Dispersion

A technology of liquid dispersion and dispersion medium, applied in the field of dispersion, which can solve the problems of increased chemical functionalization and negative effects of defect performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

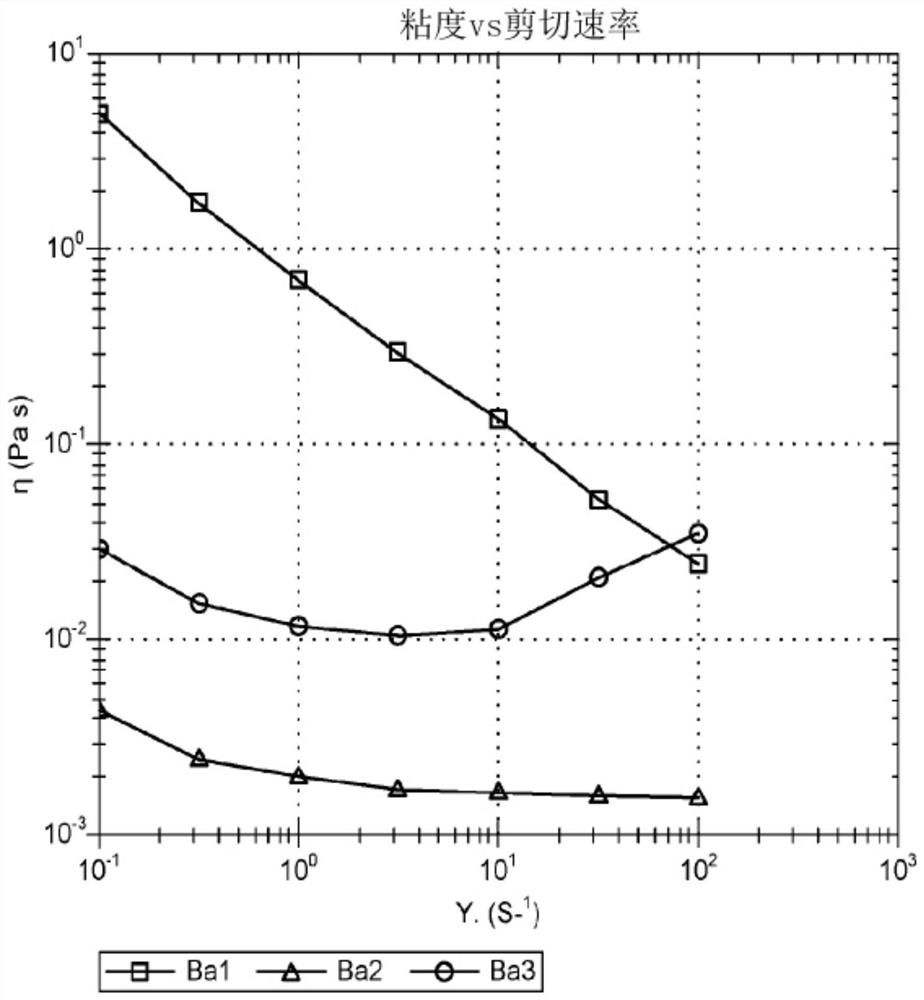

[0080] Example 1: Dispersion of graphite material A-GNP 10 in butyl acetate

[0081] As shown in Table 1, reference dispersion samples of BA1-BA3 were fabricated, including graphite material A-GNP10 and butyl acetate.

[0082] Table 1

[0083] reference sample Graphene / Graphite Materials grinding resin D solvent BA1 10wt% AGNP-10 - - Butyl acetate BA2 10wt% AGNP-10 - DISPERBYK-2150 Butyl acetate BA3 10wt% AGNP-10 Laropal A81 - Butyl acetate

[0084] Graphite material A-GNP10 is commercially available from Applied Graphene Materials UK Limited in the United Kingdom and comprises 25-35 layers of atomically thick graphene nanoplatelets. Graphite nanoplatelets are supplied in powder form and are usually aggregated into bulk nanoplatelets.

[0085] Each of samples BA1-BA3 were fabricated using the following steps:

[0086] 1 Add any grinding resins and / or wetting agents in the sample to the butyl acetate. Stir it unti...

example 2

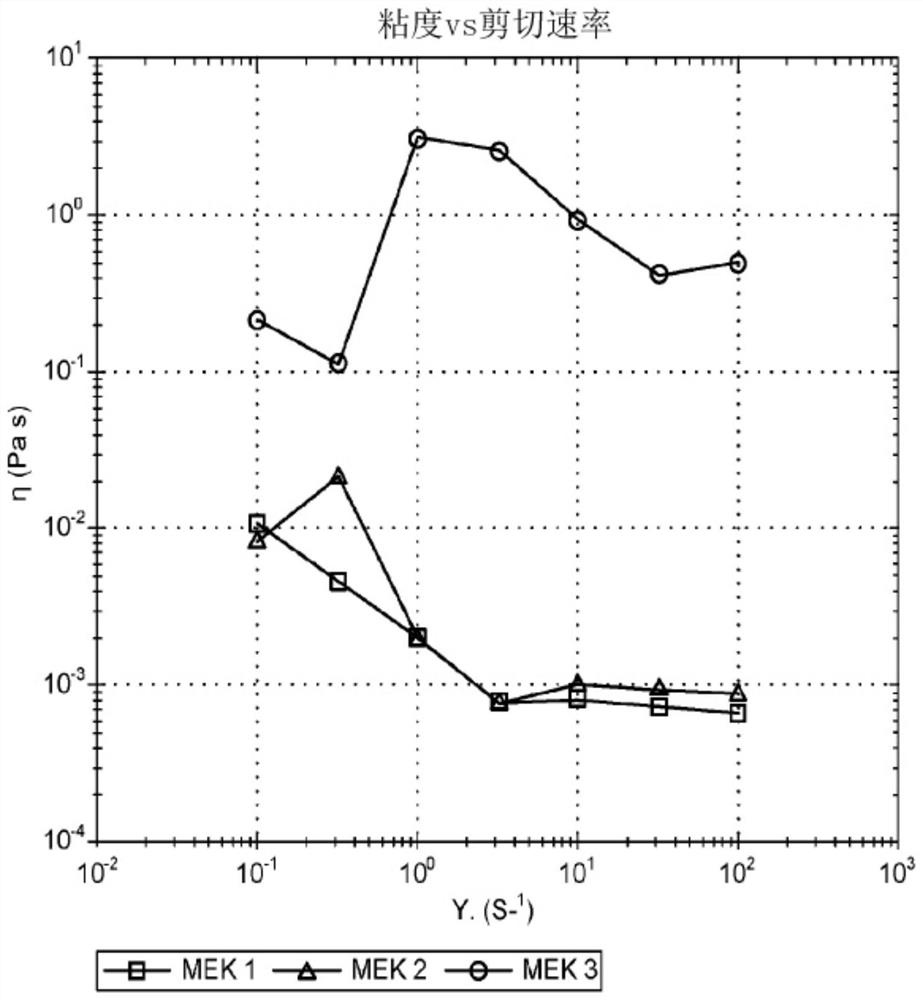

[0099] Example 2: Dispersion of graphite material A-GNP10 in methyl ethyl ketone

[0100] As shown in Table 6, reference dispersion samples of MEK1-MEK3 including graphite material A-GNP10 and methyl ethyl ketone were fabricated.

[0101] Table 6

[0102] reference sample Graphene / Graphite Materials grinding resin D solvent MEK1 10wt% AGNP-10 - - methyl ethyl ketone MEK2 10wt% AGNP-10 - DISPERBYK-2150 methyl ethyl ketone MEK3 10wt% AGNP-10 Laropal A81 - methyl ethyl ketone

[0103] Each of samples MEK1-MEK3 was fabricated using the same procedure set forth above in relation to samples BA1-BA3.

[0104] Table 7: Particle size distribution of MEK dispersions

[0105]

[0106] Table 8: Shear rate (v) for 10s at 23°C -1 Viscosity measurements of MEK dispersions produced when

[0107] reference sample GNP type Initial viscosity (Pa.s) MEK1 A-GNP10 0.000826 MEK2 A-GNP10 0.00104 ...

example 3

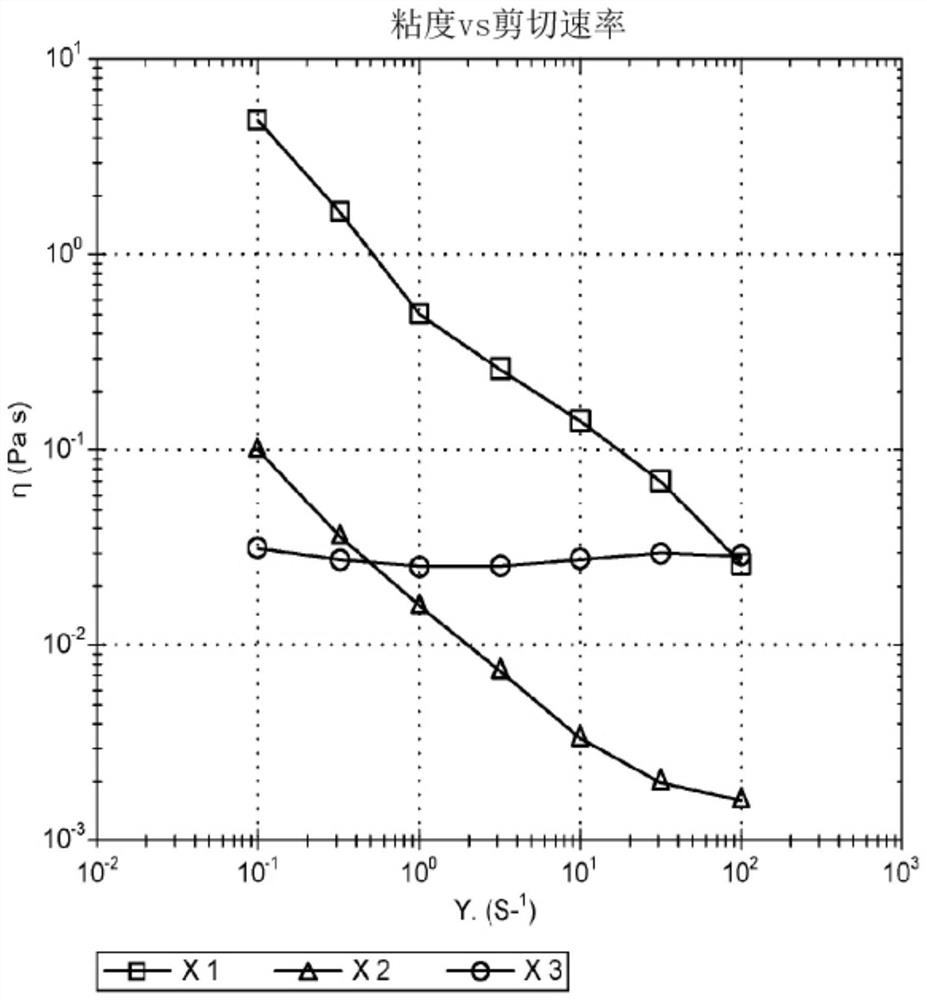

[0114] Example 3: Dispersion of graphite material A-GNP10 in xylene

[0115] As shown in Table 11, reference dispersion samples of X1-X3 were fabricated, including graphite material A-GNP10 and xylene.

[0116] Table 11

[0117] reference sample Graphene / Graphite Materials grinding resin D solvent X1 10wt% AGNP-10 - - Xylene X2 10wt% AGNP-10 - DISPERBYK-2150 Xylene X3 10wt% AGNP-10 Laropal A81 - Xylene

[0118] Each of samples X1-X3 was fabricated using the same procedure as stated above in relation to samples BA1-BA3.

[0119] Table 12: Particle Size Distribution of Xylene Dispersions

[0120]

[0121] Table 13: Shear rate (v) for 10s at 23°C -1 Viscosity measurements of MEK dispersions produced when

[0122] reference sample GNP type Initial viscosity (Pa.s) X1 A-GNP10 0.1453 X2 A-GNP10 0.00337 X3 A-GNP10 0.2846

[0123] image 3 A graph showing the relationship betw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com