Efficient rapid dissolving equipment for rare earth production

A high-efficiency, rare-earth technology, applied in the direction of dissolving, dissolving, driving agitator to dissolve, etc., can solve the problems of no layered, framed and chained structures, long time, lack of sulfides and sulfates, etc., to achieve improved stirring Effect, Ease of Dissolution, Effect of Accelerated Dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

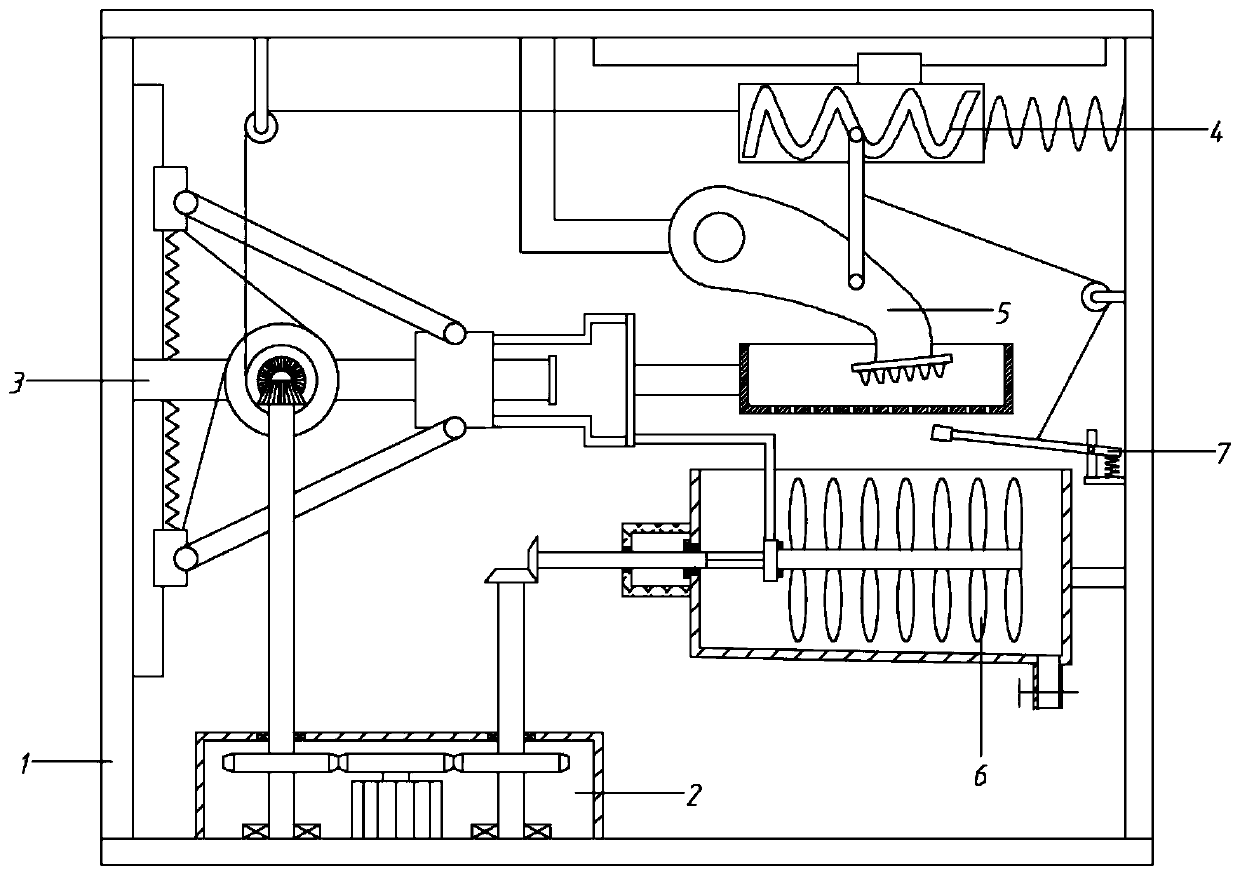

[0061] A high-efficiency rapid dissolution equipment for rare earth production, including a frame 1, a driving assembly 2, a reciprocating assembly 3, a transmission assembly 4, a crushing assembly 5, and a dissolving assembly 6;

[0062] The frame 1 includes a base 101, a left side plate 102, a right side plate 103 and a top plate 104. The left and right sides of the base 101 are fixedly connected with a left side plate 102 and a right side plate 103 respectively, and the top of the left side plate 102 and the right side plate 103 pass through the top plate 104 connection; the left part of the base 101 is provided with a driving assembly 2, and the right side of the left side plate 102 is provided with a reciprocating assembly 3, and the driving assembly 2 cooperates with the reciprocating assembly 3; The feeding hole 106; the pulverization assembly 5 is arranged above the pulverization tank 105, and the pulverization assembly 5 cooperates with the reciprocating assembly 3 thr...

Embodiment 2

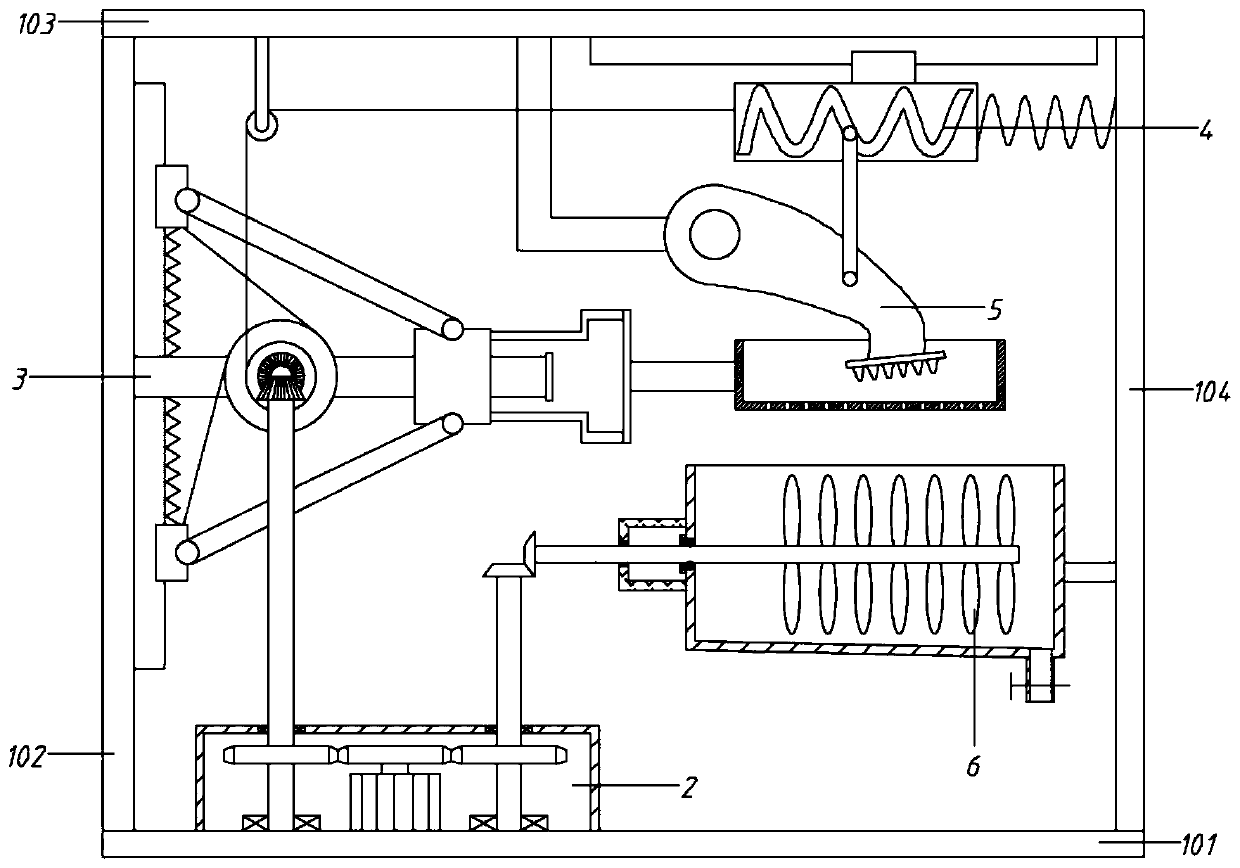

[0064] A high-efficiency rapid dissolution equipment for rare earth production, including a frame 1, a driving assembly 2, a reciprocating assembly 3, a transmission assembly 4, a crushing assembly 5, and a dissolving assembly 6;

[0065] The frame 1 includes a base 101, a left side plate 102, a right side plate 103 and a top plate 104. The left and right sides of the base 101 are fixedly connected with a left side plate 102 and a right side plate 103 respectively, and the top of the left side plate 102 and the right side plate 103 pass through the top plate 104 connection; the left part of the base 101 is provided with a driving assembly 2, and the right side of the left side plate 102 is provided with a reciprocating assembly 3, and the driving assembly 2 cooperates with the reciprocating assembly 3; The feeding hole 106; the pulverization assembly 5 is arranged above the pulverization tank 105, and the pulverization assembly 5 cooperates with the reciprocating assembly 3 thr...

Embodiment 3

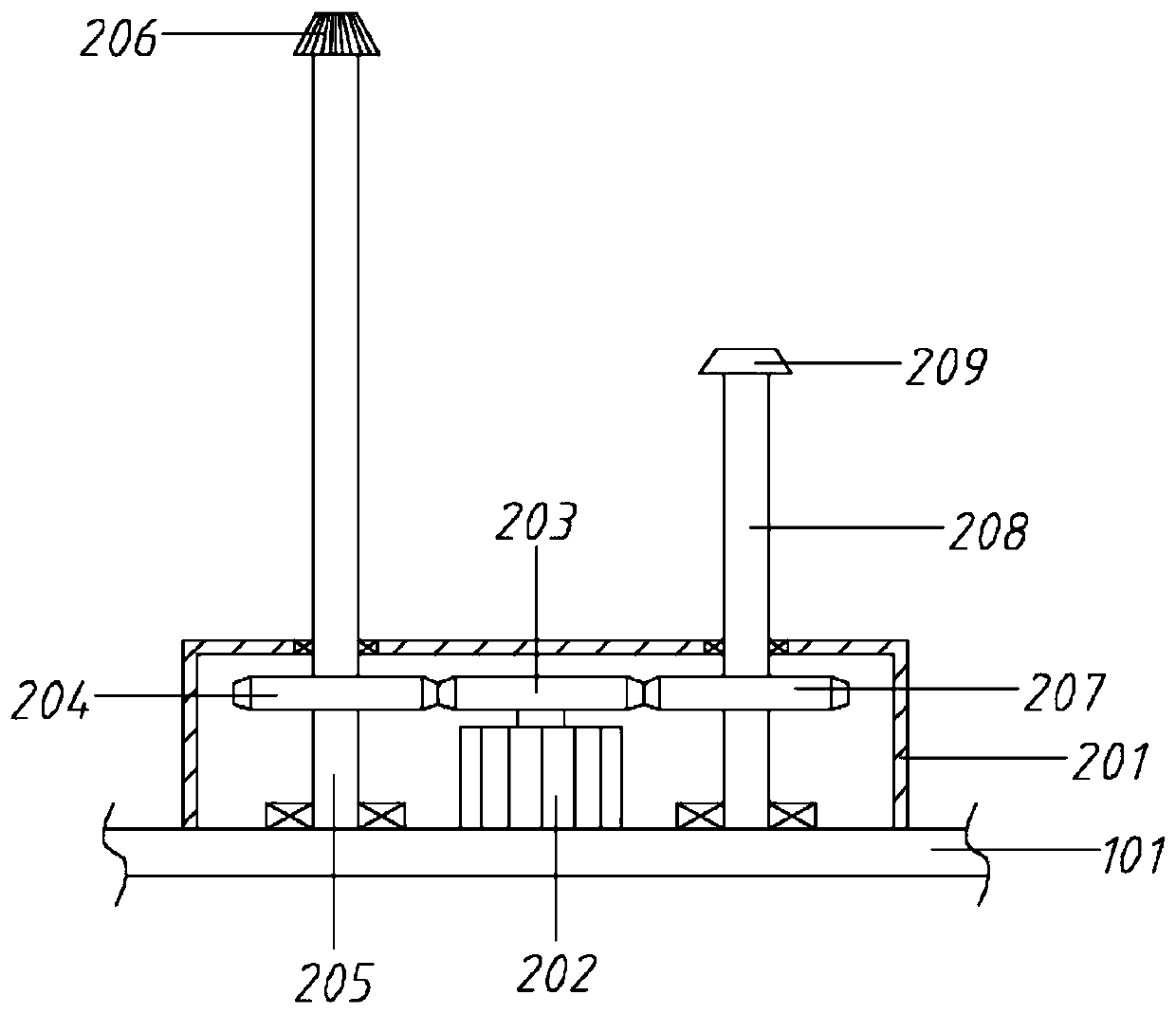

[0082] The difference from Example 2 is that

[0083] Among them, the dissolving assembly 6 includes the fourth bevel gear 601, the third rotating shaft 602, the first support plate 604, the third connecting rod 605, the installation plate 606, the outer cylinder 607 and the stirring blade 608;

[0084] The left side of the dissolution box 108 is fixedly connected with a No. 1 support plate 604; the dissolution box 108 is provided with an outer cylinder 607, and the outer cylinder 607 is evenly equipped with stirring blades 608; The No. 4 bevel gear 601 is installed on the left end of the No. 3 rotating shaft 602, and the No. 4 bevel gear 601 and the No. 2 bevel gear 209 are vertically meshed; the No. 3 rotating shaft 602 includes a circular shaft section on the left 6021 and the special-shaped shaft section 6022 on the right. The circular shaft section 6021 passes through the No. 1 support plate 604 and extends into the dissolution tank 108 from the left side.

[0085] Where...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com