Efficient crushing device for producing coating

A high-efficiency, coating technology, applied in grain processing and other directions, can solve the problems of low crushing efficiency, scattered power source, poor crushing effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

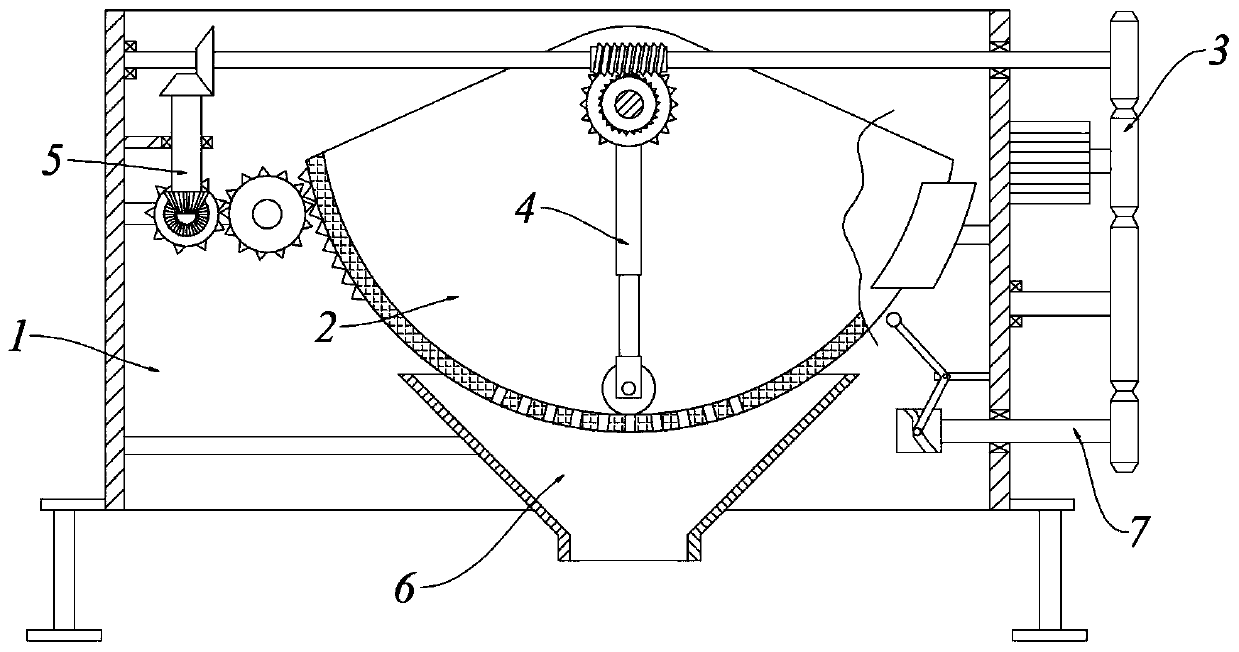

[0047] With reference to the accompanying drawings, a high-efficiency crushing device for paint production includes a housing 1, a crushing box 2, a drive assembly 3, a crushing assembly 4, a gear assembly 5, a hopper 6 and a shock assembly 7;

[0048] The crushing box 2 is arranged in the housing 1, and the front and rear sides are rotationally connected with the housing 1 through the outer mounting shaft 202; a crushing assembly 4 is arranged in the crushing box 2, and a driving assembly 3 is arranged above the crushing assembly 4; The left side of the box 2 is provided with a gear assembly 5; the bottom of the crushing box 2 is provided with a guide hopper 6;

Embodiment 2

[0050] With reference to the accompanying drawings, a high-efficiency crushing device for paint production includes a housing 1, a crushing box 2, a drive assembly 3, a crushing assembly 4, a gear assembly 5, a hopper 6 and a shock assembly 7;

[0051]The crushing box 2 is arranged in the housing 1, and the front and rear sides are rotationally connected with the housing 1 through the outer mounting shaft 202; a crushing assembly 4 is arranged in the crushing box 2, and a driving assembly 3 is arranged above the crushing assembly 4; The left side of the box 2 is provided with a gear assembly 5; the bottom of the crushing box 2 is provided with a guide hopper 6;

[0052] Wherein, the casing 1 runs through from top to bottom, the two ends of the bottom are connected with support legs 101 , and the bottom ends of the support legs 101 are fixedly connected with a support 102 .

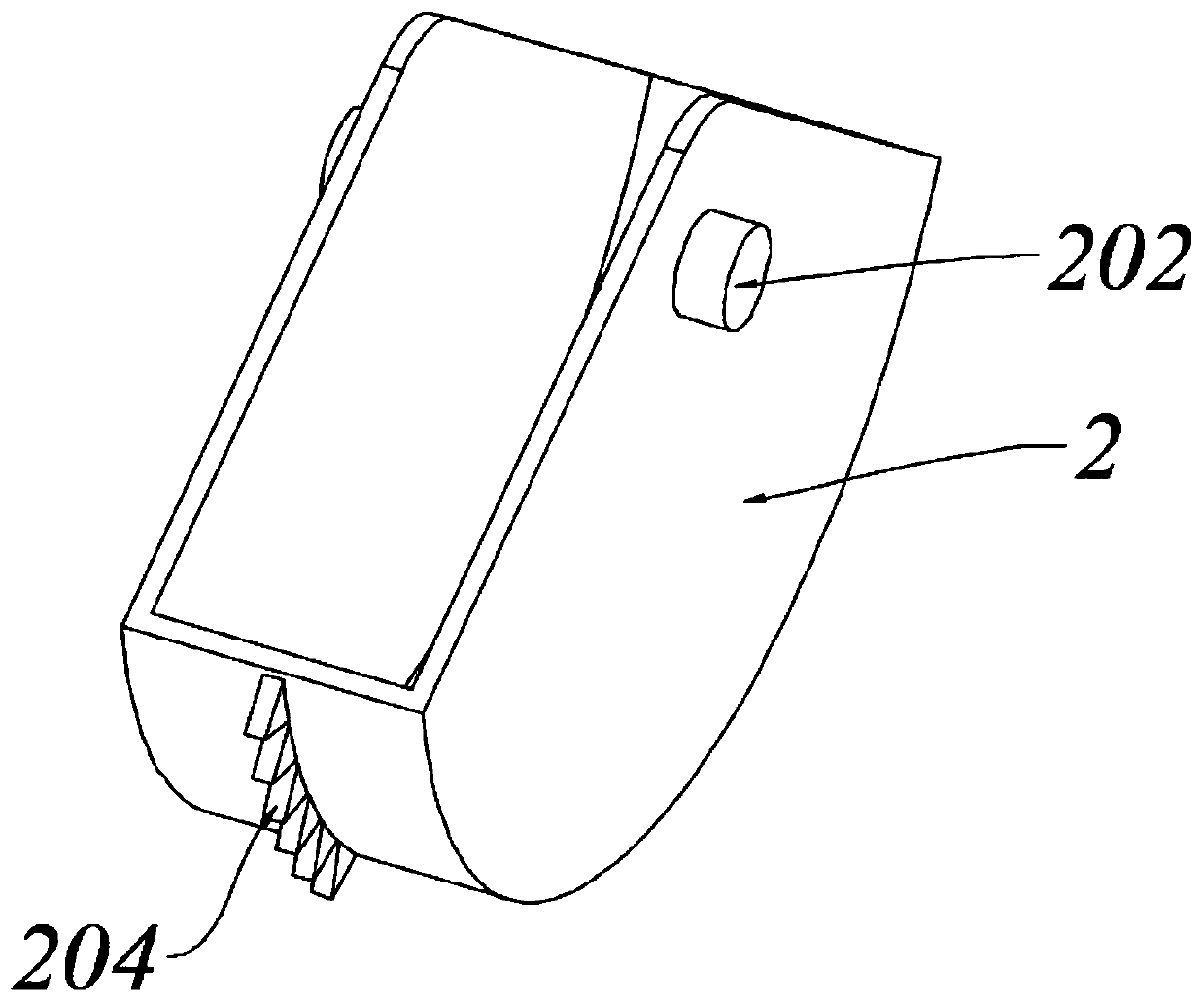

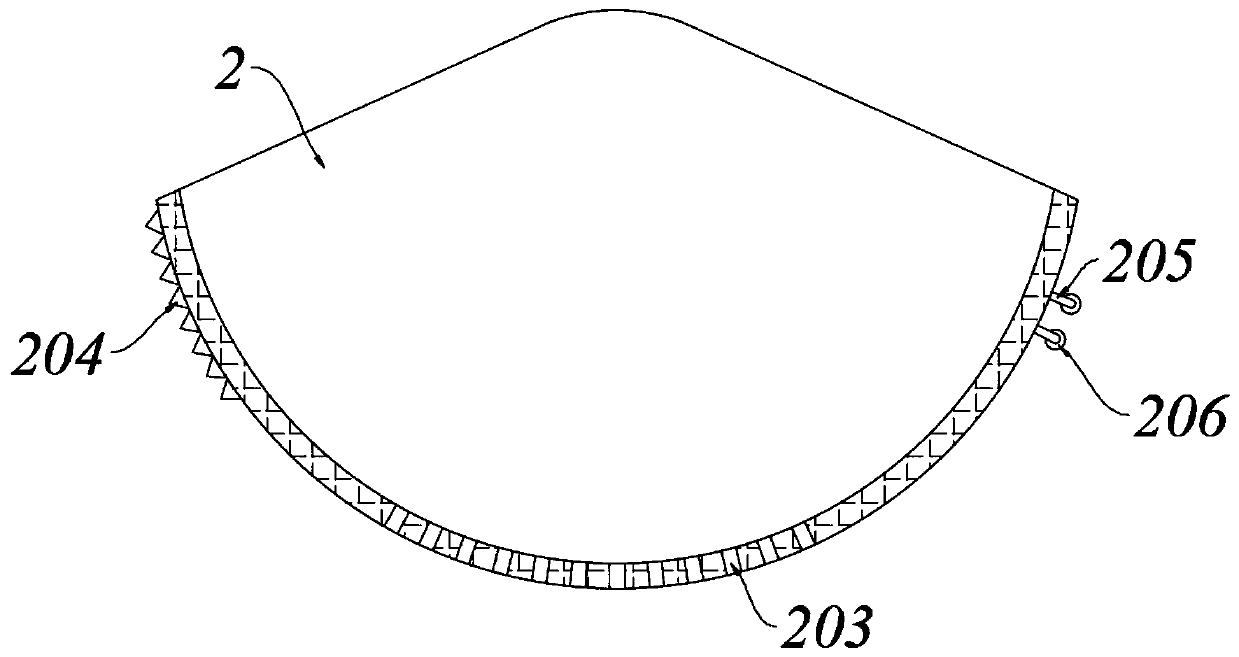

[0053] Among them, the top of the crushing box 2 is provided with an opening, the bottom surface is arc...

Embodiment 3

[0071] Wherein, the same or corresponding components as in Embodiment 1 and Embodiment 2 adopt the reference numerals corresponding to Embodiment 1 and Embodiment 2. For the sake of brevity, only the differences from Embodiment 2 are described below. The difference between this embodiment and embodiment two is:

[0072] The right section of the bottom of the crushing box 2 is connected with a roller 206 through a strut 205; the left side of the right side wall of the housing 1 is connected with a support 207 through a connecting rod 209, and the support 207 has an arc groove 208, and the roller 206 and the arc groove 208 rolling fit.

[0073] When the left side of the crushing box 2 is driven, the right side roller 206 cooperates with the arc groove 208 to support and guide.

[0074] The electrical components mentioned above are all equipped with a power supply, and the control means and circuits are all prior art, and will not be described in detail herein.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com