Method for exploiting shale gas by utilizing biomass energy heat power

A technology of biomass energy and shale gas, which is applied in the direction of exploitation fluid, earthwork drilling, wellbore/well components, etc., can solve the problems of environmental pollution and high mining cost, and achieve improved recovery, avoid accumulation and pollution, The effect of high recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

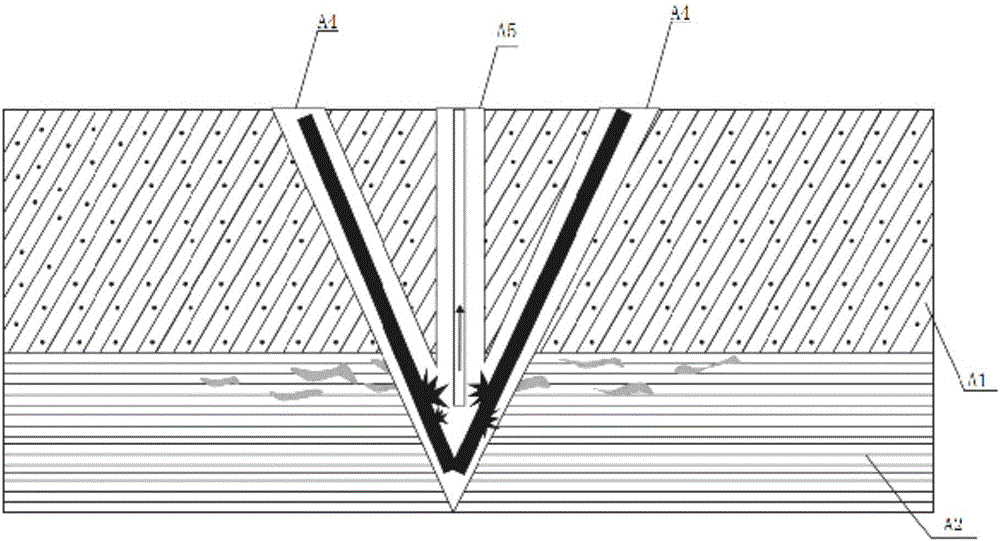

[0051] A method for thermally exploiting shale gas using biomass energy, the method is to set two inclined injection wells A4 and a vertical collection well A5 in the underlying sandstone layer A1 and shale layer A2 to be exploited, and the three wells The bottoms are connected directly together. Inject fuel, combustion accelerant, ignition agent respectively in two injection wells A4, and ignite described fuel, then obtain shale gas in collecting well A5, described fuel is biomass pellet material, and this biomass pellet material is A kind of granular fuel made by pressing dry raw materials such as rotten wood slag, sawdust, wood powder, straw, corn stalks in the mountains and forests through an outdoor biomass pellet manufacturing machine. The combustion enhancer is air, and the ignition agent is Industrial paraffin.

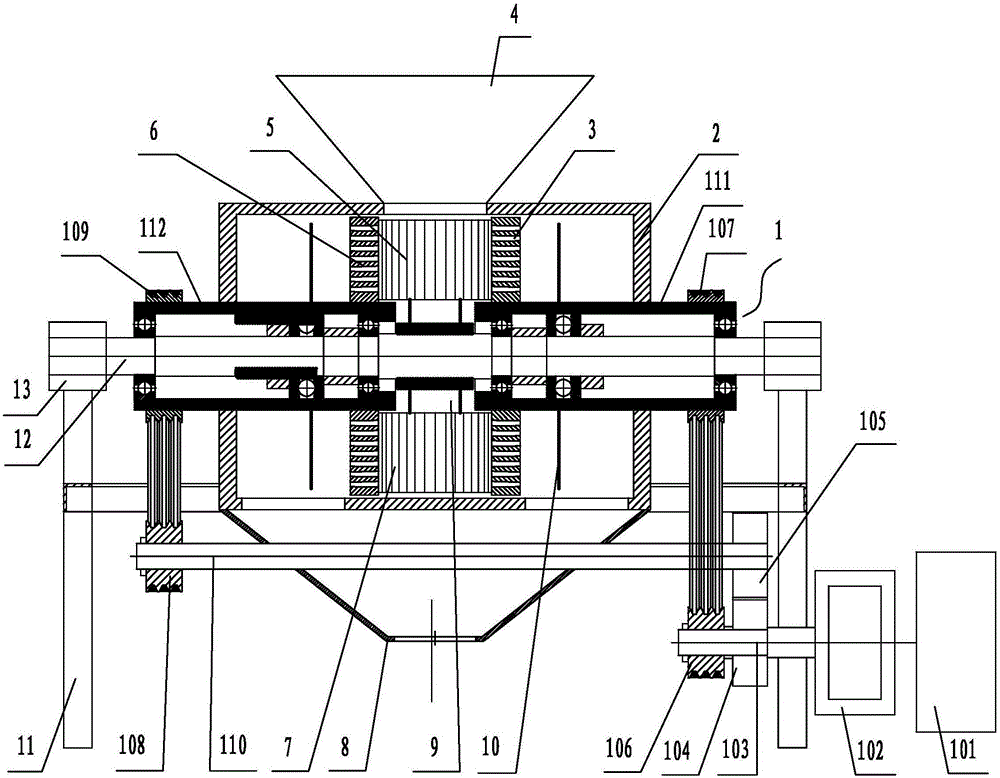

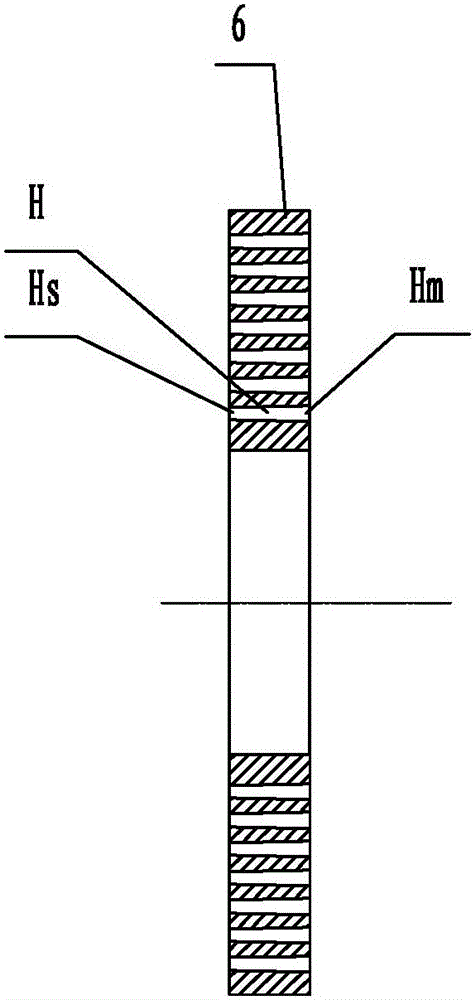

[0052] The biomass particle manufacturing machine in the field includes a power transmission mechanism 1, a casing 2, a base frame 11, a main shaft 12, a chu...

Embodiment 2

[0066] A method for thermally exploiting shale gas using biomass energy, the method is basically the same as that of Embodiment 1, the difference is that: the method is to set two vertical wells in the underlying sandstone layer A1 and shale layer A2 to be mined Injection well A4 and a vertical collection well A5, the bottom of the three wells are connected together by a horizontal well.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com