Building paint powder ingredient grinding device

A technology of architectural coatings and grinding devices, which is applied in the field of construction, can solve the problems of affecting the processing site environment, architectural coating powder scattering, and adjusting grinding output, so as to protect the processing site environment, prevent retention, and speed up material discharge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical scheme of this patent is described in further detail below in conjunction with specific embodiments

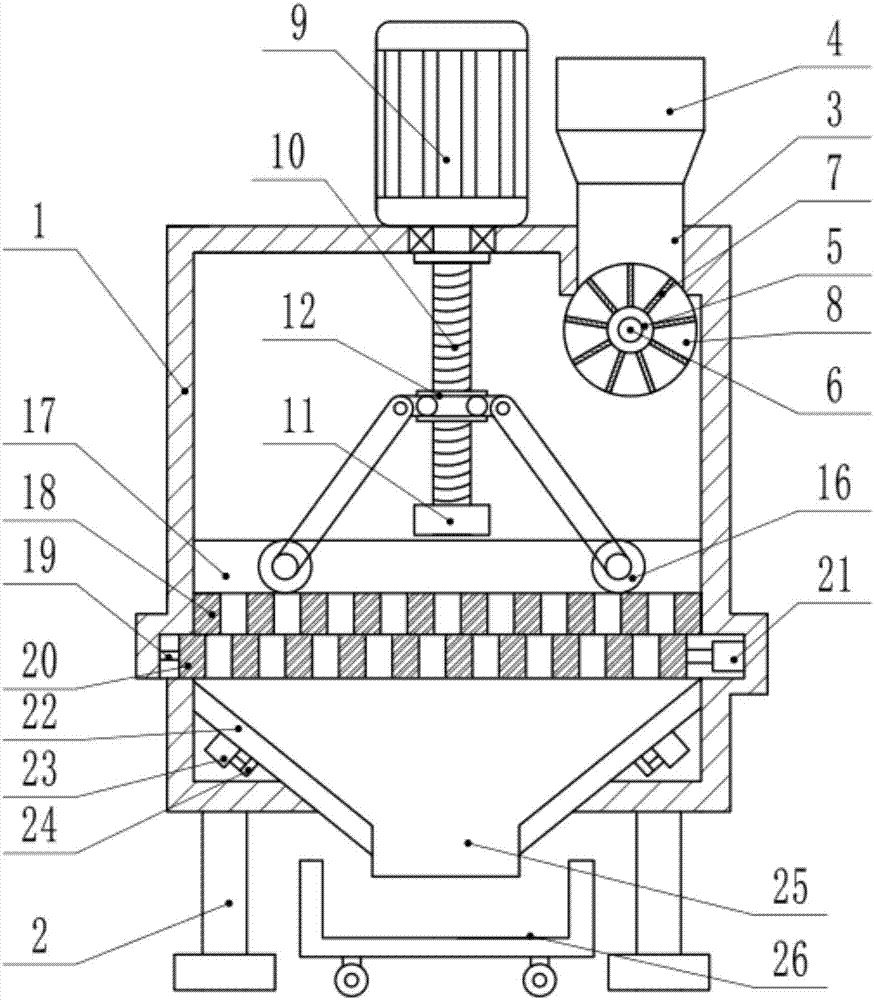

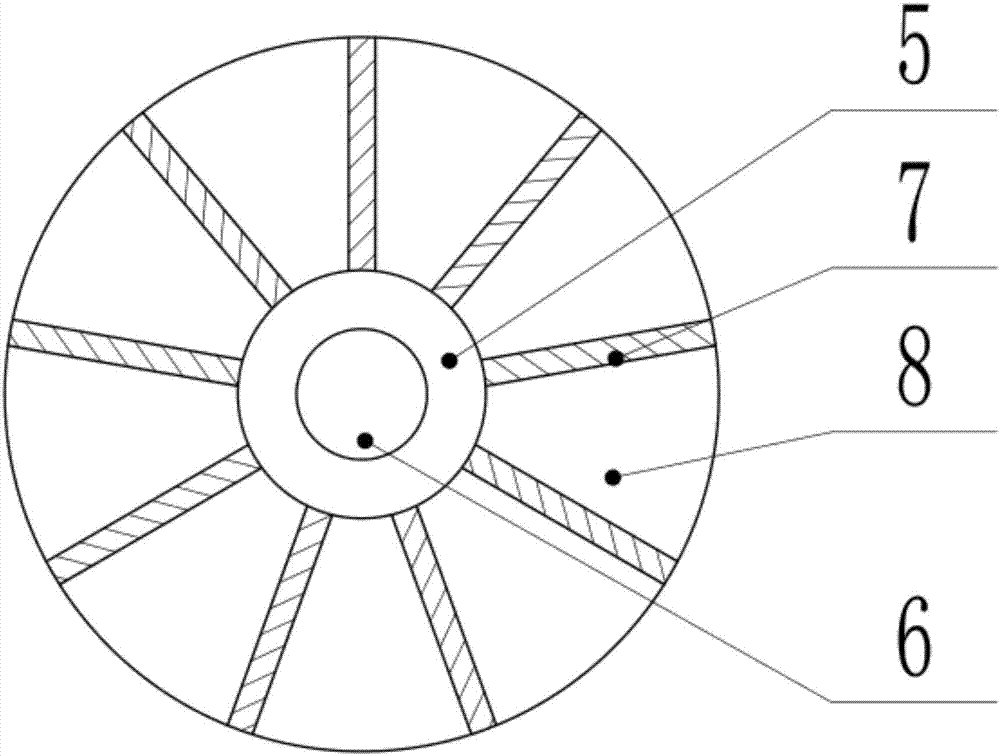

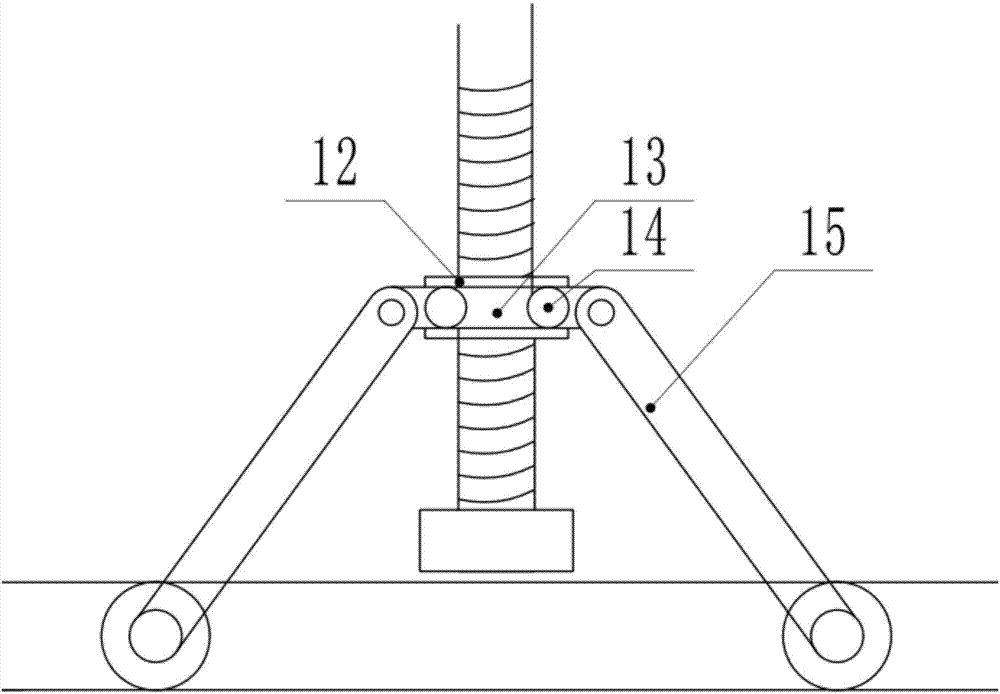

[0023] see Figure 1-5 , a kind of architectural paint powder batching grinding device, comprising casing 1, feeding funnel 4, first driving motor 9, screw mandrel 10, sliding sleeve 12, connecting rod 15, grinding roller 16, grinding table 17, fixed sieve plate 18 , a slide bar 19, a second drive motor 23 and a vibrating hammer 24, the lower side of the casing 1 is fixedly equipped with a leg 2, at least two groups of legs 2 are arranged, and a fixed base is installed at the lower end of the leg 2, so that the device is more stable when working The upper side of the casing 1 is provided with a feed inlet 3, a feed funnel 4 is installed on the feed inlet 3, a windproof device 5 is installed below the feed inlet 3, and the windproof device 5 is arranged inside the casing 1, A rotating shaft 6 is fixedly installed inside the casing 1, and the windproof devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com