Feed device with function of dispersing feed for aquaculture

An aquaculture and feed technology, which is applied in application, fish farming, transportation and packaging, etc., can solve the problems of larger horizontal footprint of the device, uneven material throwing, and fragmented distance, and achieve the effect of avoiding blockage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

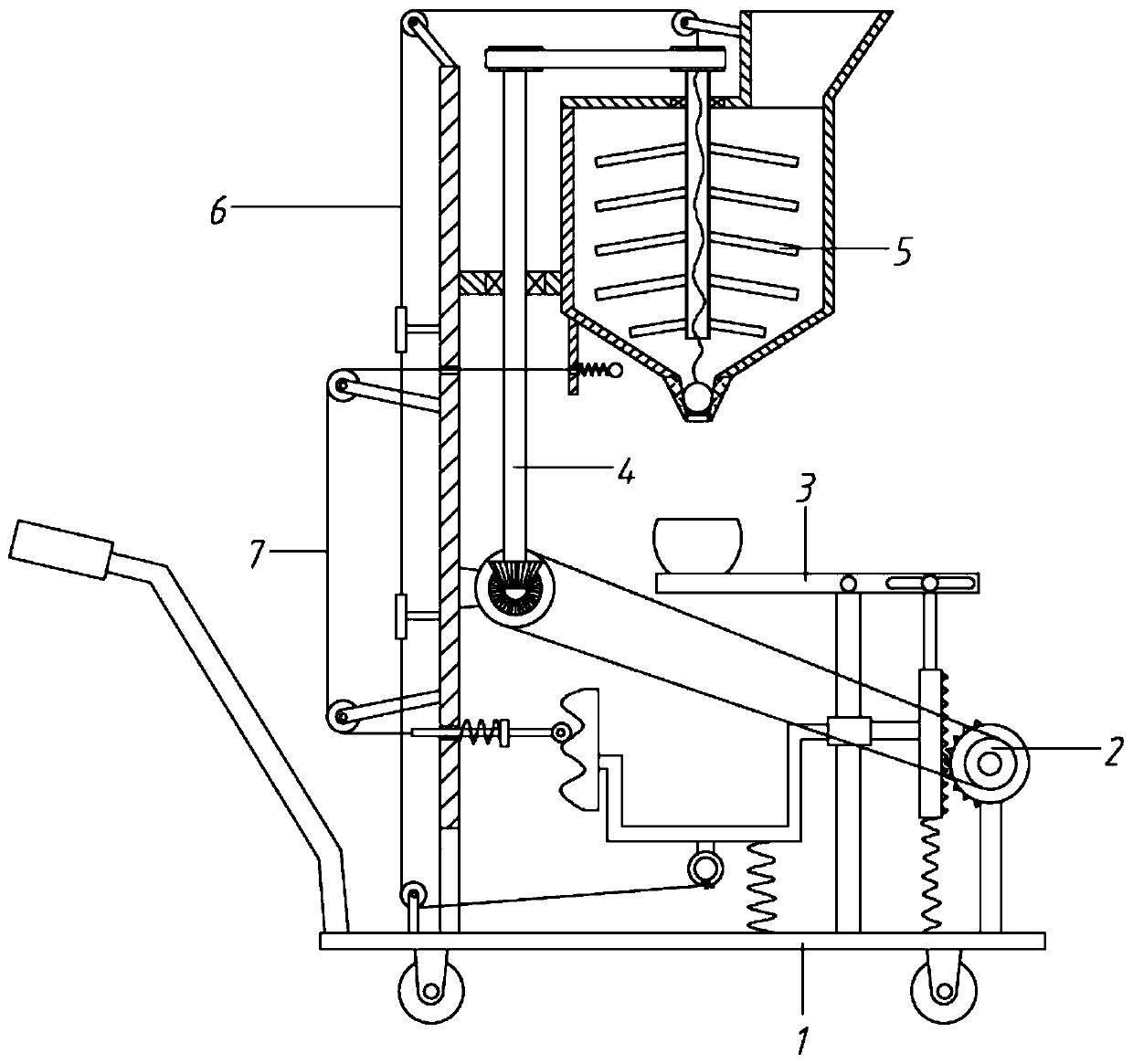

[0057] A feeding device for aquaculture capable of throwing feed, comprising a frame 1, a driving component 2, a throwing component 3, a transmission component 4, a stirring component 5 and a feeding component 6;

[0058] Frame 1 comprises base 101, wheel 102, push rod 103, handle 104, vertical plate 105, support plate 106 and bucket 107, and wheel 102 is housed below base 101, base 101 left end is connected with push rod 103, and push rod 103 outer end A handle 104 is connected; the left part of the base 101 is connected with a vertical plate 105, and the upper part of the vertical plate 105 is connected to the left through the support plate 106 with a bucket 107; ; Bucket 107 is provided with stirring assembly 5, stirring assembly 5 through transmission assembly 4 and drive assembly 2;

Embodiment 2

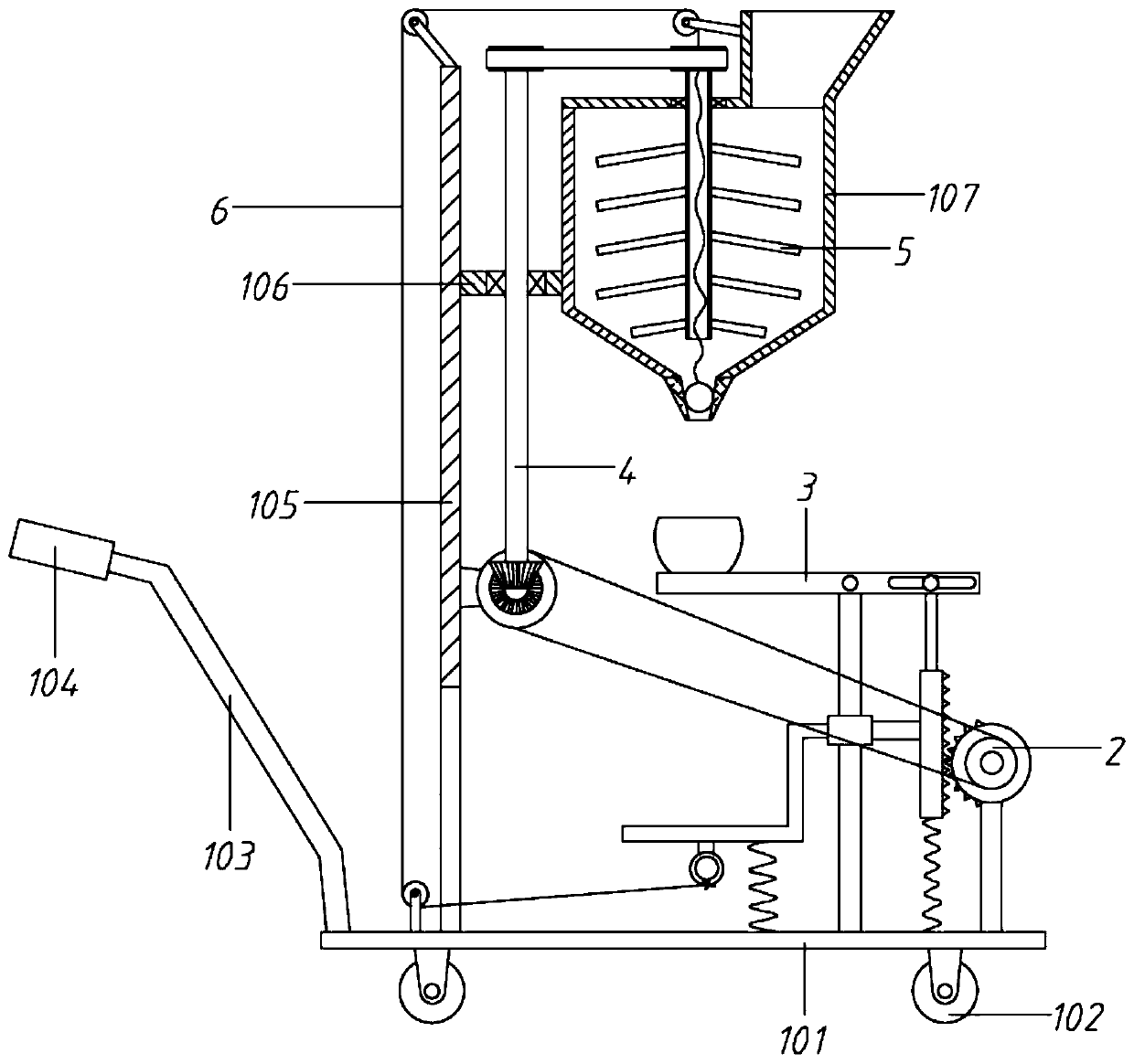

[0060] A feeding device for aquaculture capable of throwing feed, comprising a frame 1, a driving component 2, a throwing component 3, a transmission component 4, a stirring component 5 and a feeding component 6;

[0061] Frame 1 comprises base 101, wheel 102, push rod 103, handle 104, vertical plate 105, support plate 106 and bucket 107, and wheel 102 is housed below base 101, base 101 left end is connected with push rod 103, and push rod 103 outer end A handle 104 is connected; the left part of the base 101 is connected with a vertical plate 105, and the upper part of the vertical plate 105 is connected to the left through the support plate 106 with a bucket 107; ; Bucket 107 is provided with stirring assembly 5, stirring assembly 5 through transmission assembly 4 and drive assembly 2;

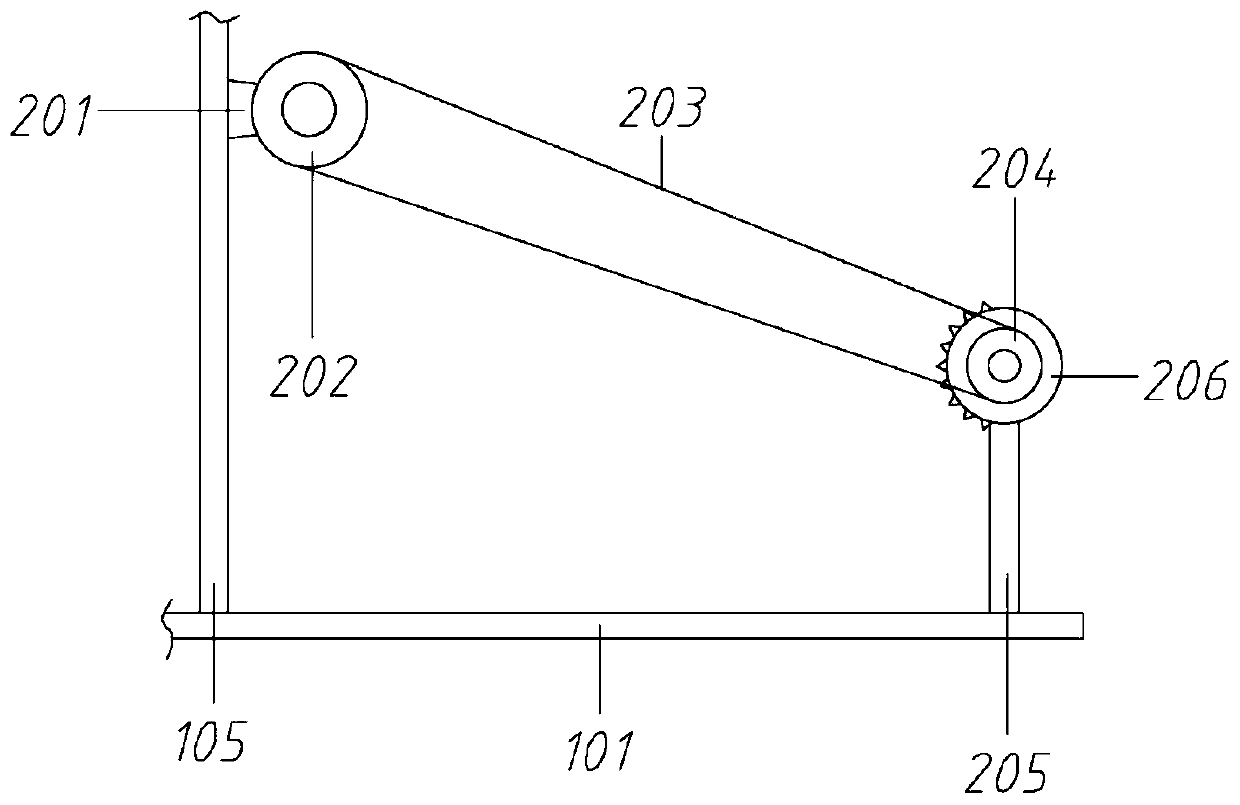

[0062] Wherein, the driving assembly 2 includes a servo motor 201, a No. 1 transmission wheel 202, a No. 1 transmission belt 203, a No. 2 transmission wheel 204, a No. 1 installation rod 205...

Embodiment 3

[0080] On the basis of embodiment 2,

[0081] In order to ensure that the blocking ball 608 moves down, the blocking ball 608 is a ferromagnetic material, and the outer wall of the tapered tube is uniformly equipped with a circular magnet 1073, so that the blocking ball 608 is also subjected to the adsorption force of the magnet 1073 during work to help it move down.

[0082] The left side of the vertical plate 105 is connected with a vertical limit tube 604 through the No. 4 connecting rod 605, and the No. 1 stay cord 602 passes through the limit tube 604, so as to avoid the excessive deviation of the No. 1 stay cord 602 when loosening.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com