Cable crushing copper-plastic separation device

A separation device, copper-plastic technology, applied in circuits, electrical components, electronic waste recycling and other directions, can solve the problems of low separation efficiency, safety and hidden dangers of hook type cable cutters, and achieve the effect of improving separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

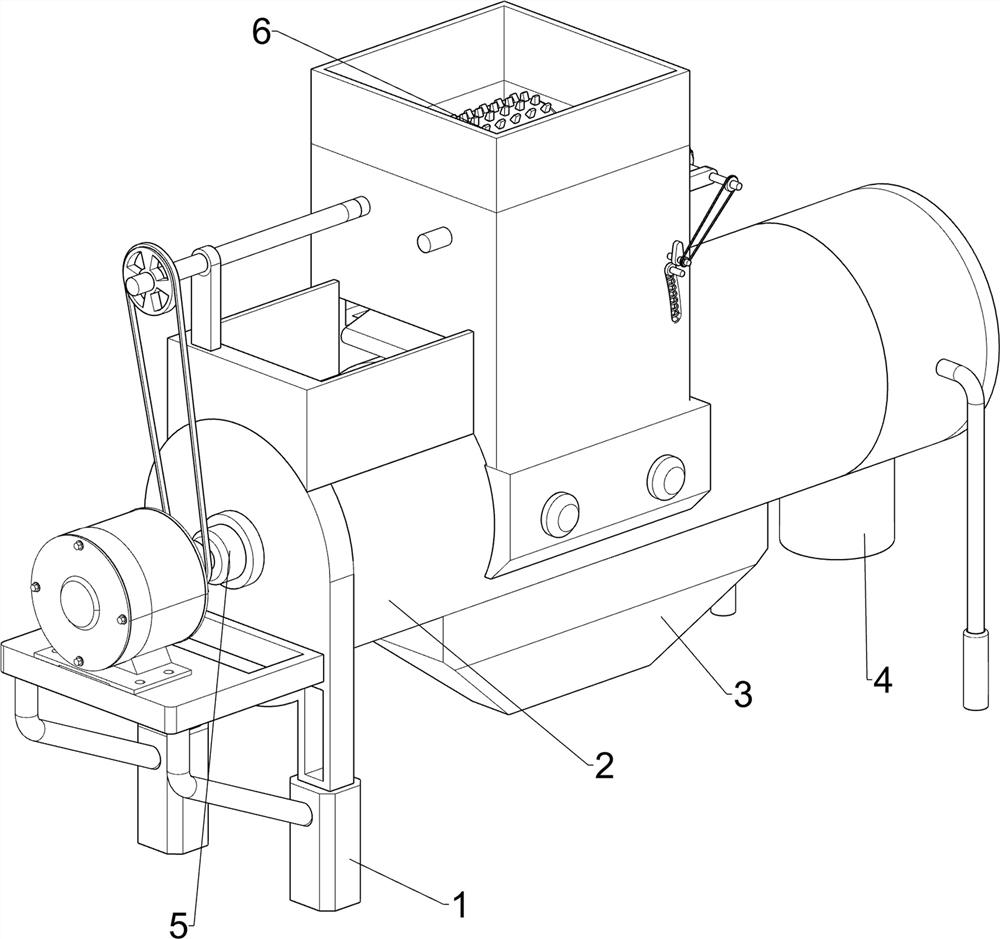

[0024] Such as figure 1 , figure 2 and image 3 As shown, a copper-plastic separation device for cable crushing includes a first bearing seat 1, a cylinder 2, a discharge box 3, a discharge pipe 4, a separation mechanism 5 and a crushing mechanism 6, and the upper side of the first bearing seat 1 is set There is a cylinder 2, a discharge box 3 is provided on the lower side of the middle part of the cylinder 2, a discharge pipe 4 is provided on the lower side of the cylinder 2 away from the first bearing seat 1, and a separation mechanism 5 is provided on the first bearing seat 1. The cylinder 2 is provided with a crushing mechanism 6 .

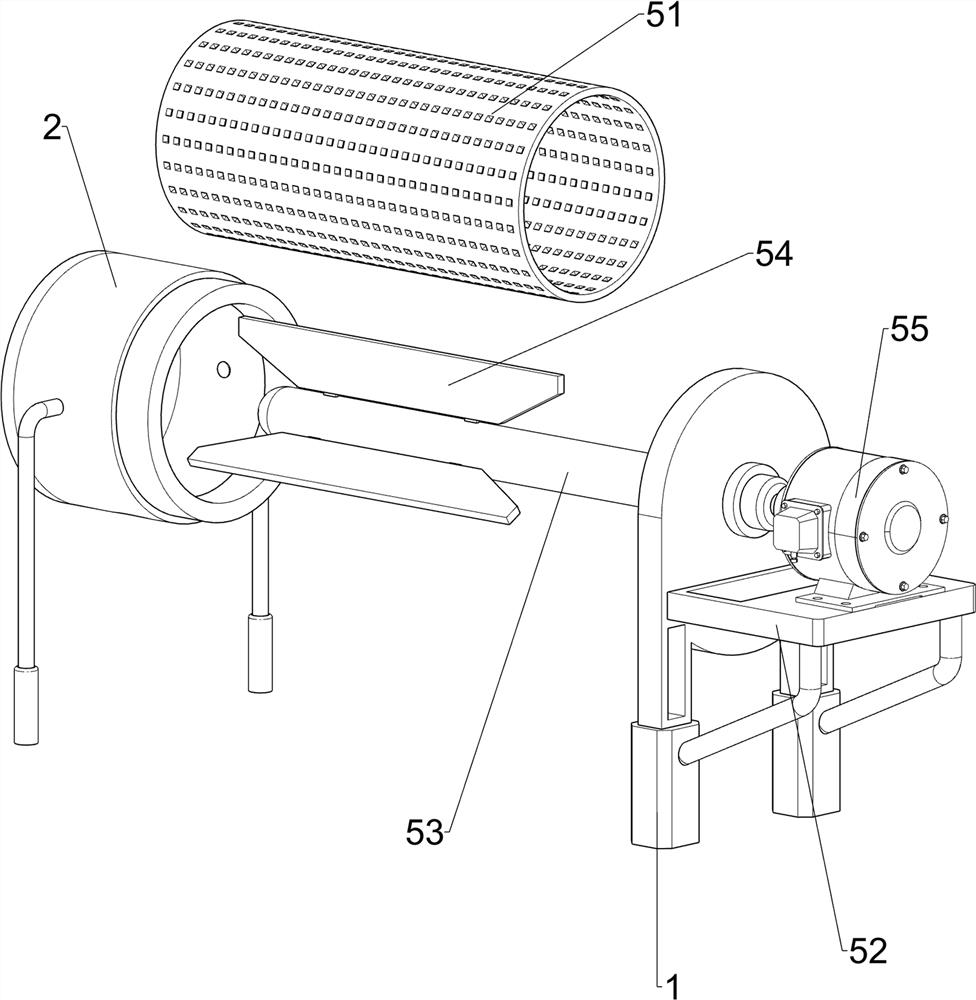

[0025] The separation mechanism 5 includes a circular tube 51, a support plate 52, a first rotating shaft 53, a fan blade 54 and a servo motor 55. The circular tube 51 is arranged in the cylinder 2, and small holes are evenly spaced on the tube wall of the circular tube 51. A support plate 52 is provided on the left side of the first beari...

Embodiment 2

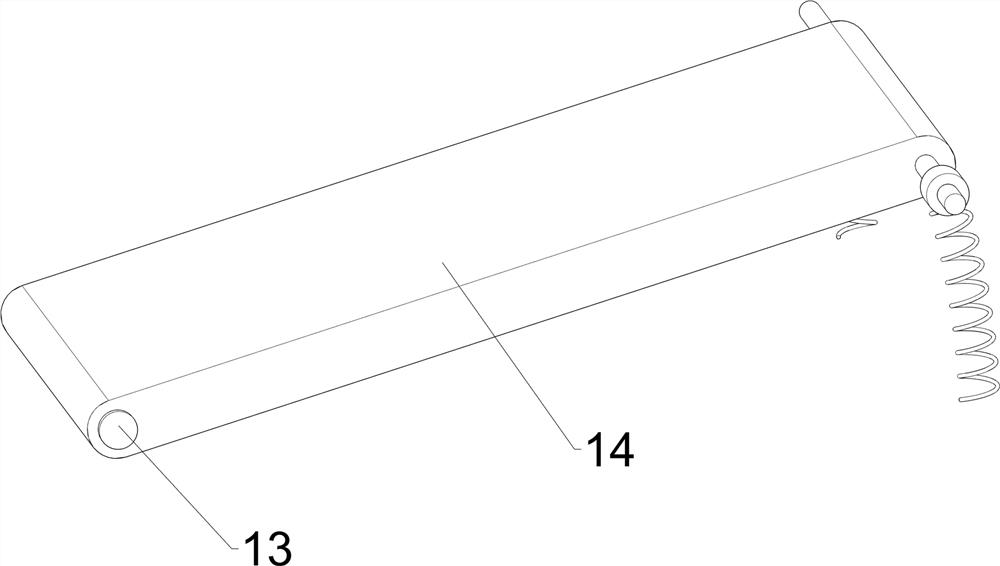

[0029] Such as Figure 4 , with 5 and Figure 6 As shown, on the basis of Embodiment 1, a copper-plastic separation device for cable crushing also includes a third bearing seat 7, a fourth rotating shaft 8, a bevel gear 9, a fifth rotating shaft 10, a cam 11, and a second belt transmission Mechanism 12, the sixth rotating shaft 13, blanking plate 14, slide bar 15 and elastic member 16, the third bearing seat 7 is arranged symmetrically front and back on the right box wall of the blanking box 61, and is provided with between the two third bearing seats 7 The fourth rotating shaft 8, a bevel gear 9 is arranged between the right end of the second rotating shaft 62 on the front side and the adjacent position of the fourth rotating shaft 8, and the two bevel gears 9 mesh with each other, and the right side of the middle part of the box wall on both sides of the front and rear sides of the feeding box 61 is rotated. The fifth rotating shaft 10 is provided with the fifth rotating sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com