Swirl type cooling system of sleeve limekiln

A sleeve lime kiln and cooling system technology, which is applied in lime production and other fields, can solve problems such as poor cooling effect and uneven distribution of cooling air, and achieve the effects of improving quality, saving energy and reducing consumption, and eliminating air flow deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

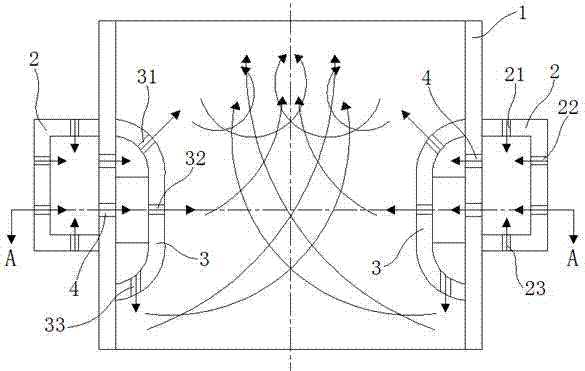

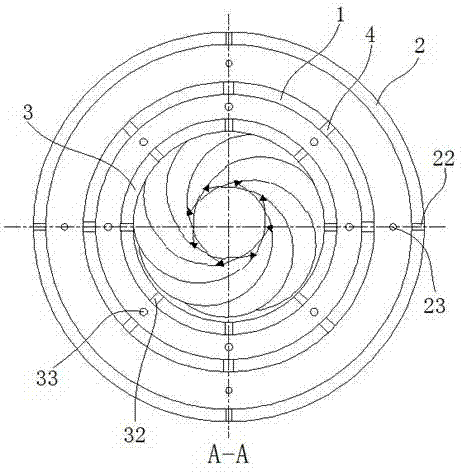

[0028] to combine figure 1 and figure 2 , a vortex cooling system of a sleeve lime kiln in this embodiment, comprising a kiln body cooling section 1, an outer wind box 2 and an inner wind box 3, wherein: the outer wind box 2 is located outside the kiln body cooling section 1, and the inner wind box 3 is located Inside the kiln body cooling section 1, the above-mentioned outer air box 2 and inner air box 3 are communicated through the air passage hole 4 on the side wall of the kiln body cooling section 1. The air passage hole 4 in the present invention is a circle with a diameter of 140-160 mm. In this embodiment, its diameter is 150 mm, and the above-mentioned air passage holes 4 are annularly distributed 16 around the side wall of the kiln body cooling section 1, and the center lines of all air passage holes 4 are horizontally arranged, and the center lines intersect In the center of the kiln body cooling section 1; in this embodiment, the contact span between the inner ai...

Embodiment 2

[0032] The structure of this embodiment is the same as that of Embodiment 1, the difference being that the number of upper air inlet holes 21, side air inlet holes 22 and lower air inlet holes 23 distributed circularly on the outer bellows 2 in this embodiment is 6, of which The diameters are all 80 mm; in this embodiment, there are 8 air passage holes 4 arranged in a circle, and their diameters are 160 mm; in this embodiment, the upper air outlet 31, the side air outlet 32 and the lower air outlet are annularly distributed on the inner bellows 3. The quantity of hole 33 is 6, and last air outlet hole 31 diameters are 40mm, and the included angle of its center line direction and horizontal line is 60 °, and side air outlet hole 32 diameters are 80mm, and lower air outlet holes 33 diameters are 120mm.

Embodiment 3

[0034] The structure of this embodiment is the same as that of Embodiment 1, except that the number of upper air inlet holes 21, side air inlet holes 22 and lower air inlet holes 23 distributed circularly on the outer bellows 2 in this embodiment is 30. The diameters are all 60 mm; in this embodiment, there are 20 air passage holes 4 arranged in a circle, and their diameter is 140 mm; in this embodiment, the upper air outlet 31, the side air outlet 32 and the lower air outlet are annularly distributed on the inner bellows 3. The quantity of hole 33 is 20, and last air outlet hole 31 diameters are 20mm, and the included angle of its center line direction and horizontal line is 30 °, and side air outlet hole 32 diameters are 60mm, and lower air outlet holes 33 diameters are 100mm.

[0035] Through the actual production verification, the lime kiln using the cooling system of Examples 1-3 has an energy consumption of 850-900 KCal / kg, an ash discharge temperature of 80-90°C, and a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com