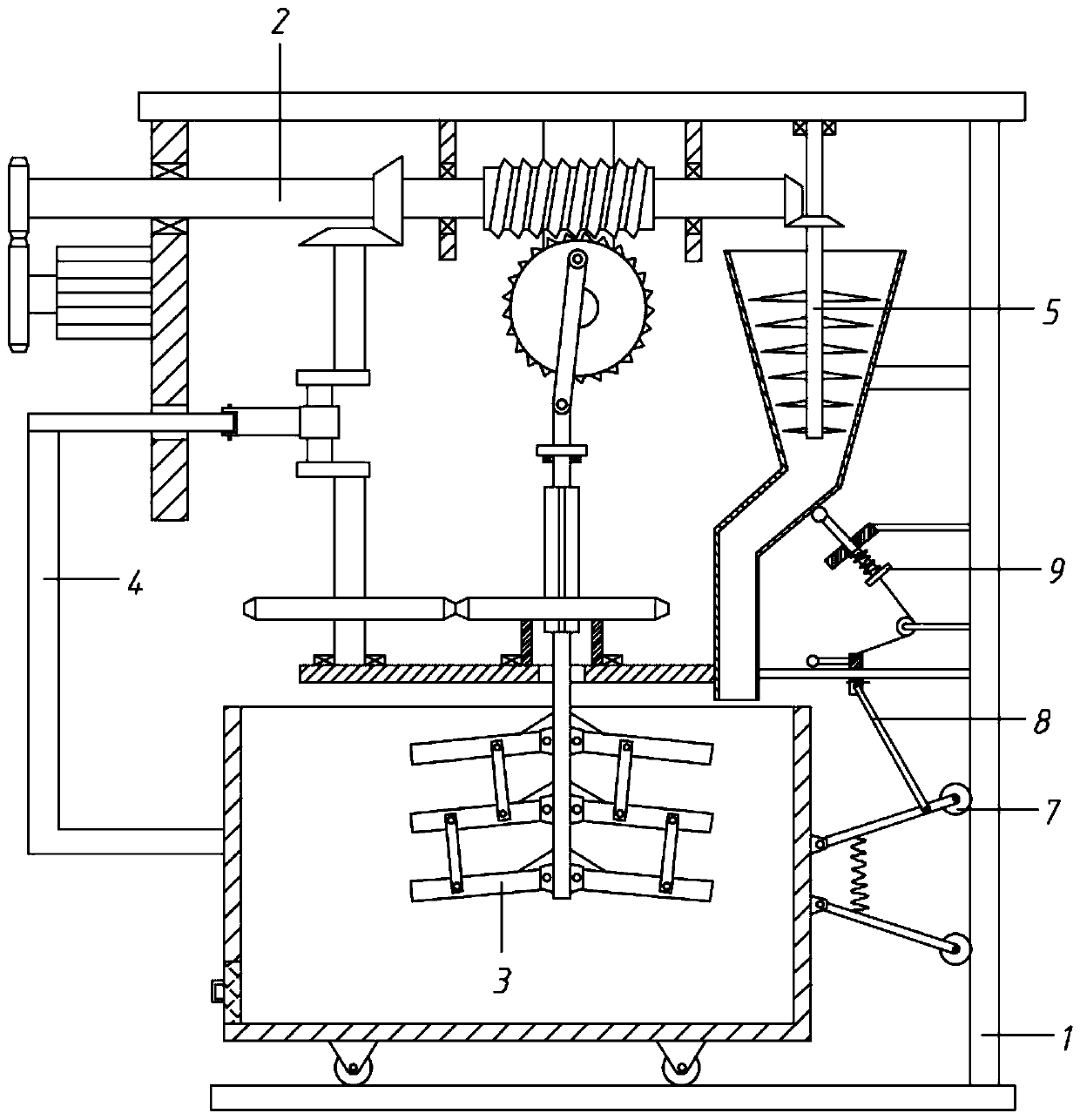

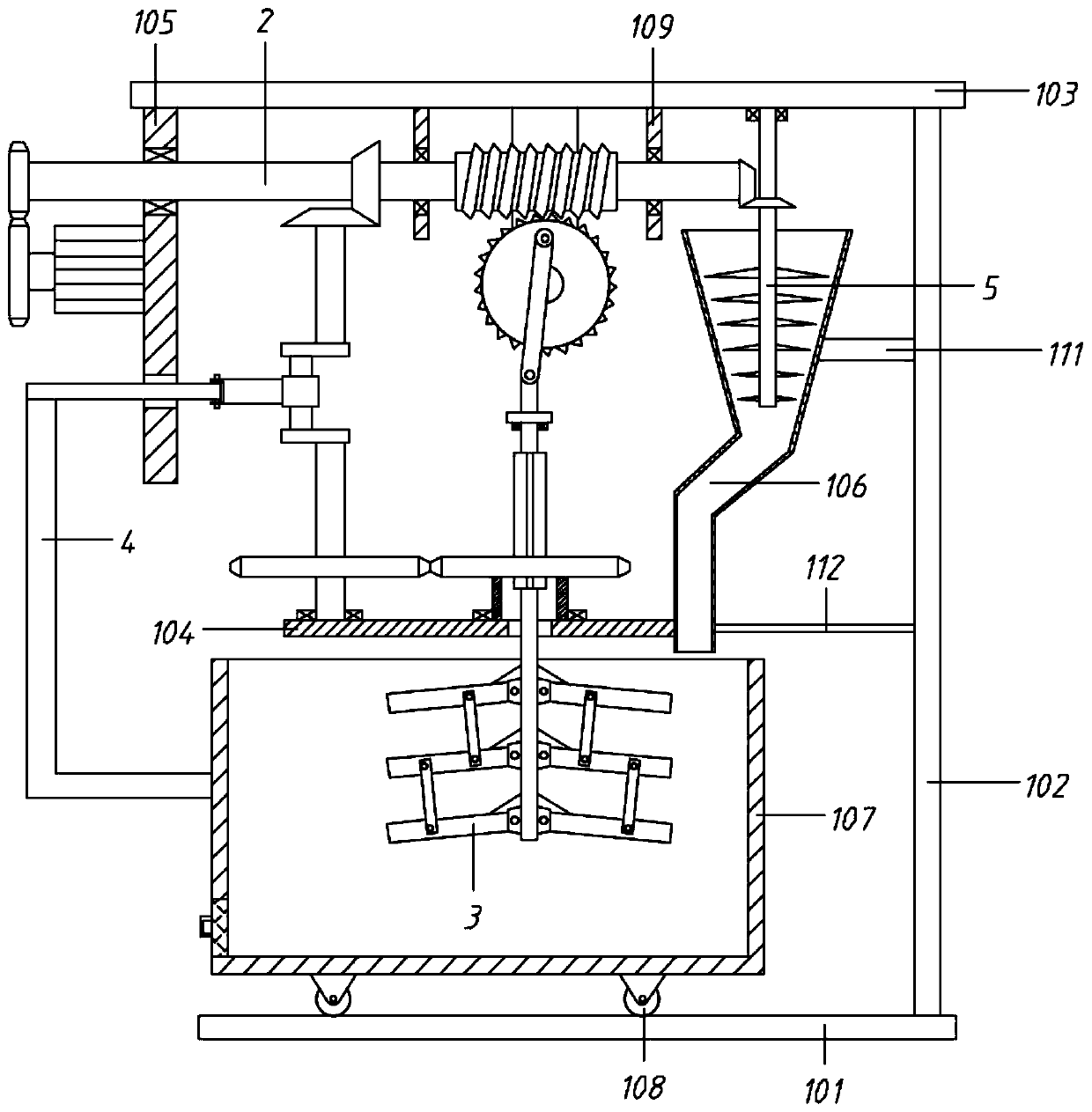

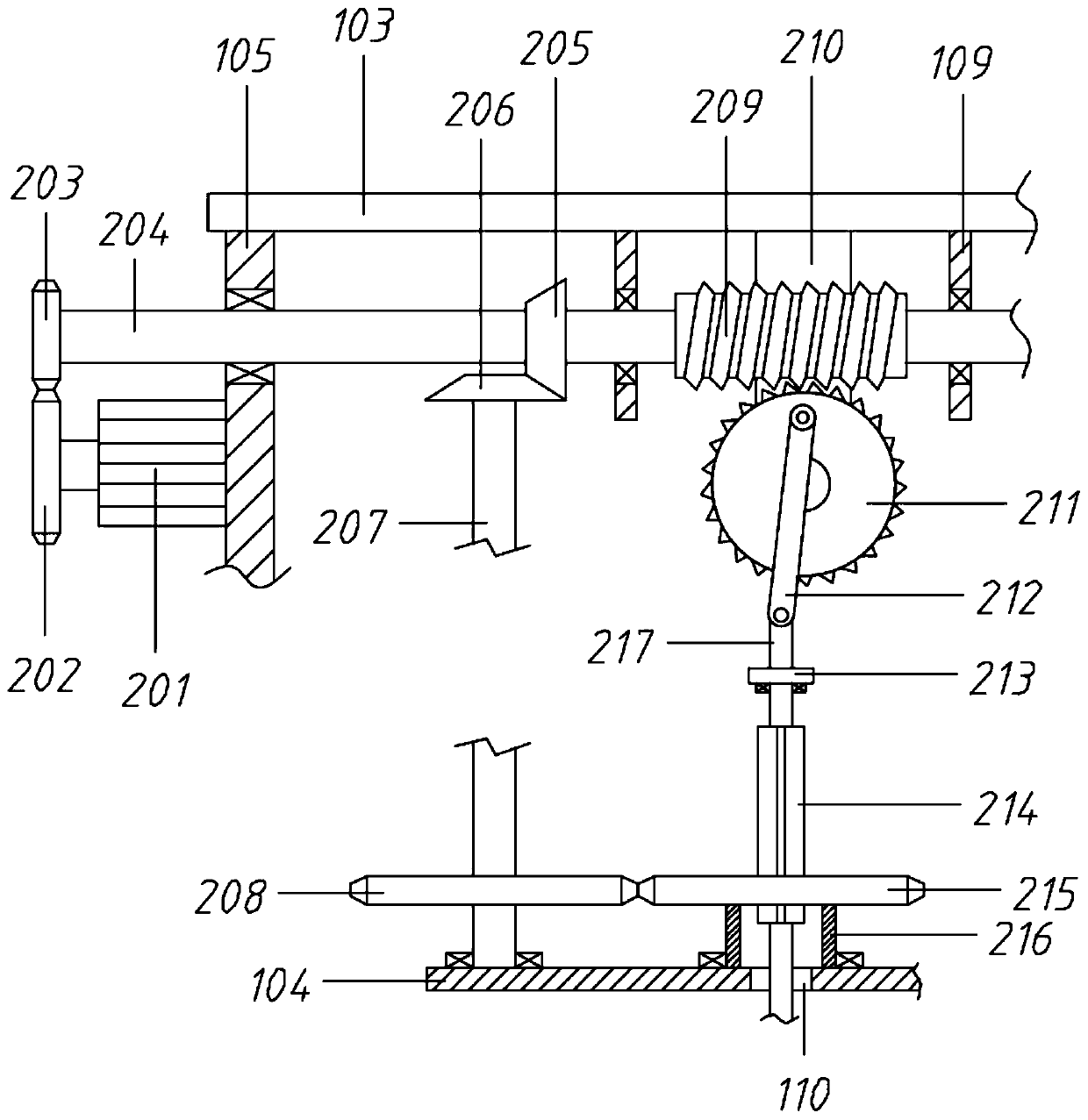

Chopping and mixing device for vegetable and fruit enzyme production

InactiveCN110975729AImprove mixing efficiencyImprove uniformityTransportation and packagingMixer accessoriesControl engineeringAgricultural engineering

The invention relates to the technical field of vegetable and fruit enzyme mixing equipment, in particular to a chopping and mixing device for vegetable and fruit enzyme production. A servo motor is adopted to drive a first rotating shaft to rotate through a gear transmission belt. A second rotating shaft rotates through bevel gear transmission, a third gear rotates along with the second rotatingshaft and a fourth gear rotates and the fourth gear drives a transmission rod to rotate due to the fact that a special-shaped column is matched with a special-shaped through groove and then a stirringassembly is driven to rotate for stirring and mixing. The worm rotates along with the first rotating shaft, the worm wheel rotates through transmission of the worm wheel and the worm, the first rod rotates along with the worm and drives the mounting plate to move upward and downward through the second rod, and thus the transmission rod drives the stirring assembly to move upward and downward, thestirring area is changed and the mixing uniformity is improved; when the first rotating shaft rotates, the third rotating shaft is driven to rotate through rotation of the bevel gear so that the crushing cutters crush the input vegetable and fruit materials and the crushed vegetable and fruit materials fall into the stirring box to be mixed.

Owner:安徽易码数据科技有限公司

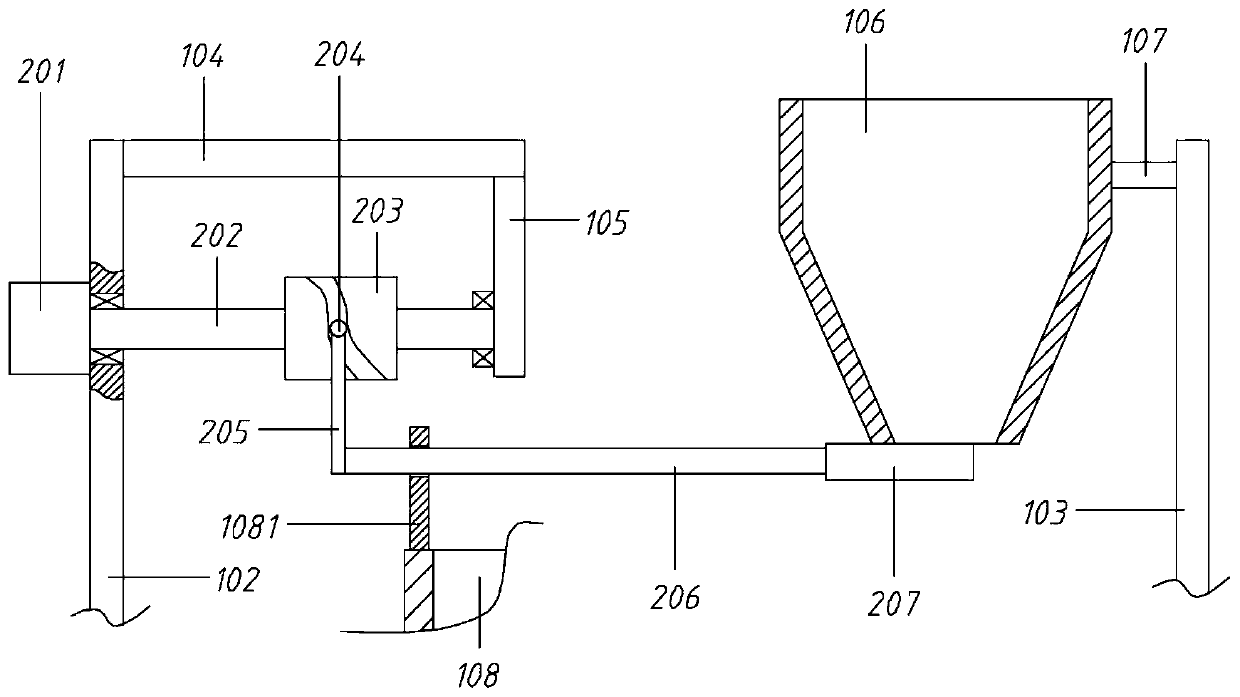

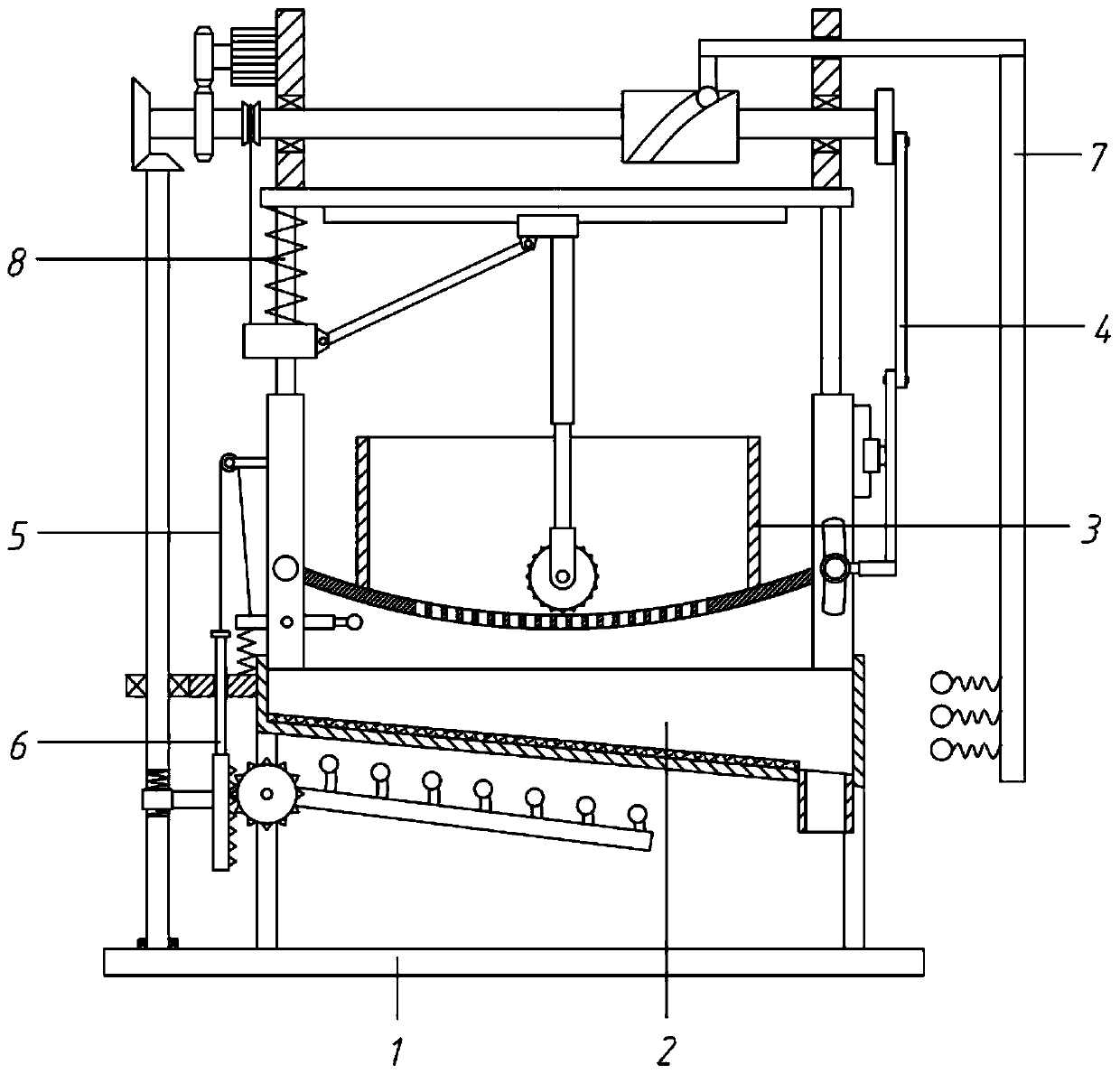

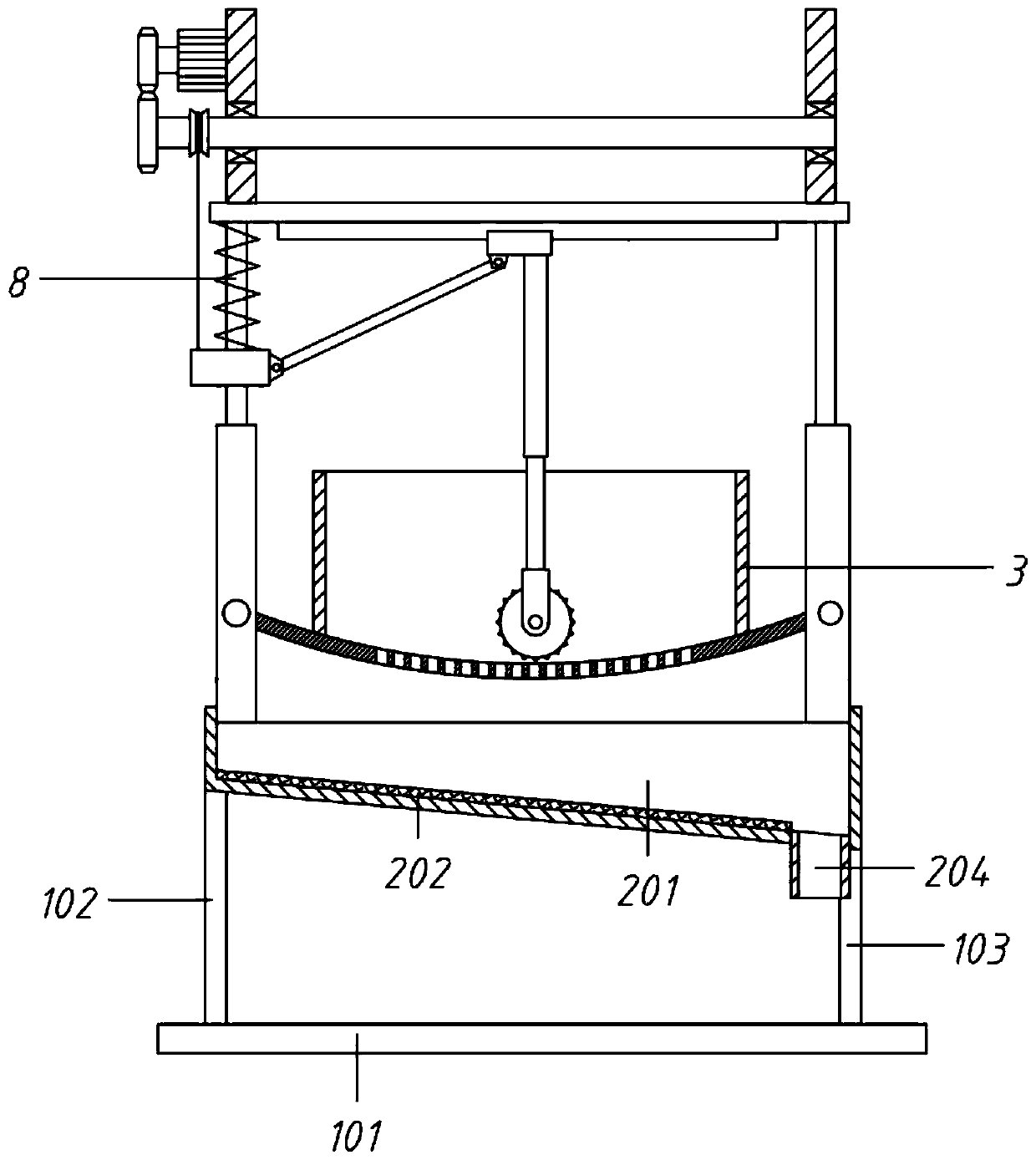

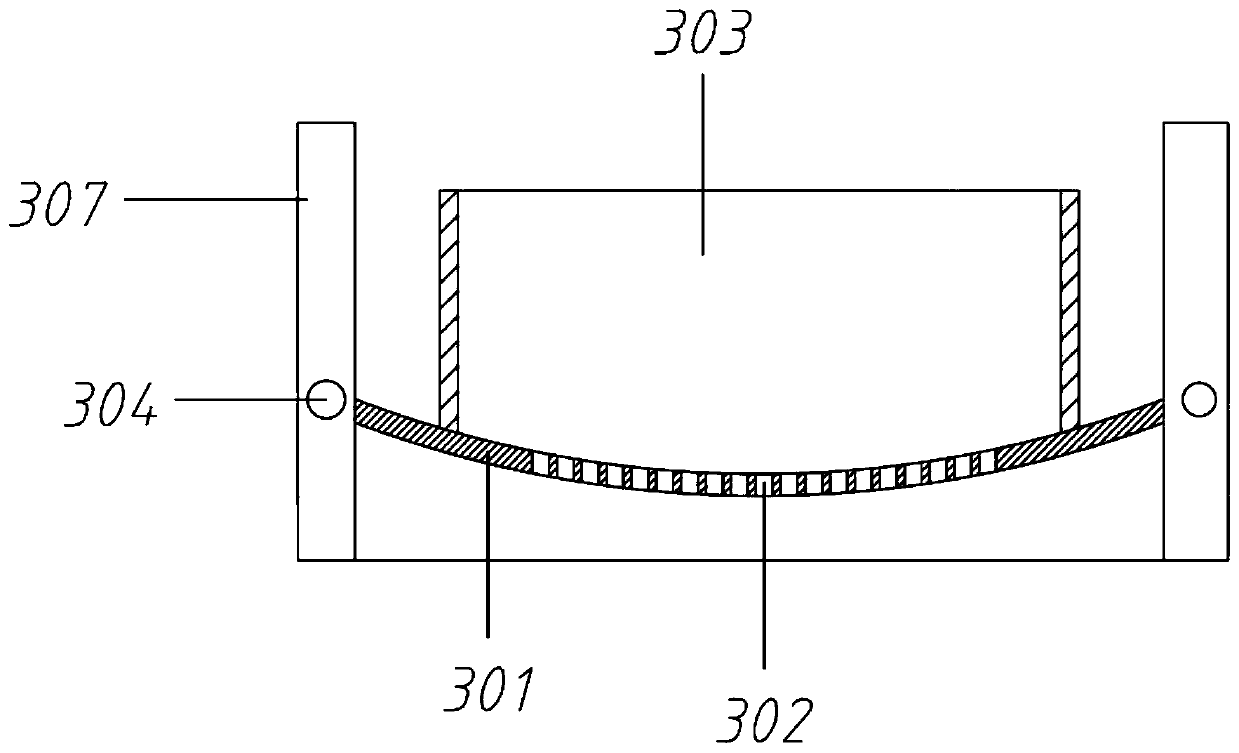

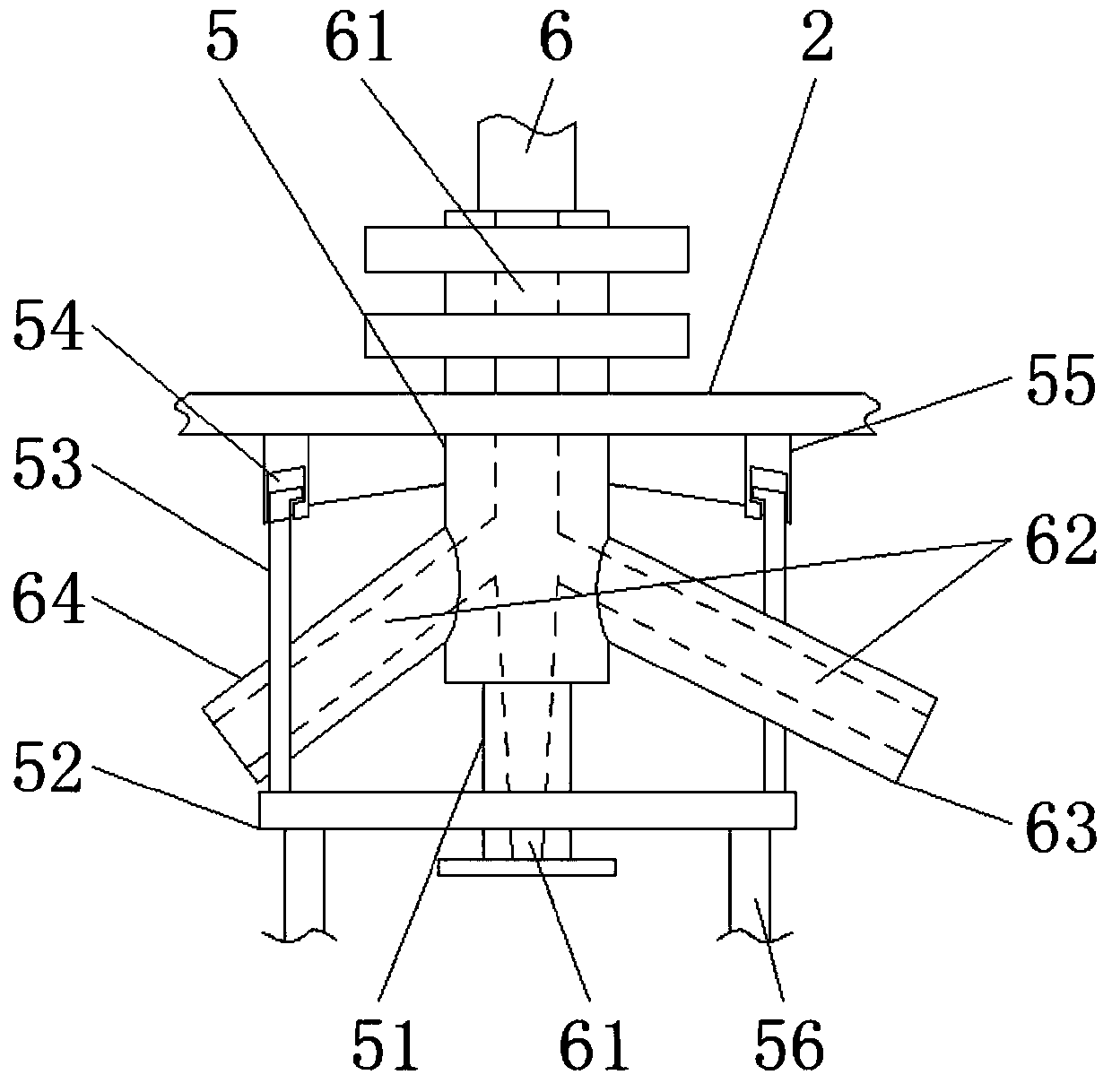

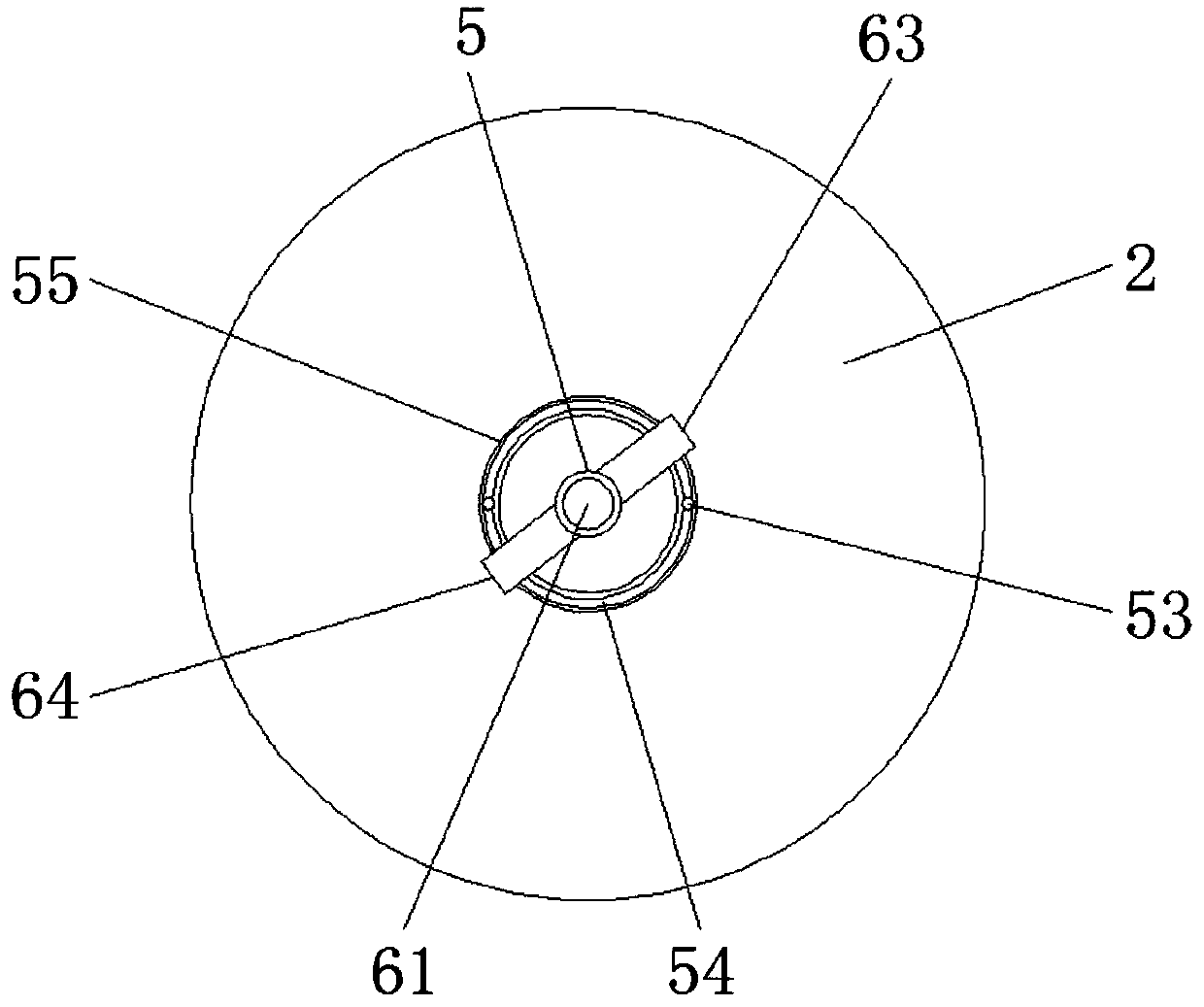

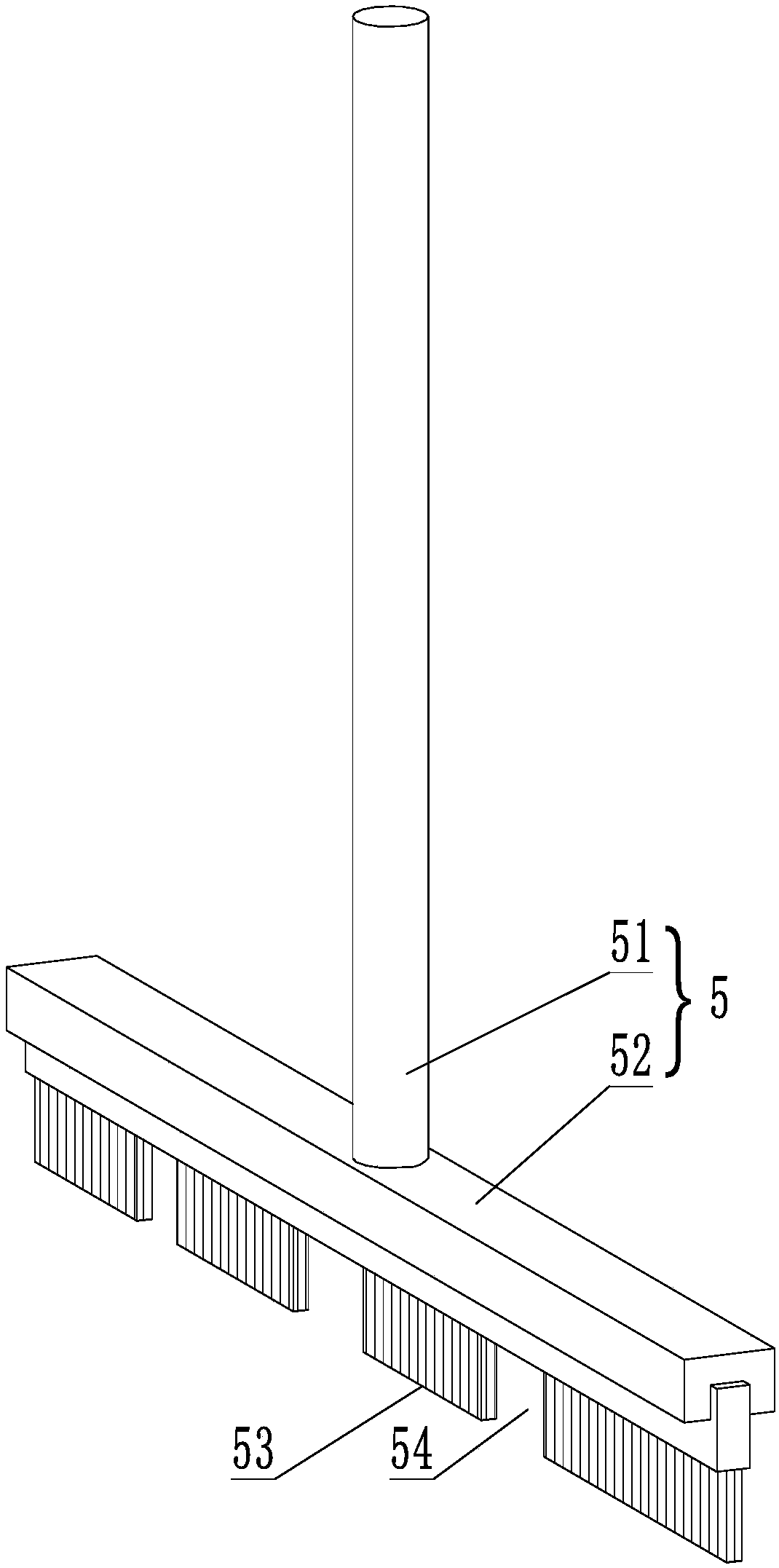

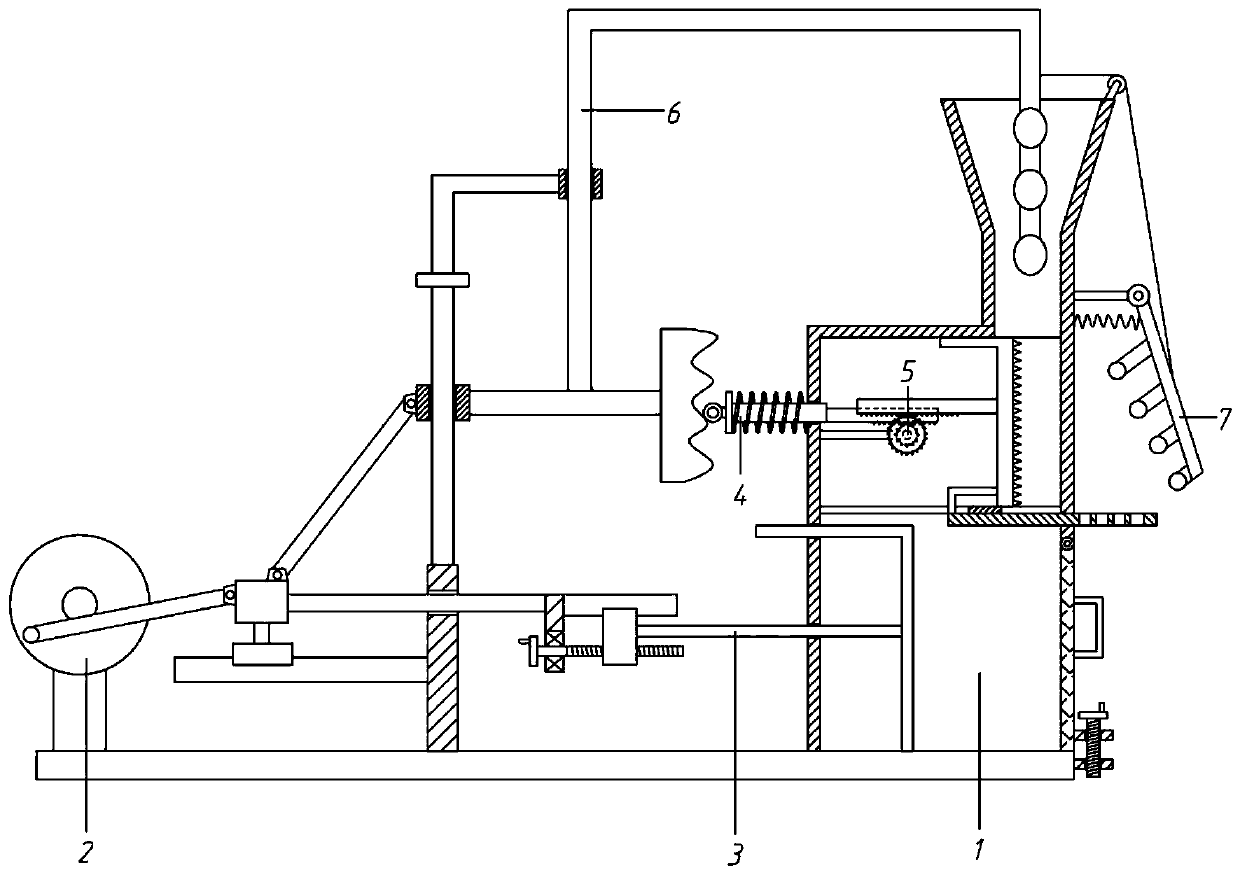

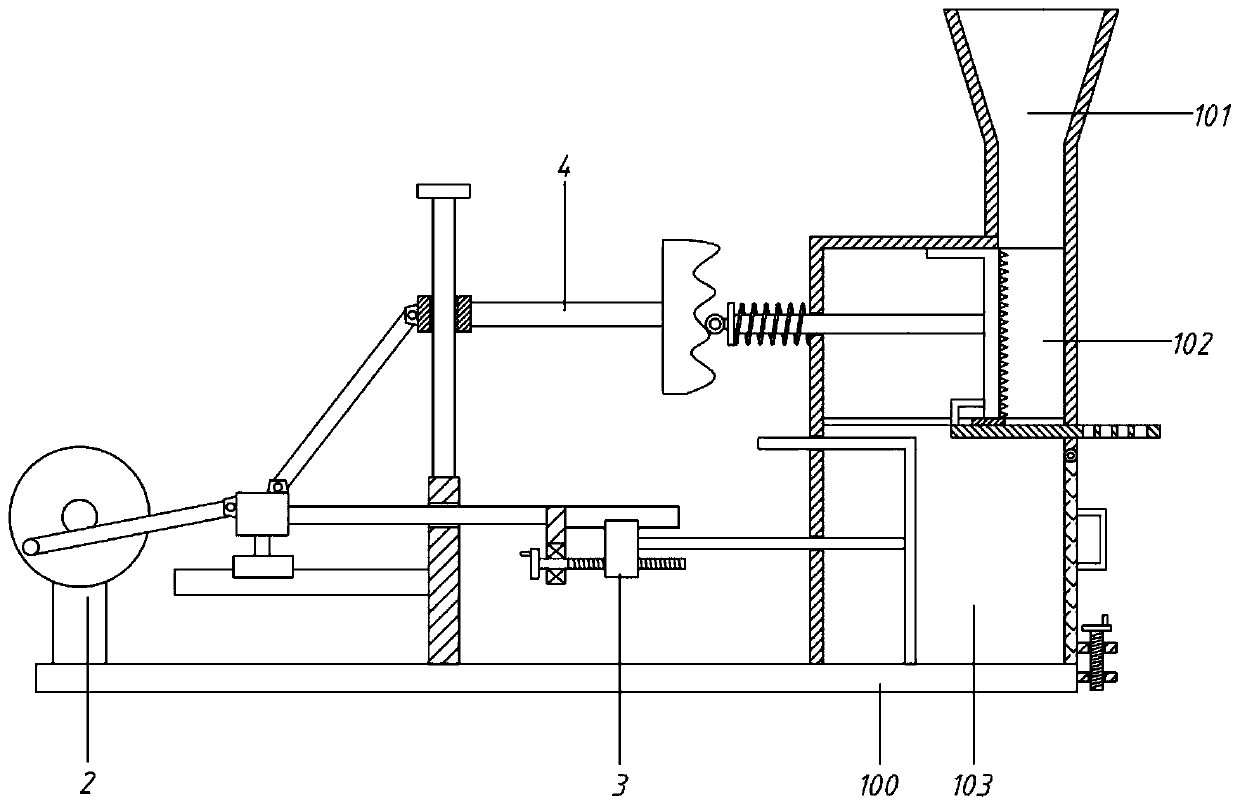

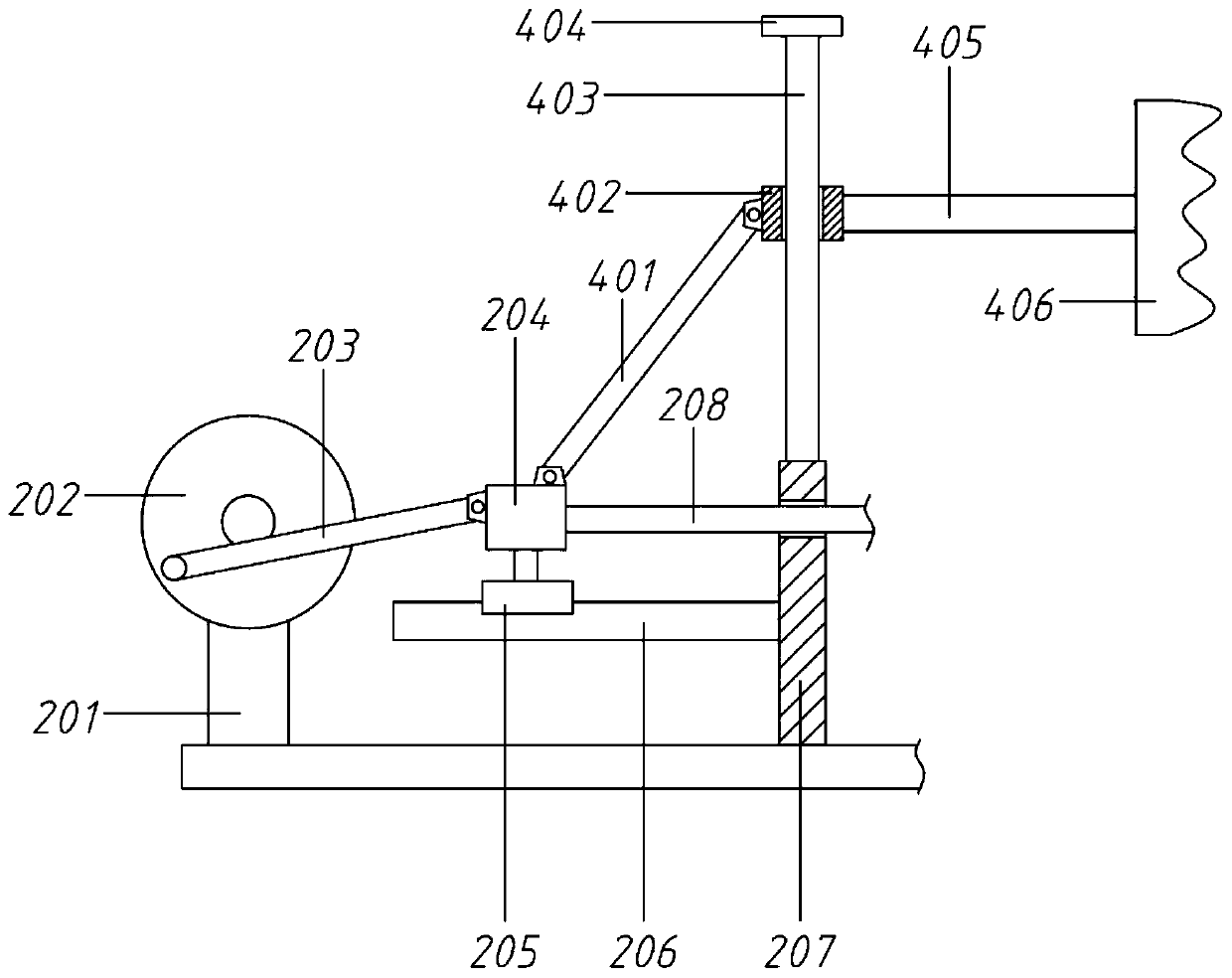

Mechanical reciprocating-type multi-face arch breaking structure for powder stock bin

The invention discloses a mechanical reciprocating-type multi-face arch breaking structure for a powder stock bin. The mechanical reciprocating-type multi-face arch breaking structure comprises a stock bin body and a bearing seat; a cover plate is arranged at the top of the stock bin body; the top end of a rotary tube is connected with a feeding pipe through a bearing, and the rotary tube is connected with a vertical shaft through a second belt; a transverse plate is mounted at the top end of the vertical shaft, and meanwhile the vertical shaft is rotationally mounted on the cover plate; and avertical rod is welded to the edge of the upper end face of the transverse plate, the bearing seat is mounted on the side wall of the stock bin body, and a sleeve is fixedly mounted on the lower halfsection of the bin wall of the stock bin body. According to the mechanical reciprocating-type multi-face arch breaking structure for the powder stock bin, by redesigning internal and external structures of the stock bin, the problem that powder in the large stock bin is prone to being arched, and thus discharging is influenced is solved, and adhering materials in the stock bin can be effectivelycleared; and meanwhile, by resigning a relevant feeding structure, it is guaranteed that the materials are not stacked in the center of the stock bin directly, and thus the design is more reasonable.

Owner:HUNAN CHUANGYUAN NEW MATERIALS

Nano-coating material mixing device convenient for blanking

PendingCN110559906AConvenient whereaboutsEasy to unloadRotary stirring mixersTransportation and packagingEngineeringCoating materials

The invention provides a nano-coating material mixing device convenient for blanking. The nano-coating material mixing device convenient for blanking includes a box body, a frame body is fixedly connected to the inner wall top of the box body, a first blanking plate and a second blanking plate are rotatably connected to both sides at the bottom of the frame body respectively, a first support plateand a second support plate are fixedly connected to both sides on the inner wall of the box body respectively, a telescopic rod is fixedly connected to one side at the top of the first support plate,the top end of the telescopic rod is fixedly connected to the bottom of the first blanking plate, a first base is fixedly connected to the other side at the top of the first support plate, and a first motor is fixedly connected to the top of the first base. The nano-coating material mixing device convenient for blanking provided by the invention enables more convenient blanking through vibrationof the blanking plates, avoids the problem of blockage during blanking, also makes blanking faster through vibration, and greatly improves the blanking efficiency.

Owner:LINYI UNIVERSITY

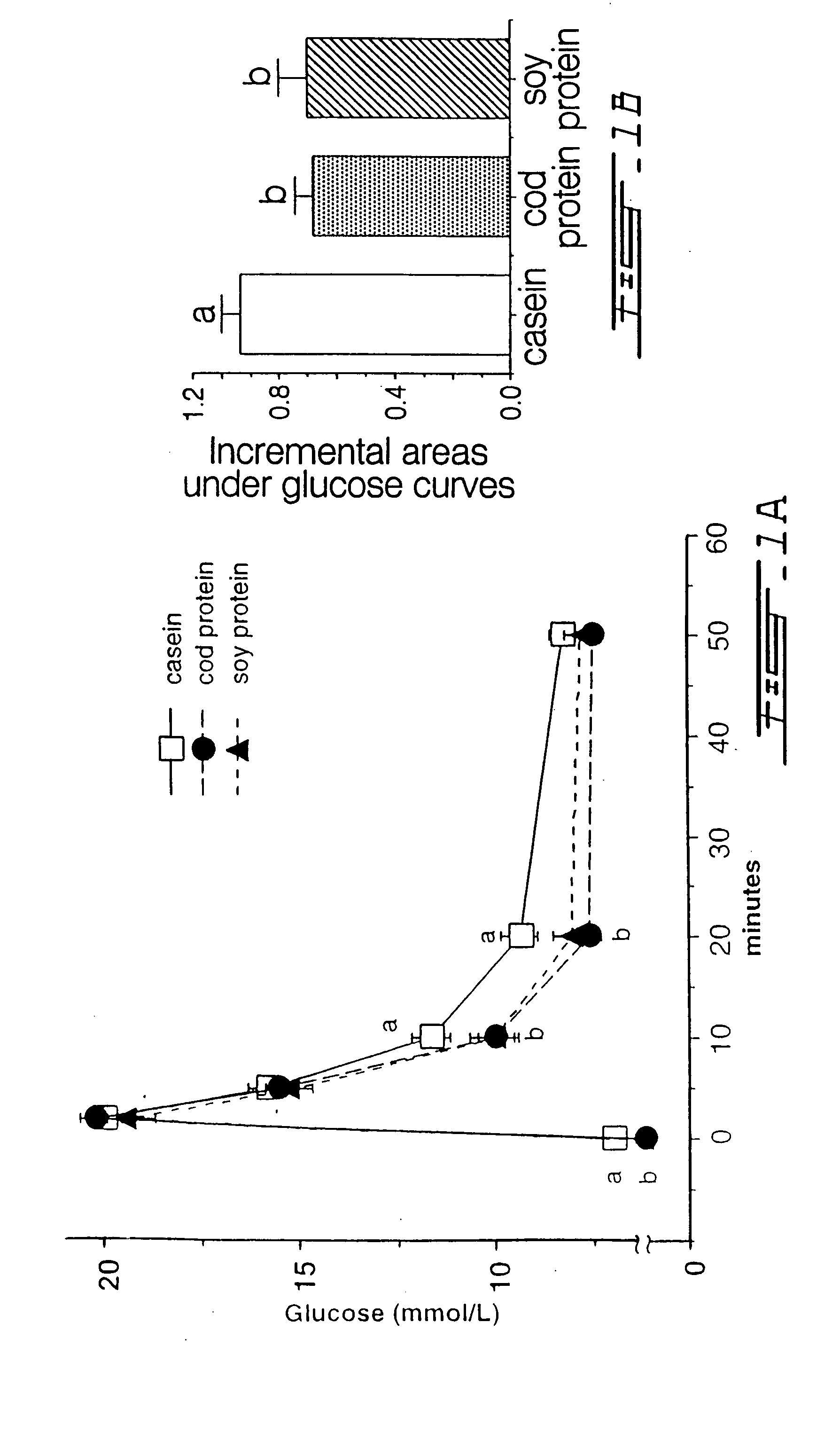

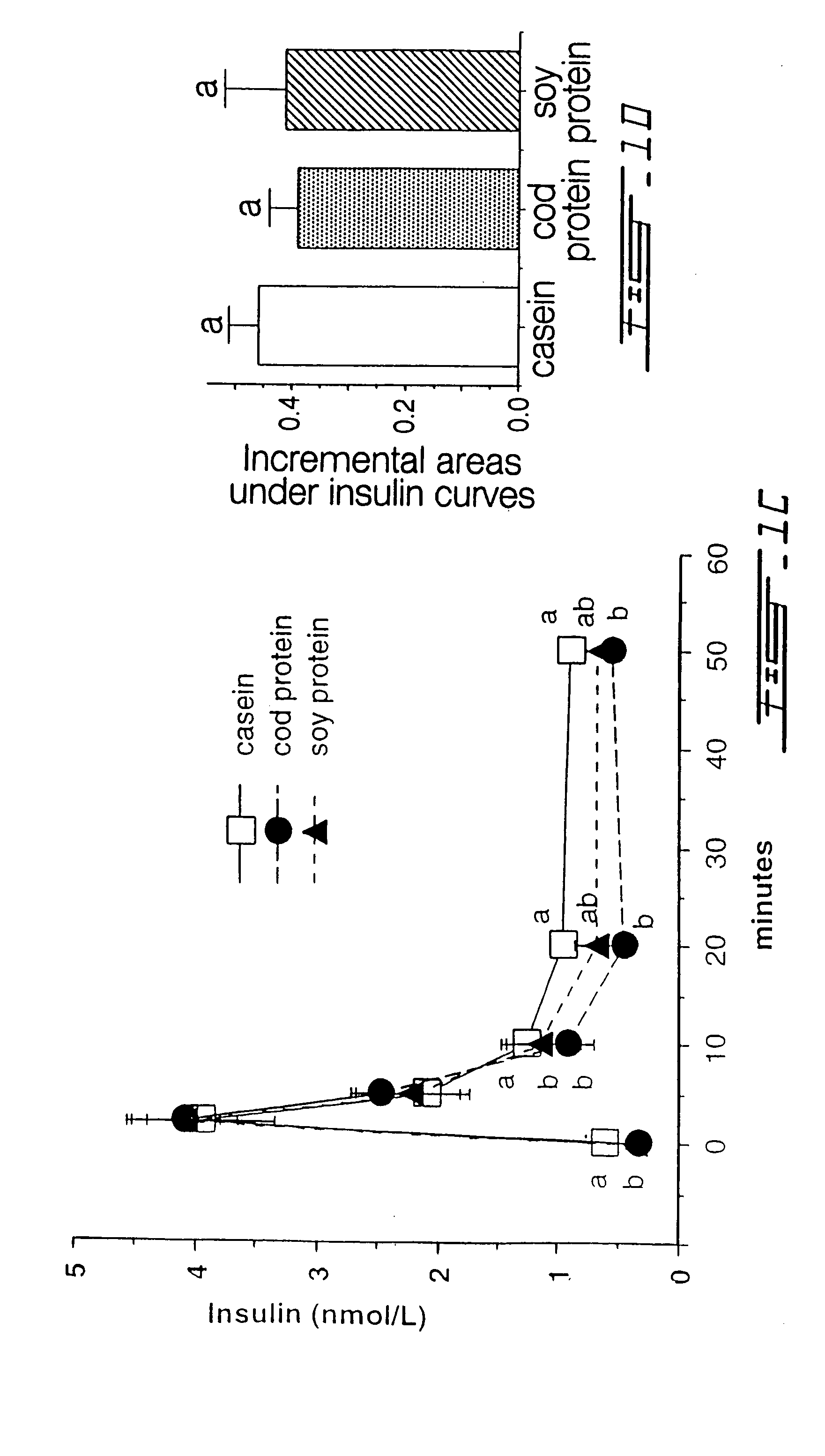

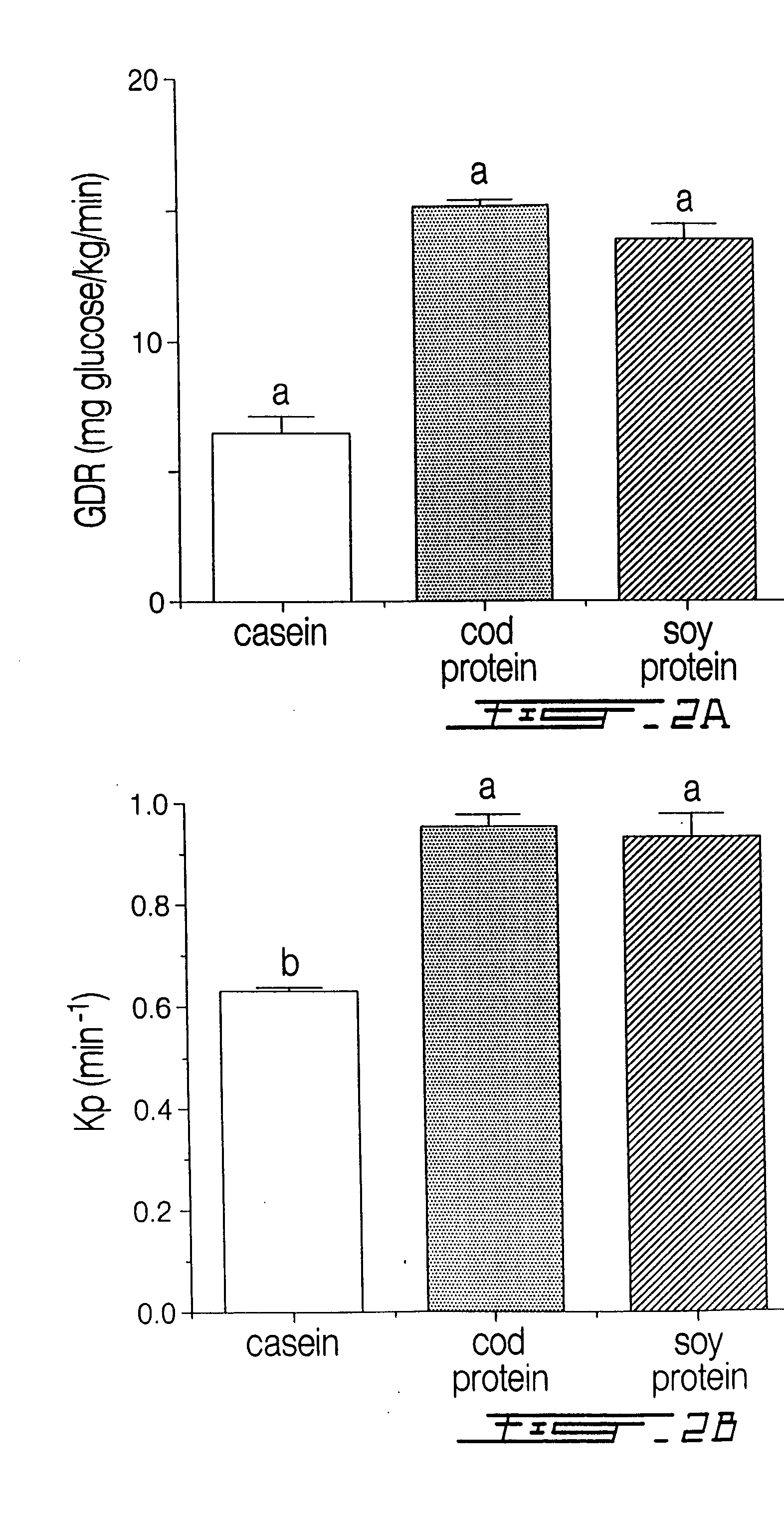

Amino acids from fish and soy proteins improve insulin sensitivity

InactiveUS20050101523A1Increase chanceImproved peripheral insulin sensitivityOrganic active ingredientsBiocideMuscle tissueGlucose utilization

The present invention describes the use of fish protein (namely cod protein) and soy protein to improve the peripheral insulin resistance in a human or non-human animal. Fish and soy protein were administered to rats submitted to high-sucrose or high-fat / sucrose diets, which are animal models for diabetes. It was found that fish and soy protein efficiently control glucose utilization, and that fish protein is particularly effective in muscle tissue. This effect is not observed when rats are given casein. Fish and soy protein are therefore promising for controlling insulin-resistance, diabetes and complications resulting therefrom, such as obesity.

Owner:UNIV LAVAL

Efficient rapid dissolving equipment for rare earth production

The invention relates to the technical field of dissolving equipment for rare earth production, in particular to efficient rapid dissolving equipment for rare earth production. A servo motor is adopted and controlled to drive a first gear to rotate forwards and backwards, a first bevel gear and a second bevel gear are driven to rotate through transmission, one bevel gear serves as a power source of a reciprocating assembly, and the other bevel gear serves as a power source of a stirring assembly. And when the first bevel gear rotates, the second bevel gear is driven to rotate, and a first take-up wheel rotates to carry out take-up and pay-off. A first-class pull rope is synchronously tightened or loosened under the action of the first take-up wheel, and the first-class pull rope is matchedwith a first-class spring to drive a sliding sleeve to move in the axial direction of a sliding rod through a push-pull rod. The first bevel gear rotates forwards and reversely, namely, the sliding sleeve reciprocates, so that a moving plate moves along with the first bevel gear, a crushing groove moves left and right, and comprehensive crushing is achieved through cooperation with a crushing assembly; and when the second bevel gear rotates, the stirring assembly is driven to work, so that stirring blades generate a stirring and mixing effect to realize rapid dissolution.

Owner:安徽延创通讯科技有限公司

Drying device for refractory material production

InactiveCN108444228AImplement rotationShorten the timeDrying chambers/containersDrying solid materialsRefractoryEngineering

The invention discloses a drying device for refractory material production. The drying device for refractory material production comprises a base plate, wherein two symmetrically arranged side platesare welded to the top of the base plate; a top plate is welded to the tops of the side plates; a rack is fixedly connected to the bottom of the top plate; a slide bar is fixedly mounted between the two side plates; the slide bar is located below the rack; a rail plate is slidably mounted on the slide bar; a first motor is fixedly mounted on the top of the rail plate; a first motor is fixedly mounted on the top of the rail plate; a gear is fixedly mounted on the output shaft of the first motor; the gear is engaged to a rack; a rail groove is formed in the bottom of the rail plate; a movable block is slidably mounted on the rail groove; a threaded rod is rotatably mounted in the rail groove; and the threaded rod is in threaded connection to the movable block. The drying device disclosed by the invention achieves automatic loading and unloading, reduces the manpower and improves the efficiency and lowers the cost, and meanwhile, two drying boxes dry the material alternately; the loading and unloading work is finished within the drying waiting time, so that the a lot of time is saved, and the drying efficiency is improved.

Owner:浙江康斯迪冶金科技有限公司

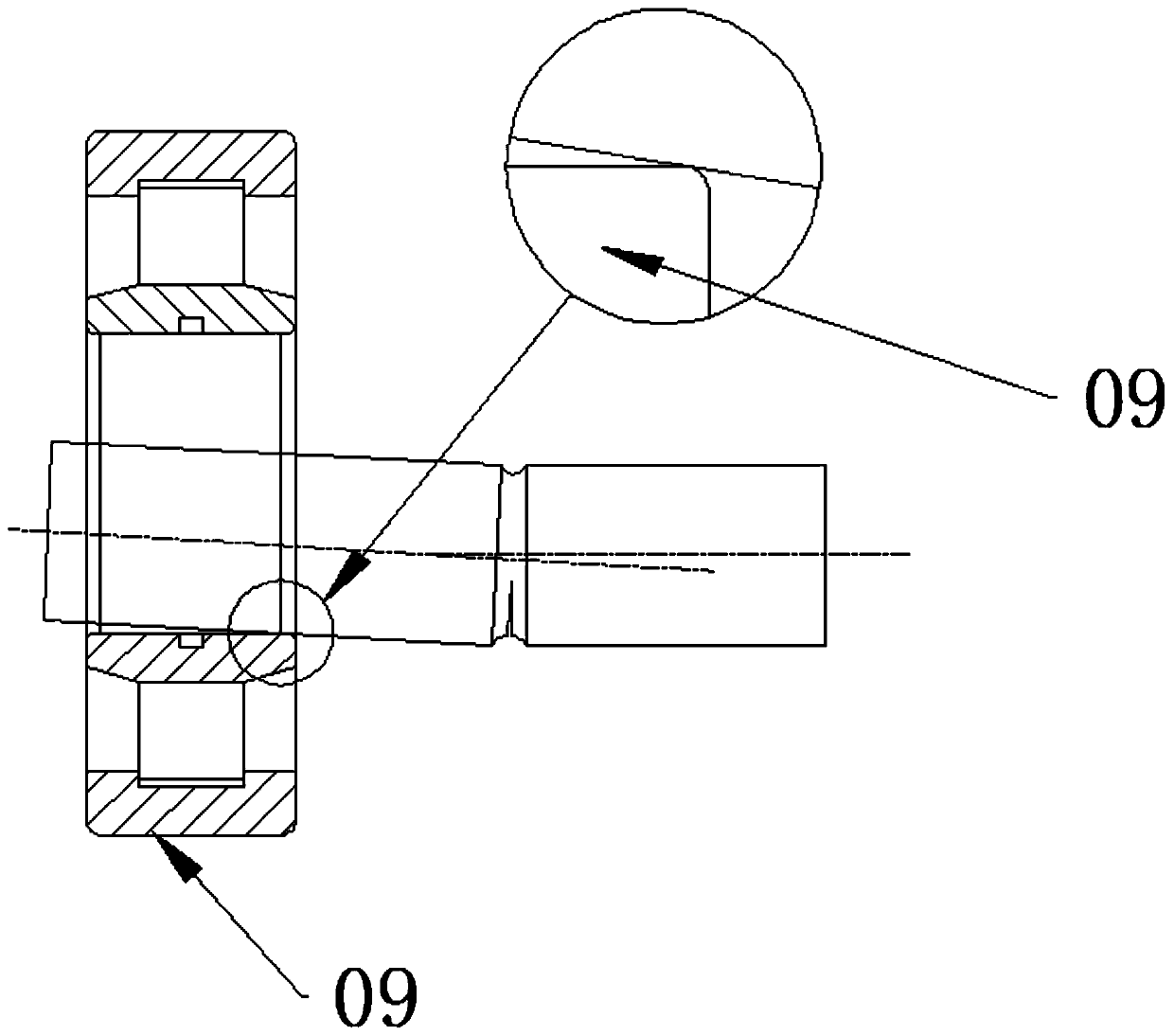

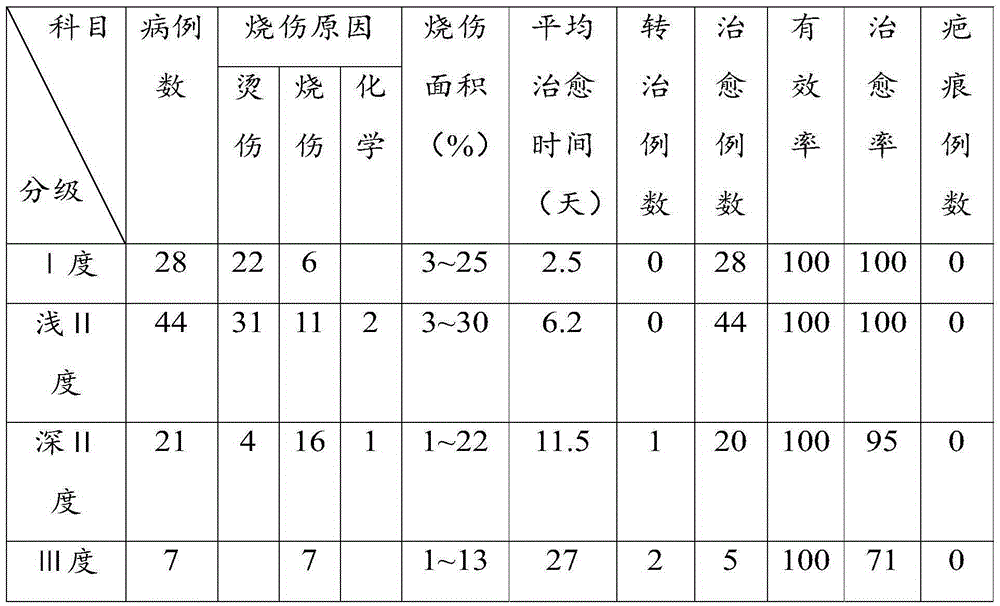

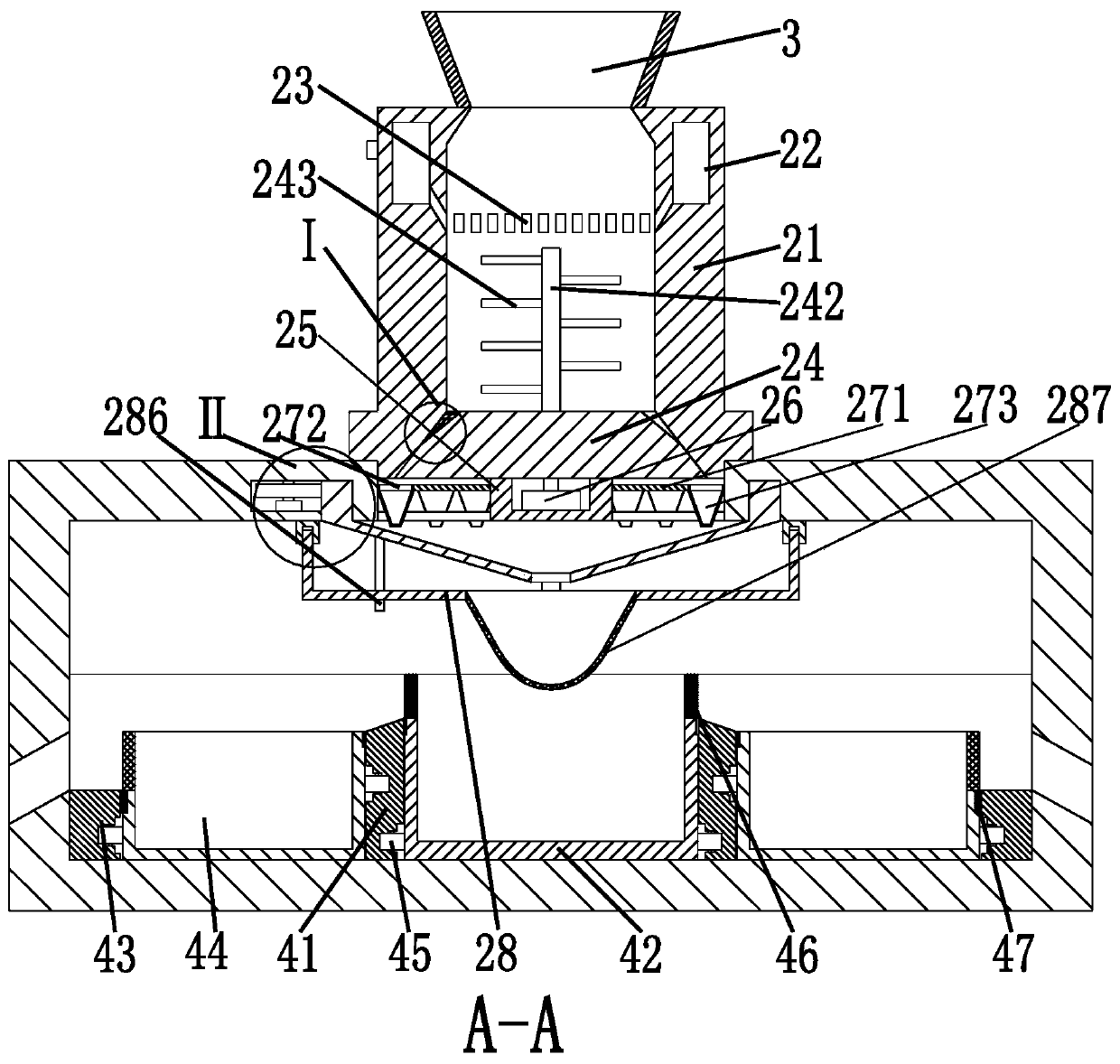

Blanking die for low-stress blanking machine

InactiveCN110014073AReduce contact stressRealize the shock absorption effectNon-rotating vibration suppressionEngineeringMechanical engineering

The invention discloses a blanking die for a low-stress blanking machine, and belongs to the technical field of intelligent manufacturing. An upper sliding block and a lower sliding block are splicedto form a hammer head containing cavity. An inner hammer head is arranged in the hammer head containing cavity. A bearing is fixed in an outer end inner cavity of the inner hammer head. The outer endof the inner hammer head is supported on an inner wall of the hammer head containing cavity by adopting a spring seat matched with a spring. The inner hammer head can do eccentric motion relative to the center line of the hammer head containing cavity in the hammer head containing cavity, namely, the inner hammer head can swing in the hammer head containing cavity according to needs, so that a rodcan completely make contact with the inner surface of the bearing when the rod is deflected, the friction contact surface between the rod and the bearing becomes large, the contact stress is reduced,and the friction abrasion of the contact surface of the rod is reduced. In addition, the outer end of the inner hammer head is supported on the inner wall of the hammer head containing cavity by adopting the spring seat matched with the spring, so that the damping effect can be realized, rapid centering can be realized during blanking next time, and the blanking process is more stable and reliable.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Feed device with function of dispersing feed for aquaculture

InactiveCN111066707ARealize periodic automatic throwingNo human intervention requiredShaking/oscillating/vibrating mixersTransportation and packagingAnimal scienceGear wheel

The invention relates to the technical field of aquaculture feed equipment and particularly relates to a feed device with a function of dispersing feed for aquaculture. According to the feed device, athrowing component based on the lever principle is adopted and matched with work of a blanking component; a first rack is driven through a half-gear, so that the rack I is moved upward with a connecting rod III; a rotating rod is deflected counterclockwise, at the moment, a stay cord I is gradually strained due to a tether I, a blocking ball is driven to move upward at a certain distance, a conical cylinder is opened, and feed falls into a filling box from a conical pipe; then, the half-gear is separated from the rack I, the rack I is used for driving the connecting rod III to move downward under the effect of a spring I, the rotating rod is inverted clockwise, the feed in the filling box is thrown out, and the connecting rod III is used for loosening the stay cord I, so that the conicalcylinder is blocked once again by the blocking ball and stops blanking; and along with constant rotation of the half-gear, the rack I and the half-gear repeat the above process, so that cyclic automatic dispersing of feed can be realized, manual intervention is not needed, and the feed device is simple and convenient.

Owner:安徽陆明科技有限公司

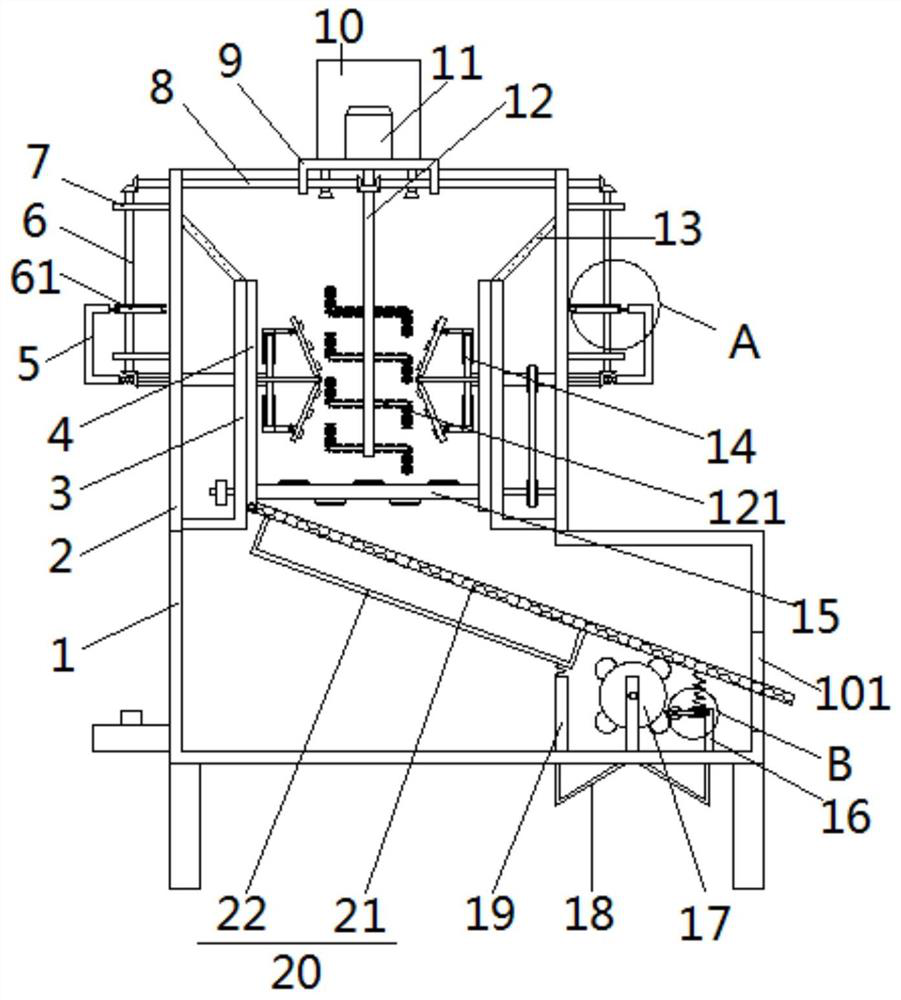

Efficient crushing device for producing coating

The invention relates to the technical field of liquid coating preparation devices, in particular to an efficient crushing device for producing coating. A single servo motor is adopted, and is adjusted to rotate in the positive and negative directions, gears rotate to drive a first rotating shaft to rotate, a worm rotates along with the first rotating shaft, and drives a worm gear to rotate, a coaxial driven gear is rotated along with the worm gear, a crushing box is rolled to and fro by a spring rod and a crushing roller to complete the crushing of coating raw materials, and the crushed raw materials are discharged to the bottom of a housing from discharging holes. The efficient crushing driving adopts driving design, and is convenient to control, and by means of the driving force of theservo motor, a crushing assembly is driven by a driving assembly to crush the raw materials, drive a gear assembly to shake together with the crushing box, and drive a vibrating assembly to vibrate the crushing box, so that the coating raw materials are quickly and efficiently crushed; and a guide hopper at the lower part of the efficient crushing device facilitates the diversion and the collection of the crushed coating.

Owner:阜阳市金亮涂料有限公司

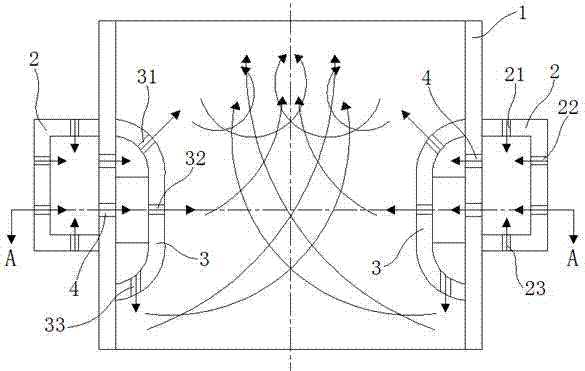

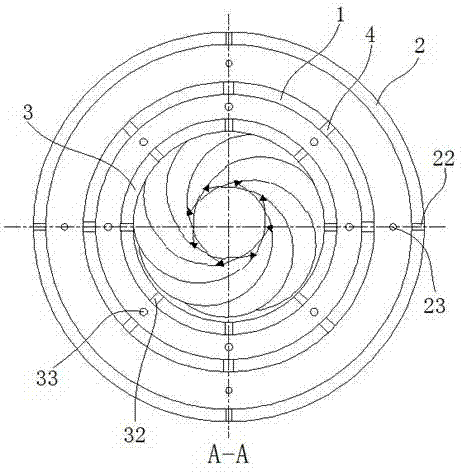

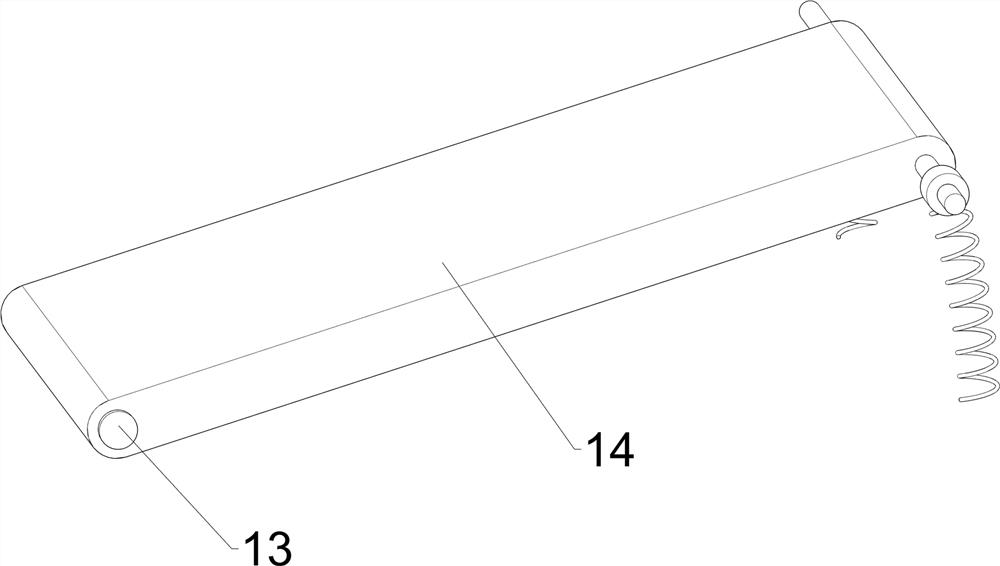

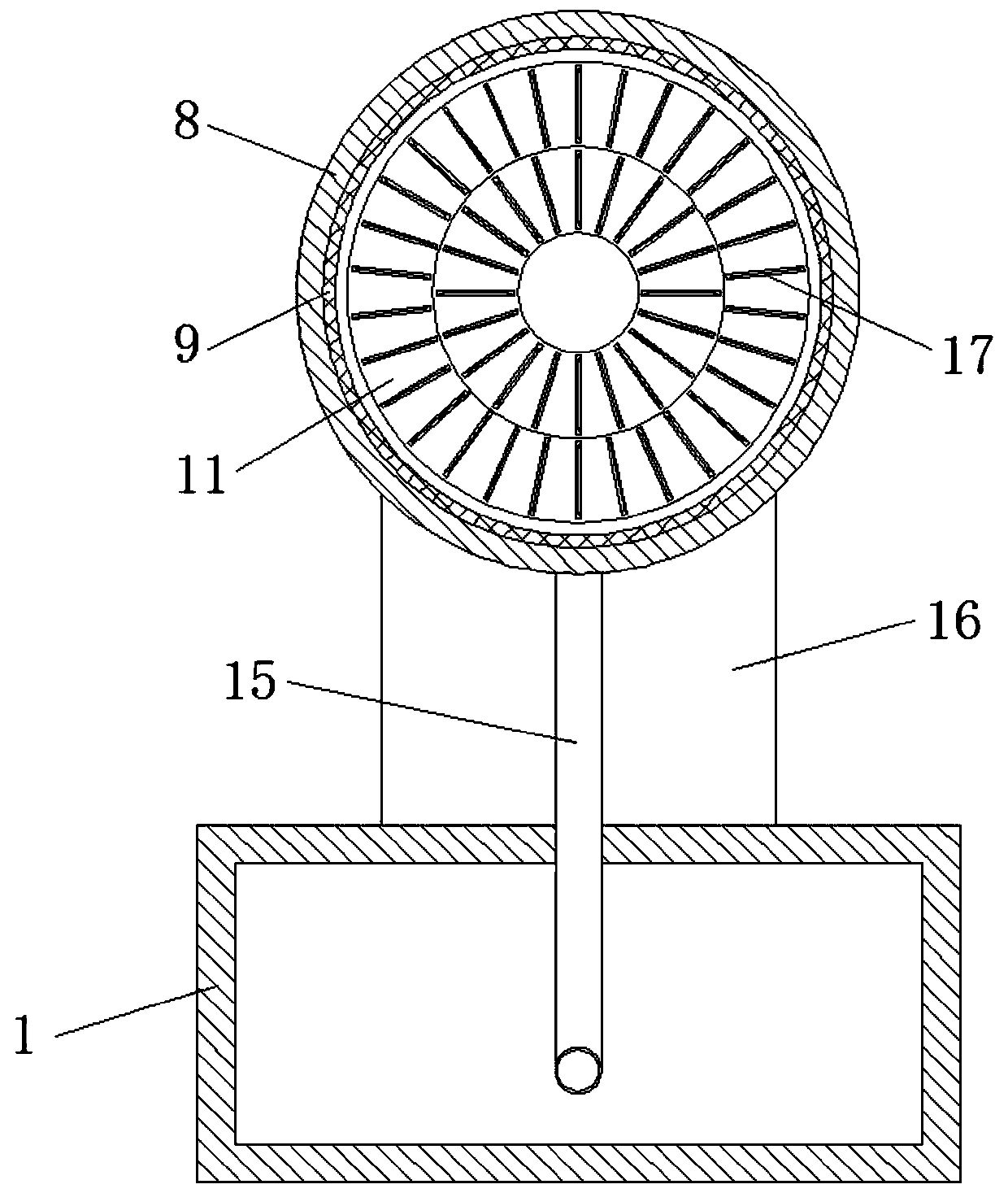

Swirl type cooling system of sleeve limekiln

The invention discloses a swirl type cooling system of a sleeve limekiln and belongs to the technical field of the limekiln equipment. The swirl type cooling system of the sleeve limekiln comprises a kiln body cooling section, an outer air bellow and an inner air bellow, wherein the outer air bellow and the inner air bellow are communicated with each other through air via holes formed on the sidewalls of the kiln body cooling section; the air via holes are annularly distributed along the sidewalls of the kiln body cooling section and the center lines thereof intersect at the center of the kiln body cooling section; the outer air bellow and the outer sidewall of the kiln body cooling section form an annular outer air bellow channel; annularly distributed upper air inlet, side air inlet and lower air inlet are formed on the outer air bellow; the inner air bellow and the inner sidewall of the kiln body cooling section form an annular inner air bellow channel; and annularly distributed upper air outlet, a side air outlet and a lower air outlet are formed on the inner air bellow. The swirl type cooling system enables cooling air to be formed into swirl in the kiln body, thereby enhancing the cooling effect of the cooling air, guaranteeing even distribution of the cooling air in the kiln body, eliminating the air flow deviation phenomenon and improving the quality of the lime product; as a result, the swirl type cooling system is obvious in energy saving and consumption reduction effects.

Owner:TAIZHOU HONGWEI IND FURNACE EQUIP CO LTD

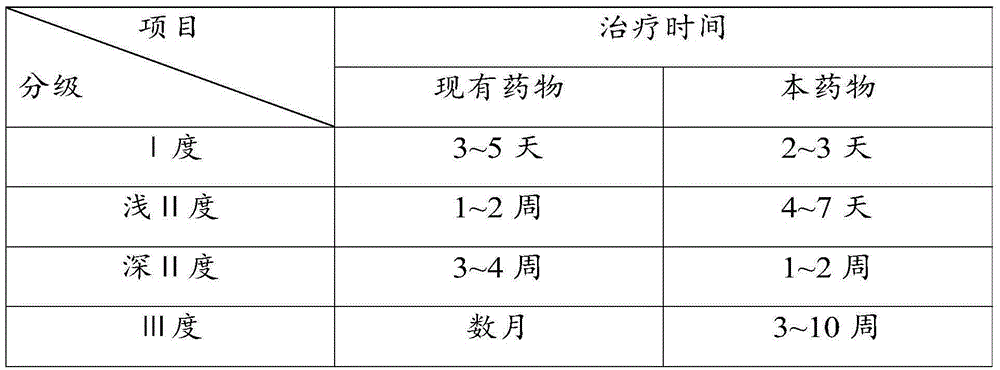

Medicine used for treating burns, scalds and bedsore and preparation method thereof

InactiveCN105381101AInhibit bacterial growthReduce secondary damageHydroxy compound active ingredientsTetracycline active ingredientsScarsBacteria

The invention provides a medicine used for treating burns, scalds and bedsore, which belongs to the technical field of drugs. The medicine used for treating burns, scalds and bedsore is mainly prepared from the following raw materials through pulverizing: in terms of weight parts, 5 to 60 parts of tetracycline antibiotic, 5 to 15 parts of charcoal, 5 to 15 parts of borneol, 5 to 15 parts of alum, 3 to 7 parts of musk and 10 to 30 parts of vitamin B2, wherein the charcoal is originated from a grape vine. The medicine used for treating burns, scalds and bedsore can effectively inhibit propagation of bacteria, has good drug effect, prevents generation of scars after curing and shows good practicality.

Owner:张东 +1

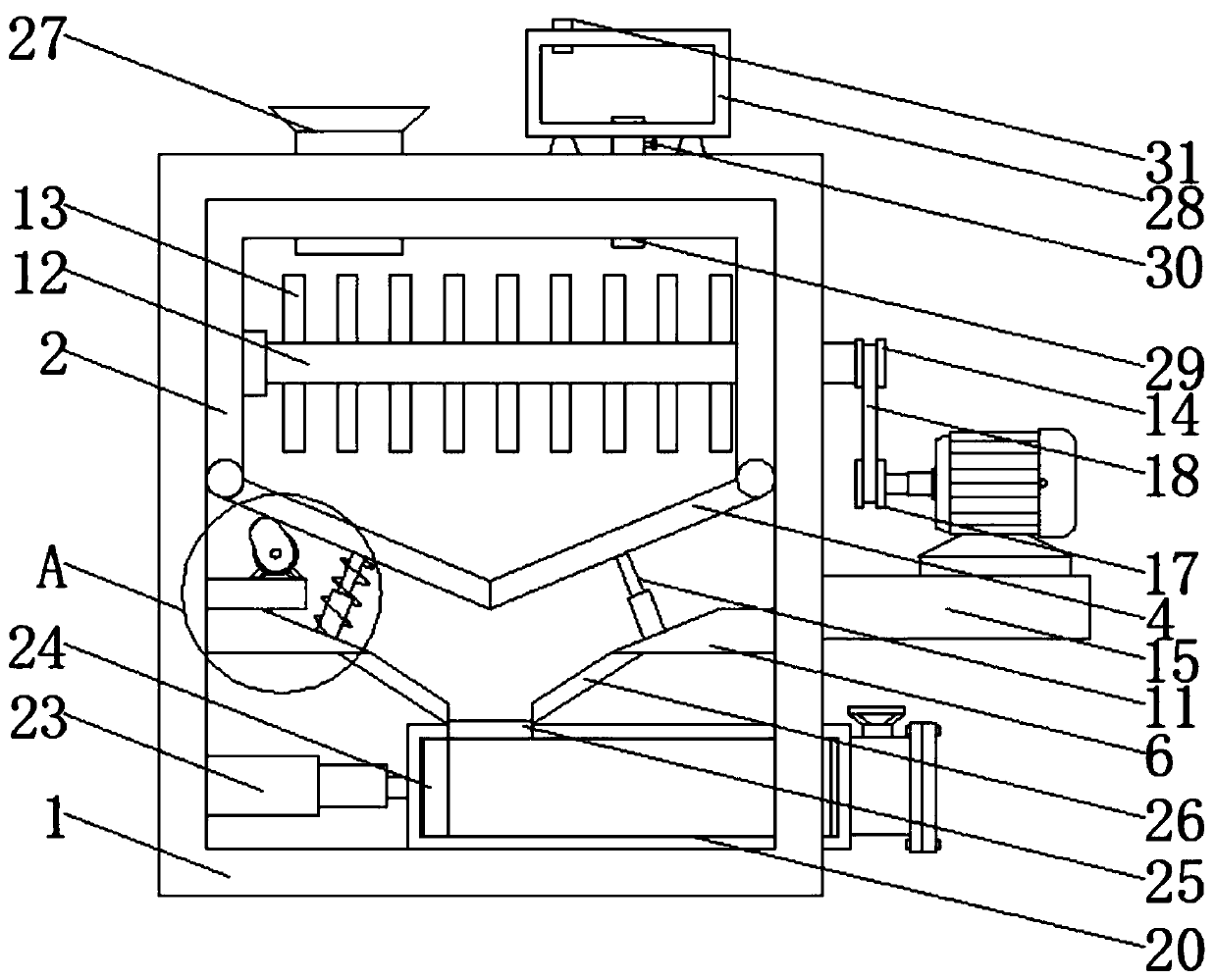

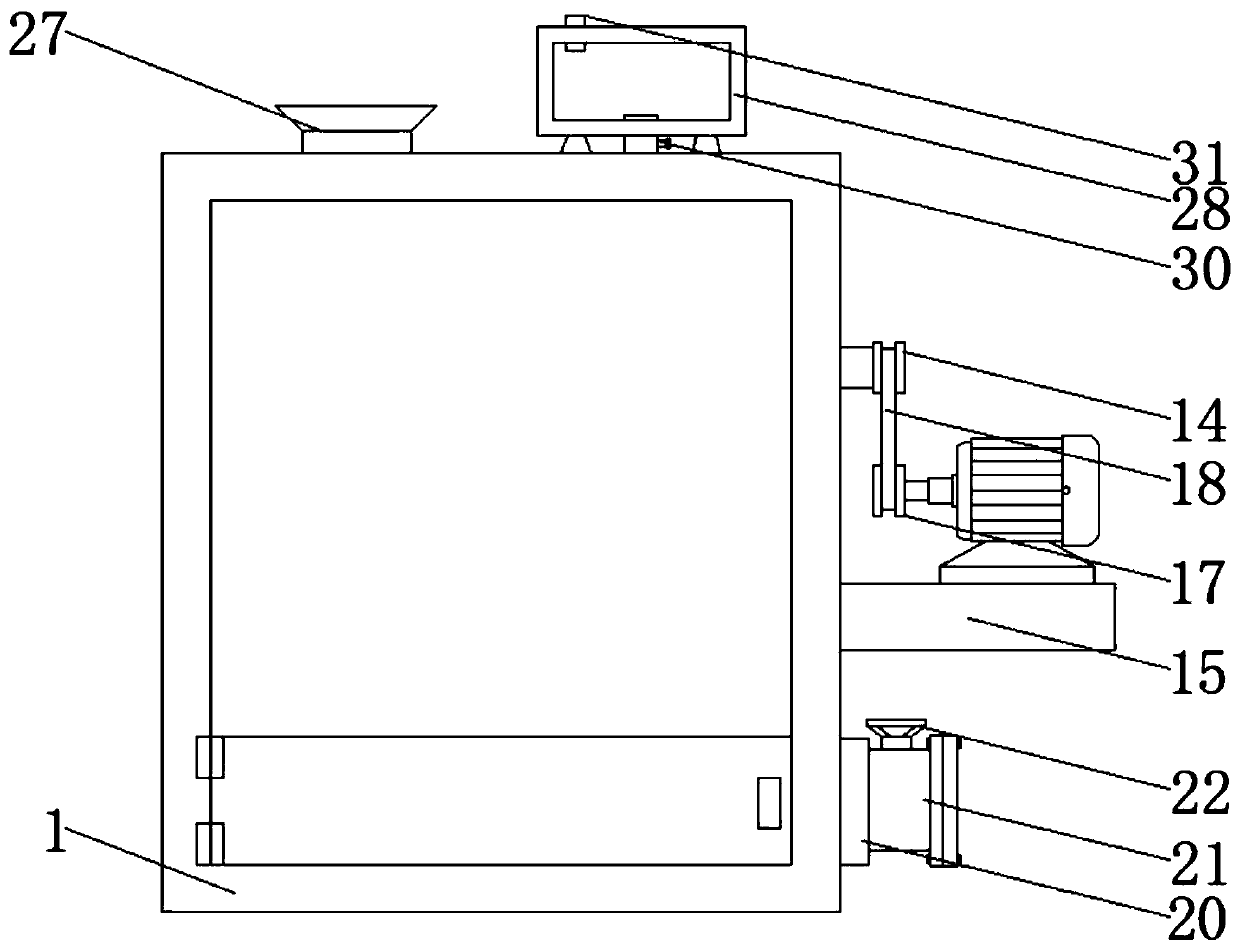

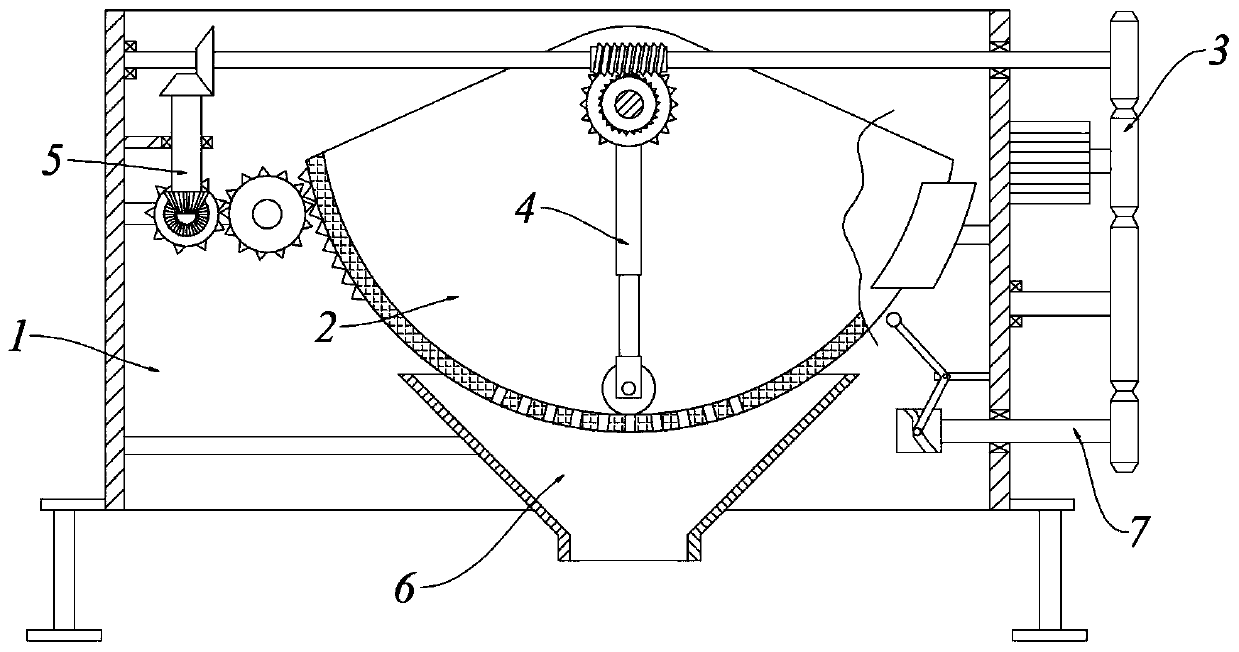

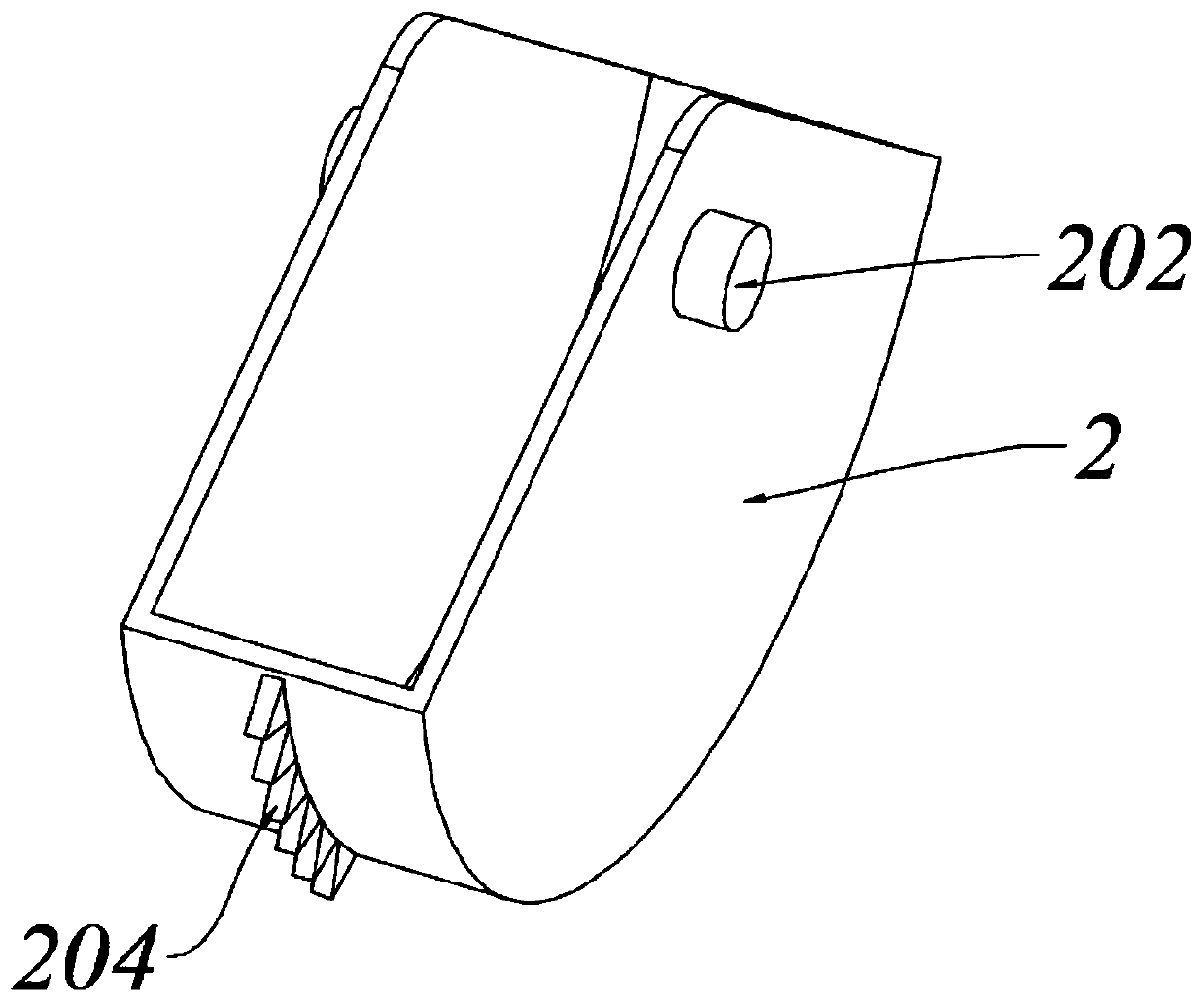

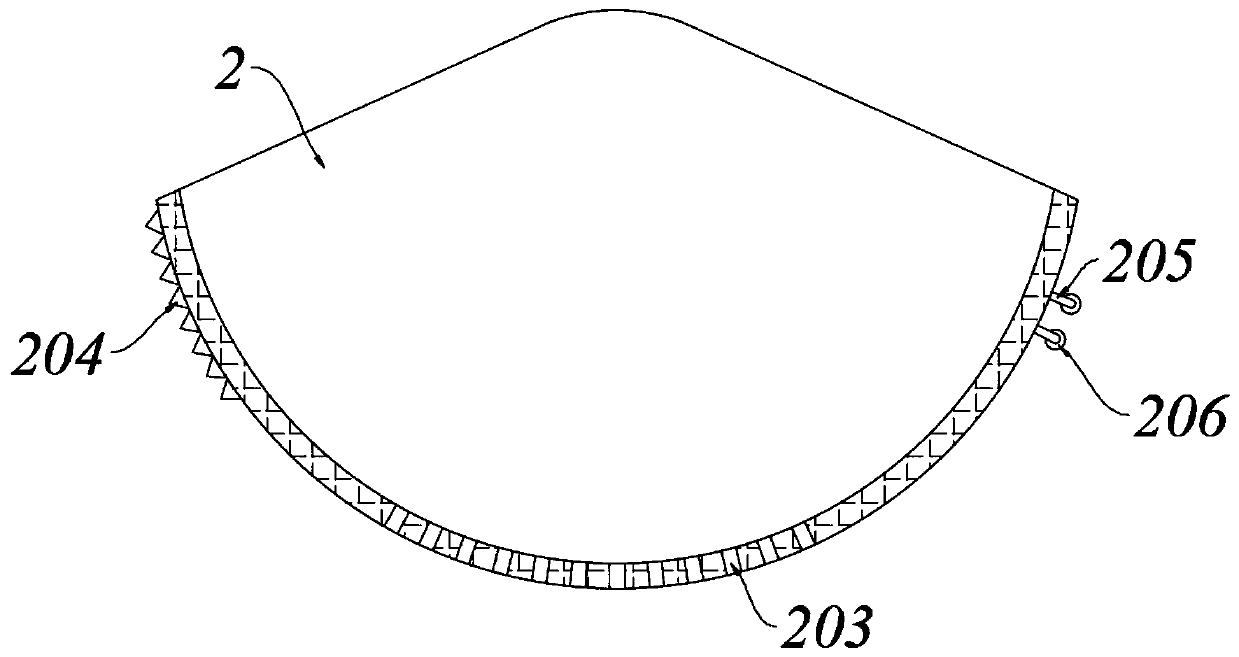

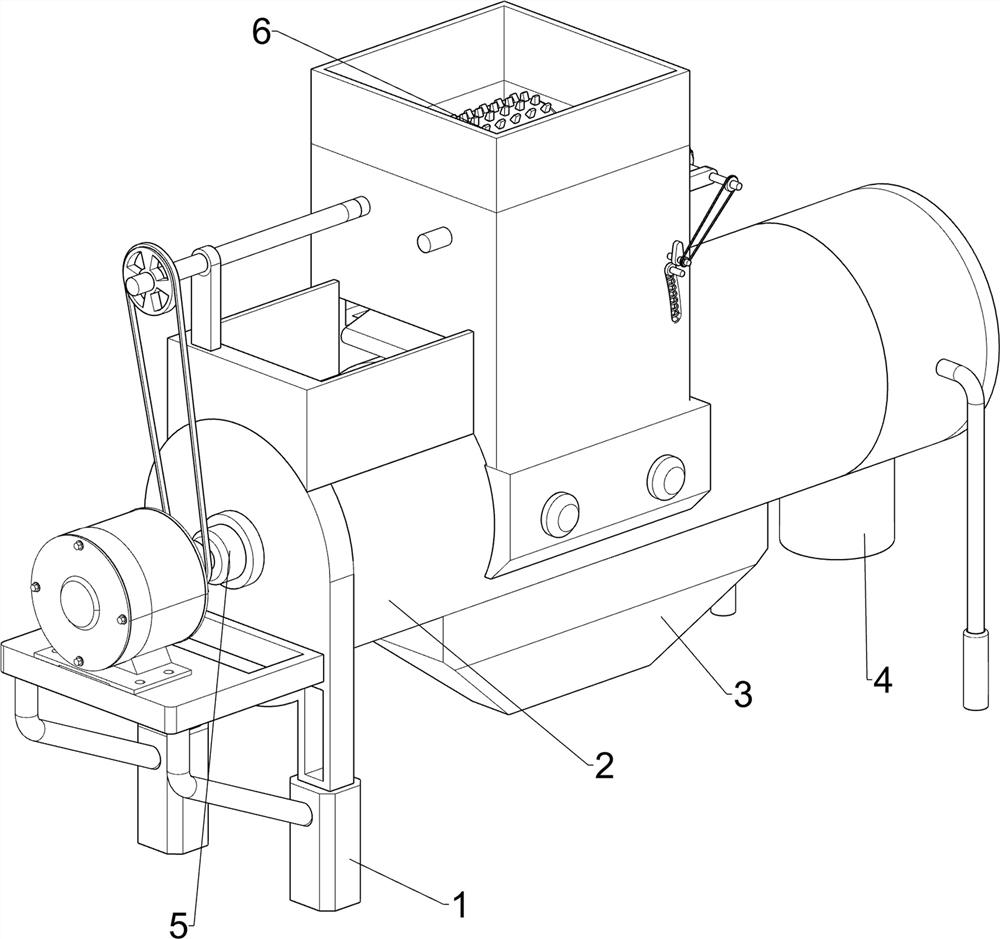

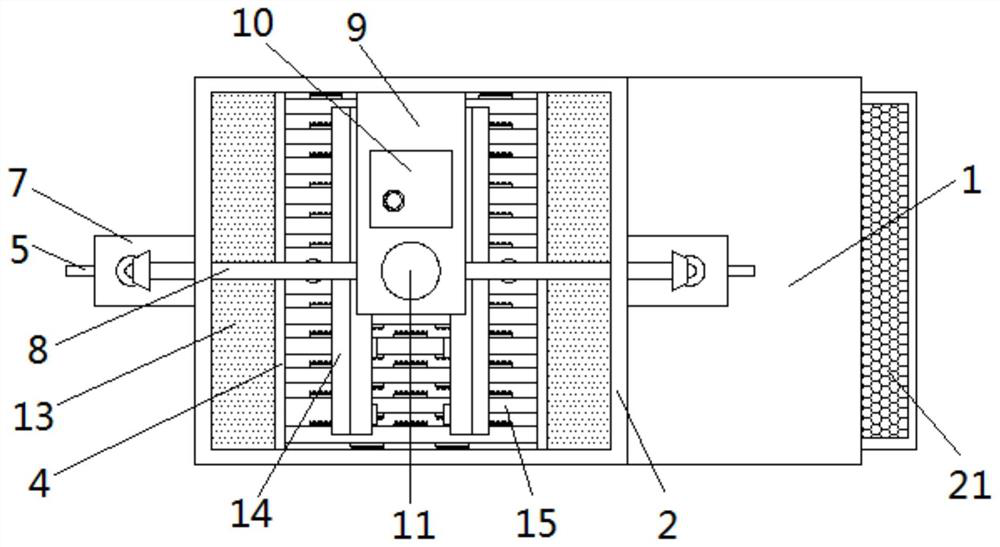

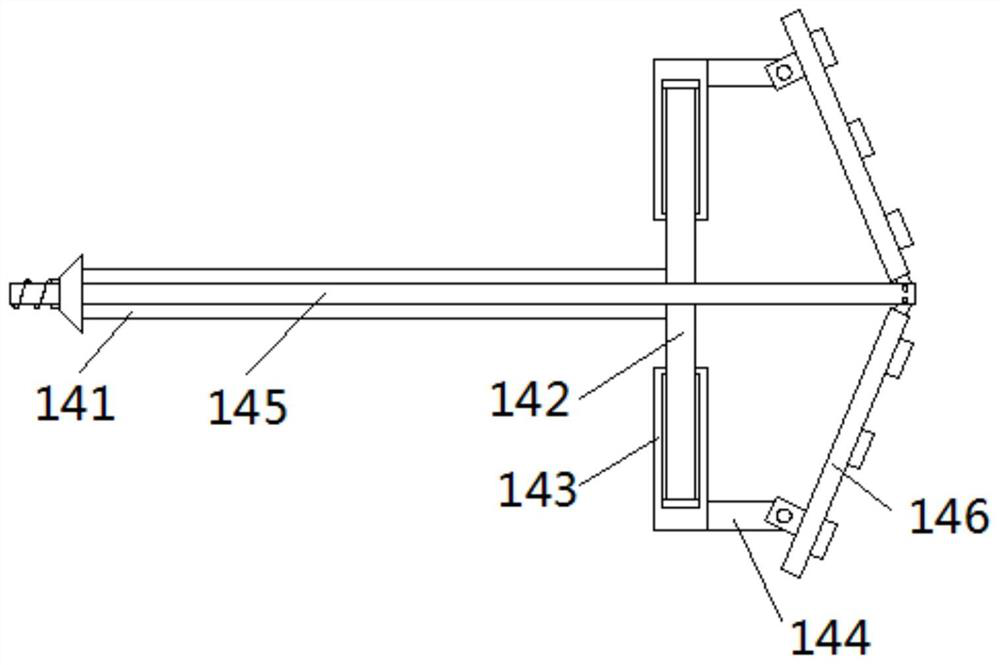

Cable crushing copper-plastic separation device

ActiveCN112271041AImprove separation efficiencyCutting fastBasic electric elementsElectronic waste recyclingStructural engineeringFan blade

The invention relates to a separation device, in particular to a cable crushing copper-plastic separation device. The invention provides a cable breaking copper-plastic separation device which changesa conventional stripping treatment method, realizes efficient separation treatment and can ensure safe operation of workers. The cable breaking copper-plastic separation device comprises a first bearing seat, wherein the upper side of the first bearing seat is provided with a cylinder; a discharging box which is arranged on the lower side of the middle of the cylinder; a discharging pipe which isarranged on the lower side of the side, away from the first bearing seat, of the cylinder; a separation mechanism which is arranged on the first bearing seat; and a crushing mechanism which is arranged on the cylinder. A worker puts a cable needing to be crushed and subjected to copper-plastic separation into the discharging box, the servo motor is started, then the fan blades are driven to rotate around the first rotating shaft to form flowing airflow, meanwhile, the two rollers are driven to oppositely rotate to crush the cable, and the crushed cable is separated in high-speed airflow in the cylinder.

Owner:安徽省金鸿电线电缆有限公司

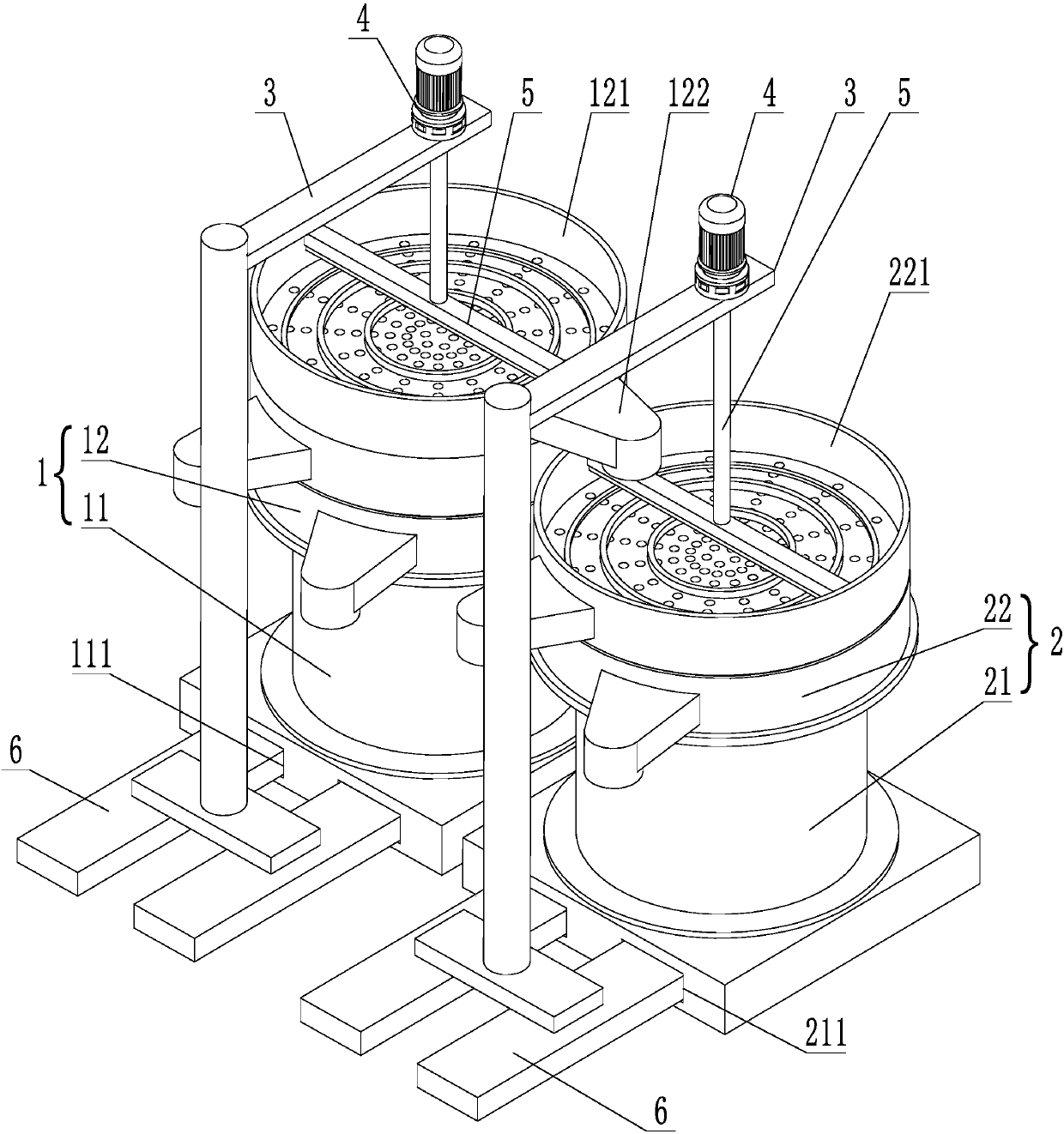

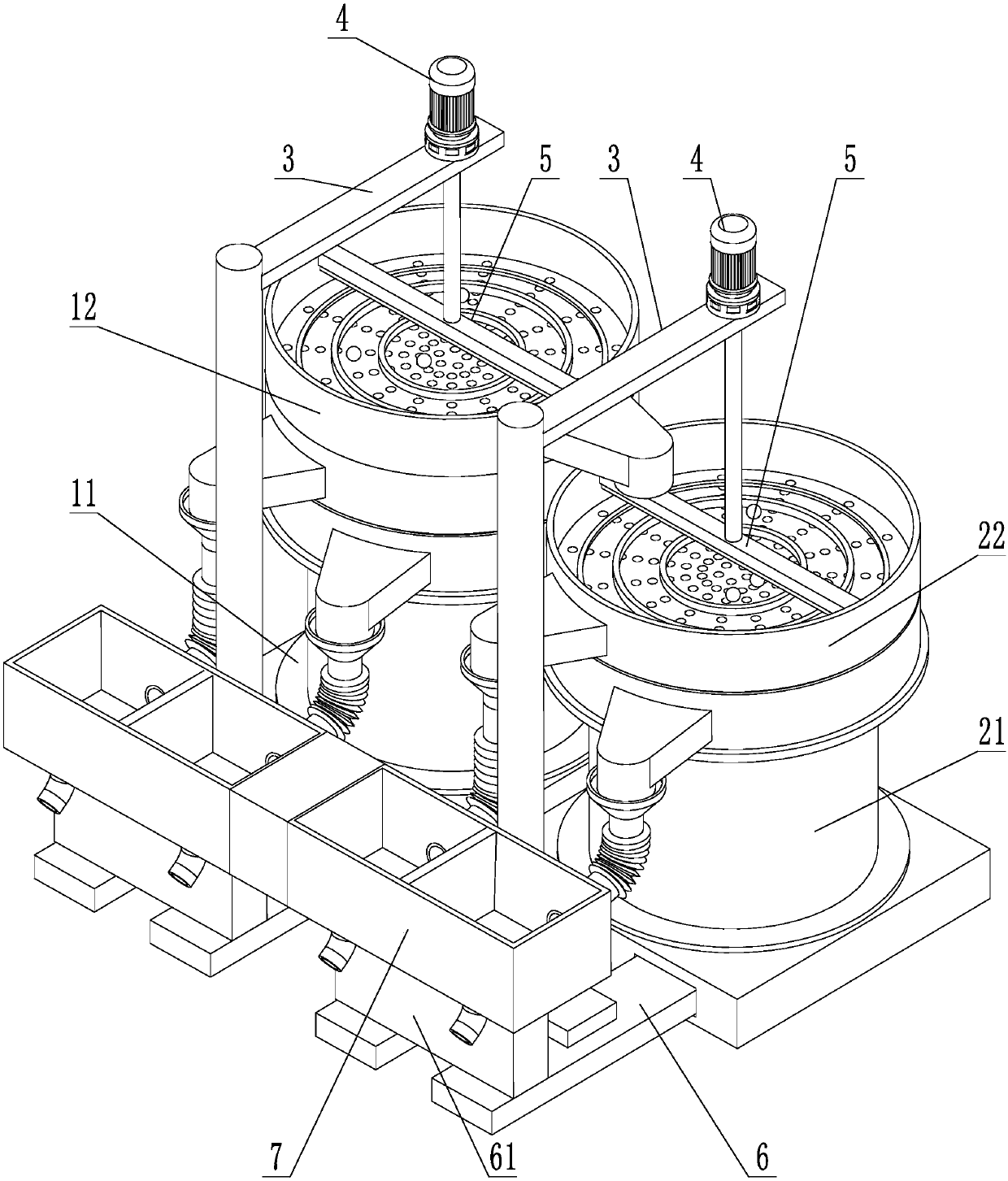

Stirring type sieving screen

InactiveCN107737726AImprove screening effectMeet screening requirementsSievingGas current separationElectric machineryEngineering

The invention relates to a stirring type sieving screen. The sieving screen comprises a first screen body and a second screen body, wherein the first screen body and the second screen body are arranged side by side and can be polarized; the first screen body comprises a first base and a first screen disc which is arranged on the first base and is provided with at least three overlapped screens; the second screen body comprises a second base and a second screen disc which is arranged on the second base and is provided with at least two overlapped screens; a discharge port of the first upper-layer screen of the first screen disc communicates with the second upper-layer screen of the second screen disc; a feeding device is arranged on the first upper-layer screen; and mounting racks are arranged above the first screen disc and the second screen disc, stirring motors which are coaxial with the first screen disc and the second screen disc are arranged on the mounting racks, and output shafts of the stirring motors are connected with stirrers which extend into the first upper-layer screen and the second upper-layer screen and are used for stirring seed materials. By means of the stirringmode, the stirring type sieving screen has the advantages that the more seed materials are screened at the same time, the screening speed is high, the effect is good, and the screening efficiency ofthe sieving screen is greatly improved.

Owner:青岛佳成食品有限公司

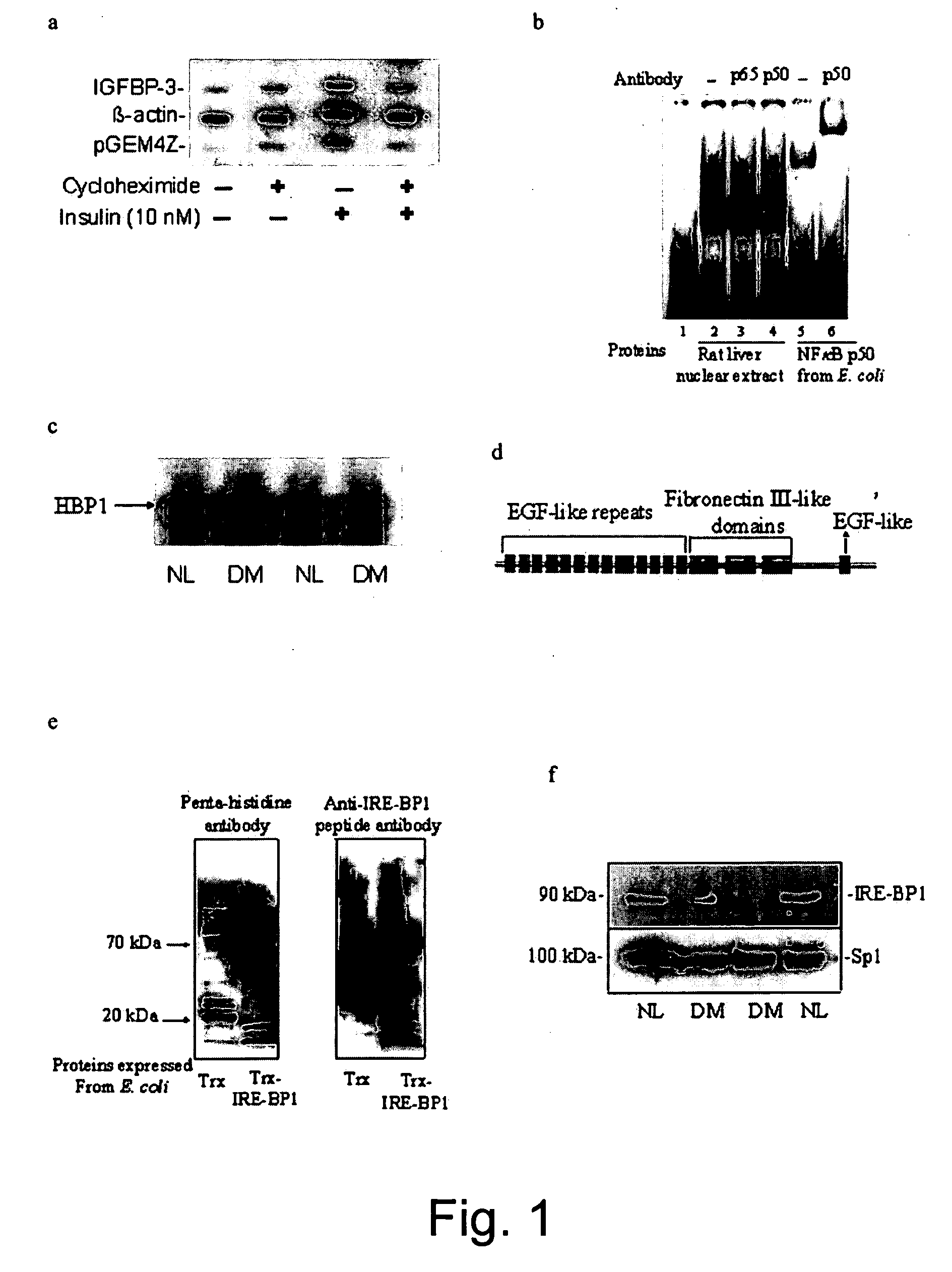

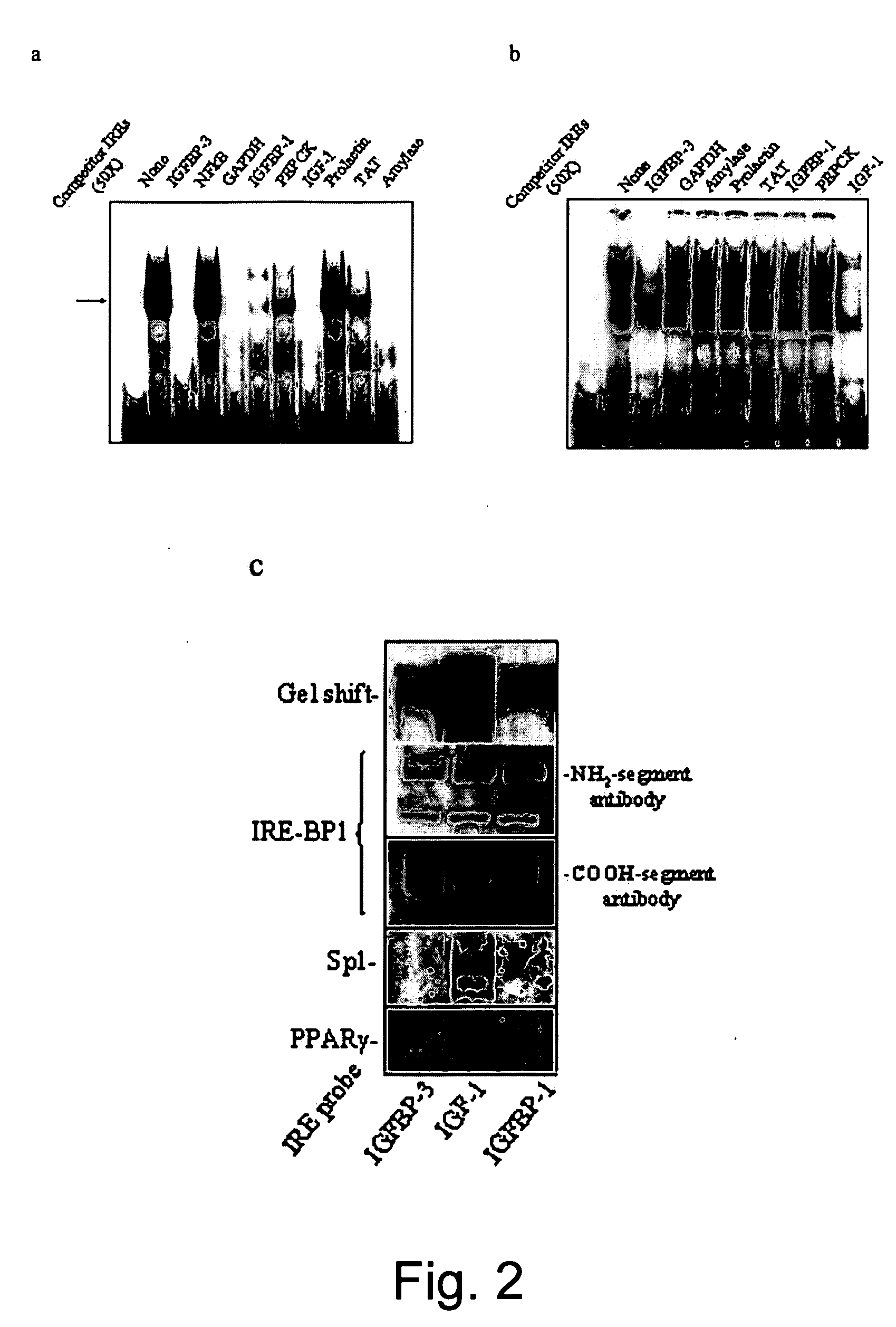

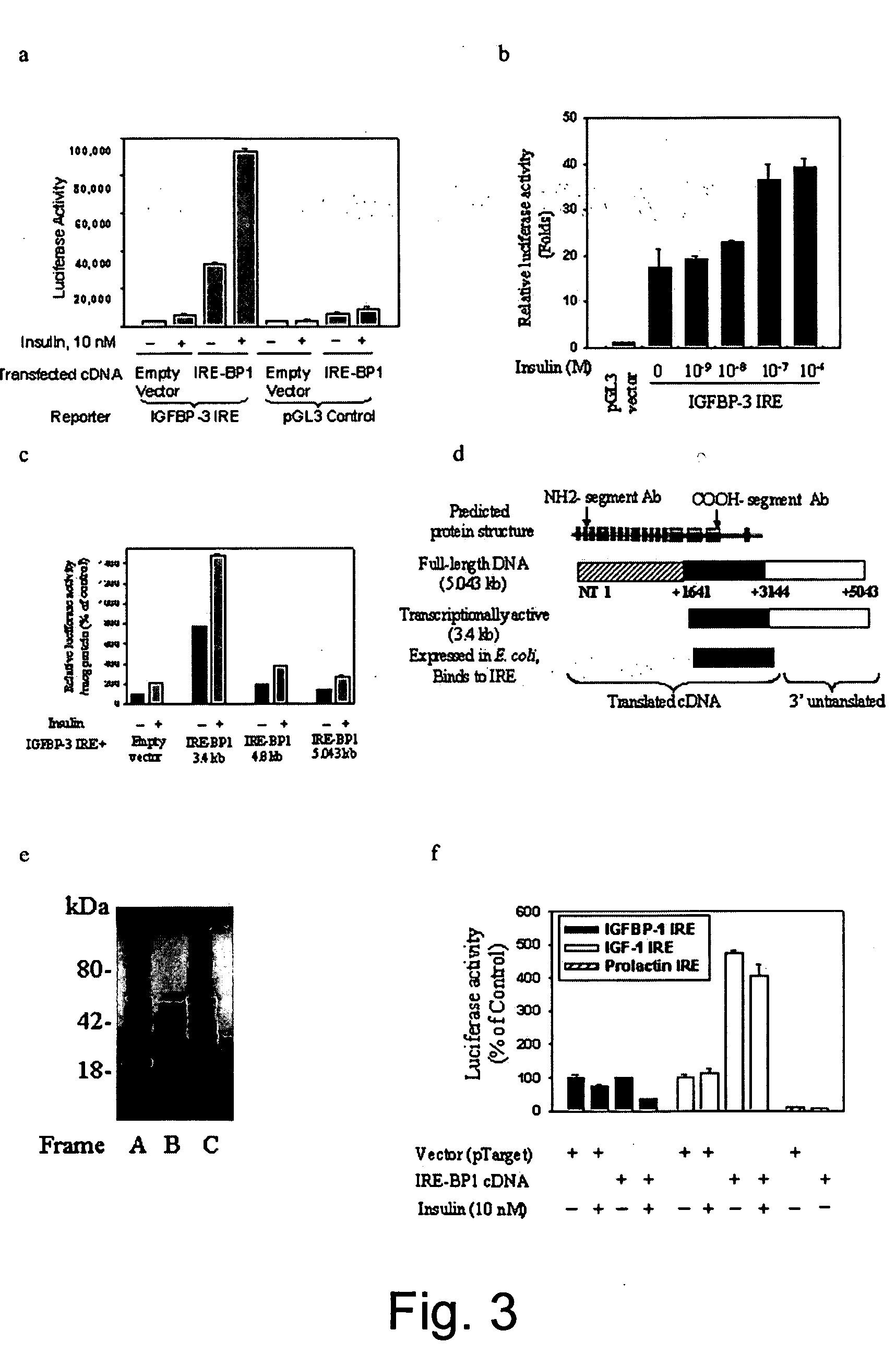

Transcript factor and an Akt substrate related to transcriptional action of insulin and applications of same

InactiveUS20060154864A1Cutting fastLower post-prandial glucose levelPeptide/protein ingredientsMetabolism disorderEGF-like domainC-terminus

A transcription factor capable of activating multiple insulin-responsive genes. In one embodiment, the transcription factor includes an NH2-domain containing thirteen epidermal growth factor (EGF)-like repeats proximate to the N-terminus, a solitary calcium-binding EGF-like domain proximate to the C-terminus, and three consecutive fibronectin type III (fn3) domains between the NH2-domain and the EGF-like domain.

Owner:EMORY UNIVERSITY

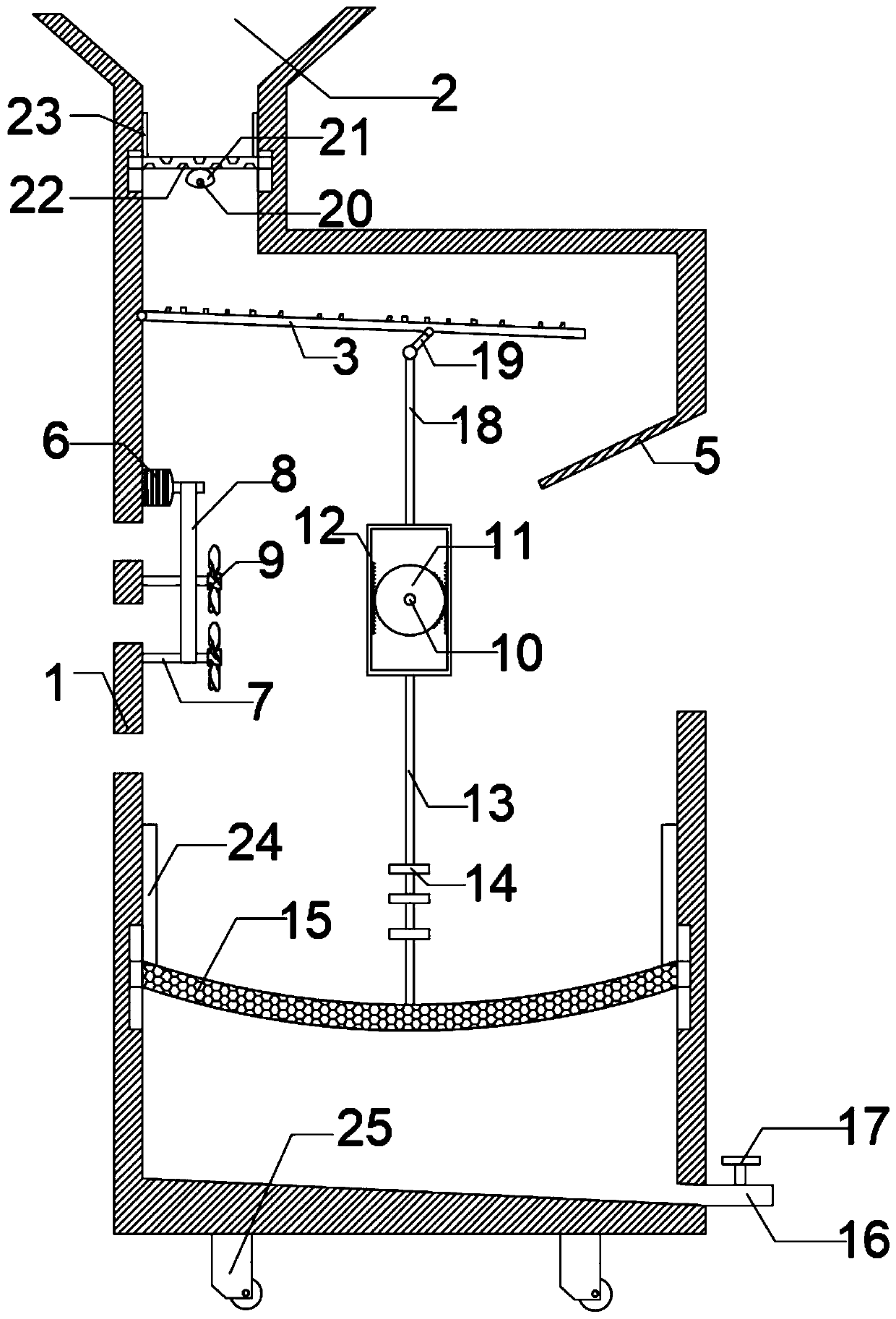

Seed screening device

InactiveCN111299156AUniform feedingCutting fastSievingGas current separationAgricultural scienceHusk

The invention discloses a seed screening device. The seed screening device comprises a device shell, a feeding opening, a liquid discharging opening and a switch valve, wherein the upper end and the lower end of the device shell are provided with the feeding opening used for feeding and the liquid discharging opening used for discharging water respectively, the liquid discharging opening is provided with the switch valve used for controlling opening and closing of the liquid discharging opening, the device further comprises a winnowing mechanism, a movable baffle, a water separation mechanismand a driving mechanism, and the winnowing mechanism comprises a winnowing mechanism body, a limiting baffle and an air blowing mechanism. According to the seed screening device, by arranging the winnowing mechanism and the water separation mechanism, wizened seeds and the like in seeds can be separated out, by arranging the driving mechanism, the separation effect can be further improved, and byarranging a uniform discharging mechanism, the seeds can be uniformly discharged, so that the separation effect can be further improved.

Owner:郑文康

Waste paper recycling device

The invention provides a waste paper recycling device. The waste paper recycling device comprises a supporting box and a connecting box, wherein a discharging opening is formed in the lower end of theright side of the supporting box, the connecting box is fixedly connected to the left side of the top of the supporting box, fixing plates are vertically and fixedly connected to the upper ends and the lower ends of the left side and the right side of the connecting box, first shafts are vertically, horizontally, and rotationally connected between the fixing plates, conical gears are fixedly connected to the upper ends and the lower ends of the first shafts, a partition plate is vertically and fixedly connected to the position, located at the lower end of the lower inclined end of a fixing box, of the bottom of the supporting box, a material distributing attraction device and a metal cleaning device are sequentially and fixedly arranged at the positions, located between the partition plate and the discharging opening, of the bottom inside the supporting box, discharging hoppers arranged opposite to the discharging opening are fixedly connected to the positions, located on the left side and the right side of the lower end of the material distributing attraction device, of the bottom of the supporting box, supporting legs are vertically and fixedly connected to the periphery of thebottom of the supporting box, and a drainage pipe is fixedly arranged at the lower end of the side, away from the discharging opening, of the supporting box. The waste paper recycling device aims to solve the problems of low waste paper recycling efficiency and incomplete crushing in a pulping process in the prior art.

Owner:王自诚

Environment-friendly processing device for waste battery

InactiveCN109524737AReduce rigid wearFast crushingSolid waste disposalWaste accumulators reclaimingChemical reactionElectrical battery

The invention discloses an environment-friendly processing device for a waste battery. The environment-friendly processing device comprises a reaction tank, wherein brackets are welded to two sides ofthe outer wall of the top of the reaction tank, and a conveying tank is welded to the outer walls of the tops of the brackets; a filtering plate is welded to the inner wall of one side of the conveying tank, conveying shaft mounting holes are formed in the outer wall of one side of the filtering plate and the outer wall of one side of the conveying tank, a conveying shaft are connected to the inner walls of the two conveying shaft mounting holes through bearings, and a lantern ring is connected to the outer wall of one side of the conveying shaft through a key; and a driving motor is fixed onthe outer wall of one side of the conveying tank through screws. According to the environment-friendly processing device, the waste battery is heated through heat released through chemical reaction,so that the rigid abrasion of the battery crushed by a slicer and grinding teeth is reduced, the crushing speed of the waste battery is increased, the crushing effect of the waste battery is improved,the unloading is accelerated, the reaction speed is increased, and the abrasion of the filtering plate and rotating scraping pieces is reduced.

Owner:文露

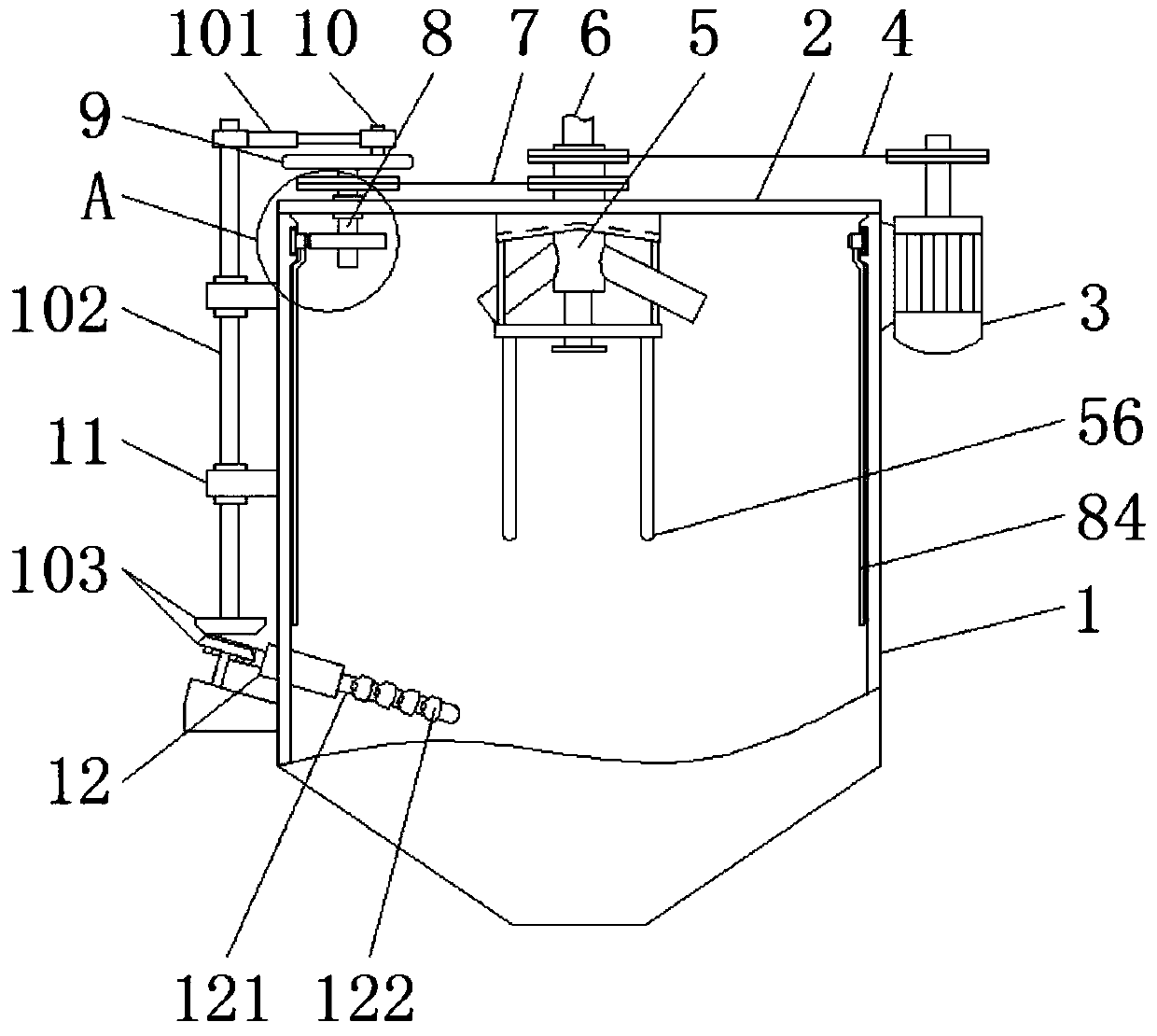

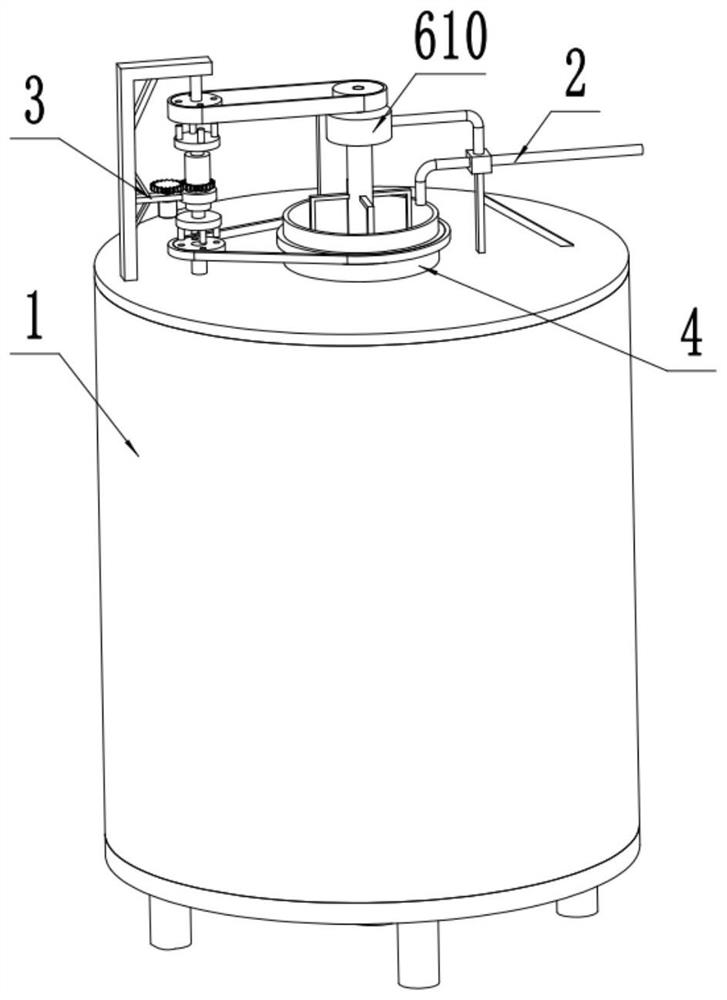

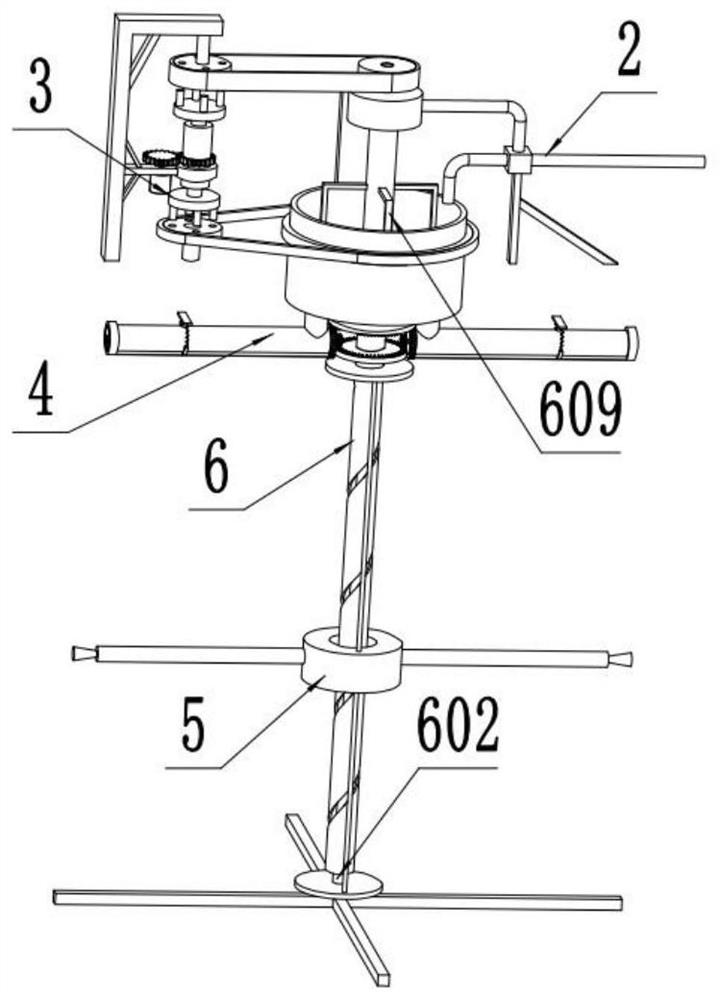

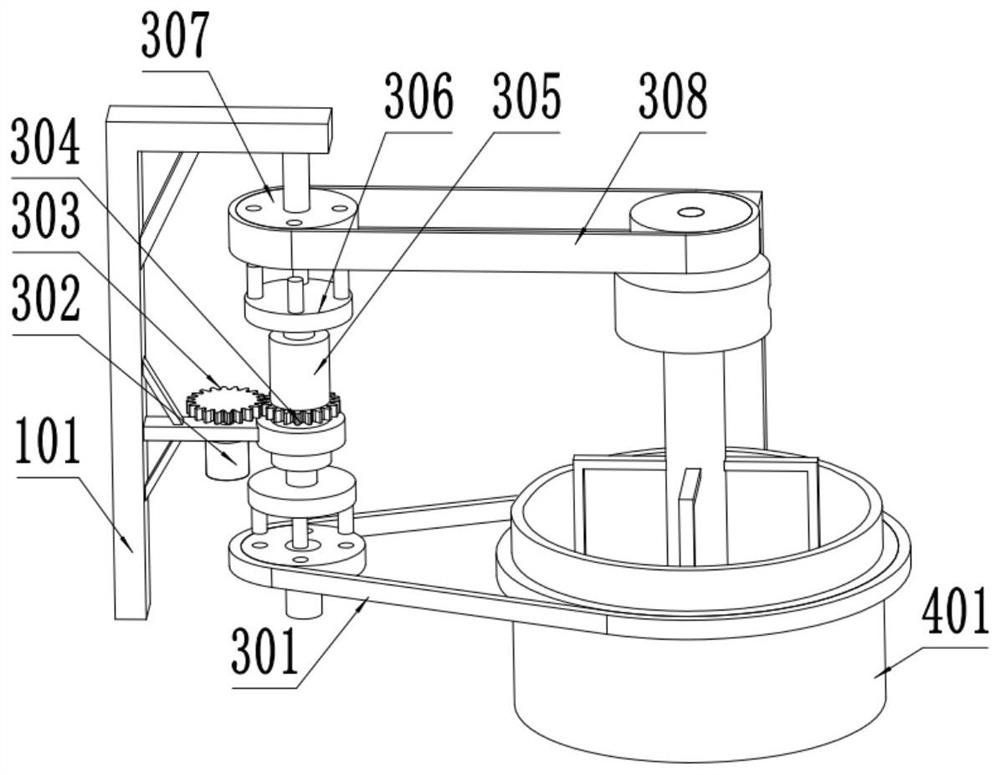

Coating mixing equipment

ActiveCN114870681ACutting fastSpeed up the mixingTransportation and packagingRotary stirring mixersMechanical engineeringWater pipe

The invention discloses coating mixing equipment, and belongs to the technical field of coating production equipment. Comprising a coating barrel, a water pipe, a power mechanism, a discharging mechanism, a stirring mechanism and a guide mechanism, the power mechanism is used for driving the discharging mechanism and the guiding mechanism to rotate. The discharging mechanism comprises a feeding barrel and two discharging pipes, the stirring mechanism is installed on the guiding mechanism and comprises two first stirring rods which are symmetrically arranged, and the first stirring rods are used for cleaning the inner wall of the coating barrel and stirring coating in the coating barrel. The guide mechanism comprises a center pipe, the center pipe is fixedly installed on the coating barrel, a rotating shaft is rotationally installed in the center pipe, the first end of the rotating shaft is connected with the power mechanism, and the second end of the rotating shaft is fixedly connected with the vertical guide rod. The coating is automatically mixed through the power mechanism, the discharging mechanism, the stirring mechanism and the guiding mechanism, the structure is simple, and operation is convenient.

Owner:ZHEJIANG RIDING COATING TECH CO LTD

Briquetting machine for PVC plastic waste treatment

InactiveCN110978333AEasy to operateImprove efficiencyPlastic recyclingLarge containersPlastic wasteMachine

The invention relates to the technical field of PVC plastic waste treatment equipment, in particular to a briquetting machine for PVC plastic waste treatment. A servo motor is adopted for driving a rotary disc to rotate, and a first rod drives a movable block to move left and right along with the rotary disc. On one hand, a third rod drives a sliding sleeve to vertically move along a sliding rod,and therefore a fourth rod drives a convex block to vertically move, the convex block cooperates with a roller, and a movable rod drives a second pressing plate to move left and right under the actionof a first spring; in cooperation with a second movable separation plate and a first movable separation plate, materials falling into a smashing cavity are smashed through smashing teeth when the second pressing plate moves rightwards, and the smashed materials fall into a compressing cavity when the second pressing plate moves leftwards; and on the other hand, a second rod drives a compressing assembly to move left and right, and PVC waste falling into the compressing cavity is compressed. The compressing assembly is convenient to adjust, a first hand wheel drives a first screw rod to rotate, a second sliding block moves along a second sliding rail, and therefore the initial position of the a first pressing plate is adjusted, and the compression section of the first pressing plate is adjusted.

Owner:安徽瞬达信息科技有限公司

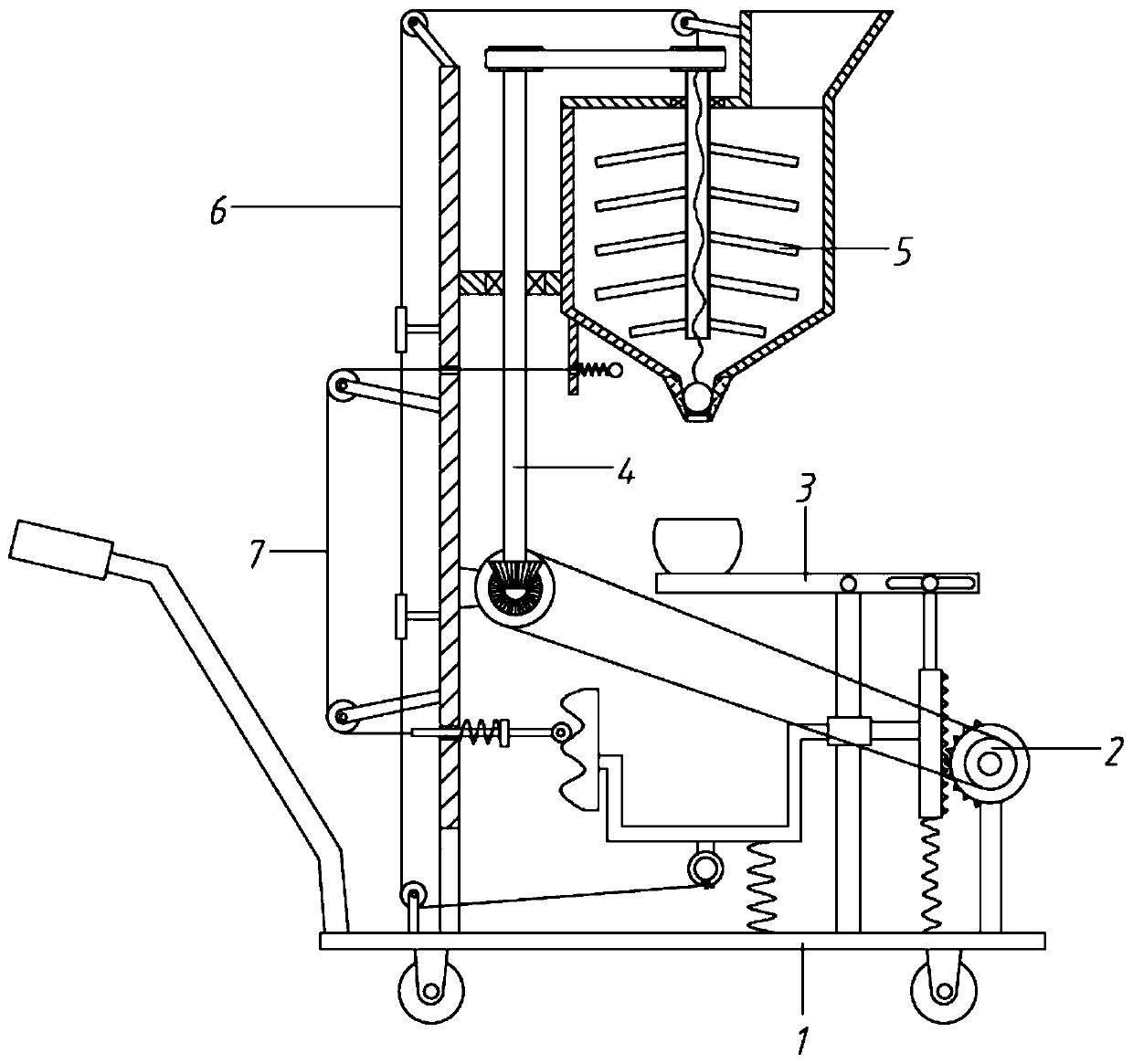

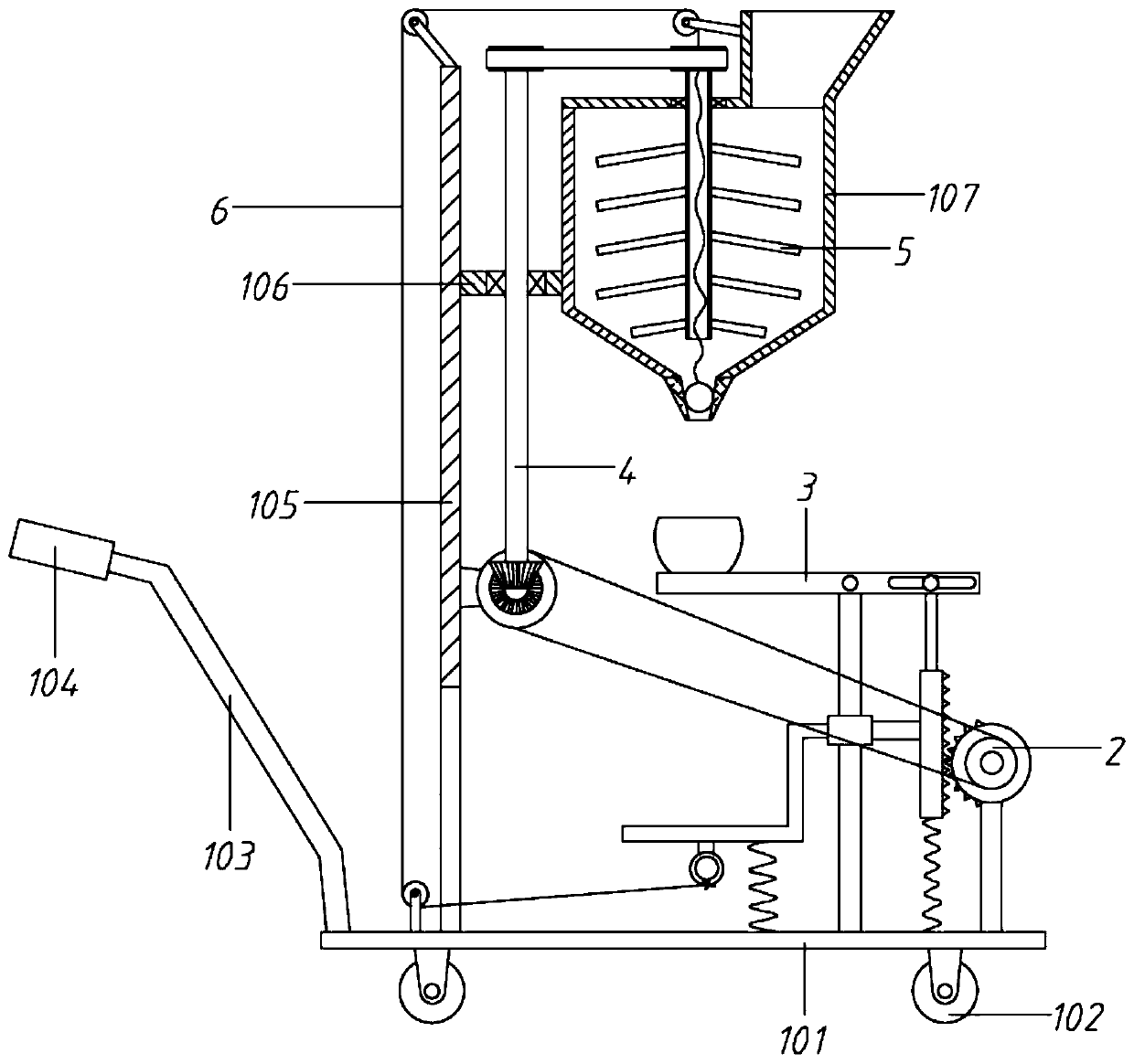

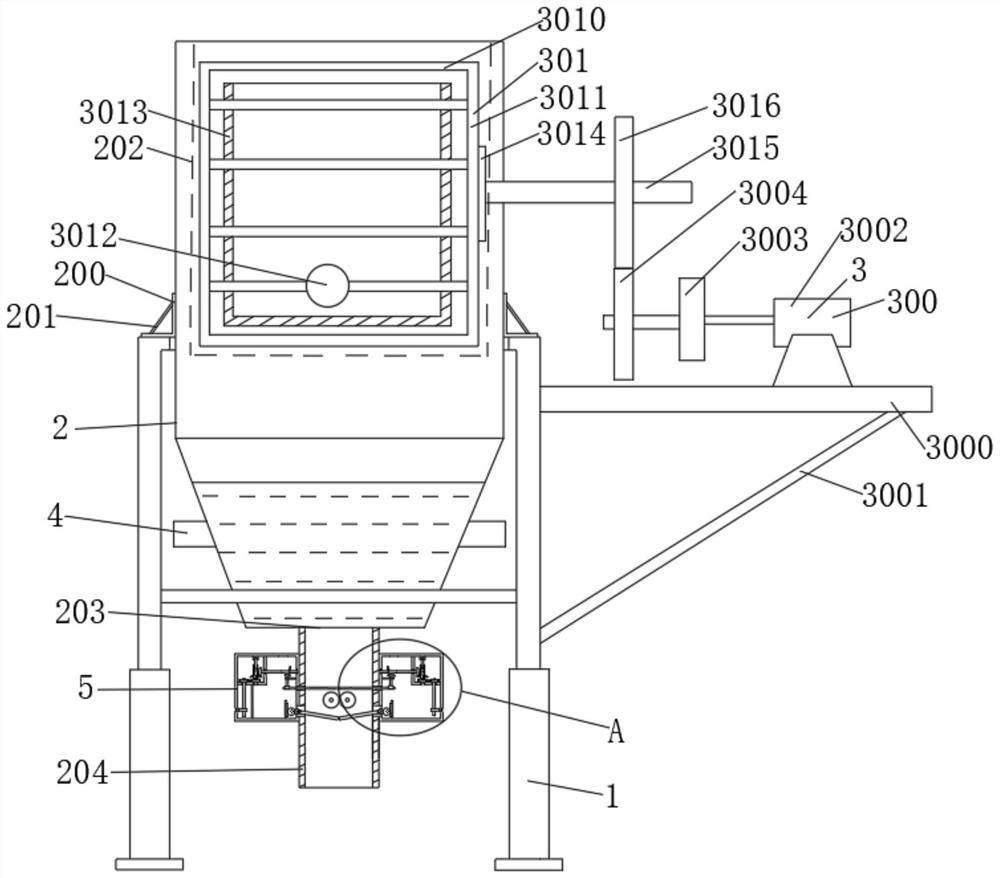

Turnover device for power battery raw material production line

PendingCN114560185ACutting fastAccelerated disengagementFinal product manufactureLarge containersPower batteryDischarge efficiency

The invention provides a turnover device for a power battery raw material production line, which comprises a support, a blanking bin is arranged on the support, a turnover mechanism is arranged in the blanking bin, and an air hammer is arranged on the blanking bin. The battery raw material production line discharging turnover device can solve the technical problem that due to the fact that a discharging bin of an existing battery raw material production line discharging turnover device conducts discharging through the gravity of raw materials, the raw materials are extremely prone to being attached to the inner wall of the discharging bin and do not flow, and the discharging efficiency is affected.

Owner:GUANGZHOU LIZHILI MACHINERY EQUIP CO LTD

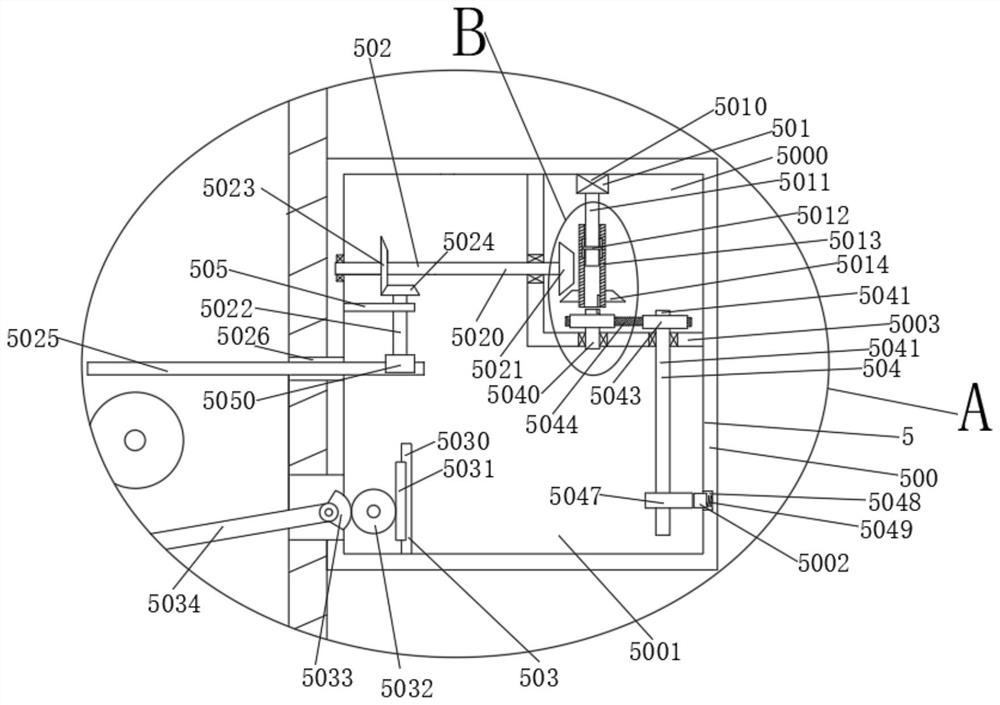

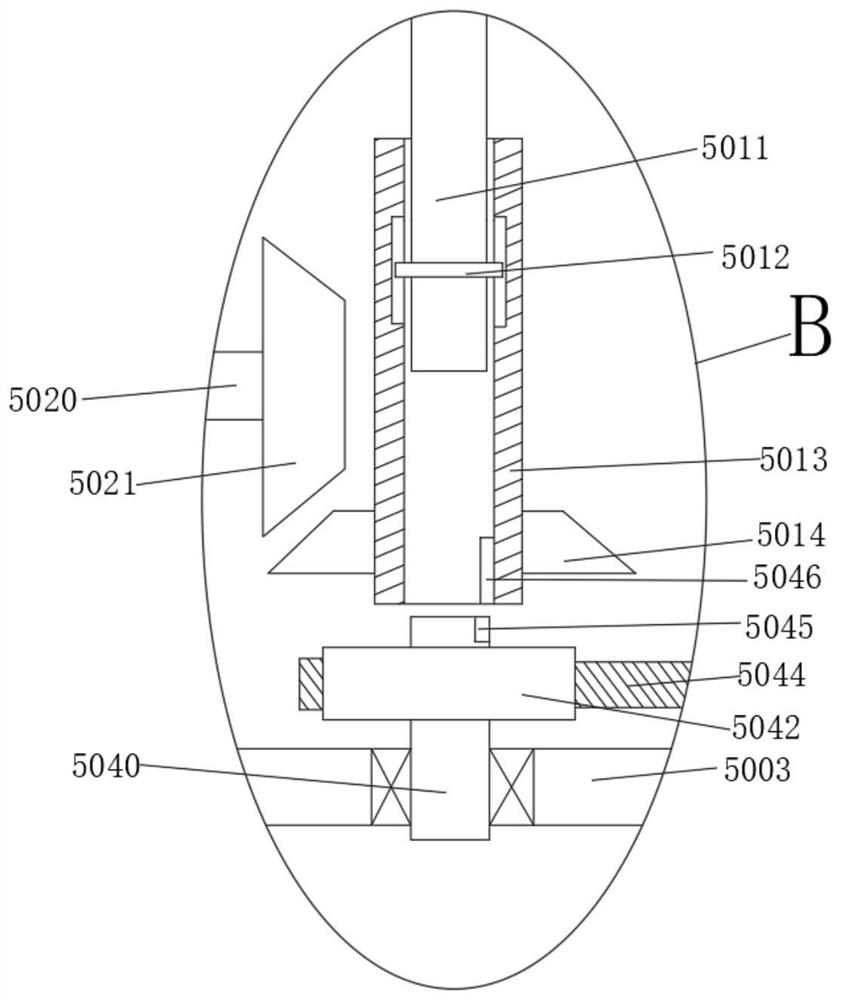

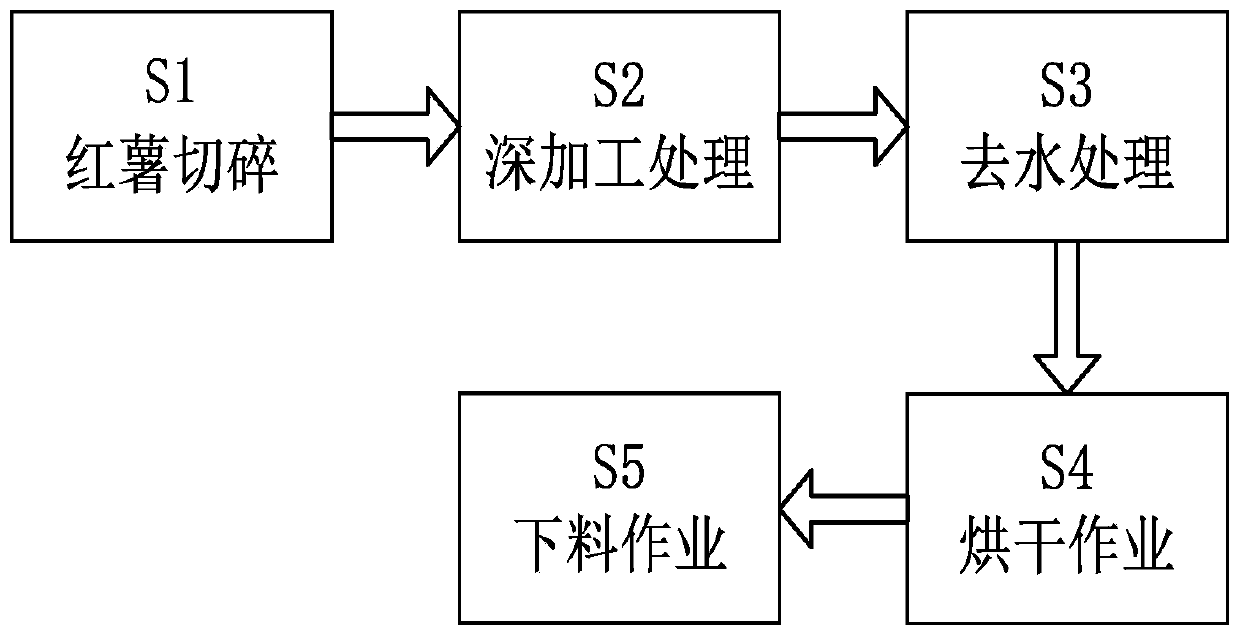

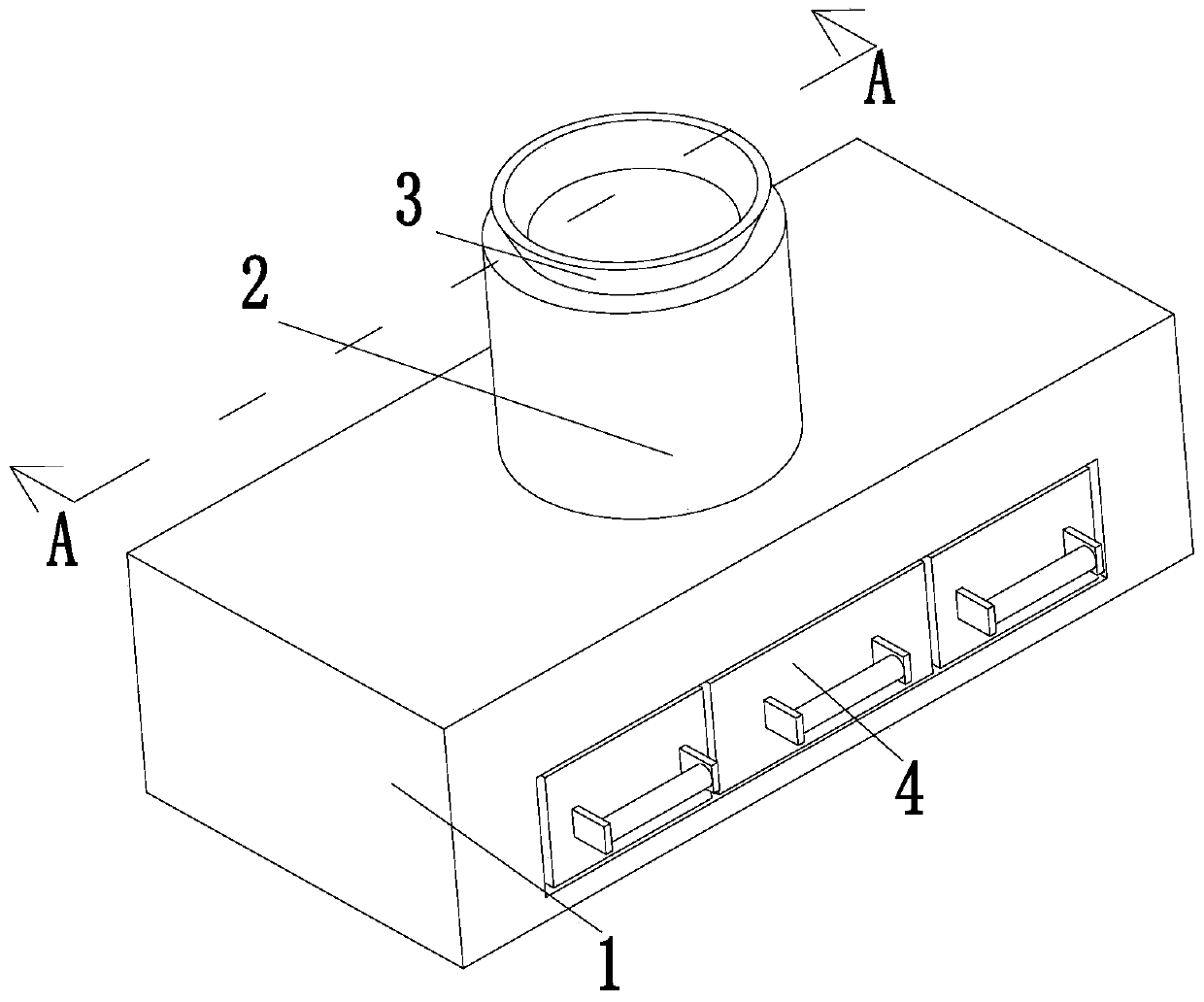

Method for deep processing and treating starch for foods

InactiveCN111357974ASolve the problem of lower yieldPrevent problems affecting blankingFood mechanical treatmentFood ingredientsProcess engineeringStarch solution

The invention relates to a method for deep processing and treating starch for foods. A food processing device is used by the method. The food processing device comprises a discharging frame, a mincingunit, a feeding opening, and a discharging unit, wherein the mincing unit is arranged at the upper end of a discharging frame; the feeding opening is formed in the upper end of the mincing unit; andthe discharging unit is arranged on the inner wall at the lower end of the discharging frame. According to the method for deep processing and treating starch for foods disclosed by the invention, through the two-stage crushing and milling method, sweet potatoes are completely crushed; through triangular material waiting regions formed between a cooperation block and smashing strips, the problem that an inlet of a milling mechanism is blocked by sweet potato blocks which are not completely crushed, and the discharging of the sweet potato blocks is influenced is solved; and by a method of performing discharging, performing precipitation, performing dividing and performing precipitation again, most of a starch solution is reserved, so that the problem that a part of starch is discharged alongwith moisture, and the yield of the collected starch is reduced, is solved.

Owner:朱运霞

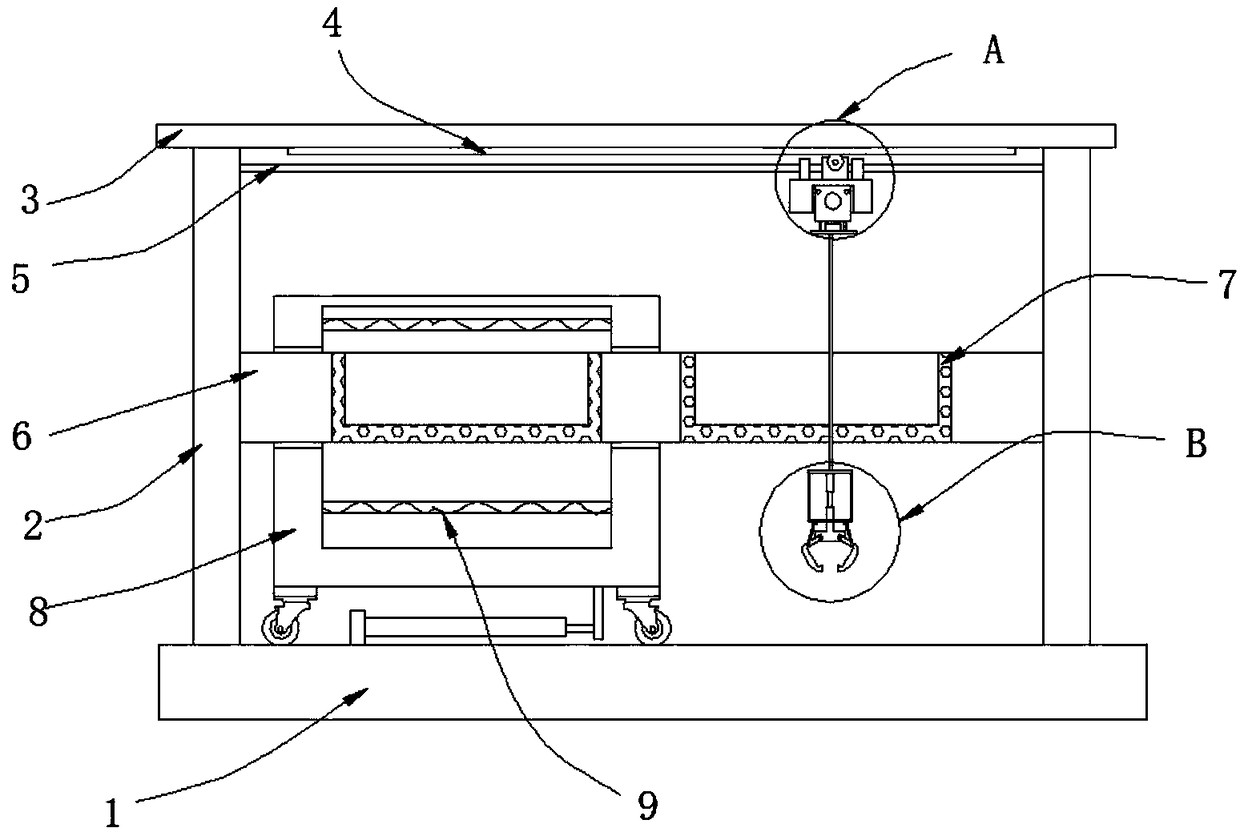

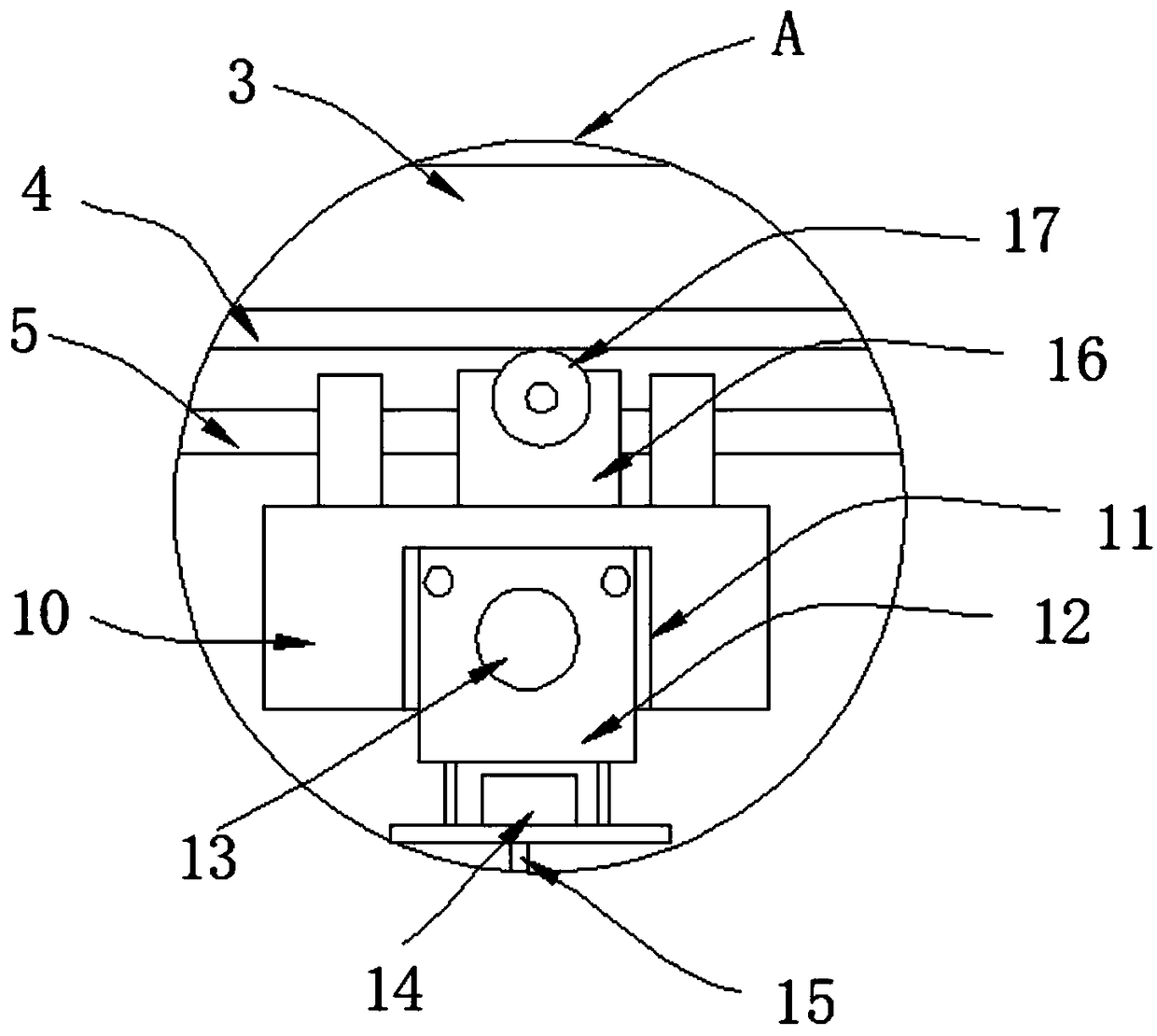

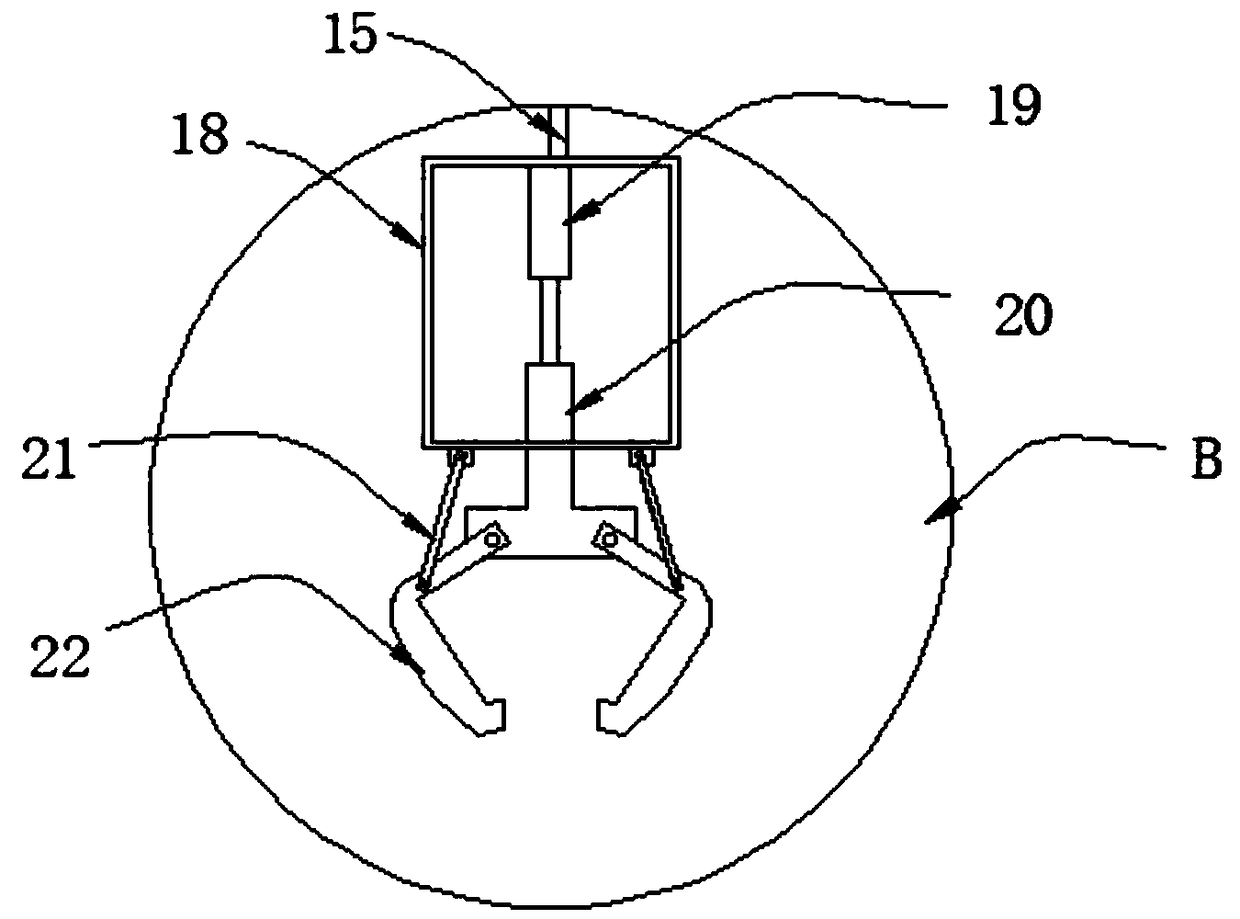

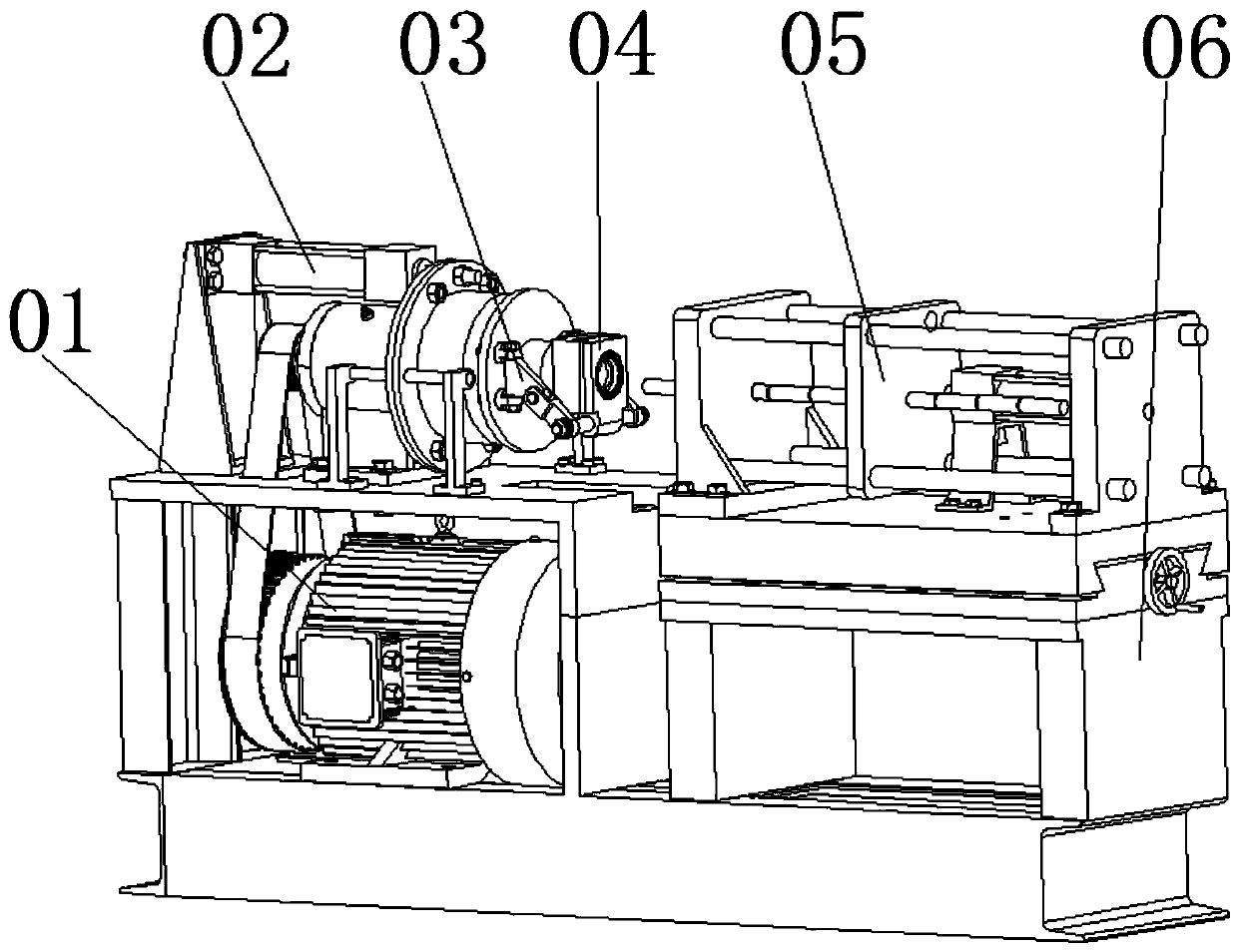

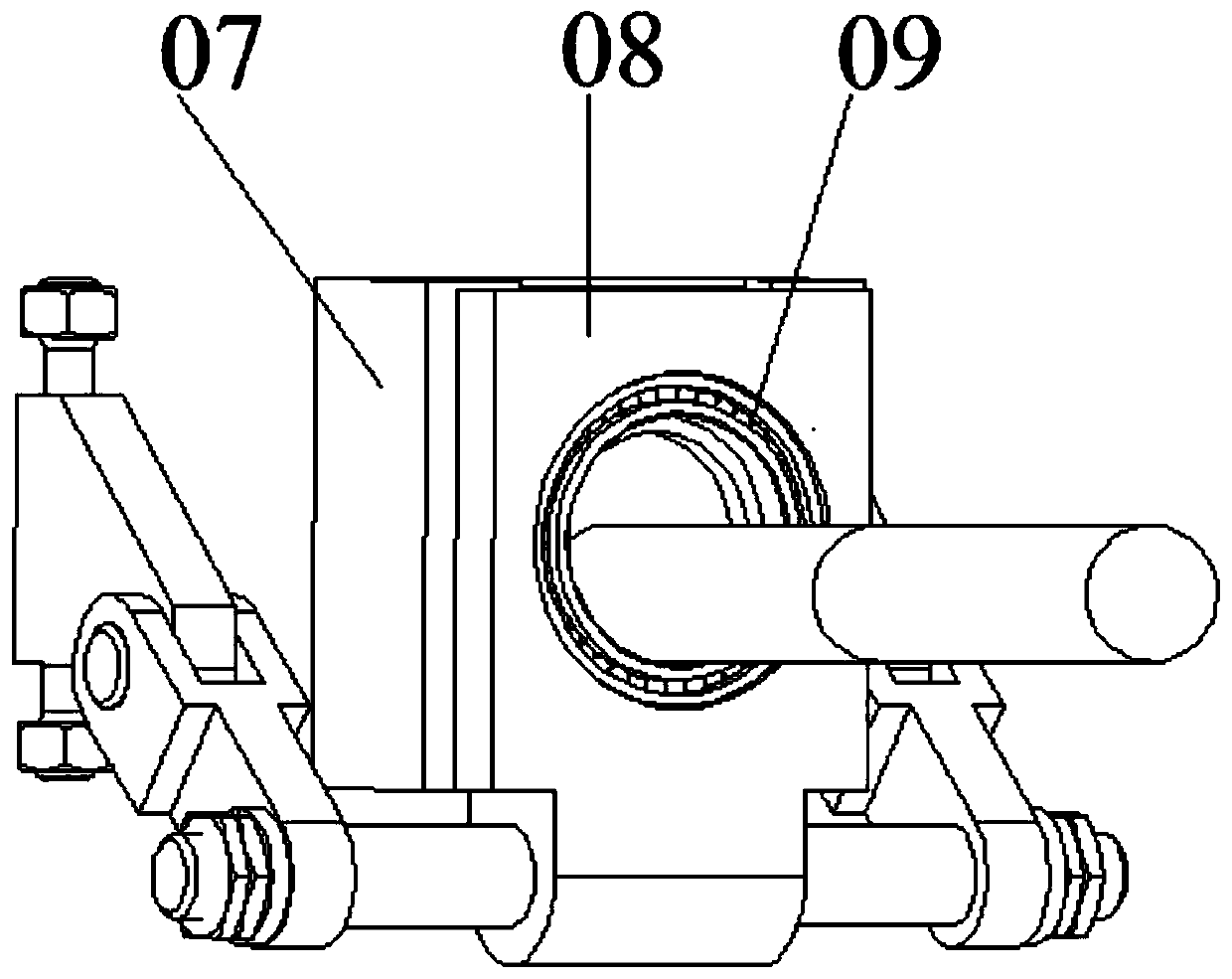

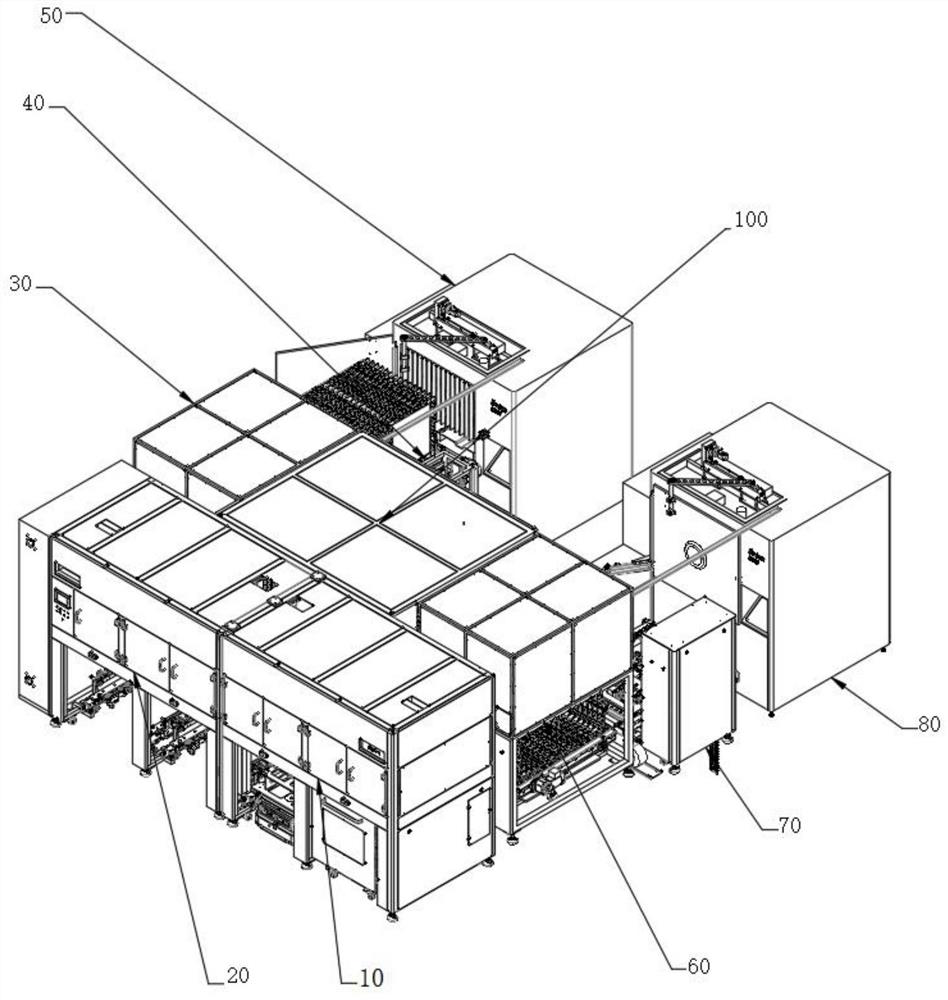

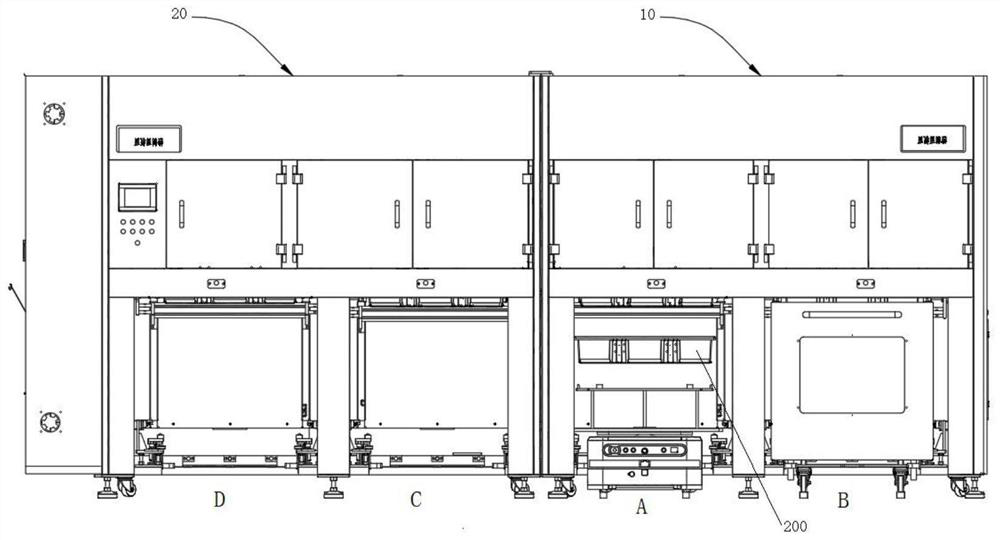

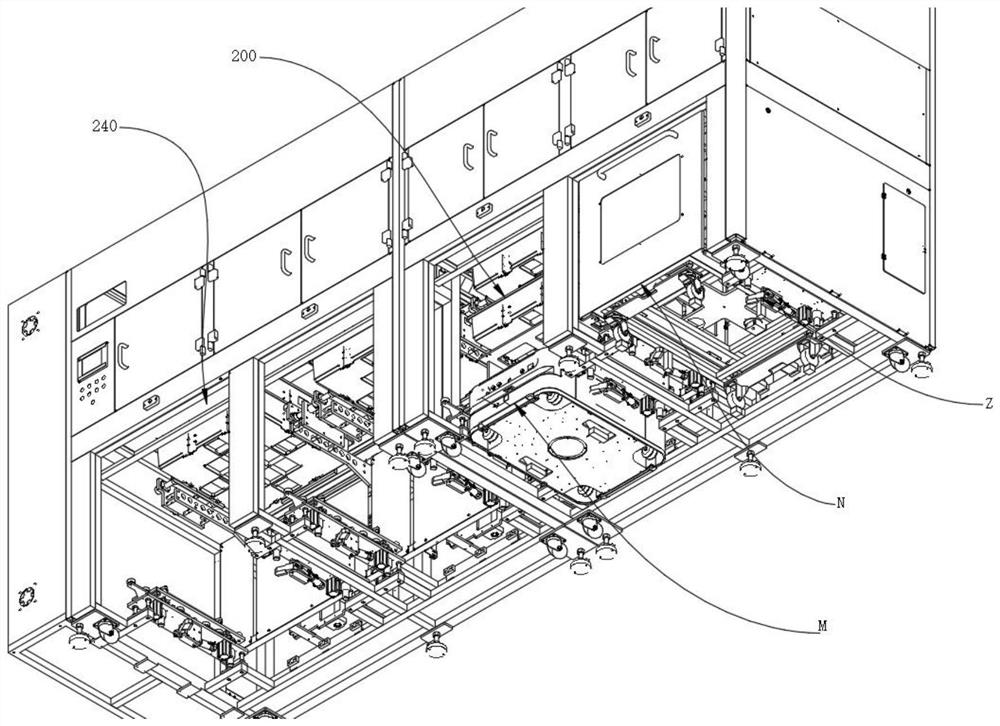

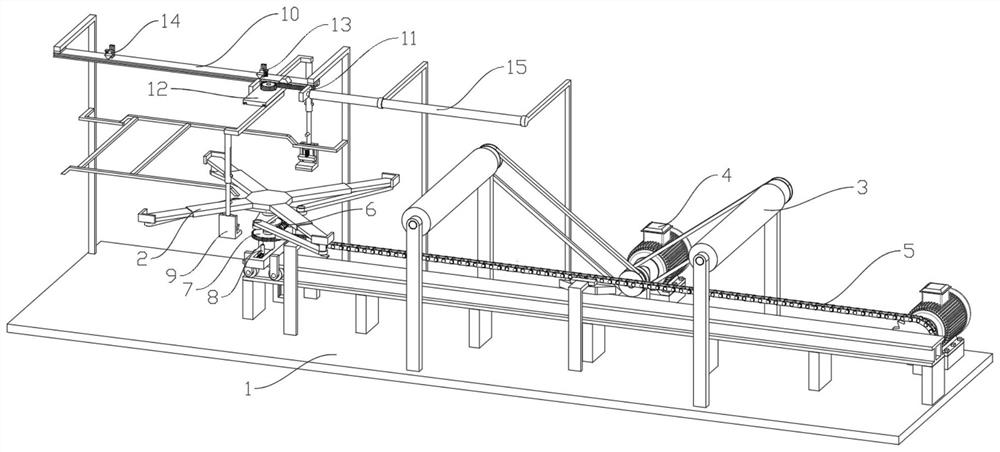

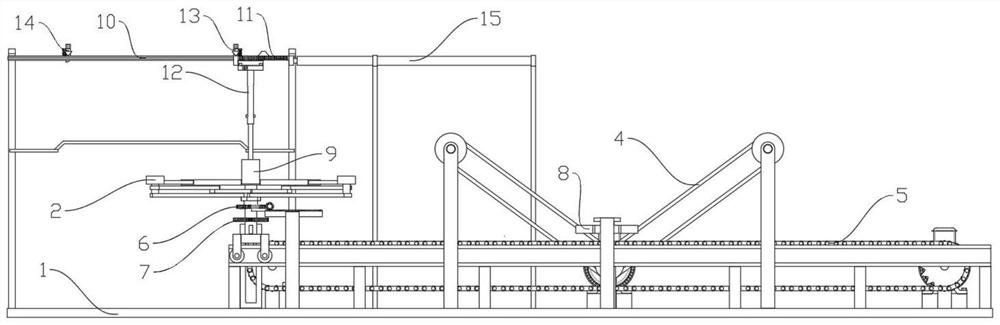

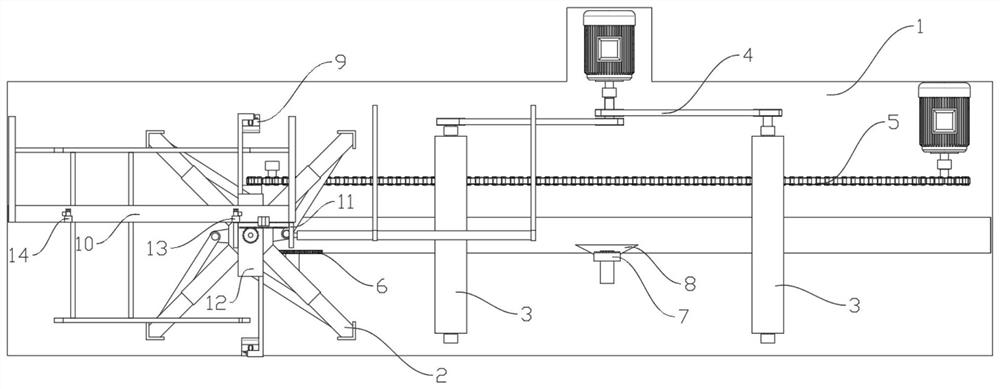

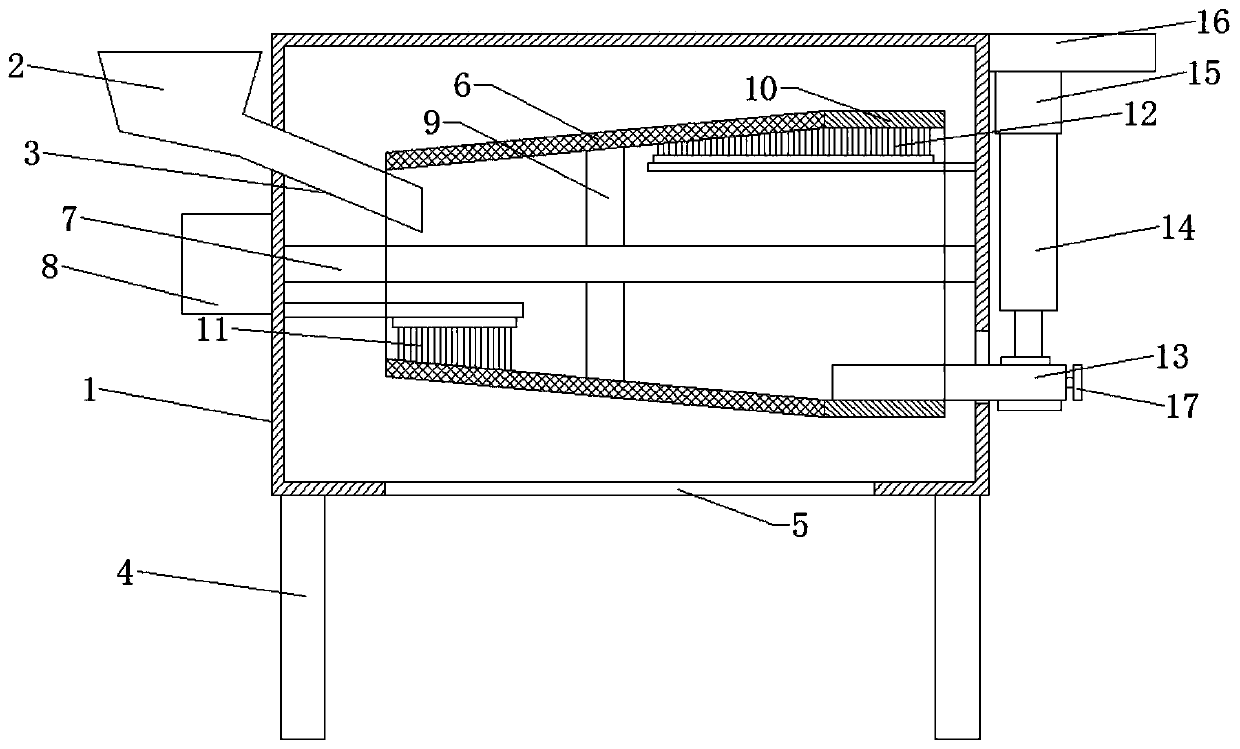

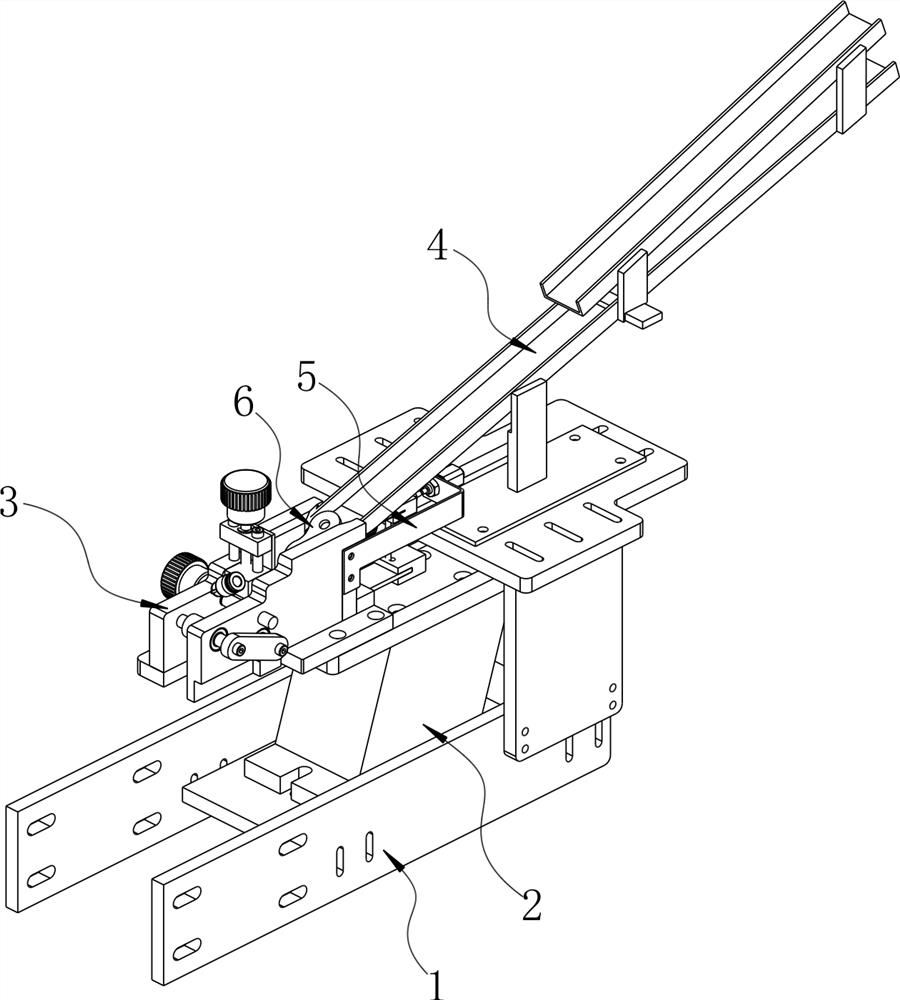

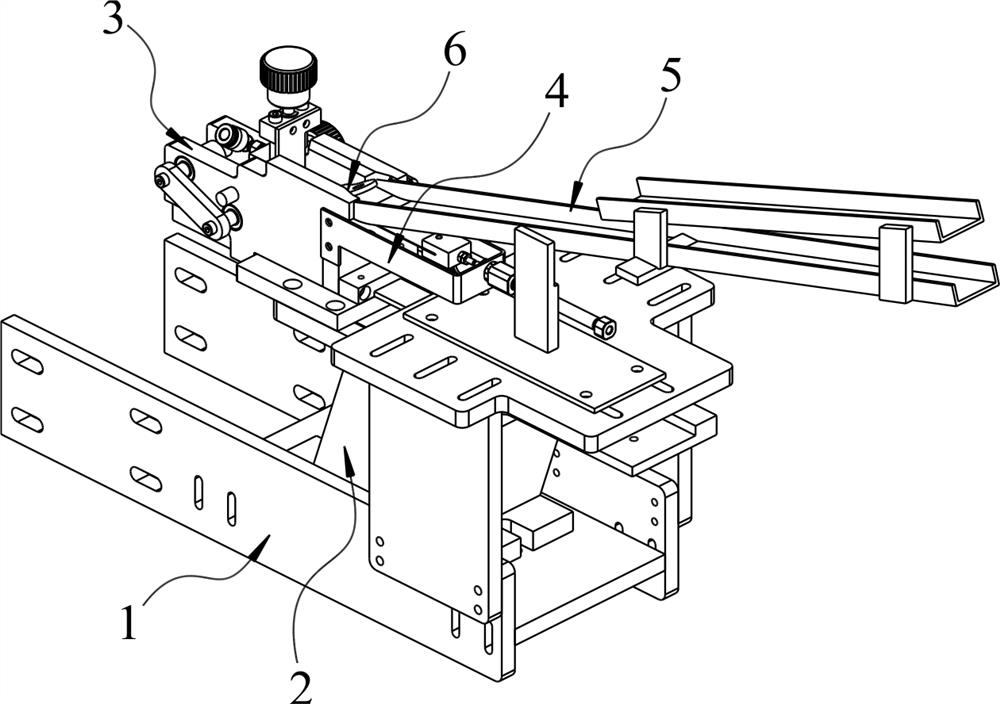

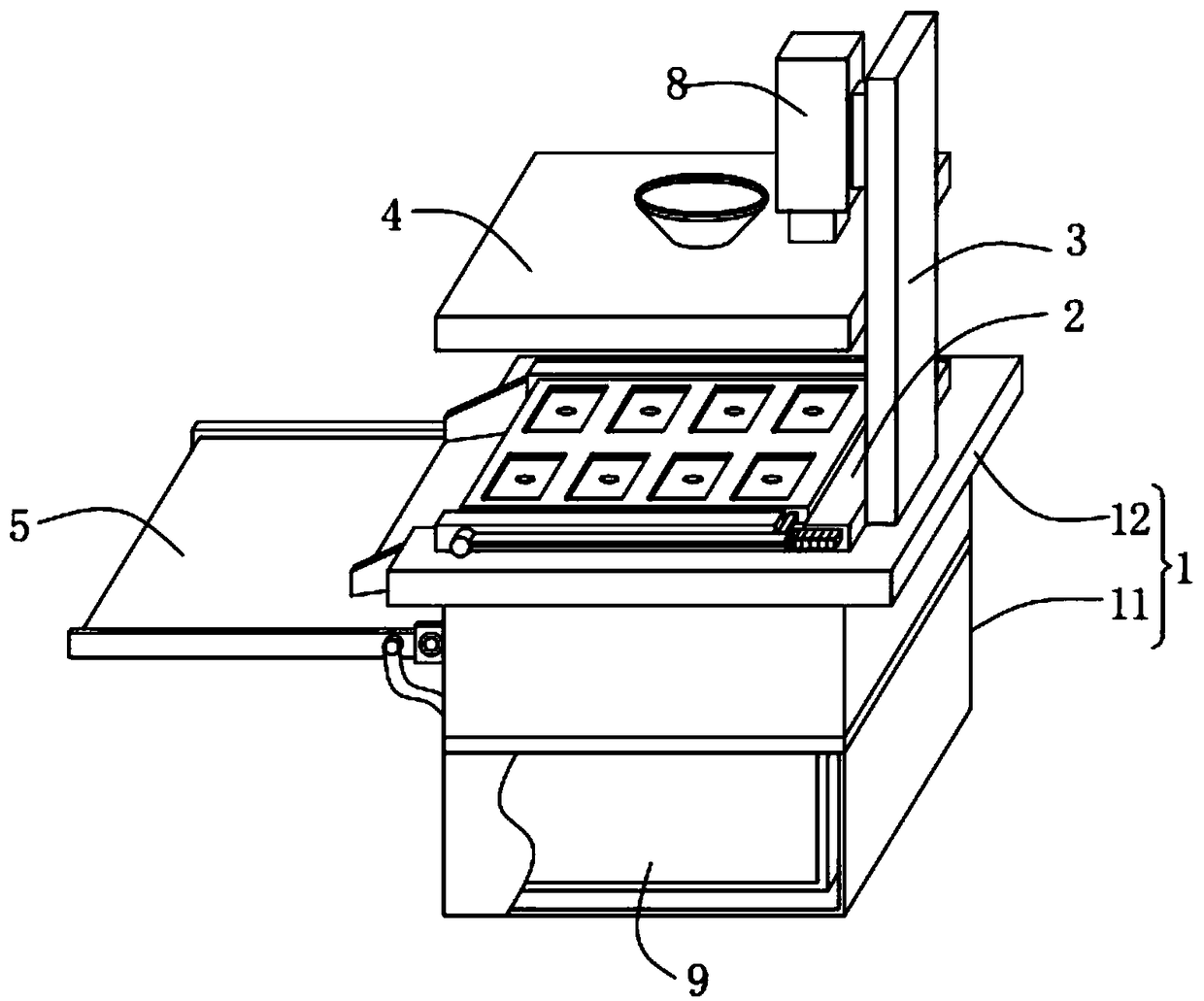

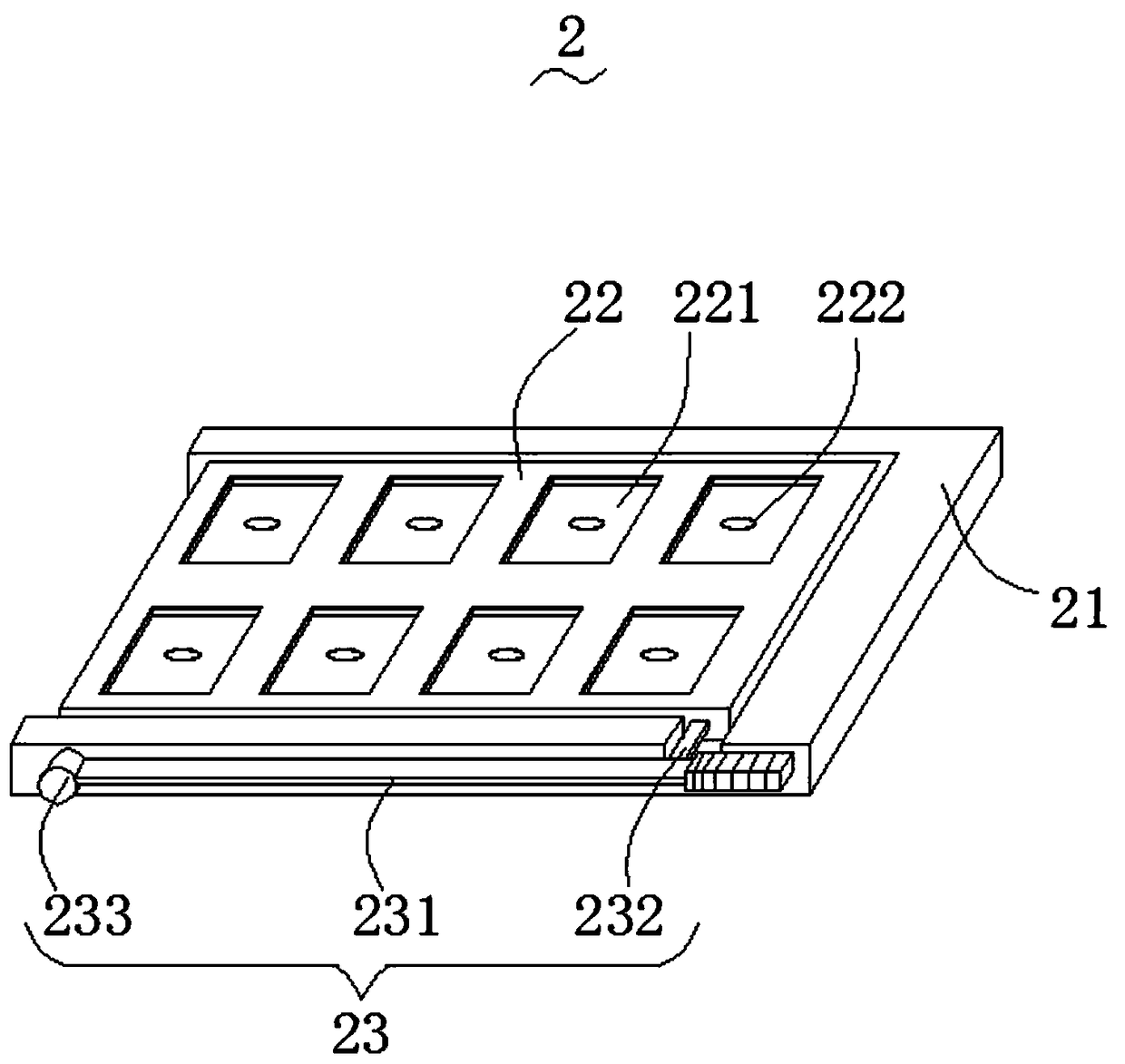

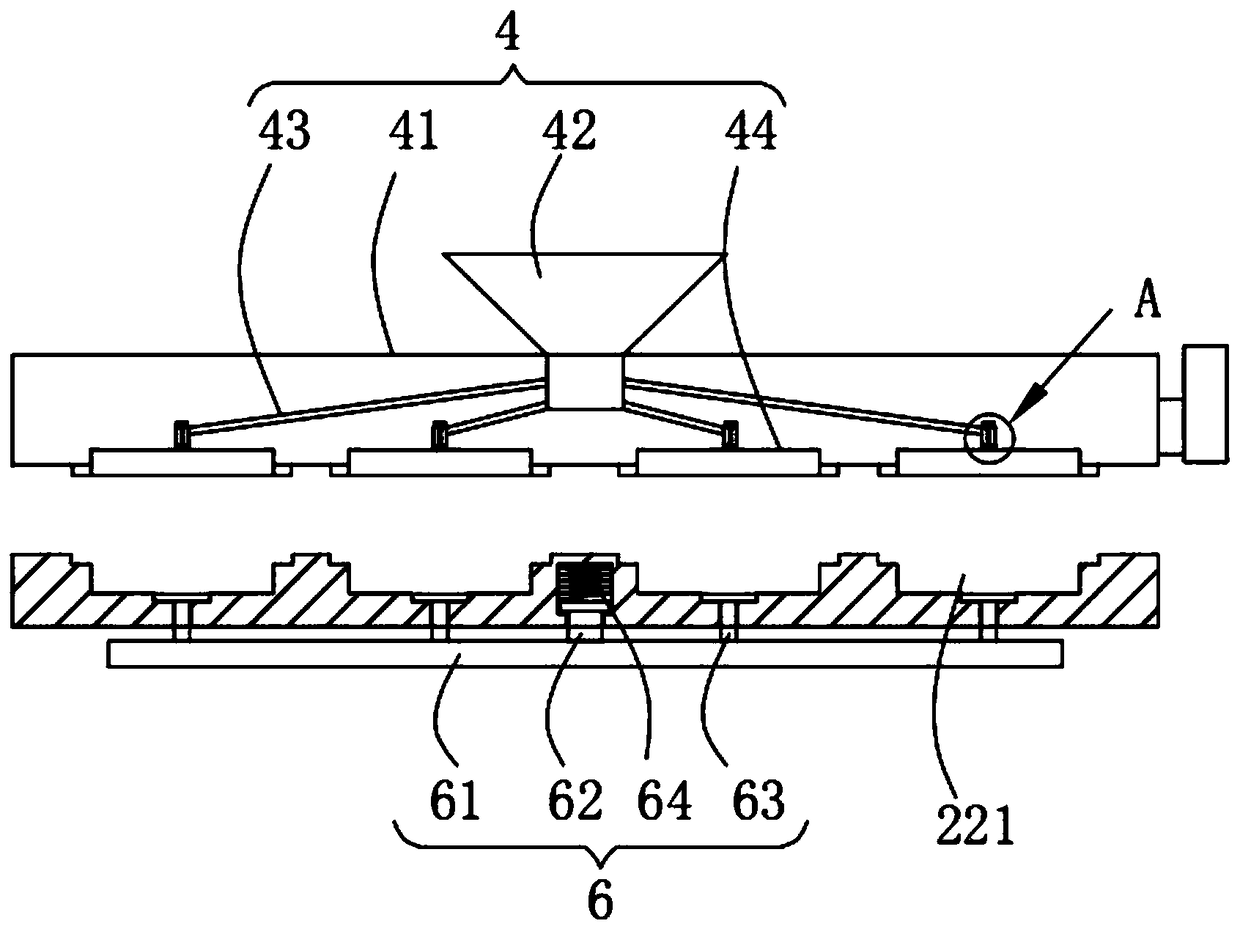

Double-station full-automatic plasma feeding and discharging device

ActiveCN112678460ACutting fastIncrease the feeding speedStacking articlesDe-stacking articlesProcess engineeringMechanical engineering

The invention discloses a double-station full-automatic plasma feeding and discharging device. The double-station full-automatic plasma feeding and discharging device has the following beneficial effects that 1, based on the arrangement of a discharging mechanism, a feeding mechanism, a first corner mechanism and a second corner mechanism, PCB can be received at three positions, namely a first empty frame tray, a second empty frame tray and a third empty frame tray, and a high feeding speed and a high discharging speed are ensured; 2, based on a double plasma cleaning mechanism, double-station work is achieved, cyclic utilization of the three empty frame trays is achieved, the work continuity of a plasma cleaning mechanism is guaranteed, and the cleaning efficiency is greatly improved; and 3, all functional mechanisms of feeding, transferring and cleaning are integrated into a whole, automatic production is achieved, and the stability is high.

Owner:广东智联半导体装备有限公司

Automatic discharging device for leather carving type flexible decorative material

ActiveCN112025525ARealize automatic unloadingAchieve transshipmentPolishing machinesGrinding drivesHydraulic cylinderIndustrial engineering

The invention discloses an automatic discharging device for a leather carving type flexible decorative material, and relates to the technical field of leather carving type flexible decorative materialproduction processes. The automatic discharging device comprises two clamps and a second guide rail, wherein a pushing assembly is slidably arranged on the second guide rail, the pushing assembly comprises a third rack slidably arranged on the second guide rail, a first pushing block is fixedly connected to one end of the third rack, a second pushing block is fixedly connected to the other end ofthe third rack, the pushing assembly is driven by a hydraulic cylinder arranged on a machine frame, a linkage assembly is arranged between the pushing assembly and the two clamps, and the linkage assembly comprises a folding linkage unit and a lifting linkage unit. According to the automatic discharging device for the leather carving type flexible decorative material, through cooperation of the pushing assembly, the linkage assembly, a second locking mechanism, a third locking mechanism and the clamps, the leather carving type flexible decorative material loosened on a clamping mechanism canbe moved away from the clamping mechanism, automatic discharging is achieved, the leather carving type flexible decorative material is transferred to a downward moving processing procedure place or aconveying belt, manual discharging is not needed, and the discharging efficiency is high.

Owner:富晶智造(东莞)科技有限公司

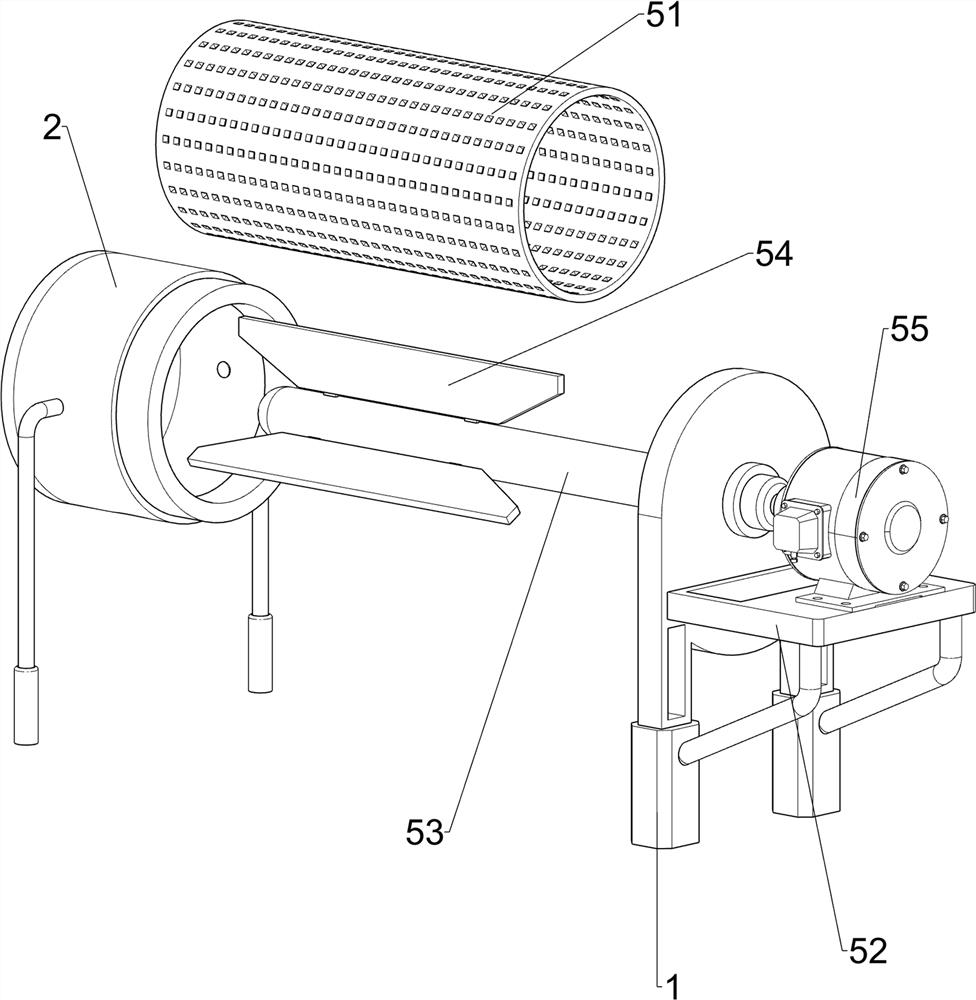

Soil screening equipment for agricultural seedling culture

InactiveCN110404772AAvoid cloggingCutting fastSievingGas current separationHollow cylinderAgricultural engineering

The invention relates to the field of agriculture, and particularly discloses soil screening equipment for agricultural seedling culture. The soil screening equipment for agricultural seedling culturecomprises a box body, a feed hopper, a discharging pipe, supporting legs and a discharge port; a horizontal screening cylinder is installed in the box body, the screening cylinder is of a round tablestructure, and a cleaning cylinder is coaxially fixed at the other end of the screening cylinder; a horizontal separation box is arranged at the inner bottom of the cleaning cylinder and comprises adischarging box and a shoveling box, and the discharging box is a hollow cylinder of a cuboid structure and is formed by welding stainless steel mesh plates; and the shoveling box is of a right-angletriangular prism structure. According to the soil screening equipment for agricultural seedling culture, screened large-particle soil, stones and the like are turned over through the arranged cleaningcylinder, the large-particle soil, the stones and the like are collected through the action of the separation box, and the large-particle soil, the stones and the like are taken out from the rotatingscreening cylinder in time, so that the operation can be carried out in the screening process, the cleaning is carried out without stopping, the soil screening is carried out continuously, and the rapid formation of agricultural seedling soil is facilitated.

Owner:曲昭硕

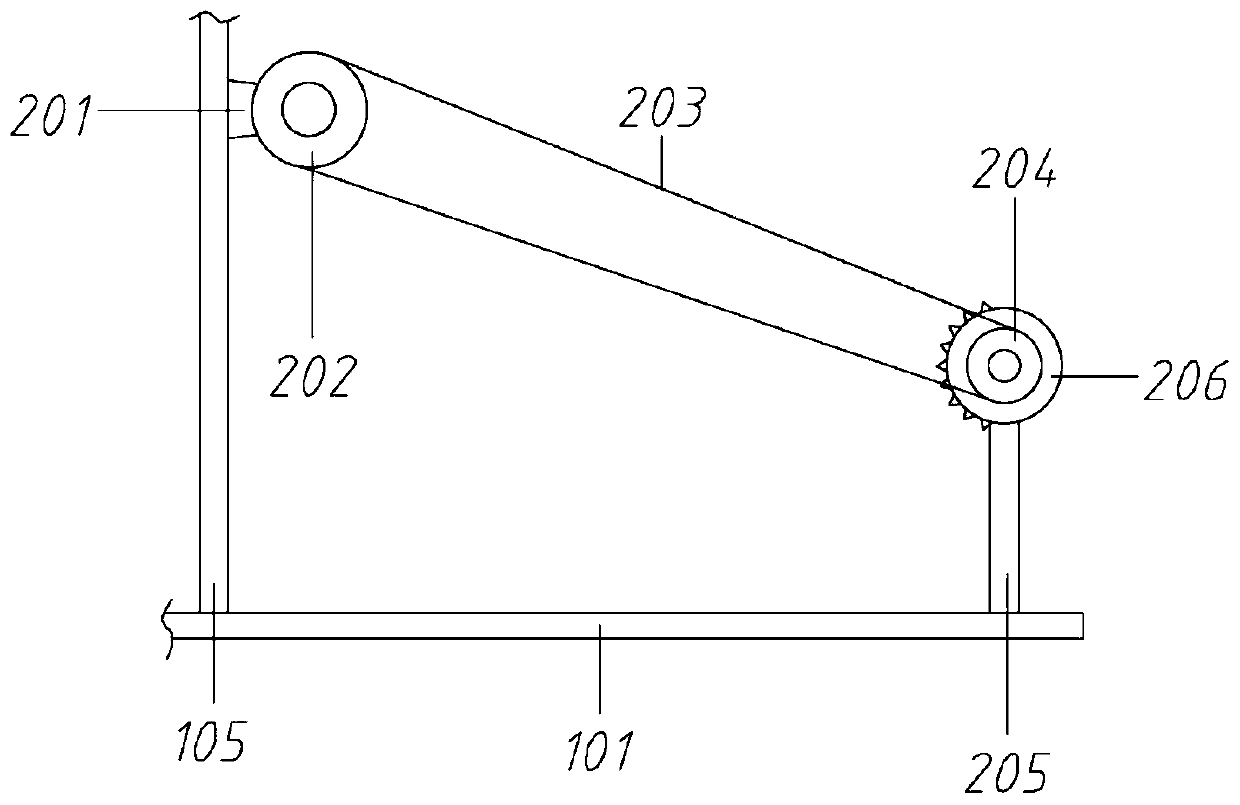

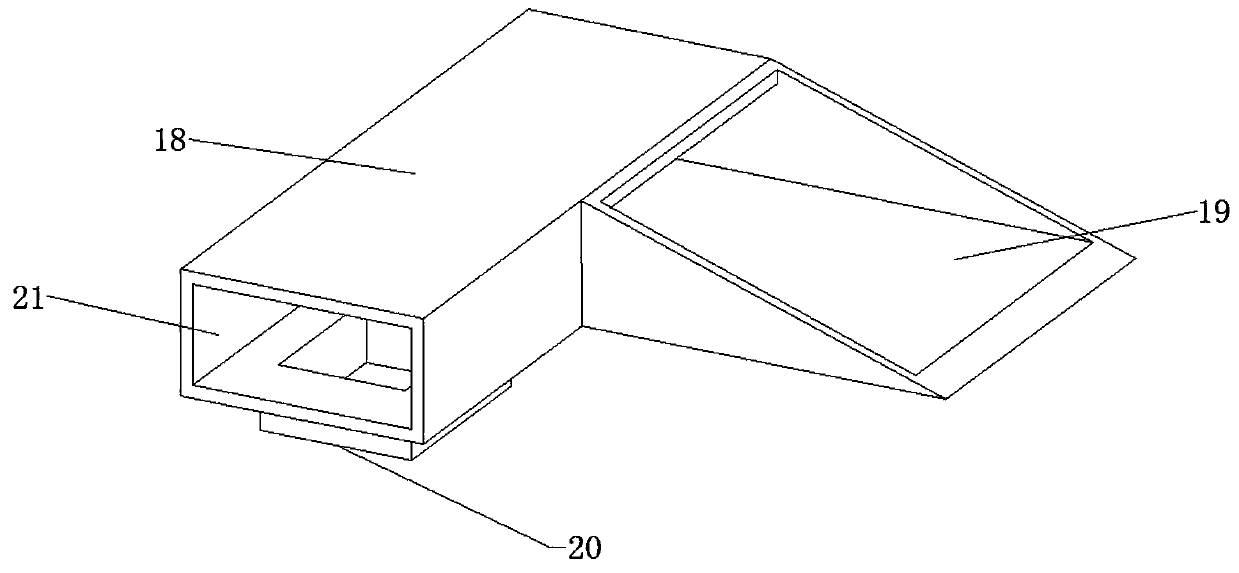

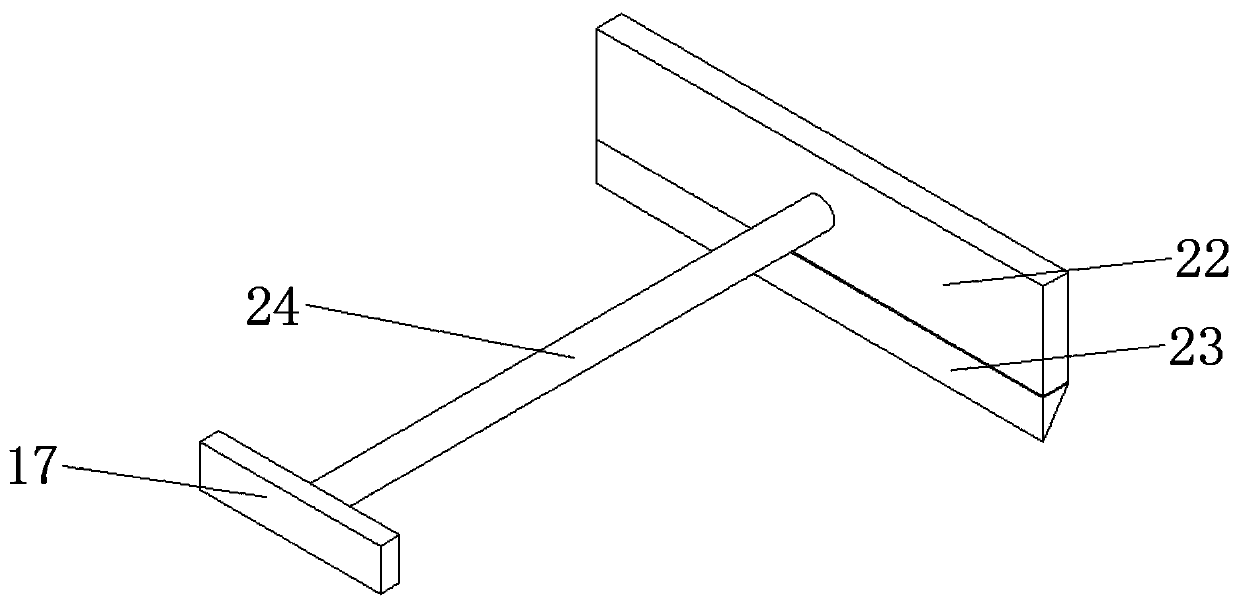

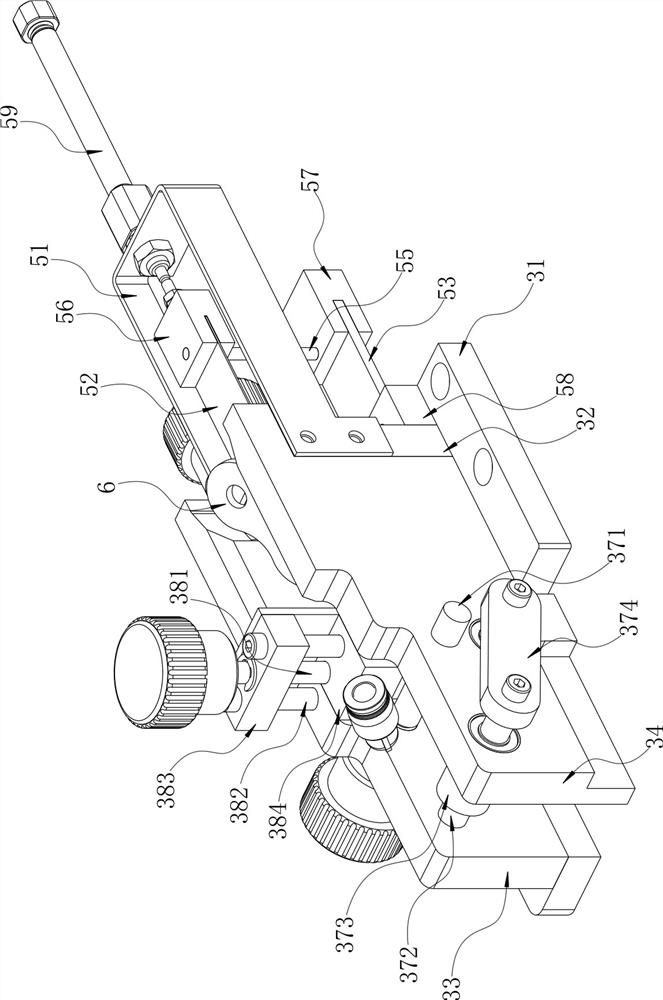

Feeding device for chain piece inspection system

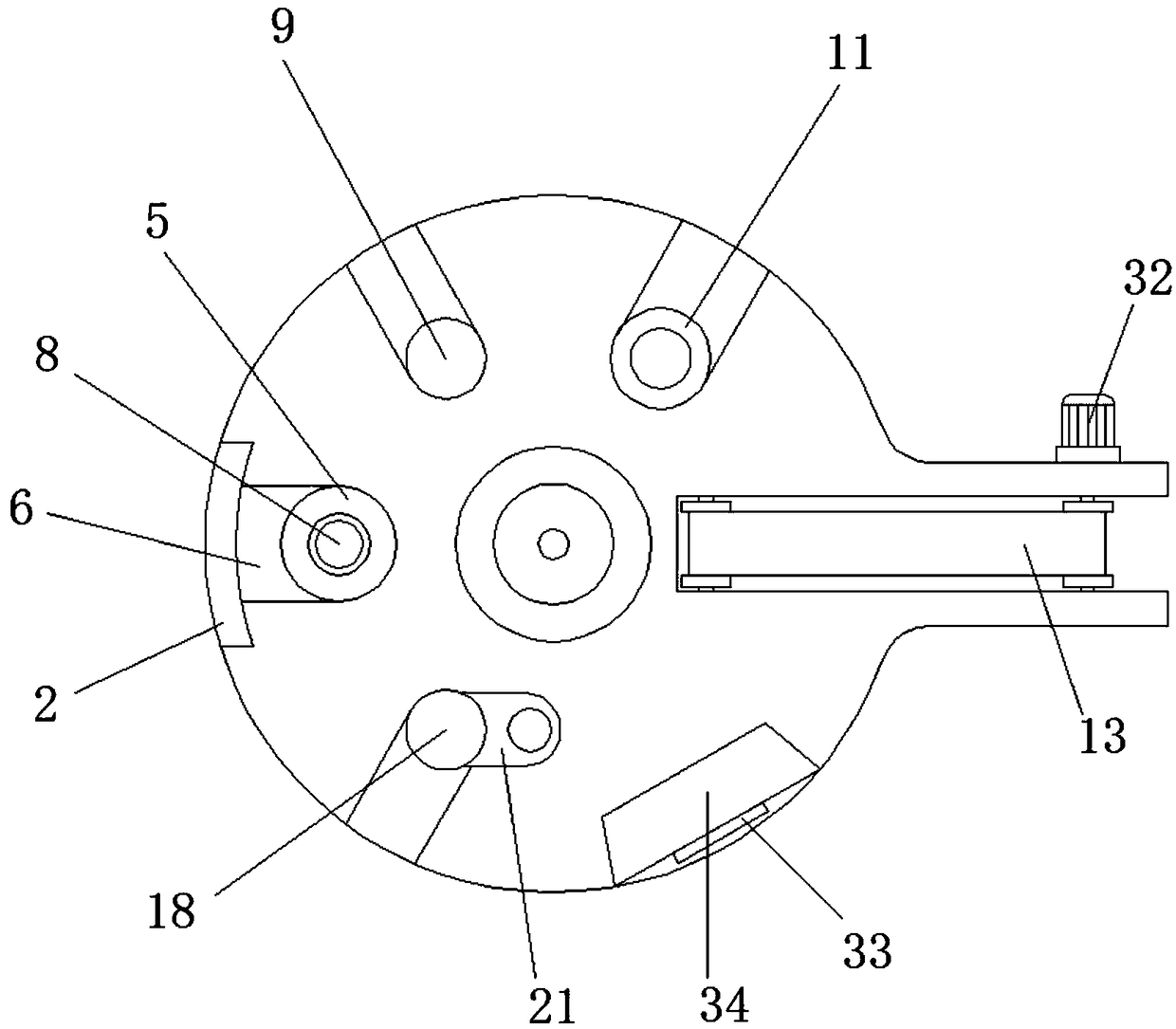

ActiveCN113697508ARealize automatic orientationAvoid getting stuckStacking articlesDe-stacking articlesLinear vibrationMechanical engineering

The invention discloses a feeding device for a chain piece inspection system. The feeding device comprises a support, a linear vibration feeder, a temporary storage material box, a slideway and a material pushing device, wherein the support is used as a supporting base frame and fixedly connected to the chain piece inspection system; the linear vibration feeder is mounted on the support and used for providing a power source, so that chain pieces can be fed into the chain piece inspection system from the temporary storage material box; the temporary storage material box is mounted at the top of the linear vibration feeder; the temporary storage material box is used for temporarily storing the chain pieces and adjusting directions and angles of the chain pieces; the slideway is fixed on the support; the slideway is used for receiving the chain pieces and feeding the chain pieces into the temporary storage material box in a sliding manner; the material pushing device is mounted on the temporary storage material box; and the material pushing device is used for driving the chain pieces to be stacked in the temporary storage material box layer by layer and assisting the linear vibration feeder to push the chain pieces into the chain piece inspection system at the same time. According to the feeding device for the chain piece inspection system, before the inspection of the chain pieces, automatic alignment of the chain pieces is achieved under the action of the temporary storage material box. In addition, the chain pieces are pushed out through the cooperation of the linear vibrator and the material pushing device, so that the directions and angles of the fed chain pieces meet the inspection requirements.

Owner:YANGZHOU POLYTECHNIC INST

Silicone rubber mould

The invention relates to the technical field of moulds, in particular to a silicone rubber mould. The silicone rubber mould comprises a supporting mechanism, a lower mould mechanism, a sliding plate,an upper mould mechanism, a material receiving mechanism, an ejection mechanism, a blocking mechanism, a hydraulic rod and a water tank. According to the silicone rubber mould, automatic sealing of aliquid separation groove can be realized, a blockage block and a liquid hole are parallel and level, and unlevel molding parts can be avoided; when injection molding is completed, a handle can be heldand rotated upwards, a lower template is driven to rotate upward through a supporting rod, so that the molding parts rapidly drop, discharging is more convenient and rapid, the molding parts can be ejected through the ejection mechanism, and the molding parts are prevented from being attached to the inner wall of a cavity; and cold water is always maintained in a plastic mat, workpieces with materials dropping can be buffered, so that the molding parts drop and are damaged, and the plastic mat can cool the molding parts, so that the molding effect is better.

Owner:张旭

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com