Impurity separator for rare earth permanent magnetic materials for civil engineering

A technology of rare earth permanent magnet and civil engineering, which is applied in the direction of solid separation, filter screen, grid, etc., can solve the problems of poor corrosion resistance, waste of rare earth resources, loss of magnetic properties, etc., achieve simple and convenient operation, improve crushing effect, and accelerate The effect of feeding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

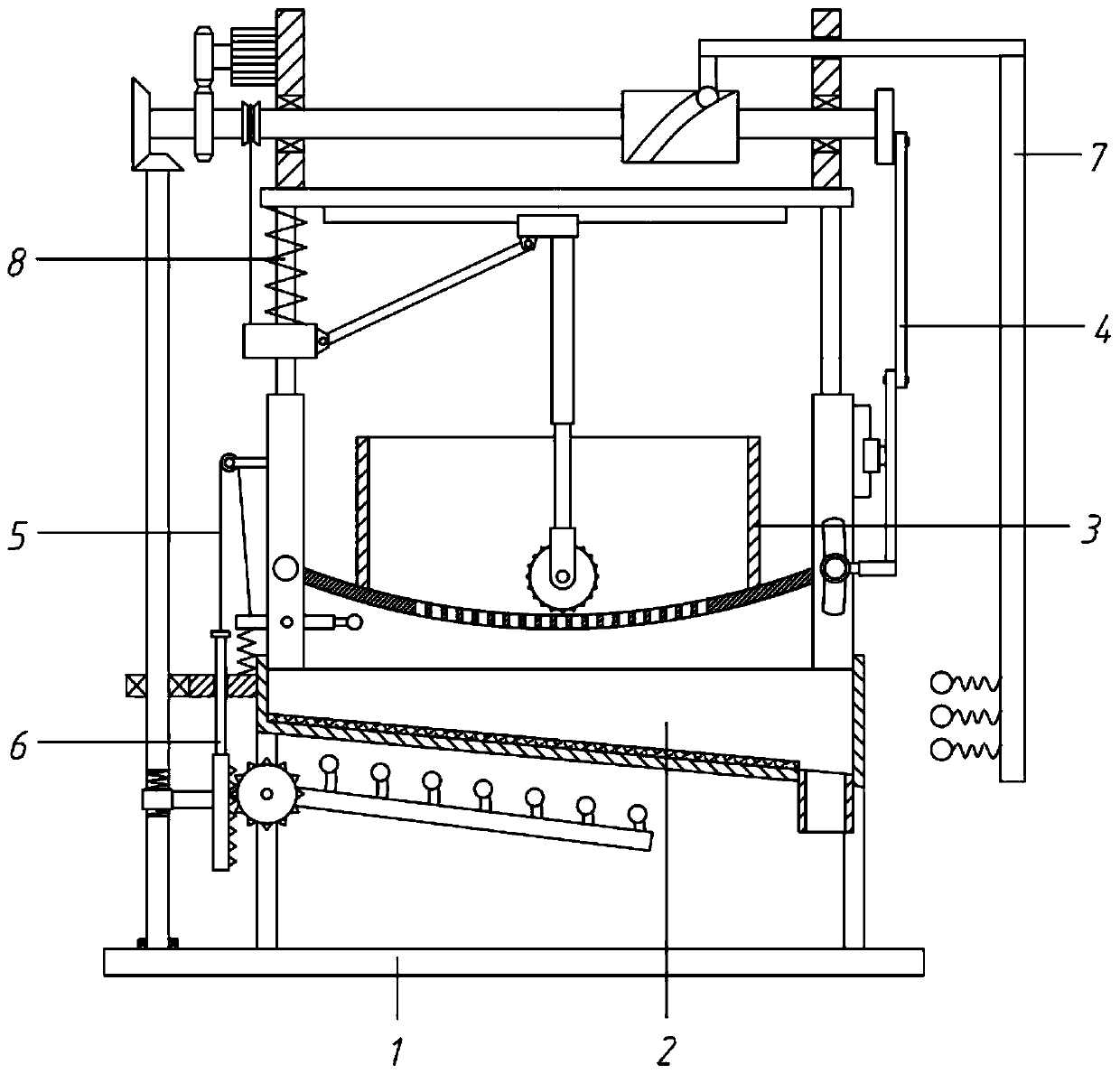

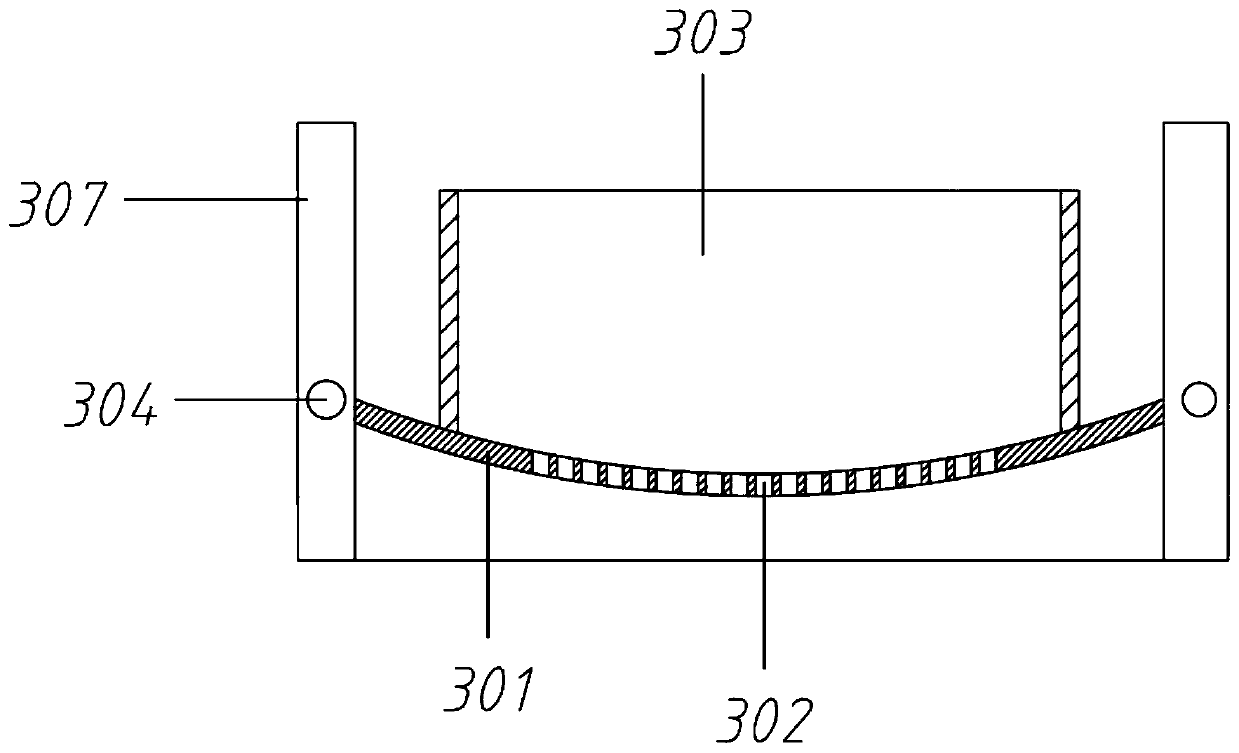

[0063] An impurity separator for rare earth permanent magnet materials used in civil engineering, including a frame assembly 1, an impurity removal assembly 2, a material storage assembly 3 and a crushing assembly 8;

[0064] The frame assembly 1 includes a base 101, a left pole 102 and a right pole 103. The left pole 102 is vertically fixed on the left end of the base 101, and the right pole 103 is vertically fixed on the right end of the base 101; The top of the component 1; the material storage component 3 is arranged above the impurity removal component 2;

Embodiment 2

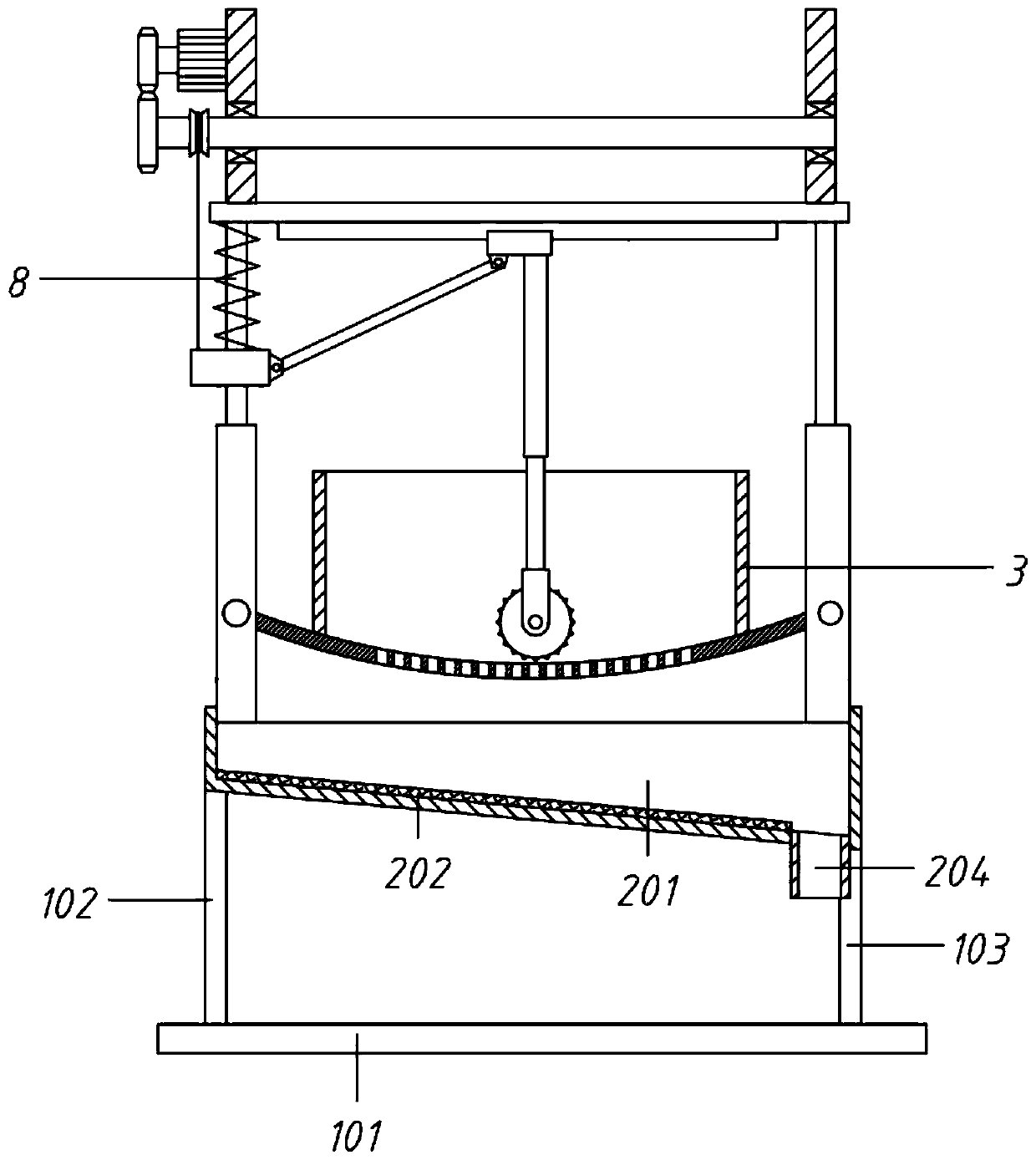

[0066] An impurity separator for rare earth permanent magnet materials used in civil engineering, including a frame assembly 1, an impurity removal assembly 2, a material storage assembly 3 and a crushing assembly 8;

[0067] The frame assembly 1 includes a base 101, a left pole 102 and a right pole 103. The left pole 102 is vertically fixed on the left end of the base 101, and the right pole 103 is vertically fixed on the right end of the base 101; The top of the component 1; the material storage component 3 is arranged above the impurity removal component 2;

[0068] Wherein, the impurity removal assembly 2 includes an impurity removal box 201, an electromagnetic chuck 202 and a feeding pipe 204;

[0069] The two ends of the miscellaneous removal box 201 are fixedly connected to the top of the left pole 102 and the top of the right pole 103 respectively; the top of the miscellaneous removal box 201 is provided with an opening; the bottom of the miscellaneous removal box 201 ...

Embodiment 3

[0078] On the basis of embodiment 2,

[0079] Also includes the lower vibration material assembly 6, the lower vibration material assembly 6 includes No. 1 bevel gear 601, No. 2 bevel gear 602, No. 2 rotating shaft 603, support seat 604, reciprocating thread 606, moving nut 607, rack 608, guide rod 609 , limit block 610, driven gear 611, No. 1 rocker 612, installation rod 613 and No. 1 collision end 614;

[0080] The left end of No. 1 rotating shaft 807 passes through the left side plate 801 and is equipped with No. 1 bevel gear 601. No. 1 bevel gear 601 is vertically meshed with No. 2 bevel gear 602, and No. 2 bevel gear 602 is installed on the top of No. 2 rotating shaft 603; The left side of the box 201 is connected with a support seat 604, the second rotating shaft 603 passes downwards and rotates to connect to the supporting seat 604, and the bottom end of the second rotating shaft 603 rotates to connect with the base 101; the second rotating shaft 603 is processed with a r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com