Coating mixing equipment

A technology for mixing equipment and coatings, which is applied to mixers, mixers with rotating stirring devices, mixer accessories, etc., can solve the problems of increasing the difficulty of use and not solving the problem of raw material feeding and accumulation, and achieves simple structure, accelerated feeding, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

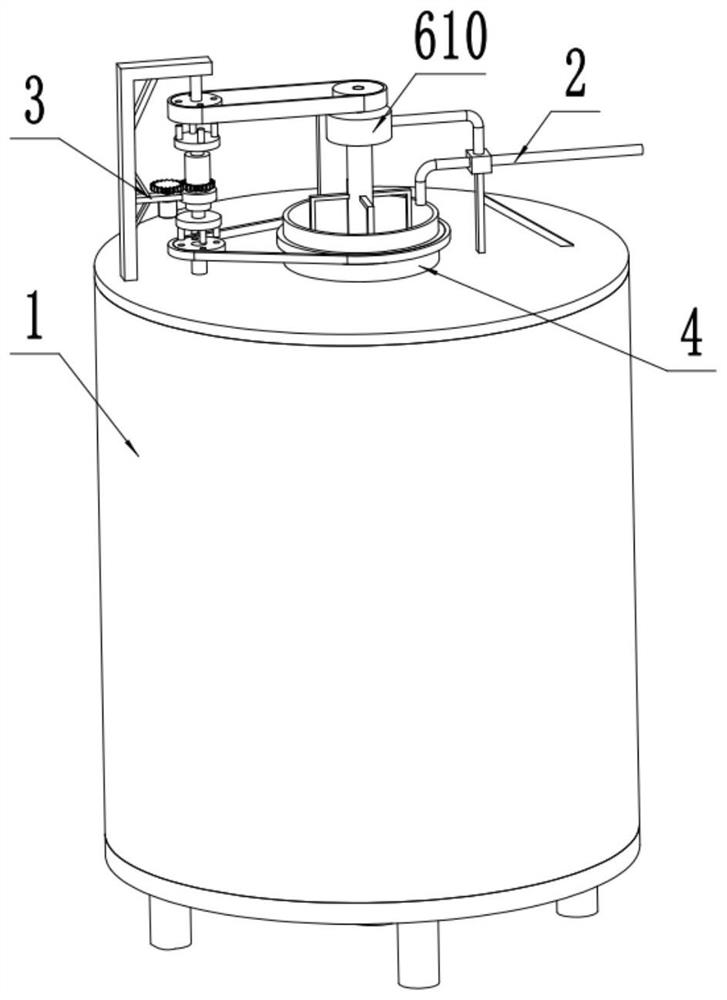

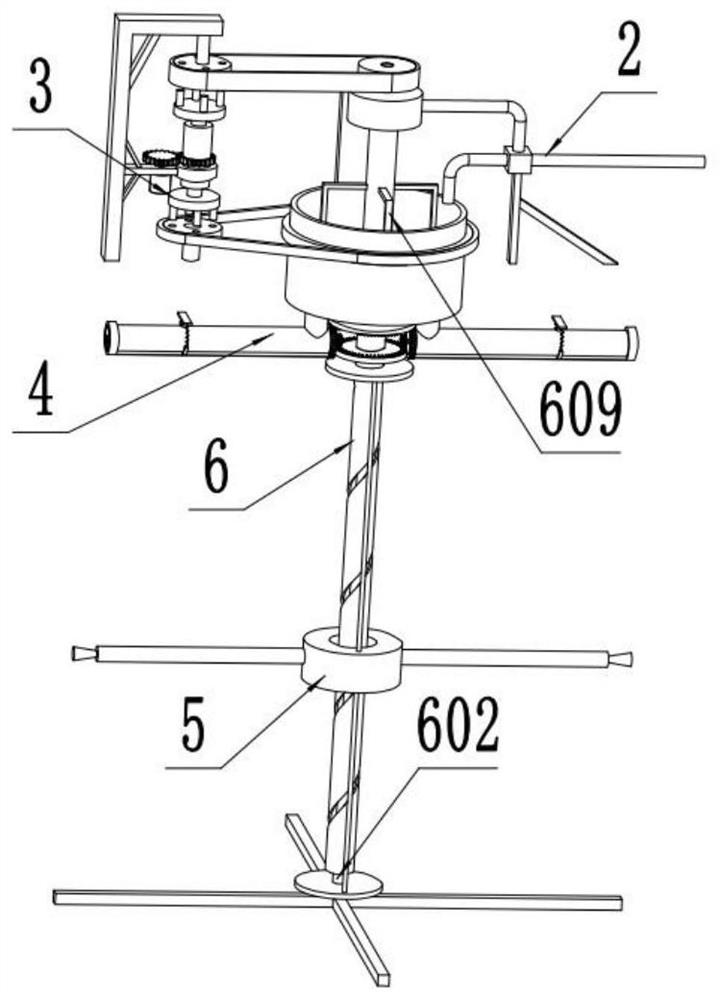

[0033] Example: as figure 1 — Figure 11 The shown paint mixing equipment includes a paint drum 1 , a water pipe 2 , a power mechanism 3 , a feeding mechanism 4 , a stirring mechanism 5 , and a guiding mechanism 6 . The water pipe 2 is fixedly installed on the paint cartridge 1 .

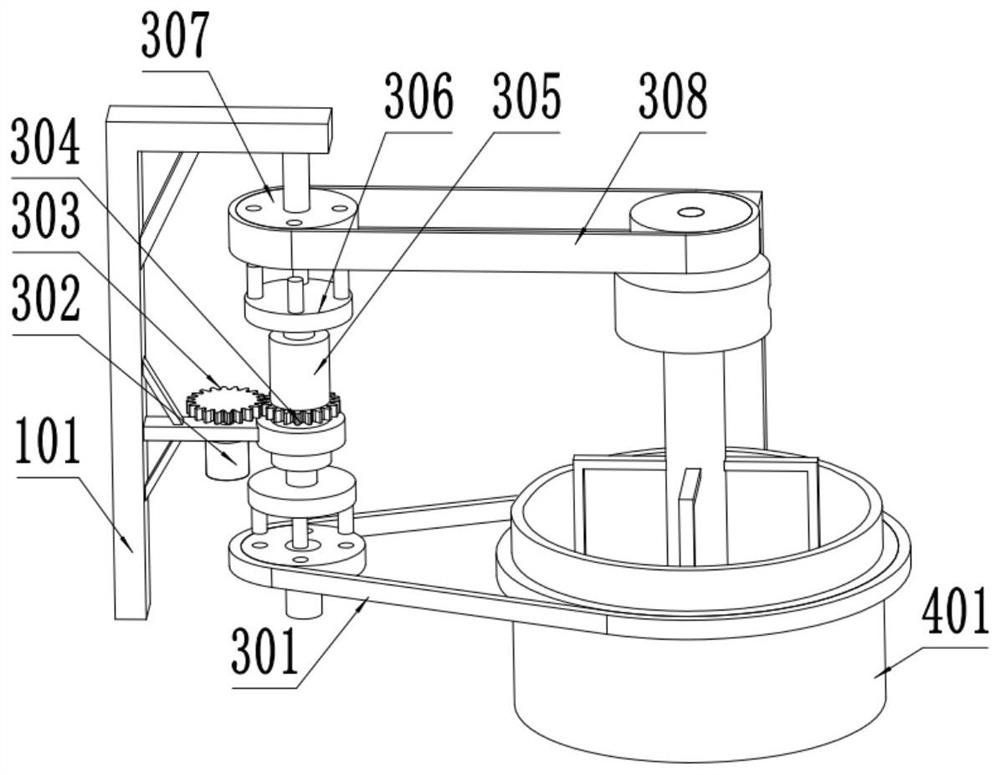

[0034] Specifically, a straight rod 101 is provided above the paint cylinder 1; the water pipe 2 has a water inlet and two water outlets, the water inlet is used for water inlet, and a water outlet is connected to the water tank 610, and the water tank 610 is fixedly installed on the upper end of the central pipe 601, The other water outlet is located above the feeding barrel 401 .

[0035] The power mechanism 3 is installed on the paint drum 1, and the power mechanism 3 is used to drive the unloading mechanism 4 and the guide mechanism 6 to rotate. The power mechanism 3 includes a bidirectional electric cylinder 305. The bidirectional electric cylinder 305 is rotatably installed above the paint ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com