Feeding device for chain piece inspection system

A detection system and feeding device technology, applied in the field of visual inspection, can solve problems such as low efficiency, backward detection methods, and insufficient convenience, and achieve the effect of improving detection efficiency and avoiding excessive interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

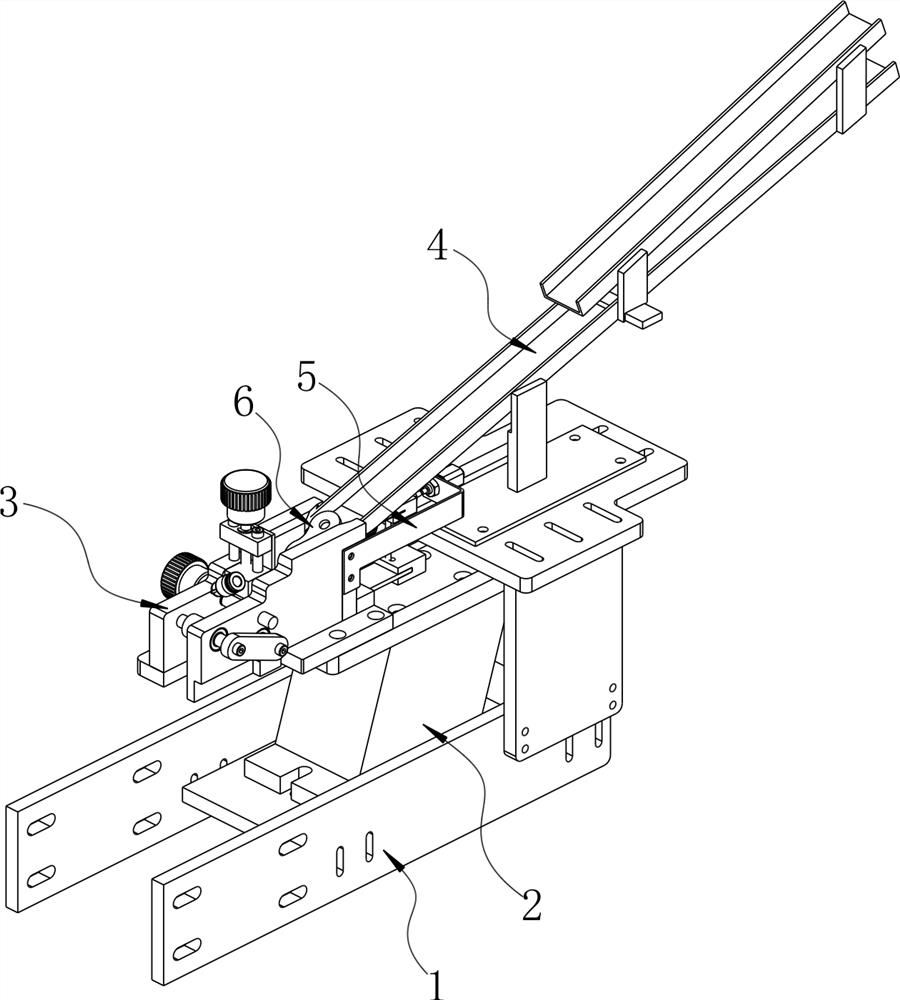

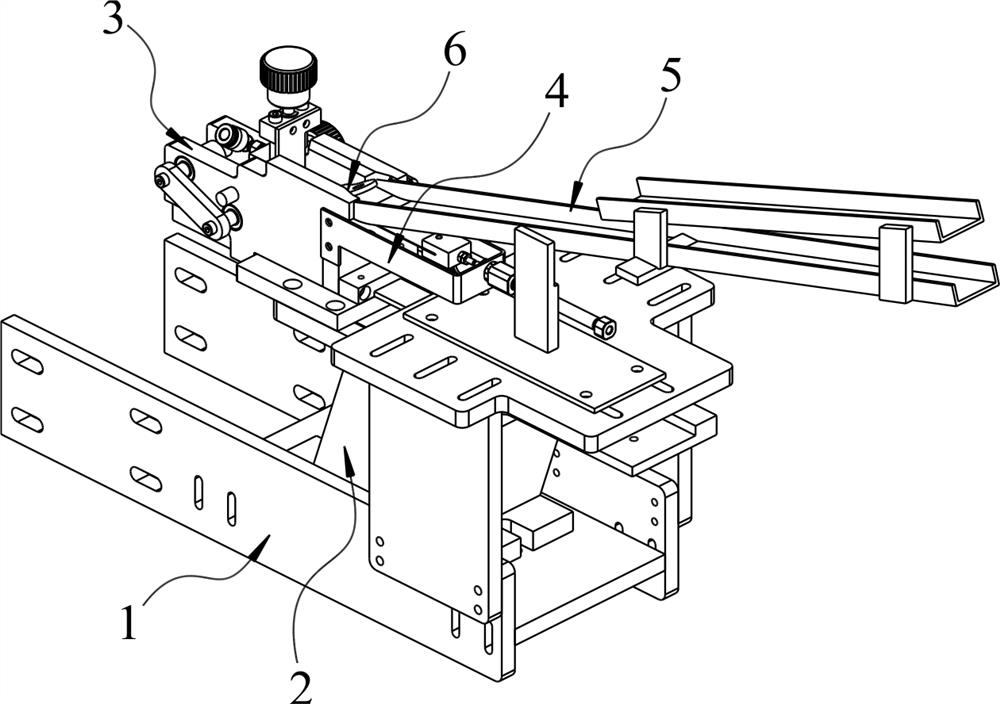

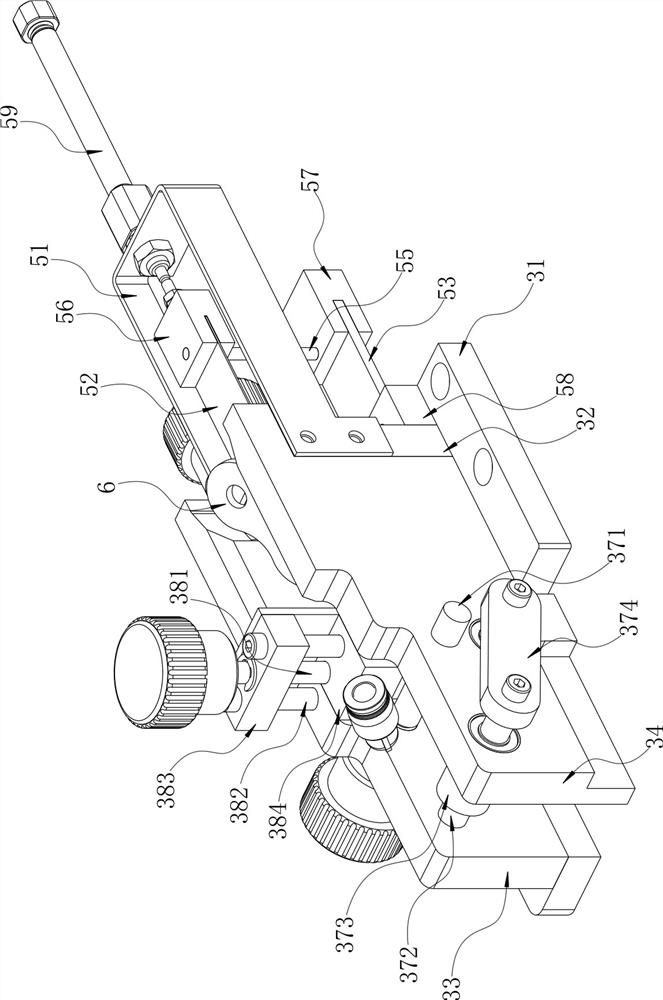

[0040] Such as Figure 1-8 The feeding device for a chain detection system shown includes:

[0041] Bracket 1, which is used as a supporting base frame, is fixedly connected with the detection system of the chain sheet 6, and a conveyor belt is arranged in the detection system of the chain sheet 6, and the front end of the conveyor belt is placed directly below the outlet of the buffer box 3;

[0042] The linear vibrating feeder 2 is installed on the bracket 1 to provide a power source, so that the chain piece 6 is sent from the buffer material box 3 to the chain piece 6 detection system, and the vibration will be transmitted to the slideway 4 at the same time, which is convenient for the slideway 4 blanking;

[0043] The buffer material box 3 is installed on the top of the linear vibrating feeder 2 to buffer the chain piece 6 and adjust the direction and angle of the chain piece 6;

[0044]The slideway 4, which is fixed on the bracket 1, receives the chain piece 6 (loaded b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com