Chopping and mixing device for vegetable and fruit enzyme production

A mixing device and a technology for vegetable and fruit enzymes, which are applied in the field of chopping and mixing devices for vegetable and fruit enzyme production, can solve the problems of uneven stirring, large stirring resistance, large particles, etc., so as to improve the uniformity, enhance the turbulent stirring effect, improve the The effect of mixing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

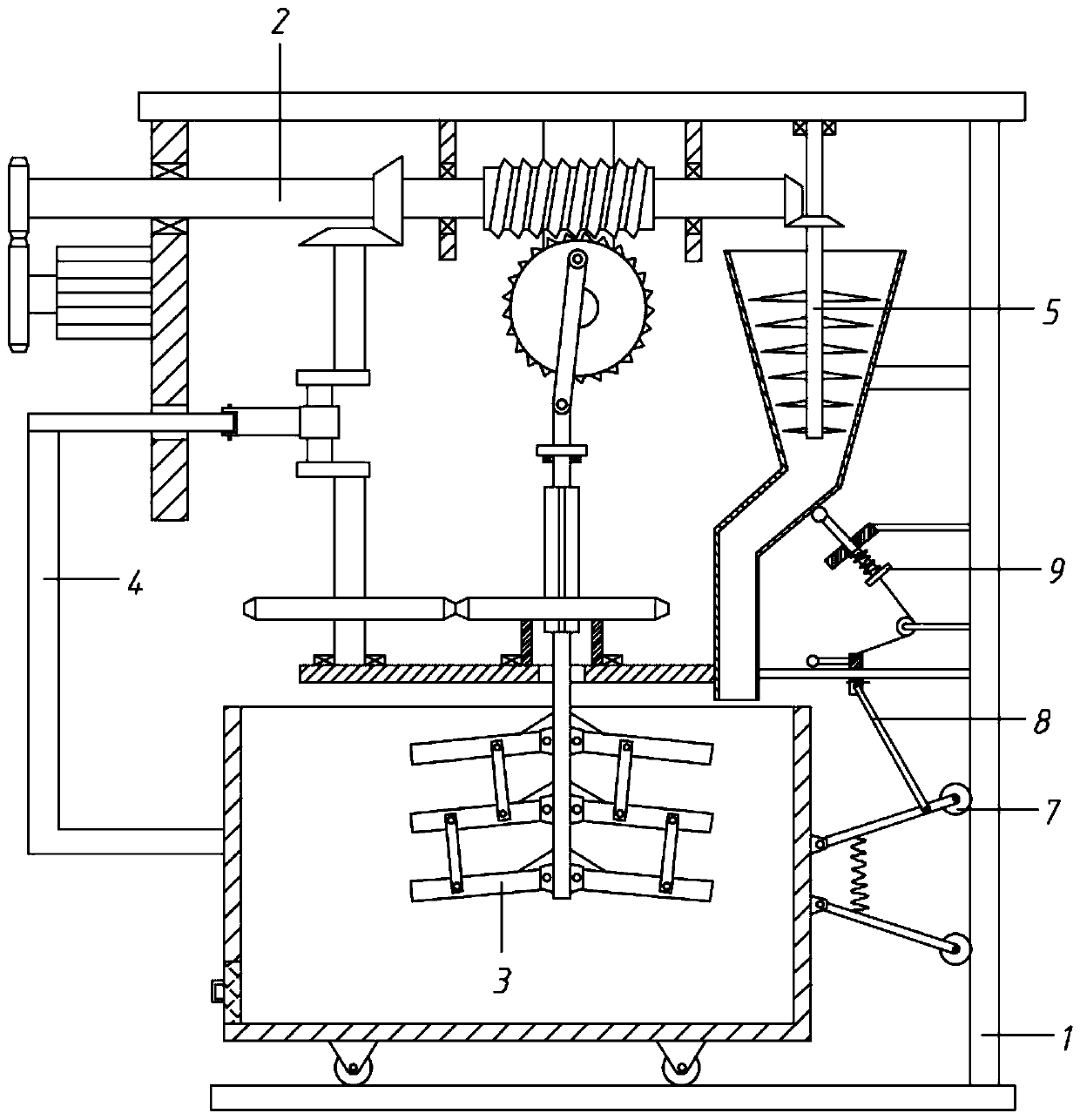

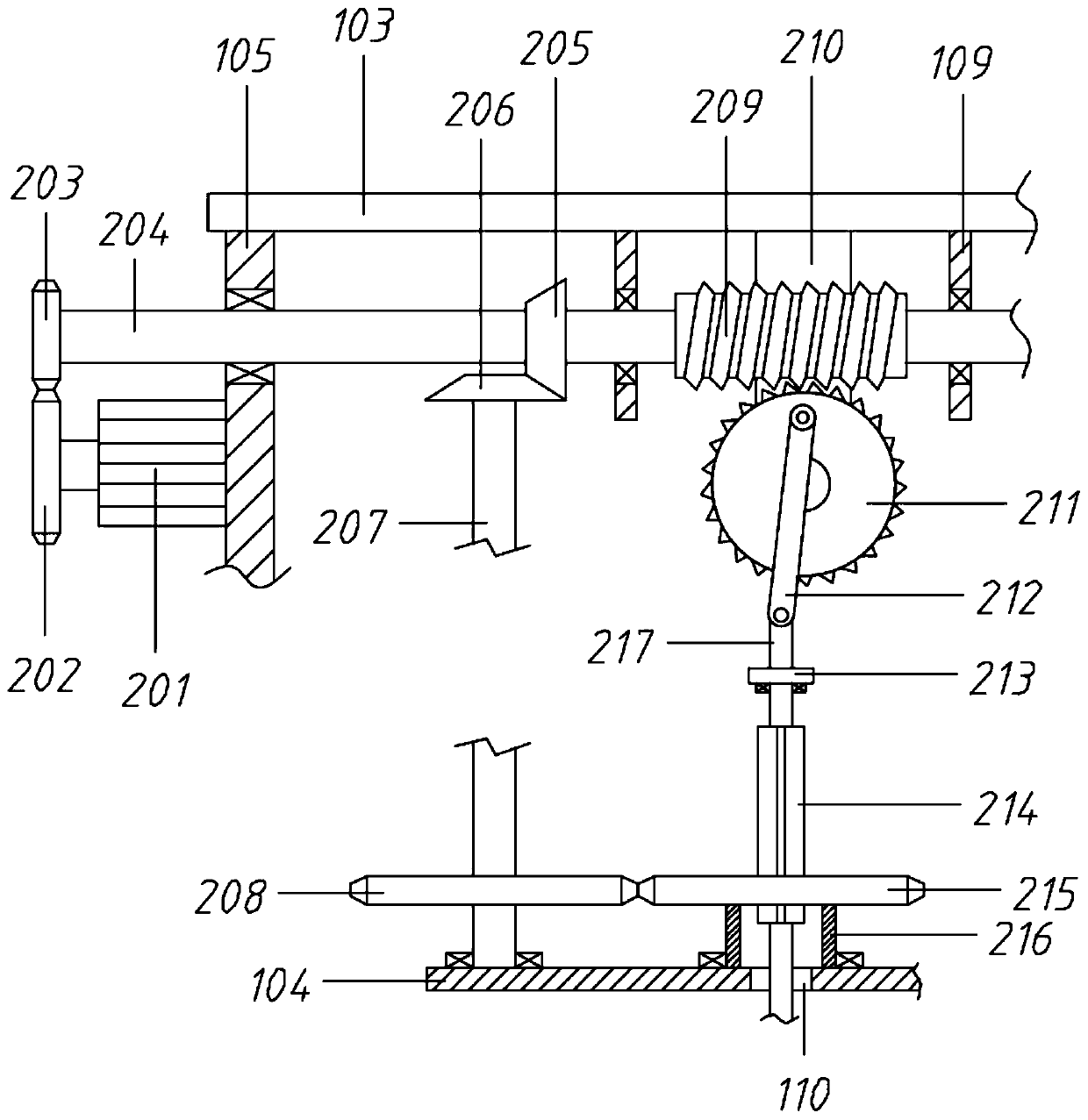

[0063] A chopping and mixing device for the production of fruit and vegetable enzymes, comprising a frame 1, a driving component 2, a stirring component 3, a push-pull component 4, and a crushing component 5;

[0064] The frame 1 includes a base 101, a side plate 102, a top plate 103, a horizontal support plate 104, a vertical support plate 105, a barrel 106, and a mixing box 107. The right end of the base 101 is fixed with a vertical side plate 102, and the middle of the side plate 102 is on the left The side is connected by a sliding rod 112 with a horizontal support plate 104, the top is connected with a top plate 103 to the left, and the right end of the side plate 102 is downwardly connected with a vertical support plate 105; a drive assembly 2 is provided between the top plate 103 and the horizontal support plate 104; A mixing box 107 is provided under the supporting plate 104. The bottom of the left side wall of the mixing box 107 is provided with a discharge port, and the ...

Embodiment 2

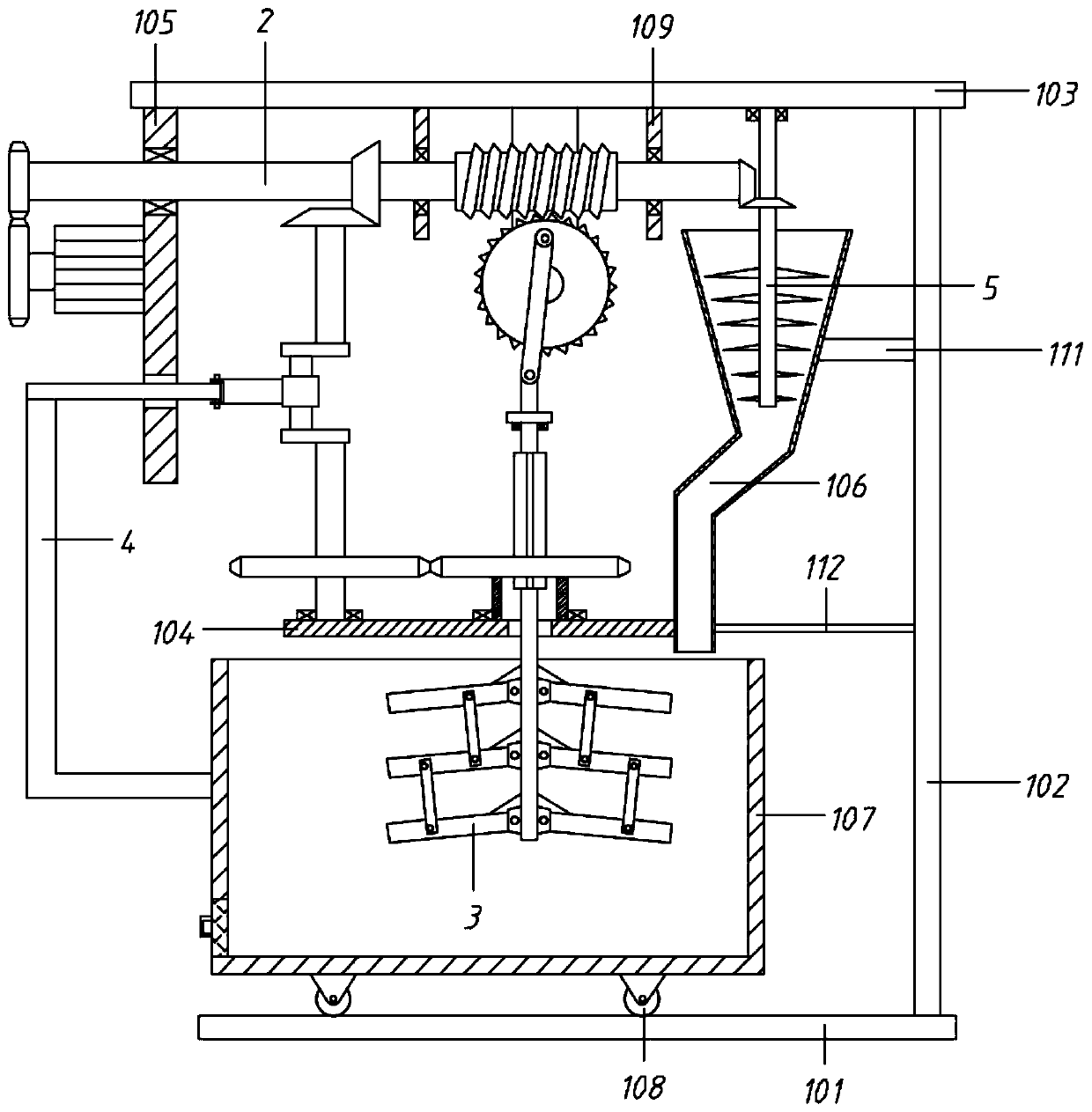

[0066] A chopping and mixing device for the production of fruit and vegetable enzymes, comprising a frame 1, a driving component 2, a stirring component 3, a push-pull component 4, and a crushing component 5;

[0067] The frame 1 includes a base 101, a side plate 102, a top plate 103, a horizontal support plate 104, a vertical support plate 105, a barrel 106, and a mixing box 107. The right end of the base 101 is fixed with a vertical side plate 102, and the middle of the side plate 102 is on the left The side is connected by a sliding rod 112 with a horizontal support plate 104, the top is connected with a top plate 103 to the left, and the right end of the side plate 102 is downwardly connected with a vertical support plate 105; a drive assembly 2 is provided between the top plate 103 and the horizontal support plate 104; A mixing box 107 is arranged under the supporting plate 104. The bottom of the left side wall of the mixing box 107 has a discharge port. The discharge port is...

Embodiment 3

[0083] On the basis of Example 2,

[0084] It also includes a buffer assembly 7; the buffer assembly 7 is installed on the right side of the mixing box 107, and includes a rotating rod 701, a second type roller 702 and a third spring 703;

[0085] Two rotating rods 701 are arranged symmetrically up and down, and they are connected by a No. 3 spring 703; the left end of the rotating rod 701 is hinged with the mixing box 107, and the right end is equipped with a second type roller 702, and the second type roller 702 is in rolling contact with the side plate 102.

[0086] Specifically, while the stirring box 107 moves left and right, the rotating rod 701 is subjected to pressure and spring action to make an opening and closing movement to provide a buffer from the right side of the stirring box 107.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com